Abstract

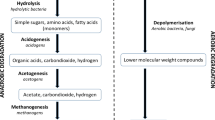

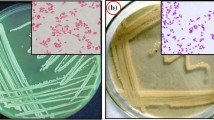

This study was designed to determine the potential of indigenous mixed microbial consortium isolated from palm oil mill effluent (POME) in reducing organic load and biodegradation of POME. Isolation and identification of indigenous microorganisms was subjected to standard microbiological methods and sequencing of the 16S rRNA and 18S rRNA genes. Sequencing of the 16S rRNA and 18S rRNA genes of the microbial strains suggests that they were identified as Micrococcus luteus101PB, Stenotrophomonas maltophilia102PB, Bacillus cereus103PB, Providencia vermicola104PB, Klebsiella pneumoniae105PB, Bacillus subtilis106PB, Aspergillus fumigatus107PF, Aspergillus nomius108PF, Aspergillus niger109PF, and Meyerozyma guilliermondii110PF. Results revealed that total percent reduction efficiency by the aerobic mixed microbial consortium for all bacteria–fungi combination (ABFC) gave a biochemical oxygen demand (BOD) reduction efficiency of about 90.23%, chemical oxygen demand (COD) 91.06%, and total suspended solids (TSS) 92.23% and bacteria–fungi stepwise (BFSW) recorded BOD reduction efficiency of 85.28%, COD 84.45%, and TSS 86.18% in 1000 mL of POME. The HPLC chromatogram results revealed increase in glucose level due to breakdown of cellulose which represents the cellulosic materials in POME by mixed microbial consortium signifying biodegradation of cellulose as a clean-up process for the tested POME sample. Therefore, the indigenous microbial strains are promising organisms for industrial applications. These microbes have direct applications in industrial process such as bioremediation and biodegradation of wastewaters.

Similar content being viewed by others

References

Abass AO, Jameel TA, Muyibi AS, Abdul Karim IM, Alam Z (2012) Investigation of the viability of selected microorganisms on the biodegradation of palm oil mill effluents (POME). Int J Chem Environ Engineer 3(3):182–186

AbdulKarim MI, Daud NA, Alam MDZ (2011) Treatment of palm oil mill effluent using microorganisms. In: M.D.Z, Alam, A.T, Jameel and A, Amid, (eds). Current research and development in biotechnology engineering at International Islamic University Malaysia (IIUM) Vol. III. IIUM Press, Kuala Lumpur, p. 269-275. ISBN 9789674181444

Agamuthu P, Tan EL, Shaifal AA (1986) Effect of aeration and soil inoculum on the composition of palm oil effluent (POME). Agri Wast 15(2):121–132. https://doi.org/10.1016/0141-4607(86)90043-0

Agustin MB, Sengpracha WP, Phutdhawong W (2008) Electrocoagulation of palm oil mill effluent. Int J Environ Res Public Health 5(3):177–180. https://doi.org/10.3390/ijerph5030177

Ahmad AL, Ismail S, Bhatia S (2003) Water recycling from palm oil mill effluent (POME) using membrane technology. Desalination 157(1-3):87–95. https://doi.org/10.1016/S0011-9164(03)00387-4

Ahmad AL, Sumathi S, Hameed BH (2005) Residual oil and suspended solid removal using natural adsorbents chitosan, bentonite and activated carbon: a comparative study. Chem Eng J 108(1–2):179–185. https://doi.org/10.1016/j.cej.2005.01.016

Alade AO, Jameel AT, Muyubi SA, Abdul Karim MI, Alam MDZ (2011) Removal of oil and grease as emerging pollutants of concern (EPC) in wastewater stream. IIUM Engineer J 12(4):161–169

Alam MZ, Rashid SS, Karim MIA, Salleh MH (2009) Management of palm oil mill effluent through production of cellulases by filamentous fungi. World J Microb Biotechnol 25:2219–2226

Al-Gheethi AAS (2015) Recycling of sewage sludge as production medium for cellulase by a Bacillus megaterium strain. Int J Recycl Org Waste Agricult 4(2):105–119. https://doi.org/10.1007/s40093-015-0090-6

Al-Gheethi AAS, Efaq AN, Mohamed RMSR, Bala JD, Amir Hashim MK (2016) Cellulase: Production, Applications and Health Benefits. In: Stevenson M (ed) Microbial cellulase: production and application in enzymatic treatment of biosolids. Biochemistry Research Trends. Nova Science Publishers Inc, Hauppauge, New York ISBN: 978-1-63485-788-8; ISBN: 978-1-63485-802-1 pp. 45–62

