Abstract

There has been increasing interest in developing micro/nanostructured aluminum-based materials for sustainable, dependable and high-efficiency electrochemical energy storage. This review chiefly discusses the aluminum-based electrode materials mainly including Al2O3, AlF3, AlPO4, Al(OH)3, as well as the composites (carbons, silicons, metals and transition metal oxides) for lithium-ion batteries, the development of aluminum-ion batteries, and nickel-metal hydride alkaline secondary batteries, which summarizes the methodologies, related charge-storage mechanisms, the relationship between nanostructures and electrochemical properties found in recent years, latest research achievements and their potential applications. In addition, we raise the relevant challenges in recently developed electrode materials and put forward new ideas for further development of micro/nanostructured aluminum-based materials in advanced battery systems.

摘要

微/纳米铝基材料用作可持续、可靠、高效电化学储能材料一直是近些年的研究热点. 本文主要论述了铝基电极材料在锂离子电池方面的应用(材料包括氧化铝、氟化铝、磷酸铝、氢氧化铝以及一些铝基复合材料, 包含碳、硅、金属和过渡金属氧化物), 铝离子电池与镍氢碱性二次电池的发展. 对近年来发现的方法论、相关的电荷存储机制、纳米结构与电化学性能之间的关系、最新的研究成果以及它们的潜在应用进行了总结. 此外, 提到了近年来电极材料发展过程中遇到的相关挑战, 并且对未来发展微/纳米铝基材料于先进的电池系统进行了展望.

Similar content being viewed by others

References

Armand M, Tarascon JM. Building better batteries. Nature, 2008, 451: 652–657

Liu C, Li F, Ma LP, et al. Advanced materials for energy storage. Adv Mater, 2010, 22: E28–E62

Cheng F, Liang J, Tao Z, et al. Functionalmaterials for rechargeable batteries. Adv Mater, 2011, 23: 1695–1715

Goodenough JB, Kim Y. Challenges for rechargeable batteries. J Power Sources, 2011, 196: 6688–6694

Bruce PG, Scrosati B, Tarascon JM. Nanomaterials for rechargeable lithium batteries. Angew Chem Int Ed, 2008, 47: 2930–2946

Gao XP, Yang HX. Multi-electron reaction materials for high energy density batteries. Energ Environ Sci, 2010, 3: 174–189

Li H, Wang Z, Chen L, et al. Research on advanced materials for Li-ion batteries. Adv Mater, 2009, 21: 4593–4607

Winter M, Brodd RJ. What are batteries, fuel cells, and supercapacitors? Chem Rev, 2004, 104: 4245–4270

Dominko R, Arčon D, Mrzel A, et al. Dichalcogenide nanotube electrodes for Li-ion batteries. Adv Mater, 2002, 14: 1531–1534

Park CM, Kim JH, Kim H, et al. Li-alloy based anode materials for Li secondary batteries. Chem Soc Rev, 2010, 39: 3115–3141

Brutti S, Gentili V, Menard H, et al. TiO2-(B) nanotubes as anodes for lithium batteries: origin and mitigation of irreversible capacity. Adv Energ Mater, 2012, 2: 322–327

Lindsay MJ, Wang GX, Liu HK. Al-based anodematerials for Li-ion batteries. J Power Sources, 2003, 119–121: 84–87

Hamon Y, Brousse T, Jousse F, et al. Aluminum negative electrode in lithium ion batteries. J Power Sources, 2001, 97–98: 185–187

Fauteux D, Koksbang R. Rechargeable lithium battery anodes: alternatives to metallic lithium. J Appl Electrochem, 1993, 23: 1–10

Kim SW, Seo DH, Ma X, et al. Electrode materials for rechargeable sodium-ion batteries: potential alternatives to current lithium-ion batteries. Adv Energ Mater, 2012, 2: 710–721

Li Q, Bjerrum NJ. Aluminum as anode for energy storage and conversion: a review. J Power Sources, 2002, 110: 1–10

Sun D, Xu G, Wang H, et al. Multi-layered Al2O3/LixV2O5/LiV3O8 nanoflakes with superior cycling stability as cathode material for Li-ion battery. Electrochim Acta, 2015, 157: 211–217

Hu YS, Demir-Cakan R, Titirici MM, et al. Superior storage performance of a Si@SiOx/C nanocomposite as anode material for lithium-ion batteries. Angew Chem Int Ed, 2008, 47: 1645–1649

Gao P, Fu J, Yang J, et al. Microporous carbon coated silicon core/shell nanocomposite via in situ polymerization for advanced Li-ion battery anode material. Phys Chem Chem Phys, 2009, 11: 11101

Li H. The crystal structural evolution of nano-Si anode caused by lithium insertion and extraction at room temperature. Solid State Ion, 2000, 135: 181–191

Chan CK, Peng H, Liu G, et al. High-performance lithium battery anodes using silicon nanowires. Nat Nanotech, 2008, 3: 31–35

Kim H, Cho J. Superior lithium electroactive mesoporous Si@carbon core−shell nanowires for lithium battery anodematerial. Nano Lett, 2008, 8: 3688–3691

Wang W, Kumta PN. Nanostructured hybrid silicon/carbon nanotube heterostructures: reversible high-capacity lithium-ion anodes. ACS Nano, 2010, 4: 2233–2241

Jung H, Park M, Han SH, et al. Amorphous silicon thin-film negative electrode prepared by low pressure chemical vapor deposition for lithium-ion batteries. Solid State Commun, 2003, 125: 387–390

Takamura T, Ohara S, Uehara M, et al. A vacuum deposited Si film having a Li extraction capacity over 2000 mAh/g with a long cycle life. J Power Sources, 2004, 129: 96–100

Maranchi JP, Hepp AF, Kumta PN. High capacity, reversible silicon thin-film anodes for lithium-ion batteries. Electrochem Solid-State Lett, 2003, 6: A198

Zhang Y, Fu ZW, Qin QZ. Microstructure and Li alloy formation of nano-structured amorphous Si and Si/TiN composite thin film electrodes. Electrochem Commun, 2004, 6: 484–491

Aurbach D, Markovsky B, Talyossef Y, et al. Studies of cycling behavior, ageing, and interfacial reactions of LiNi0.5Mn1.5O4 and carbon electrodes for lithium-ion 5-V cells. J Power Sources, 2006, 162: 780–789

Feldgitscher C, Peterlik H, Puchberger M, et al. Structural investigations on hybrid polymers suitable as a nanoparticle precipitation environment. Chem Mater, 2009, 21: 695–705

Duncan H, Abu-Lebdeh Y, Davidson IJ. Study of the cathode–electrolyte interface of LiMn1.5Ni0.5O4 synthesized by a sol–gel method for Li-ion batteries. J Electrochem Soc, 2010, 157: A528

Dedryvére R, Foix D, Franger S, et al. Electrode/electrolyte interface reactivity in high-voltage spinel LiMn1.6Ni0.4O4/Li4Ti5O12 lithium-ion battery. J Phys Chem C, 2010, 114: 10999–11008

He Y, Yu X, Wang Y, et al. Alumina-coated patterned amorphous silicon as the anode for a lithium-ion battery with high coulombic efficiency. Adv Mater, 2011, 23: 4938–4941

Li GR, Feng X, Ding Y, et al. AlF3-coated Li(Li0.17Ni0.25Mn0.58)O2 as cathode material for Li-ion batteries. Electrochim Acta, 2012, 78: 308–315

