Abstract

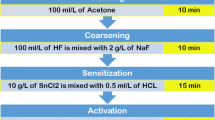

In this research work, fabrication of Al alloy metal matrix composites (MMCs) reinforced with electroless Ni-P-coated Al2O3 is carried out using the stir-squeeze casting method. Scrap Al alloy wheels as matrix materials and Al2O3 particles as reinforcements are used to develop the MMCs. The Ni-P coating on Al2O3 particles is carried out using an electroless process to improve mechanical and tribological properties by increasing the bonding strength between the ceramic particles and the matrix material. A pre-treatment process on Al2O3 particles is done before the electroless Ni-P coating. To analyse the properties, the composites are fabricated in three different variations, i.e. as-cast scrap Al alloy, scrap Al alloy with uncoated Al2O3 (5 wt%), and scrap Al alloy with coated Al2O3 (5 wt%). Metallurgical properties are analysed using an optical microscope (OM), scanning electron microscope (SEM), energy-dispersive X-ray analysis (EDAX), and X-ray diffraction (XRD). The test results show that the porosity is reduced by 15.45% in a composite reinforced with coated Al2O3 compared to the as-cast scrap Al alloy. Also, the mechanical properties such as hardness, tensile strength, and impact strength are improved significantly by 15.2, 23, and 31.25%, respectively. Reduction of 31.47% in specific wear rate and 7.34% in coefficient of friction are achieved in the composite reinforced with coated Al2O3 particles compared to the as-cast scrap Al alloy. The compressive strength is decreased significantly with the addition of uncoated Al2O3 particles. After the addition of coated Al2O3, the compressive strength of the composite is increased compared with the uncoated Al2O3-reinforced composite.

Similar content being viewed by others

Data Availability

The corresponding author [Dega Nagaraju] can provide the data and materials that support the findings of this study.

Code availability

Not Applicable

References

M.A. Khan, An overview on effect of reinforcement and process parameters on properties of aluminium based metal matrix composite. Int. J. Res. Eng. Sci. 10, 08–12 (2014)

K.K. Chawla, Metal matrix composites, in Composite materials (Springer, New York, 2012), pp. 197–248. https://doi.org/10.1007/978-0-387-74365-3_6

C. Bulei, M.P. Todor, I. Kiss, Metal matrix composites processing techniques using recycled aluminium alloy. IOP. Conf. Ser. Mater. Sci. Eng. 393, 012089 (2018)

M.B. Shuvho, M.A. Chowdhury, M. Kchaou, B.K. Roy, A. Rahman, M.A. Islam, Surface characterization and mechanical behavior of aluminum based metal matrix composite reinforced with nano Al2O3, SiC, TiO2 particles. Chem. Data Collect. (2020). https://doi.org/10.1016/j.cdc.2020.100442

H. Ahmadian, R. Sallakhniknezhad, T. Zhou, S.R. Kiahosseini, Mechanical properties of Al-Mg/MWCNT nanocomposite powder produced under different parameters of ball milling process. Diam. Relat. Mater. (2022). https://doi.org/10.1016/j.diamond.2021.108755

V. Bharath, M. Nagaral, V. Auradi, S.A. Kori, Preparation of 6061Al-Al2O3 MMC’s by stir casting and evaluation of mechanical and wear properties. Proc. Mater. Sci. (2014). https://doi.org/10.1016/j.mspro.2014.07.151

A. Mazahery, H. Abdizadeh, H.R. Baharvandi, Development of high-performance A356/nano-Al2O3 composites. Mater. Sci. Eng.: A. 518(1–2), 61–64 (2009). https://doi.org/10.1016/j.msea.2009.04.014

S. Ozden, R. Ekici, F. Nair, Investigation of impact behaviour of aluminium based SiC particle reinforced metal–matrix composites. Compos. A Appl. Sci. Manuf. (2007). https://doi.org/10.1016/j.compositesa.2006.02.026

X. Yang, N.S. Barekar, S. Ji, B.K. Dhindaw, Z. Fan, Influence of reinforcing particle distribution on the casting characteristics of Al-SiCp composites. J. Mater. Process. Technol. (2020). https://doi.org/10.1016/j.jmatprotec.2019.116580