Allcock ER, Woods DR (1981) Carboxymethyl cellulase and cellobiase production by Clostridium acetobutylicum in an industrial fermentation medium. Appl Environ Microbiol 41(2):539–541

APHA (2005) Standard methods for the examination of water and wastewater, in, 21st edn, American Public Health Association (APHA), Washington, DC

Bala JD, Lalung J, Ismail N, (2014a) Biodegradation potential and removal of oil and grease by bacterial isolated from palm oil mill effluent (POME). Proceedings of the International Conference on Beneficial Microbes ICOBM 2014: Microbes for the Benefits of Mankind, May 27–29, 2014, PARKROYAL Penang Resort, Penang, Malaysia. Editors: Liong M.T, Ahmad, R, Hena, S, Wan-Abdullah, W.N, Lee, C.K, Serri, N.A, Tajaruddin, H.A.B, Ong, J.S, Amy-Lau. S.Y. School of Industrial Technology, Universiti Sains Malaysia 2014. Pages 138–144. ISBN 978-967-394-186-5

Bala JD, Lalung J, Ismail N (2014b) Biodegradation of palm oil mill effluent (POME) by bacterial. Int J Sci Res Publ 4(3):502–511

Bala JD, Lalung J, Ismail N (2014c) Palm oil mill effluent (POME) treatment “microbial communities in an anaerobic digester”: a review. Int J Sci Res Publ 4(6):2250–3153

Bala JD, Lalung J, Ismail N (2015a) Studies on the reduction of organic load from palm oil mill effluent (POME) by bacterial strains. Int J Recycl Org Waste Agric 4(1):1–10. https://doi.org/10.1007/s40093-014-0079-6

Bala JD, Lalung J, Al-Gheethi AAS, Ismail N (2015b) Reduction of oil and grease by fungi isolated from palm oil mill effluent (POME). Proceedings of the 4th ICERT 2015: International Conference on Environmental Research and Technology: Exploring the Frontiers in Environmental Science and Technology Research, 27–29 May 2015, Parkroyal Hotel Penang, Malaysia. Editors: Tow, TT, Yusup, Y, Fadhlullah, W. School of Industrial Technology, Universiti Sains Malaysia 2015. Pages 79–91. ISBN 978-967-394-211-4

Bala JD (2016) Aerobic treatment and biodegradation of palm oil mill effluent by indigenous microorganisms. PhD Thesis, Environmental Technology Division, School of Industrial Technology, Universiti Sains Malaysia (USM), 11800 Pulau, Pinang, Malaysia

Barr BK, Hsieh Y-L, Ganem B, Wilson DB (1996) Identification of two functionally different classes of exocellulases. Biochemist 35(2):586–592. https://doi.org/10.1021/bi9520388

Benka-coker MO, Ekundayo JA (1997) Applicability of evaluating the ability of microbes isolated from an oil spill site to degrade oil. Environ Monit Ass 45:259–272

Beguin P (1990) Molecular biology of cellulose degradation. Annu Rev Microbiol 44(1):219–248. https://doi.org/10.1146/annurev.mi.44.100190.001251

Béguin P, Aubert JP (1994) The biological degradation of cellulose. FEMS Microbiol Rev 13(1):25–58. https://doi.org/10.1111/j.1574-6976.1994.tb00033.x

Bek-Nielsen C, Singh G, Toh TS (1999) Bioremediation of palm oil mill effluent. In: In: Proceedings of the Porim International Palm Oil Congress, 16th February 1999. Malaysia, Kuala Lumpur

Boekema BKHL, Beselin A, Breuer M, Hauer B, Koster M, Rosenau F, Jaeger KE, Tommassen J (2007) Hexadecane and Tween 80 stimulate lipase production in Burkholderia glumae by different mechanisms. Appl Environ Microbiol 73(12):3838–3844. https://doi.org/10.1128/AEM.00097-07

Cao SG, Yong H, Ma L, Guo SC (1996) Enzymatic properties by the immobilization method. Appl Biochem Biotechnol 59(1):7–14. https://doi.org/10.1007/BF02787853

Cheng J, Zhu X, Ni J, Borthwick (2010) A palm oil mill effluent treatment using a two-stage microbial fuel cells system integrated with immobilized biological aerated filters. Bioresour Technol 101(8):2729–2734. https://doi.org/10.1016/j.biortech.2009.12.017

Chhatre S, Purohit HJ, Shanker R, Khanna P (1996) Bacterial consortia for crude oil spill remediation. Water Sci Technol 34:187–193