Qiao QQ, Zhang HZ, Li GR, et al. Surface modification of Li-rich layered Li(Li0.17Ni0.25Mn0.58)O2 oxide with Li–Mn–PO4 as the cathode for lithium-ion batteries. JMater Chem A, 2013, 1: 5262–5268

Kim MG, Jo M, Hong YS, et al. Template-free synthesis of Li[Ni0.25Li0.15Mn0.6]O2 nanowires for high performance lithium battery cathode. Chem Commun, 2009, 47: 218–220

Seok Jung Y, Cavanagh AS, Yan Y, et al. Effects of atomic layer deposition of Al2O3 on the Li[Li0.20Mn0.54Ni0.13Co0.13]O2 cathode for lithium-ion batteries. J Electrochem Soc, 2011, 158: A1298

Shi SJ, Tu JP, Mai YJ, et al. Effect of carbon coating on electrochemical performance of Li1.048Mn0.381Ni0.286Co0.286O2 cathodematerial for lithium-ion batteries. Electrochim Acta, 2012, 63: 112–117

Li H, Zhou H. Enhancing the performances of Li-ion batteries by carbon-coating: present and future. Chem Commun, 2012, 48: 1201–1217

Kim WK, Han DW, Ryu WH, et al. Al2O3 coating on LiMn2O4 by electrostatic attraction forces and its effects on the high temperature cyclic performance. Electrochim Acta, 2012, 71: 17–21

He W, Qian J, Cao Y, et al. Improved electrochemical performances of nanocrystalline Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathode material for Li-ion batteries. RSC Adv, 2012, 2: 3423–3429

Pang S, Wang Y, Chen T, et al. The effect of AlF3 modification on the physicochemical and electrochemical properties of Li-rich layered oxide. Ceramics Int, 2016, 42: 5397–5402

Deng H, Belharouak I, Yoon CS, et al. High temperature performance of surface-treated Li 1.1(Ni0.15Co0.1Mn0.55)O1.95 layered oxide. J Electrochem Soc, 2010, 157: A1035

Sun YK, Cho SW, Lee SW, et al. AlF3-coating to improve high voltage cycling performance of Li[Ni1/3Co1/3Mn1/3]O2 cathode materials for lithium secondary batteries. J Electrochem Soc, 2007, 154: A168

Yang K, Fan LZ, Guo J, et al. Significant improvement of electrochemical properties of AlF3-coated LiNi0.5Co0.2Mn0.3O2 cathode materials. Electrochim Acta, 2012, 63: 363–368

Liu B, Zhang Q, He S, et al. Improved electrochemical properties of Li1.2Ni0.18Mn0.59Co0.03O2 by surface modification with LiCoPO4. Electrochim Acta, 2011, 56: 6748–6751

Kim HB, Park BC, Myung ST, et al. Electrochemical and thermal characterization of AlF3-coated Li[Ni0.8Co0.15Al0.05]O2 cathode in lithium-ion cells. J Power Sources, 2008, 179: 347–350

Zheng JM, Zhang ZR, Wu XB, et al. The effects of AlF3 coating on the performance of Li[Li0.2Mn0.54Ni0.13Co0.13]O2 positive electrode material for lithium-ion battery. J Electrochem Soc, 2008, 155: A775

Kim JW, Kim DH, Oh DY, et al. Surface chemistry of LiNi0.5Mn1.5O4 particles coated by Al2O3 using atomic layer deposition for lithiumion batteries. J Power Sources, 2015, 274: 1254–1262

Huang B, Li X, Wang Z, et al. A novel carbamide-assistant hydrothermal process for coating Al2O3 onto LiMn1.5Ni0.5O4 particles used for cathodematerial of lithium-ion batteries. J Alloys Compd, 2014, 583: 313–319

Riley LA, Van Atta S, Cavanagh AS, et al. Electrochemical effects of ALD surface modification on combustion synthesized LiNi1/3Mn1/3Co1/3O2 as a layered-cathodematerial. J Power Sources, 2011, 196: 3317–3324

Huang Y, Chen J, Cheng F, et al. A modified Al2O3 coating process to enhance the electrochemical performance of Li(Ni1/3Co1/3Mn1/3)O2 and its comparison with traditional Al2O3 coating process. J Power Sources, 2010, 195: 8267–8274

Fey GTK, Chang CS, Kumar TP. Synthesis and surface treatment of LiNi1/3Co1/3Mn1/3O2 cathode materials for Li-ion batteries. J Solid State Electrochem, 2010, 14: 17–26

Cheng F, Xin Y, Huang Y, et al. Enhanced electrochemical performances of 5 V spinel LiMn1.58Ni0.42O4 cathode materials by coating with LiAlO2. J Power Sources, 2013, 239: 181–188

Memarzadeh EL, Kalisvaart WP, Kohandehghan A, et al. Silicon nanowire core aluminum shell coaxial nanocomposites for lithium ion battery anodes grown with and without a TiN interlayer. J Mater Chem, 2012, 22: 6655–6668

Hwang G, Park H, Bok T, et al. A high-performance nanoporous Si/Al2O3 foam lithium-ion battery anode fabricated by selective chemical etching of the Al–Si alloy and subsequent thermal oxidation. Chem Commun, 2015, 51: 4429–4432

Panero S. Rechargeable Li/Li1+x V3O8 cells. J Electrochem Soc, 1983, 130: 1225–1227

Kawakita J, Miura T, Kishi T. Lithium insertion and extraction kinetics of Li1+x V3O8. J Power Sources, 1999, 83: 79–83

Gao XW, Wang JZ, Chou SL, et al. Synthesis and electrochemical performance of LiV3O8/polyaniline as cathode material for the lithium battery. J Power Sources, 2012, 220: 47–53

Benedek R, Thackeray MM, Yang LH. First-principles calculation of atomic structure and electrochemical potential of Li1+x V3O8. J Power Sources, 1999, 81–82: 487–490

Jouanneau S, Le Gal La Salle A, Verbaere A, et al. The origin of capacity fading upon lithium cycling in Li1.1V3O8. J Electrochem Soc, 2005, 152: A1660

Huang S, Tu JP, Jian XM, et al. Enhanced electrochemical properties of Al2O3-coated LiV3O8 cathode materials for high-power lithium-ion batteries. J Power Sources, 2014, 245: 698–705

Mo R, Du Y, Zhang N, et al. Surface modification of LiV3O8 nanosheets via layer-by-layer self-assembly for high-performance rechargeable lithium batteries. J Power Sources, 2014, 257: 319–324

Lee J, Lee CL, Park K, et al. Synthesis of an Al2O3-coated polyimide nanofibermat and its electrochemical characteristics as a separator for lithium ion batteries. J Power Sources, 2014, 248: 1211–1217

Yang Z, Wu H. Electrochemical intercalation of lithium into raw carbon nanotubes. Mater Chem Phys, 2001, 71: 7–11

Frackowiak E, Béguin F. Electrochemical storage of energy in carbon nanotubes and nanostructured carbons. Carbon, 2002, 40: 1775–1787

Shin HC, Liu M, Sadanadan B, et al. Electrochemical insertion of lithium into multi-walled carbon nanotubes prepared by catalytic decomposition. J Power Sources, 2002, 112: 216–221