A. Kumar, S. Lal, S. Kumar, Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method. J. Market. Res. (2013). https://doi.org/10.1016/j.jmrt.2013.03.015

S.R. Kiahosseini, H. Ahmadian, Effect of residual structural strain caused by the addition of Co3O4 nanoparticles on the structural, hardness and magnetic properties of an Al/Co3O4 nanocomposite produced by powder metallurgy. Int. J. Minerals Metall. Mater. 27(3), 384–390 (2020). https://doi.org/10.1007/s12613-019-1917-3

M. Kok, Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. (2005). https://doi.org/10.1016/j.jmatprotec.2004.07.068

Y. Zhang, Q. Wang, G. Chen, C.S. Ramachandran, Mechanical, tribological and corrosion physiognomies of CNT-Al metal matrix composite (MMC) coatings deposited by cold gas dynamic spray (CGDS) process. Surf. Coat. Technol. (2020). https://doi.org/10.1016/j.surfcoat.2020.126380

A.A. Cerit, M.B. Karamis, F.E. Nair, K. Yildizli, Effect of reinforcement particle size and volume fraction on wear behaviour of metal matrix composites. J. Balk. Tribol. Assoc. 12(4), 482–9 (2008)

S.R. Beyanagari, J. Kandasamy, A comparative study on the mechanical and tribological characteristics of AA7075/h-BN and AA7075/h-BN/MoS2 hybrid nano-composites produced using stir-squeeze casting process. Surf. Topogr. Metrol. Prop. (2021). https://doi.org/10.1088/2051-672X/ac1915

W.S. Barakat, A. Wagih, O.A. Elkady, A. Abu-Oqail, A. Fathy, A. El-Nikhaily, Effect of Al2O3 nanoparticles content and compaction temperature on properties of Al–Al2O3 coated Cu nanocomposites. Compos. B Eng. (2019). https://doi.org/10.1016/j.compositesb.2019.107140

D.V. Praveen, D.R. Raju, M.V. Raju, T. Nancharaiah, A note on preparation of electroless nickel coating on Alumina micro-particulates as the Forerunner to reinforce Al-MMCs. Recent Adv. Smart Manuf. Mater. (2021). https://doi.org/10.1007/978-981-16-3033-0_19

M. Novak, D. Vojtěch, T. Vítů, Influence of heat treatment on tribological properties of electroless Ni–P and Ni–P–Al2O3 coatings on Al–Si casting alloy. Appl. Surf. Sci. (2010). https://doi.org/10.1016/j.apsusc.2009.11.057

S.A. Sajjadi, H.R. Ezatpour, H. Beygi, Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A (2011). https://doi.org/10.1016/j.msea.2011.08.052

T.P. Rajan, R.M. Pillai, B.C. Pai, Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. (1998). https://doi.org/10.1023/A:1004674822751

N.K. Shrestha, D.B. Hamal, T. Saji, Composite plating of Ni–P–Al2O3 in two steps and its anti-wear performance. Surf. Coat. Technol. (2004). https://doi.org/10.1016/j.surfcoat.2003.08.085

S.J. Chelladurai, R. Arthanari, R. Selvarajan, T.P. Ravichandran, S.K. Ravi, S.R. Petchimuthu, Optimisation of dry sliding wear parameters of squeeze cast AA336 aluminium alloy: copper-coated steel wire-reinforced composites by response surface methodology. Int. J. Metalcast. (2019). https://doi.org/10.1007/s40962-018-0258-8

C.A. Leon, R.A. Drew, Preparation of nickel-coated powders as precursors to reinforce MMCs. J. Mater. Sci. (2000). https://doi.org/10.1023/A:1004860326071

M.K. Gupta, P.K. Rakesh, I. Singh, Application of industrial waste in metal matrix composite. J. Polym. Compos. 4(3), 27–34 (2019)

L.F. Xavier, P. Suresh, Wear behavior of aluminium metal matrix composite prepared from industrial waste. Sci. World J. (2016). https://doi.org/10.1155/2016/6538345

