Abstract

An intense pulsed light (IPL) was irradiated for the sintering of screen-printed copper (Cu) nano/micro-paste patterns on a polyimide substrate. The pattern widths and intervals affect the sintering behavior owing to the opto-thermal relationship during IPL irradiation. The temperature histories of the patterns during the IPL sintering process were predicted using a self-developed heat transfer simulation program. By comparing the experimental and simulation results, the tendency according to the size of the Cu pattern was confirmed. At the same IPL irradiation energy, the wider the pattern and the narrower the interval between the patterns, the higher the heat generated. To demonstrate the tendency, in situ resistance monitoring of the Cu patterns was conducted and their microscopic structures were investigated using a scanning electron microscope. Through the tendency of IPL sintering according to the widths and intervals of the Cu pattern, guidelines of IPL sintering process for electrodes with multi-size pattern were suggested: A dummy pattern was added between the existing digitizer patterns to achieve uniform sintering in all regions. When IPL sintering was conducted with the dummy patterns, the uniformly sintered line resistance could be obtained in entire areas of the digitizer pattern.

Similar content being viewed by others

References

Comiskey, B., Albert, J. D., Yoshizawa, H., & Jacobson, J. (1998). An electrophoretic ink for all-printed reflective electronic displays. Nature, 394, 253.

Zyung, T., Kim, S. H., Chu, H. Y., Lee, J. H., Lim, S. C., Lee, J.-I., et al. (2005). Flexible organic LED and organic thin-film transistor. Proceedings of the IEEE, 93, 1265–1272.

Kondo, Y., Tanabe, H., & Otake, T. (2010). Novel electrochromic polymer for electronic paper. IEICE Transactions on Electronics, 93, 1602–1606.

Yang, Y., & Heeger, A. (1994). Polyaniline as a transparent electrode for polymer light-emitting diodes: Lower operating voltage and higher efficiency. Applied Physics Letters, 64, 1245–1247.

Haight, R. A., & Troutman, R. R. (1998). Optically transparent diffusion barrier and top electrode in organic light emitting diode structures, in, Google Patents.

Leem, D. S., Edwards, A., Faist, M., Nelson, J., Bradley, D. D., & de Mello, J. C. (2011). Efficient organic solar cells with solution-processed silver nanowire electrodes. Advanced Materials, 23, 4371–4375.

Zou, J., Yip, H.-L., Hau, S. K., & Jen, A. K.-Y. (2010). Metal grid/conducting polymer hybrid transparent electrode for inverted polymer solar cells. Applied Physics Letters, 96, 96.

Subramanian, V., Fréchet, J. M., Chang, P. C., Huang, D. C., Lee, J. B., Molesa, S. E., et al. (2005). Progress toward development of all-printed RFID tags: materials, processes, and devices. Proceedings of the IEEE, 93, 1330–1338.

Bansal, R. (2003). Coming soon to a Wal-Mart near you. IEEE Antennas and Propagation Magazine, 45, 105–106.

Jost, K., Stenger, D., Perez, C. R., McDonough, J. K., Lian, K., Gogotsi, Y., et al. (2013). Knitted and screen printed carbon-fiber supercapacitors for applications in wearable electronics. Energy and Environmental Science, 6, 2698–2705.

Yeo, J., Kim, G., Hong, S., Kim, M. S., Kim, D., Lee, J., et al. (2014). Flexible supercapacitor fabrication by room temperature rapid laser processing of roll-to-roll printed metal nanoparticle ink for wearable electronics application. Journal of Power Sources, 246, 562–568.

Hecht, D. S., Thomas, D., Hu, L., Ladous, C., Lam, T., Park, Y., et al. (2009). Carbon-nanotube film on plastic as transparent electrode for resistive touch screens. Journal of the Society for Information Display, 17, 941–946.

Madaria, A. R., Kumar, A., & Zhou, C. (2011). Large scale, highly conductive and patterned transparent films of silver nanowires on arbitrary substrates and their application in touch screens. Nanotechnology, 22, 245201.

Deng, D., Jin, Y., Cheng, Y., Qi, T., & Xiao, F. (2013). Copper nanoparticles: aqueous phase synthesis and conductive films fabrication at low sintering temperature. ACS Applied Materials and Interfaces, 5, 3839–3846.

Kang, H., Sowade, E., & Baumann, R. R. (2014). Direct intense pulsed light sintering of inkjet-printed copper oxide layers within six milliseconds. ACS Applied Materials and Interfaces, 6, 1682–1687.