Lahiri I, Oh SW, Hwang JY, et al. High capacity and excellent stability of lithium ion battery anode using interface-controlled binderfree multiwall carbon nanotubes grown on copper. ACS Nano, 2010, 4: 3440–3446

Lahiri I, Oh SM, Hwang JY, et al. Ultrathin alumina-coated carbon nanotubes as an anode for high capacity Li-ion batteries. J Mater Chem, 2011, 21: 13621–13626

Kim K, Kim Y, Oh ES, et al. The role of fluoride in protecting LiNi0.5Mn1.5O4 electrodes against high temperature degradation. Electrochim Acta, 2013, 114: 387–393

Xiong X, Wang Z, Yin X, et al. A modified LiF coating process to enhance the electrochemical performance characteristics of LiNi0.8Co0.1Mn0.1O2 cathode materials. Mater Lett, 2013, 110: 4–9

Sun YK, Lee MJ, Yoon CS, et al. The role of AlF3 coatings in improving electrochemical cycling of Li-enriched nickel-manganese oxide electrodes for Li-ion batteries. Adv Mater, 2012, 24: 1192–1196

Cho E, Mun J, Chae OB, et al. Corrosion/passivation of aluminum current collector in bis(fluorosulfonyl)imide-based ionic liquid for lithium-ion batteries. Electrochem Commun, 2012, 22: 1–3

Liu H, Tang D. The effect of nanolayer AlF3 coating on LiMn2O4 cycle life in high temperature for lithium secondary batteries. Russ J Electrochem, 2009, 45: 762–764

Myung ST, Amine K, Sun YK. Surfacemodification of cathodematerials from nano- to microscale for rechargeable lithium-ion batteries. J Mater Chem, 2010, 20: 7074–7095

Wang MS, Wang J, Zhang J, et al. Improving electrochemical performance of spherical LiMn2O4 cathode materials for lithium ion batteries by Al-F codoping and AlF3 surface coating. Ion, 2015, 21: 27–35

Zheng J, Gu M, Xiao J, et al. Functioning mechanism of AlF3 coating on the Li- and Mn-rich cathode materials. Chem Mater, 2014, 26: 6320–6327

Wu Q, Yin Y, Sun S, et al. Novel AlF3 surface modified spinel LiMn1.5Ni0.5O4 for lithium-ion batteries: performance characterization and mechanism exploration. Electrochim Acta, 2015, 158: 73–80

Lee SH, Yoon CS, Amine K, et al. Improvement of long-term cycling performance of Li[Ni0.8Co0.15Al0.05]O2 byAlF3 coating. J Power Sources, 2013, 234: 201–207

Rosina KJ, Jiang M, Zeng D, et al. Structure of aluminum fluoride coated Li[Li1/9Ni1/3Mn5/9]O2 cathodes for secondary lithiumion batteries. J Mater Chem, 2012, 22: 20602–20610

Lee DJ, Lee KS, Myung ST, et al. Improvement of electrochemical properties of Li1.1Al0.05Mn1.85O4 achieved by an AlF3 coating. J Power Sources, 2011, 196: 1353–1357

Tron A, Park YD, Mun J. AlF3-coated LiMn2O4 as cathode material for aqueous rechargeable lithiumbatterywith improved cycling stability. J Power Sources, 2016, 325: 360–364

Zhu Z, Cai F, Yu J. Improvement of electrochemical performance for AlF3-coated Li1.3Mn4/6Ni1/6Co1/6O2.40 cathode materials for Li-ion batteries. Ion, 2016, 22: 1353–1359

Wang H, Yu Y, Jin G, et al. AlF3 coated LiV3O8 nanosheets with significantly improved cycling stability as cathode material for Li-ion battery. Solid State Ion, 2013, 236: 37–42

Ding F, Xu W, Choi D, et al. Enhanced performance of graphite anode materials by AlF3 coating for lithium-ion batteries. J Mater Chem, 2012, 22: 12745–12751

Li W, Li X, Chen M, et al. AlF3 modification to suppress the gas generation of Li4Ti5O12 anode battery. Electrochim Acta, 2014, 139: 104–110

Cho J, Kim YW, Kim B, et al. A breakthrough in the safety of lithium secondary batteries by coating the cathode material with AlPO4 nanoparticles. Angew Chem Int Ed, 2003, 42: 1618–1621

Kim B, Lee JG, Choi M, et al. Correlation between local strain and cycle-life performance of AlPO4-coated LiCoO2 cathodes. J Power Sources, 2004, 126: 190–192

Cho J, Kim TJ, Kim J, et al. Synthesis, thermal, and electrochemical properties of AlPO4-coated LiNi0.8Co0.1Mn0.1O2 cathode materials for a Li-ion cell. J Electrochem Soc, 2004, 151: A1899

Lee JG, Kim B, Cho J, et al. Effect of AlPO4-nanoparticle coating concentration on high-cutoff-voltage electrochemical performances in LiCoO2. J Electrochem Soc, 2004, 151: A801

Padhi AK. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries. J Electrochem Soc, 1997, 144: 1188–1194

Appapillai AT, Mansour AN, Cho J, et al. Microstructure of LiCoO2 with and without “AlPO4” nanoparticle coating: combined STEM and XPS studies. Chem Mater, 2007, 19: 5748–5757

Lu YC, Mansour AN, Yabuuchi N, et al. Probing the origin of enhanced stability of “AlPO4” nanoparticle coated LiCoO2 during cycling to high voltages: combined XRD and XPS studies. Chem Mater, 2009, 21: 4408–4424

Wu Y, Vadivel Murugan A, Manthiram A. Surface modification of high capacity layered Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathodes by AlPO4. J Electrochem Soc, 2008, 155: A635

Cho J, Lee JG, Kim B, et al. Effect of P2O5 and AlPO4 coating on LiCoO2 cathode material. Chem Mater, 2003, 15: 3190–3193

Kim B, Kim C, Ahn D, et al. Nanostructural effect of AlPO4-nanoparticle coating on the cycle-life performance in LiCoO2 thin films. Electrochem Solid-State Lett, 2007, 10: A32

Zeng Y, He J. Surface structure investigation of LiNi0.8Co0.2O2 by AlPO4 coating and using functional electrolyte. J Power Sources, 2009, 189: 519–521

Liu D, He Z, Liu X. Increased cycling stability of AlPO4-coated LiMn2O4 for lithium ion batteries. Mater Lett, 2007, 61: 4703–4706

Jiao L, Liu L, Sun J, et al. Effect of AlPO4 nanowire coating on the electrochemical properties of LiV3O8 cathode material. J Phys Chem C, 2008, 112: 18249–18254

Shi JY, Yi CW, Kim K. Improved electrochemical performance of AlPO4-coated LiMn1.5Ni0.5O4 electrode for lithium-ion batteries. J Power Sources, 2010, 195: 6860–6866

Ma J, Li B, An L, et al. A highly homogeneous nanocoating strategy for Li-richMn-based layered oxides based on chemical conversion. J Power Sources, 2015, 277: 393–402

Wu F, Zhang X, Zhao T, et al. Multifunctional AlPO4 coating for improving electrochemical properties of low-cost Li[Li0.2Fe0.1Ni0.15Mn0.55]O2 cathode materials for lithium-ion batteries. ACS Appl Mater Interfaces, 2015, 7: 3773–3781

Jung H, Park M, Yoon YG, et al. Amorphous silicon anode for lithium-ion rechargeable batteries. J Power Sources, 2003, 115: 346–351