Chigusa S, Hasegawa T, Yamamota N, Watanabe Y (1996) Treatment of waste water from oil manufacture plant by yeasts. Water Sci Technol 34:51–58

Chin KK, Lee SW, Mohammad HH (1996) A study of palm oil mill effluent treatment using a pond system. Water Sci Technol 34:119–123

De Felice B, Pontecorvo G, Carfagna M (1997) Degradation of waste waters from olive oil mills by Yarrowia lipolytica ATCC 20255 and Pseudomonas putida. Acta Biotechnol 17(3):231–239. https://doi.org/10.1002/abio.370170306

Deobald LA, Crawford DL (1997) Lignocellulose biodegradation. In: Hurst CJ, Knudsen GR, Stetzenbach LD, Walter MV (eds) Manual of Environmental Microbiology ASM Press. USA pp, Washington DC, pp 730–737

Dhouib A, Ellouz M, Aloui F, Sayadi S (2006) Effect of bioaugmentation of activated sludge with white rot fungi on olive mill wastewater detoxification. Lett Appl Microbiol 42(4):405–411. https://doi.org/10.1111/j.1472-765X.2006.01858.x

Din MF, Ujang Z, Muhd-Yunus S, Van-Loosdrecht MCM (2006) Storage of polyhydroxyalkanoates (PHA) in fed-batch mixed culture using palm oil mill effluent (POME). In: 4th Seminar on Water Management (jsps-vcc), Johor, pp 119–127

Dipasquale L, Romano I, Picariello G, Calandrelli V, Lama L (2014) Characterization of a native cellulase activity from an anaerobic thermophilic hydrogen-producing bacterium Thermosipho sp. strain 3. Ann Microbiol 64(4):1493–1503. https://doi.org/10.1007/s13213-013-0792-9

El-Masry MH, El- Bestaway E, El-Adi NI (2004) Bioremediation of vegetable oil and grease from polluted wastewater using a sand biofilm system. World J Microbiol Biotechnol 20(6):551–557. https://doi.org/10.1023/B:WIBI.0000043162.17813.17

Environmental Management Guideline (1997) Palm oil industry. German Technical Cooperation. Thailand, Bangkok, p 5

Environmental Quality (Prescribed Premises) (crude palm oil) Regulation 1977 (2014)

Francis AR, Masilamai D (2012) Removal of zinc (II) by non-living biomass of Agaricus Bisporus. Res J Recent Sci 1(9):13–17

Glazer AN, Nikaido H (1995) Microbial biotechnology: fundamentals of applied microbiology. USA: University of California, Berkley WH Fremanand Company. ISBN0-71672-608-4

Goyal AK, Eveleigh DE (1996) Cloning, sequencing and analysis of the ggh-A gene encoding a 1,4-beta-D-glucan glucohydrolase from Microbispora bispora. Gene 172(1):93–99. https://doi.org/10.1016/0378-1119(96)00076-5

Hamme JD, Odumeru JA, Ward OP (2000) Community dynamics of a mixed-bacterial culture growing on petroleum hydrocarbons in batch culture. Can J Microbiol 46(5):441–450. https://doi.org/10.1139/w00-013

Hazaimeh M, Mutalib SA, Abdullah PS, Kee WK, Surif S (2014) Enhanced crude oil hydrocarbon degradation by self-immobilized bacterial consortium culture on sawdust and oil palm empty fruit bunch. Ann Microbiol. 64(4):1769–1777. https://doi.org/10.1007/s13213-014-0821-3

Hernández D, Riaño B, Coca M, García-González MC (2013) Treatment of agro-industrial wastewater using microalgae–bacteria consortium combined with anaerobic digestion of the produced biomass. Bioresour Technol 135(2013):598–603. https://doi.org/10.1016/j.biortech.2012.09.029

Hii KL, Yeap SP, Mashitah MD (2012) Cellulase production from palm oil mill effluent in Malaysia: economical and technical perspectives. Eng Life Sci 12(1):7–28. https://doi.org/10.1002/elsc.201000228

Ho CC, Tan YK, Wang CW (1984) The distribution of chemical constituents between the soluble and the particulate fractions of palm oil mill effluent and its significance on its utilisation/treatment. Agric Wastes 11(1):61–71. https://doi.org/10.1016/0141-4607(84)90055-6

Ibrahim AH, Dahlan I, Adlan MN, Dasti AF (2012) Comparative study on characterization of malaysian palm oil mill effluent. Res J Chem Sci 2(12):1–5

Iwara AI, Ewa EE, Ogundele FO, Adeyemi JA (2011) Ameliorating effects of palm oil mill effluent on the physical and chemical properties of soil in Ugep, Cross River state, South-Southern Nigeria. Int J App Sci Technol 1(5):106–112