Greer, J. R., & Street, R. A. (2007). Thermal cure effects on electrical performance of nanoparticle silver inks. Acta Materialia, 55, 6345–6349.

Yu, J. H., Rho, Y., Kang, H., Jung, H. S., & Kang, K.-T. (2015). Electrical behavior of laser-sintered Cu based metal-organic decomposition ink in air environment and application as current collectors in supercapacitor. International Journal of Precision Engineering and Manufacturing-Green Technology, 2, 333–337.

Yu, J. H., Kang, K.-T., Hwang, J. Y., Lee, S.-H., & Kang, H. (2014). Rapid sintering of copper nano ink using a laser in air. International journal of Precision Engineering and Manufacturing, 15, 1051–1054.

Allabergenov, B., & Kim, S. (2013). Investigation of electrophysical and mechanical characteristics of porous copper-carbon composite materials prepared by spark plasma sintering. International Journal of Precision Engineering and Manufacturing, 14, 1177–1183.

Wünscher, S., Abbel, R., Perelaer, J., & Schubert, U. S. (2014). Progress of alternative sintering approaches of inkjet-printed metal inks and their application for manufacturing of flexible electronic devices. Journal of Materials Chemistry C, 2, 10232–10261.

Ma, J., Diehl, J., Johnson, E., Martin, K., Miskovsky, N., Smith, C., et al. (2007). Systematic study of microwave absorption, heating, and microstructure evolution of porous copper powder metal compacts. Journal of Applied Physics, 101, 074906.

Sung, K.-H., Park, J., & Kang, H. (2018). Multi-layer inkjet printing of Ag nanoparticle inks and its sintering with a near-infrared system. International Journal of Precision Engineering and Manufacturing, 19, 303–307.

Kinney, L. C., & Tompkins, E. H. (1969). Method of making printed circuits, in, U.S..

Matsumoto, K., Sakoda, T., Nasu, M., & Ikeda, G. (2008). Film deposition method and film deposition system, in, U.S.

Hirai, S. K. K. (2002). Conductive path or electrode, and method for forming the same, in, Japan.

Dharmadasa, R., Jha, M., Amos, D. A., & Druffel, T. (2013). Room temperature synthesis of a copper ink for the intense pulsed light sintering of conductive copper films. ACS Applied Materials and Interfaces, 5, 13227–13234.

Patil, S. A., Ryu, C.-H., & Kim, H.-S. (2018). Synthesis and characterization of copper nanoparticles (Cu-Nps) using rongalite as reducing agent and photonic sintering of Cu-Nps ink for printed electronics. International Journal of Precision Engineering and Manufacturing-Green Technology, 5, 239–245.

Araki, T., Sugahara, T., Jiu, J., Nagao, S., Nogi, M., Koga, H., et al. (2013). Cu salt ink formulation for printed electronics using photonic sintering. Langmuir, 29, 11192–11197.

Wong, D., Yim, C., & Park, S. S. Hybrid manufacturing of oxidation resistant cellulose nanocrystals-copper-graphene nanoplatelets based electrodes. In International journal of precision engineering and manufacturing-green technology, pp. 1–15.

Schroder, K., McCool, S., & Furlan, W. (2006). Broadcast photonic curing of metallic nanoparticle films. NSTI Nanotech, 7, 11.

Schroder, K. A., McCool, S., Hamill, D., Wilson, D., Furlan, W., Walter, K., Willauer, D., & Martin, K. (2010). Electrical, plating and catalytic uses of metal nanomaterial compositions, in, U.S.

Kim, H.-S., Dhage, S. R., Shim, D.-E., & Hahn, H. T. (2009). Intense pulsed light sintering of copper nanoink for printed electronics. Applied Physics A, 97, 791.

Han, Q., Sun, S., Li, J., & Wang, X. (2011). Growth of copper sulfide dendrites and nanowires from elemental sulfur on TEM Cu grids under ambient conditions. Nanotechnology, 22, 155607.

Ryu, J., Kim, H.-S., & Hahn, H. T. (2011). Reactive sintering of copper nanoparticles using intense pulsed light for printed electronics. Journal of Electronic Materials, 40, 42–50.

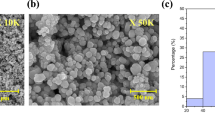

Joo, S.-J., Hwang, H.-J., & Kim, H.-S. (2014). Highly conductive copper nano/microparticles ink via flash light sintering for printed electronics. Nanotechnology, 25, 265601.

Patil, S. A., Hwang, H.-J., Yu, M.-H., Shrestha, N. K., & Kim, H.-S. (2017). Photonic sintering of a ZnO nanosheet photoanode using flash white light combined with deep UV irradiation for dye-sensitized solar cells. RSC Advances, 7, 6565–6573.