Kasavajjula U, Wang C, Appleby AJ. Nano- and bulk-silicon-based insertion anodes for lithium-ion secondary cells. J Power Sources, 2007, 163: 1003–1039

Zein El Abedin S, Borissenko N, Endres F. Electrodeposition of nanoscale silicon in a room temperature ionic liquid. Electrochem Commun, 2004, 6: 510–514

Nguyen HT, Zamfir MR, Duong LD, et al. Alumina-coated siliconbased nanowire arrays for high quality Li-ion battery anodes. J Mater Chem, 2012, 22: 24618–24626

Chan CK, Patel RN, O'Connell MJ, et al. Solution-grown silicon nanowires for lithium-ion battery anodes. ACS Nano, 2010, 4: 1443–1450

Wang W, Epur R, Kumta PN. Vertically aligned silicon/carbon nanotube (VASCNT) arrays: hierarchical anodes for lithium-ion battery. Electrochem Commun, 2011, 13: 429–432

Murugesan S, Harris JT, Korgel BA, et al. Copper-coated amorphous silicon particles as an anode material for lithium-ion batteries. Chem Mater, 2012, 24: 1306–1315

Xue L, Fu K, Li Y, et al. Si/C composite nanofibers with stable electric conductive network for use as durable lithium-ion battery anode. Nano Energ, 2013, 2: 361–367

Szczech JR, Jin S. Nanostructured silicon for high capacity lithium battery anodes. Energ Environ Sci, 2011, 4: 56–72

Wang B, Li X, Qiu T, et al. High volumetric capacity silicon-based lithium battery anodes by nanoscale system engineering. Nano Lett, 2013, 13: 5578–5584

Li H, Cheng F, Zhu Z, et al. Preparation and electrochemical performance of copper foam-supported amorphous silicon thin films for rechargeable lithium-ion batteries. J Alloys Compd, 2011, 509: 2919–2923

Wang YH, He Y, Xiao RJ, et al. Investigation of crack patterns and cyclic performance of Ti–Si nanocomposite thin film anodes for lithium ion batteries. J Power Sources, 2012, 202: 236–245

Guo S, Li H, Bai H, et al. Ti/Si/Ti sandwich-like thin film as the anode of lithium-ion batteries. J Power Sources, 2014, 248: 1141–1148

Zhang Q, Liu J, Wu ZY, et al. 3D nanostructured multilayer Si/Al film with excellent cycle performance as anode material for lithium-ion battery. J Alloys Compd, 2016, 657: 559–564

Hatchard TD, Topple JM, Fleischauer MD, et al. Electrochemical performance of SiAlSn films prepared by combinatorial sputtering. Electrochem Solid-State Lett, 2003, 6: A129

Fleischauer MD, Obrovac MN, Dahn JR. Al–Si thin-film negative electrodes for Li-ion batteries. J Electrochem Soc, 2008, 155: A851

Suk J, Kim DY, Kim DW, et al. Electrodeposited 3D porous silicon/ copper films with excellent stability and high rate performance for lithium-ion batteries. J Mater Chem A, 2014, 2: 2478–2481

Wang C, Chui YS, Ma R, et al. A three-dimensional graphene scaffold supported thin film silicon anode for lithium-ion batteries. J Mater Chem A, 2013, 1: 10092–10098

Chen LB, Xie JY, Yu HC, et al. Si–Al thin film anode material with superior cycle performance and rate capability for lithium ion batteries. Electrochim Acta, 2008, 53: 8149–8153

Krishnan R, Lu TM, Koratkar N. Functionally strain-graded nanoscoops for high power Li-ion battery anodes. Nano Lett, 2011, 11: 377–384

Zhou W, Upreti S, Whittingham MS. Electrochemical performance of Al–Si–graphite composite as anode for lithium–ion batteries. Electrochem Commun, 2011, 13: 158–161

Huang S, Wen Z, Zhang J, et al. Li4Ti5O12/Ag composite as electrode materials for lithium-ion battery. Solid State Ion, 2006, 177: 851–855

Dominko R, Gaberscek M, Bele M, et al. Carbon nanocoatings on active materials for Li-ion batteries. J Eur Ceramic Soc, 2007, 27: 909–913

Liu H, Feng Y, Wang K, et al. Synthesis and electrochemical properties of Li4Ti5O12/C composite by the PVB rheological phase method. J Phys Chem Solids, 2008, 69: 2037–2040

Huang J, Jiang Z. The preparation and characterization of Li4Ti5O12/carbon nano-tubes for lithium ion battery. Electrochim Acta, 2008, 53: 7756–7759

Yang L, Gao L. Li4Ti5O12/C composite electrode material synthesized involving conductive carbon precursor for Li-ion battery. J Alloys Compd, 2009, 485: 93–97

Wolfenstine J, Lee U, Allen JL. Electrical conductivity and rate-capability of Li4Ti5O12 as a function of heat-treatment atmosphere. J Power Sources, 2006, 154: 287–289

Li G, Zhang Z, Wang R, et al. Effect of trace Al surface doping on the structure, surface chemistry and low temperature performance of LiNi0.5Co0.2Mn0.3O2 cathode. Electrochim Acta, 2016, 212: 399–407

Hao YJ, Lai QY, Lu JZ, et al. Effects of dopant on the electrochemical properties of Li4Ti5O12 anode materials. Ion, 2007, 13: 369–373

Kubiak P, Garcia A, Womes M, et al. Phase transition in the spinel Li4Ti5O12 induced by lithium insertion. J Power Sources, 2003, 119-121: 626–630

Huang S, Wen Z, Gu Z, et al. Preparation and cycling performance of Al3+ and F− co-substituted compounds Li4AlxTi5−x FyO12−y . Electrochim Acta, 2005, 50: 4057–4062

Huang S, Wen Z, Zhu X, et al. Effects of dopant on the electrochemical performance of Li4Ti5O12 as electrode material for lithium ion batteries. J Power Sources, 2007, 165: 408–412

Yu H, Zhang X, Jalbout AF, et al. High-rate characteristics of novel anode Li4Ti5O12/polyacenematerials for Li-ion secondary batteries. Electrochim Acta, 2008, 53: 4200–4204

Tabuchi T, Yasuda H, Yamachi M. Mechanism of Li-doping into Li4Ti5O12 negative active material for Li-ion cells by new chemical method. J Power Sources, 2006, 162: 813–817

Wolfenstine J, Allen JL. Electrical conductivity and charge compensation in Ta doped Li4Ti5O12. J Power Sources, 2008, 180: 582–585

Martha SK, Nanda J, Veith GM, et al. Electrochemical and rate performance study of high-voltage lithium-rich composition: Li1.2Mn0.525Ni0.175Co0.1O2. J Power Sources, 2012, 199: 220–226

Thackeray MM, Kang SH, Johnson CS, et al. Comments on the structural complexity of lithium-rich Li1+x M1−x O2 electrodes (M=Mn, Ni, Co) for lithium batteries. Electrochem Commun, 2006, 8: 1531–1538

Iftekhar M, Drewett NE, Armstrong AR, et al. Characterization of aluminum doped lithium-manganese rich composites for higher rate lithium-ion cathodes. J Electrochem Soc, 2014, 161: A2109–A2116

