Abstract

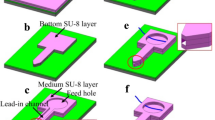

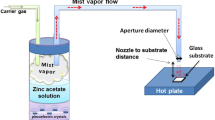

In this paper, we propose a unique micro multi-nozzle jet head to generate a stable column jet flow by applying vacuum suction to the side of a jetting nozzle. The micro multi-nozzle jet head was designed and fabricated to operate in both the jetting and suction modes selectively or simultaneously. The jet head includes eighteen jetting nozzles of 100 μm diameter, vacuum suction channels, inlets and a nozzle protection outer hole. The whole size of the micro multi-nozzle jet plate is 50 × 20 mm2. To demonstrate large area organic thin film coating, micro multi-nozzle jet coating was performed on a 5th generation size (1100 × 1300 mm2) glass substrate. A poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) solution was selected as a test ink. To uniformly coat an organic thin film, we first investigated the physical parameter conditions such as jetting pressure, head suction pressure, stage moving speed, and coating head printing pitch. The thickness of the coated PEDOT:PSS thin film was 76.86 ± 3.33 nm and its uniformity (CV) was 4.33%.

Similar content being viewed by others

Availability of Data and Materials

The datasets supporting the conclusions of this article are included within the article.

References

Cao, W., Li, J., Chen, H., & Xue, J. (2014). Transparent electrodes for organic optoelectronic devices: A review. Journal of Photon Energy, 4, 040990–040991. https://doi.org/10.1117/1.jpe.4.040990

Forrest, S. R. (2004). The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature, 428, 911–918. https://doi.org/10.1038/nature02498

Espinos, N., Hosel, M., Angmo, D., & Krebs, F. C. (2012). Solar cells with one-day energy payback for the factories of the future. Energy and Environmental Science, 5, 5117–5132. https://doi.org/10.1039/c1ee02728j

Cao, W., & Xue, J. (2014). Recent progress in organic photovoltaics: Device architecture and optical design. Energy and Environmental Science, 7, 2123–2144. https://doi.org/10.1039/c4ee00260a

Choi, K.-J., Lee, J.-Y., Shin, D.-K., & Park, J. (2016). Investigation on slot-die coating of hybrid material structure for OLED lightings. Journal of Physics and Chemistry of Solids, 95, 119–128. https://doi.org/10.1016/j.jpcs.2016.04.006

Raupp, S. M., Merkleina, L., Pathak, M., Scharfer, P., & Schabela, W. (2017). An experimental study on the reproducibility of different multilayer OLED materials processed by slot die coating. Chemical Engineering Science, 160, 113–120. https://doi.org/10.1016/j.ces.2016.11.018

Choi, K.-J., Lee, J.-Y., Park, J., & Seo, Y.-S. (2015). Multilayer slot-die coating of large-area organic light-emitting diodes. Organic Electronics, 26, 66–74. https://doi.org/10.1016/j.orgel.2015.07.025

Gorter, H., Coenen, M. J. J., Slaats, M. W. L., Ren, M., Lu, W., Kuijpers, C. J., & Groen, W. A. (2013). Toward inkjet printing of small molecule organic light emitting diodes. Thin Solid Films, 532, 11–15. https://doi.org/10.1016/j.tsf.2013.01.041

Wengeler, L., Schmitt, M., Peters, K., Scharfer, P., & Schabel, W. (2013). Comparison of large scale coating techniques for organic and hybrid films in polymer based solar cells. Chemical Engineering and Processing: Process Intensification, 68, 38–44. https://doi.org/10.1016/j.cep.2012.03.004

Krebs, F. C. (2009). All solution roll-to-roll processed polymer solar cells free from indium-tin-oxide and vacuum coating steps. Organic Electronics, 10, 761–768. https://doi.org/10.1016/j.orgel.2009.03.009

Søndergaard, R. R., Hosel, M., & Krebs, F. C. (2012). Roll-to-roll fabrication of large area functional organic materials. Journal of Polymer Science Part B: Polymer Physics, 51, 16–34. https://doi.org/10.1002/polb.23192|

Carvalho, M. S., & Kheshgi, H. S. (2000). Low-flow limit in slot coating: Theory and experiments. Journal AIChE, 46, 1907–1917. https://doi.org/10.1002/aic.690461003|

Koo, J., Kim, J. W., Kim, M., Yoon, S., & Shim, J. H. (2020). Inkjet printing of silica aerogel for fabrication of 2-D patterned thermal insulation layers. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-020-00189-4

Kang, M. G., & Kang, K.-T. (2018). Flexible 2-layer paper printed circuit board fabricated by inkjet printing for 3-D origami electronics. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(3), 421–426. https://doi.org/10.1007/s40684-018-0045-2