Abdullah, E. C., & Geldart, D. (1999). The use of bulk density measurements as flowability indicators. Powder Technology, 102, 151–165.

Ryu, C.-H., Moon, C.-J., & Kim, H.-S. (2019). A study on the relationship between print-ability and flash light sinter-ability of Cu nano/micro-ink for printed electronics. Thin Solid Films, 671, 36–43.

Lin, H.-W., Chang, C.-P., Hwu, W.-H., & Ger, M.-D. (2008). The rheological behaviors of screen-printing pastes. Journal of Materials Processing Technology, 197, 284–291.

Hwang, H.-J., Oh, K.-H., & Kim, H.-S. (2016). All-photonic drying and sintering process via flash white light combined with deep-UV and near-infrared irradiation for highly conductive copper nano-ink. Scientific Reports, 6, 19696.

Hwang, H.-J., Chung, W.-H., & Kim, H.-S. (2012). In situ monitoring of flash-light sintering of copper nanoparticle ink for printed electronics. Nanotechnology, 23, 485205.

Hwang, Y.-T., Chung, W.-H., Jang, Y.-R., & Kim, H.-S. (2016). Intensive plasmonic flash light sintering of copper nanoinks using a band-pass light filter for highly electrically conductive electrodes in printed electronics. ACS Applied Materials and Interfaces, 8, 8591–8599.

Yim, C., Greco, K., Sandwell, A., & Park, S. S. (2017). Eco-friendly and rapid fabrication method for producing polyethylene terephthalate (PET) mask using intensive pulsed light. International Journal of Precision Engineering and Manufacturing-Green Technology, 4, 155–159.

Ryu, C.-H., Joo, S.-J., & Kim, H.-S. (2019). Intense pulsed light sintering of Cu nano particles/micro particles-ink assisted with heating and vacuum holding of substrate for warpage free printed electronic circuit. Thin Solid Films, 675, 23–33.

Cengel, A. (2007). HEHT transfer.

Soares, D., Jr., & Wrobel, L. C. (2019). A locally stabilized explicit approach for nonlinear heat conduction analysis. Computers and Structures, 214, 40–47.

Agarwala, M., Bourell, D., Beaman, J., Marcus, H., & Barlow, J. (1995). Direct selective laser sintering of metals. Rapid Prototyping Journal, 1, 26–36.

El-Sayed, M. A. (2001). Some interesting properties of metals confined in time and nanometer space of different shapes. Accounts of Chemical Research, 34, 257–264.

Link, S., & El-Sayed, M. A. (2000). Shape and size dependence of radiative, non-radiative and photothermal properties of gold nanocrystals. International Reviews in Physical Chemistry, 19, 409–453.

Hartland, G. V. (2006). Coherent excitation of vibrational modes in metallic nanoparticles. Annual Review of Physical Chemistry, 57, 403–430.

Chung, W.-H., Hwang, H.-J., & Kim, H.-S. (2015). Flash light sintered copper precursor/nanoparticle pattern with high electrical conductivity and low porosity for printed electronics. Thin Solid Films, 580, 61–70.

German, R. M. (1996). Sintering theory and practice. In Solar-Terrestrial Physics, p. 568.

Shatokha, V. (2012). Sintering: Methods and products, BoD-books on demand.

Damaceanu, M.-D., Rusu, R.-D., Bruma, M., & Jarzabek, B. (2010). Photo-optical properties of poly (oxadiazole-imide) s containing naphthalene rings. Polymer Journal, 42, 663.

Kim, D., & Shen, Y. (1999). Study of wet treatment of polyimide by sum-frequency vibrational spectroscopy. Applied Physics Letters, 74, 3314–3316.

Park, S.-H., Chung, W.-H., & Kim, H.-S. (2014). Temperature changes of copper nanoparticle ink during flash light sintering. Journal of Materials Processing Technology, 214, 2730–2738.

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF), funded by the Ministry of Education (2012R1A6A1029029, 2018R1D1A1A09083236). This work was also supported by Materials & Components Technology Development Program (20002957, Development of AgNW/rGO transparent electrode material and process based on IPL for OPV) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jang, YR., Ryu, CH., Hwang, YT. et al. Optimization of Intense Pulsed Light Sintering Considering Dimensions of Printed Cu Nano/Micro-paste Patterns for Printed Electronics. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 471–485 (2021). https://doi.org/10.1007/s40684-019-00180-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00180-8