He Z, Wang Z, Chen H, et al. Electrochemical performance of zirconium doped lithium rich layered Li1.2Mn0.54Ni0.13Co0.13O2 oxide with porous hollow structure. J Power Sources, 2015, 299: 334–341

Sethuprakhash V, Basirun WJ. Structural and electrochemical investigation of LiNi0.8Co0.2−x MxO2 (M = Al, Al+Mg, Al+Mg+Fe) synthesized by solid-state method. Ion, 2008, 14: 501–507

Liu X, Li D, Mo Q, et al. Facile synthesis of aluminum-doped LiNi0.5Mn1.5O4 hollowmicrospheres and their electrochemical performance for high-voltage Li-ion batteries. J Alloys Compd, 2014, 609: 54–59

Locati C, Lafont U, Simonin L, et al. Mg-doped LiNi0.5Mn1.5O4 spinel for cathode materials. J Power Sources, 2007, 174: 847–851

Lin M, Wang SH, Gong ZL, et al. A strategy to improve cyclic performance of LiNi0.5Mn1.5O4 in a wide voltage region by Ti-doping. J Electrochem Soc, 2013, 160: A3036–A3040

Qi X, Blizanac B, DuPasquier A, et al. Influence of thermal treated carbon black conductive additive on the performance of high voltage spinel Cr-doped LiNi0.5Mn1.5O4 composite cathode electrode. J Electrochem Soc, 2015, 162: A339–A343

Liu J, Manthiram A. Improved electrochemical performance of the 5 V spinel cathode LiMn1.5Ni0.42Zn0.08O4 by surface modification. J Electrochem Soc, 2009, 156: A66

Şahan H, Göktepe H, Patat, et al. Effect of the Cr2O3 coating on electrochemical properties of spinel LiMn2O4 as a cathode material for lithium battery applications. Solid State Ion, 2010, 181: 1437–1444

Thirunakaran R, Kim KT, Kang YM, et al. Adipic acid assisted, sol–gel route for synthesis of LiCrxMn2−x O4 cathode material. J Power Sources, 2004, 137: 100–104

Arumugam D, Kalaignan GP, Vediappan K, et al. Synthesis and electrochemical characterizations of nano-scaled Zn doped LiMn2O4 cathode materials for rechargeable lithium batteries. Electrochim Acta, 2010, 55: 8439–8444

Raja MW, Mahanty S, Basu RN. Influence of S and Ni co-doping on structure, band gap and electrochemical properties of lithium manganese oxide synthesized by soft chemical method. J Power Sources, 2009, 192: 618–626

Wu YP, Rahm E, Holze R. Effects of heteroatoms on electrochemical performance of electrode materials for lithium ion batteries. Electrochim Acta, 2002, 47: 3491–3507

Patoux S, Sannier L, Lignier H, et al. High voltage nickel manganese spinel oxides for Li-ion batteries. Electrochim Acta, 2008, 53: 4137–4145

Guo D, Li B, Chang Z, et al. Facile synthesis of LiAl0.1Mn1.9O4 as cathodematerial for lithium ion batteries: towards rate and cycling capabilities at an elevated temperature. Electrochim Acta, 2014, 134: 338–346

Yuan A, Tian L, Xu W, et al. Al-doped spinel LiAl0.1Mn1.9O4 with improved high-rate cyclability in aqueous electrolyte. J Power Sources, 2010, 195: 5032–5038

Ryu WH, Eom JY, Yin RZ, et al. Synergistic effects of various morphologies and Al doping of spinel LiMn2O4 nanostructures on the electrochemical performance of lithium-rechargeable batteries. J Mater Chem, 2011, 21: 15337–15342

Wang JL, Li ZH, Yang J, et al. Effect of Al-doping on the electrochemical properties of a three-dimensionally porous lithium manganese oxide for lithium-ion batteries. Electrochim Acta, 2012, 75: 115–122

Thackeray MM, Kang SH, Johnson CS, et al. Li2MnO3-stabilized LiMO2 (M = Mn, Ni, Co) electrodes for lithium-ion batteries. J Mater Chem, 2007, 17: 3112–3125

Jafta CJ, Ozoemena KI, Mathe MK, et al. Synthesis, characterisation and electrochemical intercalation kinetics of nanostructured aluminium-doped Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathodematerial for lithium ion battery. Electrochim Acta, 2012, 85: 411–422

Trease NM, Seymour ID, Radin MD, et al. Identifying the Distribution of Al3+ in LiNi0.8Co0.15Al0.05O2. Chem Mater, 2016, 28: 8170–8180

Lin JY, Hsu CC, Ho HP, et al. Sol–gel synthesis of aluminum doped lithium titanate anode material for lithium ion batteries. Electrochim Acta, 2013, 87: 126–132

Le HTT, Kalubarme RS, Ngo DT, et al. Citrate gel synthesis of aluminum-doped lithium lanthanum titanate solid electrolyte for application in organic-type lithium–oxygen batteries. J Power Sources, 2015, 274: 1188–1199

Zhang L, Zhang J, Liu Y, et al. Al doped-ZnO nanoparticles implanted in reduced graphene oxide with improved electrochemical properties for lithium ion batteries. Mater Lett, 2016, 165: 165–168

Hou C, Ma Y, Dong X, et al. Facile synthesis of LiCo1/3Ni1/3Mn1/3O2/Al(OH)3 composite as a high-performance cathode material for lithium ion cells. J Alloys Compd, 2016, 656: 849–853

Jang SB, Kang SH, Amine K, et al. Synthesis and improved electrochemical performance of Al(OH)3-coated Li[Ni1/3Mn1/3Co1/3]O2 cathodematerials at elevated temperature. Electrochim Acta, 2005, 50: 4168–4173

Kang YJ, Kim JH, Lee SW, et al. The effect of Al(OH)3 coating on the Li[Li0.2Ni0.2Mn0.6]O2 cathode material for lithium secondary battery. Electrochim Acta, 2005, 50: 4784–4791

Zgirski M, Riikonen KP, Touboltsev V, et al. Size dependent breakdown of superconductivity in ultranarrow nanowires. Nano Lett, 2005, 5: 1029–1033

Zgirski M, Riikonen KP, Touboltsev V, et al. Quantum fluctuations in ultranarrowsuperconducting aluminum nanowires. Phys Rev B, 2008, 77: 054508

Özer MM, Thompson JR, Weitering HH. Hard superconductivity of a soft metal in the quantum regime. Nat Phys, 2006, 2: 173–176

Guo, Wan LJ, Zhu CF, et al. Ordered Ni−Cu nanowire array with enhanced coercivity. Chem Mater, 2003, 15: 664–667

Bao J, Tie C, Xu Z, et al. Template synthesis of an array of nickel nanotubules and its magnetic behavior. Adv Mater, 2001, 13: 1631–1633

Ferré R, Ounadjela K, George JM, et al. Magnetization processes in nickel and cobalt electrodeposited nanowires. Phys Rev B, 1997, 56: 14066–14075

McGary PD, Tan L, Zou J, et al. Magnetic nanowires for acoustic sensors. J Appl Phys, 2006, 99: 08B310–08B310

Kim TH, Zhang XG, Nicholson DM, et al. Large discrete resistance jump at grain boundary in copper nanowire. Nano Lett, 2010, 10: 3096–3100

Datt G, Sen Bishwas M, Manivel Raja M, et al. Observation of magnetic anomalies in one-step solvothermally synthesized nickel–cobalt ferrite nanoparticles. Nanoscale, 2016, 8: 5200–5213