Jameel AT, Muyibi SA, Olanrewaju AA (2011) Comparative study of bioreactors used for palm oil mill effluent treatment based on chemical oxygen removal efficiencies In: M.D.Z, Alam, A.T, Jameel and A, Amid, (eds). Current research and development in biotechnology engineering at International Islamic University Malaysia (IIUM) Vol. III. IIUM Press, Kuala Lumpur, p.277-284. ISBN 9789674181444

Jameel AT, Olanrewaju AA (2011) Aerobic biodegradation of oil and grease in palm oil mill effluent using consortium of microorganisms In: M.D.Z, Alam, A.T, Jameel and A, Amid, (eds). Current research and development in biotechnology engineering at International Islamic University Malaysia (IIUM) Vol. III. IIUM Press, Kuala Lumpur, pp. 43-51. ISBN 9789674181444

Kissi M, Mountadar M, Assobhei O, Gargiulo E, Palmieri G, Giardina P, Sannia G (2001) Roles of two white-rot basidiomycete fungi in decolorization and detoxification of olive mill wastewater. Appl Microbiol Biotechnol 57(1-2):221–226

Lam MK, Lee KT (2011) Renewable and sustainable bioenergies production from palm oil mill effluent (POME): win-win strategies toward better environmental protection. Biotechnol Adv 29(1):124–141. https://doi.org/10.1016/j.biotechadv.2010.10.001

Li H, Ni J (2011) Treatment of wastewater from Dioscorea zingiberensis tubers used for producing steroid hormones in a microbial fuel cell. Bioresour Technol 102(3):2731–2735. https://doi.org/10.1016/j.biortech.2010.11.030

Lynd LR, Weimer PJ, Vanzyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66(3):506–577. https://doi.org/10.1128/MMBR.66.3.506-577.2002

Maygaonkar PA, Wagh PM, Permeswaran U (2012) Biodegradation of distillery effluent by fungi. Biosci Dis 3(2):251–258

McHugh S, O’Reilly C, Mahony T, Colleran E, O’Flaherty V (2003) Anaerobic granular sludge bioreactor technology. Rev Environ Sci Biotechnol 2(2-4):225–245. https://doi.org/10.1023/B:RESB.0000040465.45300.97

Mohammed RR, Ketabachi MR, McKay G (2014) Combined magnetic field and adsorption process for treatment of biologically treated palm oil mill effluent (POME). Chem Eng J 243:31–42. https://doi.org/10.1016/j.cej.2013.12.084

Najafpour GD, Zinatizadeh AAL, Mohamed AR, Isa-Hasnain M, Nasrollahzadeh H (2006) High-rate anaerobic digestion of palm oil mill effluent in an upflow anaerobic sludge-fixed film bioreactor. Process Biochem 41(2):370–379. https://doi.org/10.1016/j.procbio.2005.06.031

Ohimain EI, Olukole CD, Izah SC, Eke RA, Okonkwo AC (2012) Microbiology of palm oil mill effluents. J Microbiol Biotech Res 2(6):852–857

Ohimain EI, Izah SC, Jenakumo N (2013) Physicochemical and microbial screening of palm oil mill effluents for amylase production. Greener J Biol Sci 3(8):307–318

Oswal N, Sarma PM, Zinjarde SS, Pant A (2002) Palm oil mill effluent treatment by a tropical marine yeast. Bioresour Technol 85(1):35–37. https://doi.org/10.1016/S0960-8524(02)00063-9

Piro P, Carbone M, Tomei G (2011) Assessing settleability of dry and wet weather flows in an urban area serviced by combined sewer. Water Air Soil Pollut 214(1–4):107–117. https://doi.org/10.1007/s11270-010-0408-y

Poh PE, Chong MF (2009) Development of anaerobic digestion methods for palm oil mill effluent (POME) treatment. Bioresour Technol 100(1):1–9. https://doi.org/10.1016/j.biortech.2008.06.022

Qingwei L, Mancl KM, Tuovinen OH (1998) Effect of inoculation on the biodegradation of butterfat-detergent mixtures in fixed-film sand columns. Bioresour Technol 64:27–32

Rahman KSM, Rahman JT, Lakshmanaperumalsamy P, Banat LM (2002) Towards efficient crude oil degradation by a mixed bacterial consortium. Bioresour Technol 85(3):257–261. https://doi.org/10.1016/S0960-8524(02)00119-0