P.K. Krishnan, J.V. Christy, R. Arunachalam, A.H. Mourad, R. Muraliraja, M. Al-Maharbi, V. Murali, M.M. Chandra, Production of aluminum alloy-based metal matrix composites using scrap aluminum alloy and waste materials: influence on microstructure and mechanical properties. J. Alloys. Compd. (2019). https://doi.org/10.1016/j.jallcom.2019.01.115

J. Gayathri, R. Elansezhian, Enhancement of mechanical properties of aluminium metal matrix composite by reinforcing waste alumina catalyst and nano Al2O3. Mater. Today Proc. (2021). https://doi.org/10.1016/j.matpr.2020.02.003

P. Chandrasekar, D. Nagaraju, Improvement of bonding strength at the interfaces in scrap Al alloy composites using electroless Ni-P coated SiC. Silicon (2021). https://doi.org/10.1007/s12633-021-01078-4

N.B. Khosroshahi, R.A. Khosroshahi, R.T. Mousavian, D. Brabazon, Effect of electroless coating parameters and ceramic particle size on fabrication of a uniform Ni–P coating on SiC particles. Ceram. Int. (2014). https://doi.org/10.1016/j.ceramint.2014.04.055

A. Ramanathan, P.K. Krishnan, R. Muraliraja, A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. (2019). https://doi.org/10.1016/j.jmapro.2019.04.017

A. Kareem, J.A. Qudeiri, A. Abdudeen, T. Ahammed, A. Ziout, A review on AA 6061 metal matrix composites produced by stir casting. Mater. (2021). https://doi.org/10.3390/ma14010175

H.A. Deore, A. Bhardwaj, A.G. Rao, J. Mishra, V.D. Hiwarkar, Consequence of reinforced SiC particles and post process artificial ageing on microstructure and mechanical properties of friction stir processed AA7075. Def. Technol. (2020). https://doi.org/10.1016/j.dt.2019.12.001

R. Gecu, A. Karaaslan, Relationship between nanoindentation and wear properties of stainless steel-reinforced aluminium matrix composite. Tribol. Lett. (2017). https://doi.org/10.1007/s11249-017-0950-5

D. Sujan, Z. Oo, ME. Rahman, MA. Maleque , CK. Tan, Physio-mechanical properties of Aluminium metal matrix composites reinforced with Al2O3 and SiC. Int. J. Mater. Metall. Eng. (2012) https://doi.org/10.5281/zenodo.1076548

U. Aybarç, O. Ertuğrul, M.Ö. Seydibeyoğlu, Effect of Al 2 O 3 particle size on mechanical properties of ultrasonic-assisted stir-casted Al A356 matrix composites. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-020-00490-7

D. Sujan, C.W. Yeo, M.E. Rahman, M.M. Reddy, M.A. Maleque, Y.A. Mohammad, Aluminium-silicon carbide composites for enhanced physio-mechanical properties. Adv. Mater. Res. (2012). https://doi.org/10.4028/www.scientific.net/AMR.576.370

A. Kamboj, S. Kumar, H. Singh, Fabrication and characterization of Al6063/SiC composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 227(12), 1777–1787 (2013). https://doi.org/10.1177/0954405413493618

Funding

No funding was received for conducting this study. The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

[P. Chandrasekar] carried out experiments on material characterization. [Dr. Dega Nagaraju] was in charge of the results analysis, which included SEM, EDAX, and XRD. [Dr. Dega Nagaraju] and [P. Chandrasekar] worked for the plotting of all of the graphs in the paper. [Dr. Dega Nagaraju] and [P. Chandrasekar] worked together for the samples preparation for experiments as well as manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interests

The authors have no potential conflicts of interest.

Informed consent

Not Applicable

Consent for Publication

The authors agreed for the publication of this study.

Human or Animal Rights

This research involves no human participants and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chandrasekar, P., Nagaraju, D. The Effect of Electroless Ni–P-Coated Al2O3 on Mechanical and Tribological Properties of Scrap Al Alloy MMCs. Inter Metalcast 17, 356–372 (2023). https://doi.org/10.1007/s40962-022-00779-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00779-9