Granqvist CG. Transparent conductors as solar energymaterials: a panoramic review. Sol EnergMater Sol Cells, 2007, 91: 1529–1598

Lee EP, Peng Z, Cate DM, et al. Growing Pt nanowires as a densely packed array on metal gauze. J Am Chem Soc, 2007, 129: 10634–10635

Shaijumon MM, Perre E, Daffos B, et al. Nanoarchitectured 3D cathodes for Li-Ion microbatteries. Adv Mater, 2010, 22: 4978–4981

Taberna PL, Mitra S, Poizot P, et al. High rate capabilities Fe3O4-based Cu nano-architectured electrodes for lithium-ion battery applications. Nat Mater, 2006, 5: 567–573

Au M, McWhorter S, Ajo H, et al. Free standing aluminum nanostructures as anodes for Li-ion rechargeable batteries. J Power Sources, 2010, 195: 3333–3337

Huber GW, Shabaker JW, Dumesic JA. Raney Ni-Sn catalyst for H2 production from biomass-derived hydrocarbons. Science, 2003, 300: 2075–2077

Sakintuna B, Lamaridarkrim F, Hirscher M. Metal hydride materials for solid hydrogen storage: a review. Int J Hydrogen Energ, 2007, 32: 1121–1140

Banerjee P, Perez I, Henn-Lecordier L, et al. Nanotubularmetal–insulator–metal capacitor arrays for energy storage. Nat Nanotech, 2009, 4: 292–296

Portet C, Taberna PL, Simon P, et al. Modification of Al current collector surface by sol–gel deposit for carbon–carbon supercapacitor applications. Electrochim Acta, 2004, 49: 905–912

Lang X, Hirata A, Fujita T, et al. Nanoporous metal/oxide hybrid electrodes for electrochemical supercapacitors. NatNanotech, 2011, 6: 232–236

Liu Y, Hudak NS, Huber DL, et al. In situ transmission electronmicroscopy observation of pulverization of aluminum nanowires and evolution of the thin surface Al2O3 layers during lithiation–delithiation cycles. Nano Lett, 2011, 11: 4188–4194

Benson J, Boukhalfa S, Magasinski A, et al. Chemical vapor deposition of aluminum nanowires on metal substrates for electrical energy storage applications. ACS Nano, 2012, 6: 118–125

Rani JV, Kanakaiah V, Dadmal T, et al. Fluorinated natural graphite cathode for rechargeable ionic liquid based aluminum-ion battery. J Electrochem Soc, 2013, 160: A1781–A1784

Rahman MA, Wang X, Wen C. High energy density metal-air batteries: a review. J Electrochem Soc, 2013, 160: A1759–A1771

Doche ML, Novel-Cattin F, Durand R, et al. Characterization of different grades of aluminum anodes for aluminum/air batteries. J Power Sources, 1997, 65: 197–205

Patnaik RSM, Ganesh S, Ashok G, et al. Heat management in aluminium/ air batteries: sources of heat. J Power Sources, 1994, 50: 331–342

Rudd EJ, Gibbons DW. High energy density aluminum/oxygen cell. J Power Sources, 1994, 47: 329–340

Linden D, Reddy TB (3rd ed.). Handbook of Batteries. New York: McGraw-Hill, 1995

Tang Y, Lu L, Roesky HW, et al. The effect of zinc on the aluminum anode of the aluminum–air battery. J Power Sources, 2004, 138: 313–318

Jiang T, Chollier Brym MJ, Dubé G, et al. Electrodeposition of aluminium from ionic liquids: Part I—electrodeposition and surface morphology of aluminium from aluminium chloride (AlCl3)–1-ethyl-3-methylimidazolium chloride ([EMIm]Cl) ionic liquids. Surface Coatings Tech, 2006, 201: 1–9

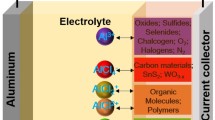

Jayaprakash N, Das SK, Archer LA. The rechargeable aluminumion battery. Chem Commun, 2011, 47: 12610–12612

Wang H, Gu S, Bai Y, et al. Anion-effects on electrochemical properties of ionic liquid electrolytes for rechargeable aluminum batteries. J Mater Chem A, 2015, 3: 22677–22686

Wang H, Gu S, Bai Y, et al. High-voltage and noncorrosive ionic liquid electrolyte used in rechargeable aluminum battery. ACS Appl Mater Interfaces, 2016, 8: 27444–27448

Sun XG, Fang Y, Jiang X, et al. Polymer gel electrolytes for application in aluminum deposition and rechargeable aluminum ion batteries. Chem Commun, 2016, 52: 292–295

Gu S, Wang H, Wu C, et al. Confirming reversible Al3+ storage mechanism through intercalation of Al3+ into V2O5 nanowires in a rechargeable aluminum battery. Energ Storage Mater, 2017, 6: 9–17

Hudak NS. Chloroaluminate-Doped Conducting Polymers as Positive Electrodes in Rechargeable Aluminum Batteries. J Phys Chem C, 2014, 118: 5203–5215

Gifford PR. An aluminum/chlorine rechargeable cell employing a roomtemperaturemolten salt electrolyte. J Electrochem Soc, 1988, 135: 650–654

Reed LD, Ortiz SN, Xiong M, et al. A rechargeable aluminum-ion battery utilizing a copper hexacyanoferrate cathode in an organic electrolyte. Chem Commun, 2015, 51: 14397–14400

Chiku M, Takeda H, Matsumura S, et al. Amorphous vanadium oxide/carbon composite positive electrode for rechargeable aluminum battery. ACS Appl Mater Interfaces, 2015, 7: 24385–24389

Lee S, Cho J. Critical requirements for rapid charging of rechargeable Al- and Li-ion batteries. Angew Chem Int Ed, 2015, 54: 9452–9455

Liu S, Ye SH, Li CZ, et al. Rechargeable aqueous lithium-ion battery of TiO2/LiMn2O4with a high voltage. J Electrochem Soc, 2011, 158: A1490

Liu S, Hu JJ, Yan NF, et al. Aluminum storage behavior of anatase TiO2 nanotube arrays in aqueous solution for aluminum ion batteries. Energ Environ Sci, 2012, 5: 9743–9746

Liu Y, Sang S, Wu Q, et al. The electrochemical behavior of Cl− assisted Al3+ insertion into titanium dioxide nanotube arrays in aqueous solution for aluminum ion batteries. Electrochim Acta, 2014, 143: 340–346

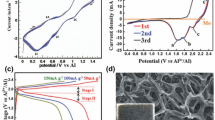

Lin MC, Gong M, Lu B, et al. An ultrafast rechargeable aluminium-ion battery. Nature, 2015, 520: 324–328

Wu Y, Gong M, Lin MC, et al. 3D graphitic foams derived from chloroaluminate anion intercalation for ultrafast aluminum-ion battery. Adv Mater, 2016, 28: 9218–9222

Chen H, Guo F, Liu Y, et al. A defect-free principle for advanced graphene cathode of aluminum-ion battery. Adv Mater, 2017, 29: 1605958

Yu X, Wang B, Gong D, et al. Graphene nanoribbons on highly porous 3D graphene for high-capacity and ultrastable Al-ion batteries. Adv Mater, 2017, 29: 1604118