Rashid SS, Alam MZ, Ismail M, Karim M, Salleh MH (2009) Management of palm oil mill effluent through production of cellulases by filamentous fungi. World J Microbiol Biotechn 25(12):2219–2226. https://doi.org/10.1007/s11274-009-0129-9

Ray, R.C., 2011. Solid-state fermentation for production of microbial cellulase: an overview. In: Golan AE (ed) Cellulase: types and action, mechanism, and uses. Nova Science Publishers Inc, New York

Sathishkumar M, Binupriya AR, Baik SH, Yun SE (2008) Biodegradation of crude oil by individual bacterial strains and a mixed bacterial consortium isolated from hydrocarbon contaminated areas. Clean 36(1):92–96

Sethupathi S (2004) Removal of residue oil from palm oil mill effluent (POME) using chitosan .Master Thesis, School of Chemical Engineering, USM, Malaysia

Shi J (2007) Microbial pretreatment of cotton stalks by Phanerochaete chrysosporium for bioethanol production. Biological and Agricultural Engineering, Raliegh, North Carolina

Sinnappa S (1978) Treatment studies of palm oil mill wastes water pollution. University Press Bangkok, Thailand, pp 21–25

Singh R, Ibrahim MH, Esa N, Iliyana M (2010) Composting of waste from palm oil mill: a sustainable waste management practice. Rev Environ Sci Biotechnol 9(4):331–344. https://doi.org/10.1007/s11157-010-9199-2

Soleimaninanadegani M, Manshad S (2014) Enhancement of biodegradation of palm oil mill effluents by local isolated microorganisms. Int Scholarly Res Notices 2014:1–8. https://doi.org/10.1155/2014/727049

Sugiura K, Ishihara M, Shimauchi T, Harayama S (1997) Physicochemical properties and biodegradability of crude oil. Environ Sci Technol 31(1):45–51. https://doi.org/10.1021/es950961r

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83(1):1–11. https://doi.org/10.1016/S0960-8524(01)00212-7

Takemoto H, Hase S, Ikenaka T (1985) Microquantitative analysis of neutral and amino sugars as fluorescent pyridylamino derivatives by high-performance liquid chromatography. Anal Biochem 145(2):245–250. https://doi.org/10.1016/0003-2697(85)90357-4

Tomme P, Warren RA, Gilkes NR (1995) Cellulose hydrolysis by bacteria and fungi. Adv Microb Physiol 37:1–81. https://doi.org/10.1016/S0065-2911(08)60143-5

Vijayaraghavan K, Ahmad D, Abdul-Aziz ME (2007) Aerobic treatment of palm oil mill effluent. J Environ Manag 82(1):24–31. https://doi.org/10.1016/j.jenvman.2005.11.016

Wanna C, Pompan W (2007) Effect of temperature on the anaerobic digestion of palm oil mill effluent. Elec. J Biotechnol 10(3):376–385

Wilson DB (2011) Microbial diversity of cellulose hydrolysis. Curr Opinion Microbiol 14:1–5

Wong KM, Nor AA, Suraini A, Vikineswary S, Mohd AH (2008) Enzymatic hydrolysis of palm oil mill effluent solid using mixed cellulases from locally isolated fungi. Res J Microbiol 3(6):474–481

Wu TY, Mohammad AW, Md-Jahim J, Anuar N (2007) Palm oil mill effluent (POME) treatment and bioresources recovery using ultrafiltration membrane: effect of pressure on membrane fouling. Biochem Eng J 35(3):309–317. https://doi.org/10.1016/j.bej.2007.01.029

Wu TY, Mohammad AW, Jahim JM, Anuar N (2010) Pollution control technologies for the treatment of palm oil mill effluent (POME) through end-of-pipe processes. J Environ Manag 91(7):1467–1490. https://doi.org/10.1016/j.jenvman.2010.02.008

Yacob S, Hassan MA, Shirai Y, Wakisaka M, Subash S (2005) Baseline study of methane emission from open digesting tanks of palm oil mill effluent treatment. Chemosphere 59(11):1575–1581. https://doi.org/10.1016/j.chemosphere.2004.11.040

Funding

The authors would like to thank Universiti Sains Malaysia for the financial support under Research University (RUI) Grant No. 1001/PTEKIND/814147.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bala, J.D., Lalung, J., Al-Gheethi, A.A.S. et al. Reduction of Organic Load and Biodegradation of Palm Oil Mill Effluent by Aerobic Indigenous Mixed Microbial Consortium Isolated from Palm Oil Mill Effluent (POME). Water Conserv Sci Eng 3, 139–156 (2018). https://doi.org/10.1007/s41101-018-0043-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41101-018-0043-9