Patil, S. A., Ryu, C.-H., & Kim, H.-S. (2018). Synthesis and characterization of copper nanoparticles (Cu-Nps) using rongalite as reducing agent and photonic sintering of Cu-Nps ink for printed electronics. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(2), 239–245. https://doi.org/10.1007/s40684-018-0024-7

Jang, Y.-R., Ryu, C.-H., Hwang, Y.-T., & Kim, H.-S. (2020). Optimization of intense pulsed light sintering considering dimensions of printed Cu nano/micro-paste patterns for printed electronics. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-019-00180-8

Lee, J., Kim, S., & Lee, C. (2019). Surface drying for brittle material coating without crack defects in large-area roll-to-roll coating system. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(4), 723–730. https://doi.org/10.1007/s40684-019-00104-6

Chesterfield, R., Johnson, A., Lang, C., Stainer, M., & Ziebarth, J. (2011). Solution-coating technology for AMOLED displays. Information Display, 1(11), 24–30. https://doi.org/10.1002/j.2637-496x.2011.tb00339.x

Bhamidipati, K. L., Didari, S., & Harris, T. A. L. (2013). Slot die coating of poly benzimiazole based membranes at the air engulfment limit. Journal of Power Sources, 239, 382–392. https://doi.org/10.1016/j.jpowsour.2013.03.132

Larsen-Olsen, T. T., Andreasen, B., Andersen, T. R., Bottiger, A. P. L., Bundgaard, E., Norrman, K., Andreasen, J. W., Jørgensen, M., & Krebs, F. C. (2012). Simultaneous multilayer formation of the polymer solar cell stack using roll-to-roll double slot-die coating from water. Solar Energy Materials and Solar Cells, 97, 22–27. https://doi.org/10.1016/j.solmat.2011.08.026

Chesterfield, R. J., Frischknecht, K. D., Stainer, M., & Truong, N. (2009). Multinozzle printing: A cost-effective process for OLED display fabrication. Journal SID, 09, 951–954. https://doi.org/10.1889/1.3256956

Kang, Y. J., Bail, R., Lee, C. W., & Chin, B. D. (2019). Inkjet printing of mixed-host emitting layer for electrophosphorescent organic light-emitting diodes. Applied Materials & Interfaces, 11, 21784–21794. https://doi.org/10.1021/acsami.9b04675

Kim, H., Lee, S., Han, D., & Yoo, S. (2014). High-density organic photovoltaic modules: Mask-free fabrication using nozzle jet printing and oblique deposition. Solar Energy Materials and Solar Cells, 120, 561–565. https://doi.org/10.1016/j.solmat.2013.09.039

Bhat, K. S., Ahmad, R., Yoo, J.-Y., & Hahn, Y.-B. (2018). Fully nozzle-jet printed non-enzymatic electrode for bio sensing applicaiton. Journal of Colloid and Interface Science, 512(2018), 480–488. https://doi.org/10.1016/j.jcis.2017.10.088

An, K., Yoon, D. G., & Kang, K.-T. (2020). Effects of residual solvent in printed phosphorescent emissive thin films as, the origin of limited efficiency in organic light emitting diodes. Progress in Organic Coatings, 147, 105781. https://doi.org/10.1016/j.porgcoat.2020.105781

An, K., Kim, J. B., Yoon, D. G., Jeong, Y.-C., & Kang, K.-T. (2019). P-72: Nozzle jet printing of organic thin films for solution process of organic light emitting diodes. SID Symposium Digest of Technical Papers, 1, 1503–1506. https://doi.org/10.1002/sdtp.13227

An, K., Kim, J. B., Yoon, D. G., Jeong, Y.-C., & Kang, K.-T. (2019). High speed nozzle jet printing for bendable organic light emitting diodes. Flexible and Printed Electronics, 4(1), 015009. https://doi.org/10.1088/2058-8585/AB0B9E

Yoon, D. G., Kang, M. G., Kim, J. B., & Kang, K.-T. (2018). Nozzle printed-PEDOT:PSS for organic light emitting diodes with various dilution rates of ethanol. Applied Sciences, 8, 203. https://doi.org/10.3390/app802020

Funding

This study has been conducted with the support of the Korea Institute of Industrial Technology as “Development of Core Technologies for a Working Partner Robot in the Manufacturing Field (KITEH EO-20-0018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no potential conflicts of interests/competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shin, KY., Kang, M., Kim, MK. et al. Large Area Organic Thin Film Coating Using a Micro Multi-nozzle Jet Head with Side Suction Channels. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 829–840 (2021). https://doi.org/10.1007/s40684-021-00334-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00334-7