Jung SC, Kang YJ, Yoo DJ, et al. Flexible few-layered graphene for the ultrafast rechargeable aluminum-ion battery. J Phys Chem C, 2016, 120: 13384–13389

Wang H, Bai Y, Chen S, et al. Binder-free V2O5 cathode for greener rechargeable aluminum battery. ACS Appl Mater Interfaces, 2015, 7: 80–84

Wang F, Yu F, Wang X, et al. Aqueous rechargeable zinc/aluminum ion battery with good cycling performance. ACS ApplMater Interfaces, 2016, 8: 9022–9029

Allman VR. Doppelschichtstrukturen mit brucitähnlichen Schichtionen [Me(II)1−x Me(III)x(OH)2]x+. Chimia, 1970, 24: 99–108

Intissar M, Segni R, Payen C, et al. Trivalent cation substitution effect into layered double hydroxides Co2Fey Al1−y (OH)6Cl·nH2O: study of the local order. J Solid State Chem, 2002, 167: 508–516

Zhao MQ, Liu XF, Zhang Q, et al. Graphene/single-walled carbon nanotube hybrids: one-step catalytic growth and applications for high-rate Li–S batteries. ACS Nano, 2012, 6: 10759–10769

Taibi M, Ammar S, Jouini N, et al. Layered nickel hydroxide salts: synthesis, characterization and magnetic behaviour in relation to the basal spacing. J Mater Chem, 2002, 12: 3238–3244

Nakahira A, Murase H, Yasuda H. Effect of application of a high magnetic field on themicrostructure of Fe substituted layered double hydroxide clay for a magnetic application. J Appl Phys, 2007, 101: 09N516–09N516

Tichit D, Ortiz MJM, Francová D, et al. Design of nanostructured multifunctional Pd-based catalysts fromlayered double hydroxides precursors. Appl Catal A-General, 2007, 318: 170–177

Nakahira A, Kubo T, Murase H. Synthesis of LDH-type clay substituted with Fe and Ni ion for arsenic removal and its application to magnetic separation. IEEE Trans Magn, 2007, 43: 2442–2444

Prasanna SV, Kamath PV, Shivakumara C. Synthesis and characterization of layered double hydroxides (LDHs) with intercalated chromate ions. Mater Res Bull, 2007, 42: 1028–1039

Kamath PV, Annal Therese GH, Gopalakrishnan J. On the existence of hydrotalcite-like phases in the absence of trivalent cations. J Solid State Chem, 1997, 128: 38–41

Sugimoto A. Preparation and characterization of Ni/Al-layered double hydroxide. J Electrochem Soc, 1999, 146: 1251–1255

Wang T, Chen S, Pang H, et al. MoS2-based nanocomposites for electrochemical energy storage. Adv Sci, 2017, 4: 1600289

Sato Y, Takeuchi S, Kobayakawa K. Cause of the memory effect observed in alkaline secondary batteries using nickel electrode. J Power Sources, 2001, 93: 20–24

Corrigan DA. Electrochemical and spectroscopic evidence on the participation of quadrivalent nickel in the nickel hydroxide redox reaction. J Electrochem Soc, 1989, 136: 613–619

Delahaye-Vidal A, Figlarz M. Textural and structural studies on nickel hydroxide electrodes. II. Turbostratic nickel (II) hydroxide submitted to electrochemical redox cycling. J Appl Electrochem, 1987, 17: 589–599

Hu M, Yang Z, Lei L, et al. Structural transformation and its effects on the electrochemical performances of a layered double hydroxide. J Power Sources, 2011, 196: 1569–1577

Hu WK, Noréus D. Alpha nickel hydroxides as lightweight nickel electrode materials for alkaline rechargeable cells. Chem Mater, 2003, 15: 974–978

Dai J, Li SFY, Xiao TD, et al. Structural stability of aluminum stabilized alpha nickel hydroxide as a positive electrode material for alkaline secondary batteries. J Power Sources, 2000, 89: 40–45

Li Y, Li W, Chou S, et al. Synthesis, characterization and electrochemical properties of aluminum-substituted alpha-Ni(OH)2 hollow spheres. J Alloys Compd, 2008, 456: 339–343

Liang J, Ma R, Iyi N, et al. Topochemical synthesis, anion exchange, and exfoliation ofCo−Ni layered double hydroxides: a route to positively charged Co−Ni hydroxide nanosheets with tunable composition. Chem Mater, 2010, 22: 371–378

Delmas C, Borthomieu Y. Chimie douce reactions: a new route to obtain well crystallized layer double hydroxides. J Solid State Chem, 1993, 104: 345–352

Iwasaki T, Yoshii H, Nakamura H, et al. Simple and rapid synthesis of Ni–Fe layered double hydroxide by a new mechanochemical method. Appl Clay Sci, 2012, 58: 120–124

Axmann P, Glemser O. Nickel hydroxide as a matrix for unusual valencies: the electrochemical behaviour of metal(III)-ion-substituted nickel hydroxides of the pyroaurite type. J Alloys Compd, 1997, 246: 232–241

Chen H, Wang JM, Zhao YL, et al. Electrochemical performance of Zn-substituted Ni(OH)2 for alkaline rechargeable batteries. J Solid State Electrochem, 2005, 9: 421–428

Tessier C. Structural and textural evolution of zinc-substituted nickel hydroxide electrode materials upon ageing in KOH and upon redox cycling. Solid State Ion, 2000, 133: 11–23

Wu MY, Wang JM, Zhang JQ, et al. Effects of coprecipitated manganese on the structure and electrochemical performance of Al-substituted α-nickel hydroxide. J Solid State Electrochem, 2006, 10: 411–415

Kameda T, Hoshi K, Yoshioka T. Preparation ofCu–Al layered double hydroxide intercalated with ethylenediaminetetraacetate by coprecipitation and its uptake of rare earth ions from aqueous solution. Solid State Sci, 2013, 17: 28–34

Lei L, Hu M, Gao X, et al. The effect of the interlayer anions on the electrochemical performance of layered double hydroxide electrode materials. Electrochim Acta, 2008, 54: 671–676

Hu M, Gao X, Lei L, et al. Behavior of a layered double hydroxide under high current density charge and discharge cycles. J Phys Chem C, 2009, 113: 7448–7455

Li J, Shangguan E, Guo D, et al. Synthesis, characterization and electrochemical performance of high-density aluminum substituted α-nickel hydroxide cathode material for nickel-based rechargeable batteries. J Power Sources, 2014, 270: 121–130

Hu M, Ji X, Lei L, et al. The effect of cobalt on the electrochemical performances of Ni–Al layered double hydroxides used in Ni–M(H) battery. J Alloys Compd, 2013, 578: 17–25

Chen H, Wang JM, Pan T, et al. The structure and electrochemical performance of spherical Al-substituted α-Ni(OH)2 for alkaline rechargeable batteries. J Power Sources, 2005, 143: 243–255

Kim Y, Kim D. Synthesis of high-density nickel cobalt aluminum hydroxide by continuous coprecipitationmethod. ACS Appl Mater Interfaces, 2012, 4: 586–589

Deroy A, Besse J. Evolution of protonic conduction in some synthetic anionic clays. Solid State Ion, 1991, 46: 95–101

Lee K, Nam JH, Lee JH, et al. Methanol and proton transport control by using layered double hydroxide nanoplatelets for direct methanol fuel cell. Electrochem Commun, 2005, 7: 113–118

Béléké AB, Mizuhata M. Electrochemical properties of nickel–aluminum layered double hydroxide/carbon composite fabricated by liquid phase deposition. J Power Sources, 2010, 195: 7669–7676

Béléké AB, Higuchi E, Inoue H, et al. Effects of the composition on the properties of nickel–aluminum layered double hydroxide/carbon (Ni–Al LDH/C) composite fabricated by liquid phase deposition (LPD). J Power Sources, 2013, 225: 215–220

Béléké AB, Higuchi E, Inoue H, et al. Durability of nickel–metal hydride (Ni–MH) battery cathode using nickel–aluminum layered double hydroxide/carbon (Ni–Al LDH/C) composite. J Power Sources, 2014, 247: 572–578

Mizuhata M, Hosokawa A, Béléké AB, et al. ECS Trans, 2009, 19: 41–46

Yu JG, Yu HG, Cheng B, et al. The effect of calcination temperature on the surface microstructure and photocatalytic activity of TiO2 thin films prepared by liquid phase deposition. J Phys Chem B, 2003, 107: 13871–13879

Deki S, Yu Yu Ko H, Fujita T, et al. Synthesis and microstructure of metal oxide thin films containing metal nanoparticles by liquid phase deposition (LPD) method. Eur Phys J D, 2001, 16: 325–328

Deki S, Iizuka S, Horie A, et al. Liquid-phase infiltration (LPI) process for the fabrication of highly nano-orderedmaterials. Chem Mater, 2004, 16: 1747–1750

Deki S, Iizuka S, Akamatsu K, et al. Fabrication and structural control of Fe/Ti oxide thin films with graded compositional profiles by liquid phase deposition. J Am Ceramic Soc, 2005, 88: 731–736

Deki S, Hosokawa A, Béléké AB, et al. α-Ni(OH)2 thin films fabricated by liquid phase deposition method. Thin Solid Films, 2009, 517: 1546–1554

Gao Z, Wang J, Li Z, et al. Graphene nanosheet/Ni2+/Al3+ layered double-hydroxide composite as a novel electrode for a supercapacitor. Chem Mater, 2011, 23: 3509–3516

Zhang L, Wang J, Zhu J, et al. 3D porous layered double hydroxides grown on graphene as advanced electrochemical pseudocapacitor materials. J Mater Chem A, 2013, 1: 9046–9053

Zhang G, Xiao X, Li B, et al. Transition metal oxides with one-dimensional/one-dimensional-analogue nanostructures for advanced supercapacitors. J Mater Chem A, 2017, 5: 8155–8186

Hu J, Lei G, Lu Z, et al. Alternating assembly of Ni–Al layered double hydroxide and graphene for high-rate alkaline battery cathode. Chem Commun, 2015, 51: 9983–9986

Liu Z, Ma R, Osada M, et al. Synthesis, anion exchange, and delamination of Co−Al layered double hydroxide: assembly of the exfoliated nanosheet/polyanion composite films and magneto-optical studies. J Am Chem Soc, 2006, 128: 4872–4880

Chen H, Wang JM, Pan T, et al. Physicochemical properties and electrochemical performance ofAl-substituted α-Ni(OH)2 with additives for Ni-metal hydride batteries. J Electrochem Soc, 2003, 150: A1399

Feng Z, Yang Z, Yang B, et al. The application of Co–Al-hydrotalcite as a novel additive of positivematerial for nickel–metal hydride secondary cells. J Power Sources, 2014, 266: 22–28

Gong M, Li Y, Zhang H, et al. Ultrafast high-capacity NiZn battery with NiAlCo-layered double hydroxide. Energ Environ Sci, 2014, 7: 2025–2032

Xie X, Yang Z, Feng Z, et al. Effect of dodecyl sulfate anions on the electrochemical performances of zinc-aluminum-hydrotalcite as anode material for zinc/nickel secondary batteries. Electrochim Acta, 2014, 149: 101–107

Fan X, Yang Z, Xie X, et al. The electrochemical behaviors of Zn–Al–La-hydrotalcite in Zn–Ni secondary cells. J Power Sources, 2013, 241: 404–409

Wang T, Yang Z, Yang B, et al. The electrochemical performances of Zn–Sn–Al-hydrotalcites in Zn–Ni secondary cells. J Power Sources, 2014, 257: 174–180

Wen X, Yang Z, Xie X, et al. The effects of element Cu on the electrochemical performances of zinc-aluminum-hydrotalcites in zinc/nickel secondary battery. Electrochim Acta, 2015, 180: 451–459

Yang B, Yang Z, Wang R, et al. Layered double hydroxide/carbon nanotubes composite as a high performance anode material for Ni–Zn secondary batteries. Electrochim Acta, 2013, 111: 581–587

Li WH, Zeng LC, Wu Y, et al. Nanostructured electrode materials for lithium-ion and sodium-ion batteries via electrospinning. Sci China Mater, 2016, 59: 287–321

C. Massé R, Uchaker E, Cao G, et al. Beyond Li-ion: electrode materials for sodium- and magnesium-ion batteries. Sci China Mater, 2015, 58: 715–766

Acknowledgements

This work was supported by the Program for New Century Excellent Talents of theUniversity in China (NCET-13-0645) and the National Natural Science Foundation of China (21201010, 21671170 and 21673203), the Innovation Scientists and Technicians Troop Construction Projects of Henan Province (164200510018), the Program for Innovative Research Team (in Science and Technology) in the University of Henan Province (14IRTSTHN004), the Six Talent Plan (2015-XCL- 030), and Qinglan Project. We also acknowledge the Priority Academic Program Development of Jiangsu Higher Education Institutions, the Undergraduate Scientific Research Innovation Projects in Jiangsu province (201611117047Y) and the technical support we received from the Testing Center of Yangzhou University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Author contributions Qiu J, Zhao M conducted the collection and arrangement of literatures, wrote and modified the manuscript. Zhao Q helped to collect and arrange the literatures. Xu Y, Zhang L, Lu X helped modify the manuscript. Pang H conceived the project and modified the manuscript. All authors contributed to the general discussion.

Conflict of interest The authors declare that they have no conflict of interest.

Jiaqing Qiu is a student at Yangzhou University, under Prof. Pang’s supervision. Her interest focuses on the nanomaterials for energy storage.

Huaiguo Xue received his PhD degree in polymer chemistry from Zhejiang University in 2002. He is currently a professor of physical chemistry and the dean of the College of Chemistry and Chemical Engineering at Yangzhou University. His research interests focus on electrochemistry, functional polymer and biosensors.

Huan Pang received his PhD degree from Nanjing University in 2011. He then founded his research group in Anyang NormalUniversitywhere hewas appointed as a distinguished professor in 2013. He has nowjointed YangzhouUniversity as a university distinguished professor. He has publishedmore than 110 papers in peer-reviewed journals including Chemical Society Reviews, Advanced Materials, Energy Environ. Sci., with 3900 citations (H-index=33). His research interests include the development of inorganic nanostructures and their applications in flexible electronics with a focus on energy devices.

Rights and permissions

About this article

Cite this article

Qiu, J., Zhao, M., Zhao, Q. et al. Aluminum-based materials for advanced battery systems. Sci. China Mater. 60, 577–607 (2017). https://doi.org/10.1007/s40843-017-9060-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-017-9060-x