Abstract

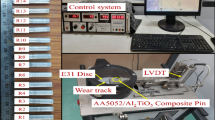

Aluminum matrix composites (AMCs) are difficult to machine due to increased tool wear. AA7075/(0–12 wt%) TiB2 in situ AMCs were prepared and turned in a modified conventional lathe using polycrystalline diamond cutting tool. A central composite rotatable design comprising of four process parameters and five levels was utilized to limit the actual experiments required for prediction. The turning parameters such as cutting speed, feed rate, depth of cut and TiB2 particulate content were counted as variables for the experiments. Two empirical relationships were formed for the prediction of the outcome of variable parameters on cutting force and surface roughness. The cutting force showed a downward trend with an increase in cutting speed and TiB2 content. The advancement in feed rate and depth of cut increased the requirement of cutting force. The predicted trends were correlated with the morphology of the tool rake face and the turned surface. The development of built-up edge increased the cutting force requirement and reduced the surface finish due to deposition on the newly turned surface.

Similar content being viewed by others

References

Dwivedi SP, Sharma S, Mishra RK (2015) Microstructure and mechanical behavior of A356/SiC/Fly-ash hybrid composites produced by electromagnetic stir casting. J Braz Soc Mech Sci Eng 37:57–67

Jojith R, Radhika N (2018) Fabrication of LM25/WC functionally graded composite for automotive applications and investigation of its mechanical and wear properties. J Braz Soc Mech Sci Eng 40:292

Basu B, Raju GB, Suri AK (2006) Processing and properties of monolithic TiB2 based materials. Int Mat Rev 51:352–374

Suresh S, Moorthi NSV, Vettivel SC, Selvakumar N (2014) Mechanical behavior and wear prediction of stir cast Al–TiB2 composites using response surface methodology. Mater Des 59:383–396

Rajan HM, Ramabalan S, Dinaharan I, Vijay SJ (2014) Effect of TiB2 content and temperature on sliding wear behavior of AA7075/TiB2 in situ aluminum cast composites. Arch Civ Mech Eng 14:72–79

Sobhani M, Mirhabibi A, Arabi H, Brydson RMD (2013) Effects of in situ formation of TiB2 particles on age hardening behavior of Cu–1 wt% Ti–1 wt% TiB2. Mater Sci Eng A 577:16–22

Sekhar R, Singh TP (2015) Mechanisms in turning of metal matrix composites: a review. J Mater Res Technol 4:197–207

Nicholls CJ, Boswell B, Davies IJ, Islam MN (2017) Review of machining metal matrix composites. Int J Adv Manuf Technol 90:2429–2441

Basavarajappa S, Chandramohan G, Rao KN, Radhakrishanan R, Krishnaraj V (2006) Turning of particulate metal matrix composites—review and discussion. Proc Int Mech Eng Part B J Eng Manuf 220:1189–1204

Dandekar CR, Shin YC (2012) Modeling of machining of composite materials: a review. Int J Mach Tools Manuf 57:102–121

Anandakrishnan V, Mahamani A (2011) Investigations of flank wear cutting force and surface roughness in the machining of Al-6061–TiB2 in situ metal matrix composites produced by flux-assisted synthesis. Int J Adv Manuf Technol 55:65–73

Sahoo AK, Pradhan S, Rout AK (2013) Development and machinability assessment in turning Al/SiCp-metal matrix composite with multilayer coated carbide insert using Taguchi and statistical techniques. Arch Civ Mech Eng 13:27–35

Senthil P, Selvaraj T, Sivaprasad K (2013) Influence of turning parameters on the machinability of homogenized Al–Cu/TiB2 in situ metal matrix composites. Int J Adv Manuf Technol 67:1589–1596

Shoba C, Ramanaiah N, Rao DN (2015) Effect of reinforcement on the cutting forces while machining metal matrix composites—an experimental approach. Eng Sci Technol Int J 18:658–663

Joardar H, Das NS, Sutradhar G, Singh S (2014) Application of response surface methodology for determining cutting force model in turning of LM6/SiCp metal matrix composite. Measurement 47:452–464

Suresh P, Marimuthu K, Ranganathan S, Rajmohan T (2014) Optimization of machining parameters in turning of Al–SiC–Gr hybrid metal matrix composites using grey-fuzzy algorithm. Trans Nonferrous Met Soc China 24:2805–2814

Shoba C, Ramanaiah N, Rao DN (2015) Influence of dislocation density on the residual stresses induced while machining Al/SiC/RHA hybrid composites. J Mater Res Technol 4:273–277

Rui-song J, Wen-hu W, Guo-dong S, Zeng-qiang W (2016) Experimental investigation on machinability of in situ formed TiB2 particles reinforced Al MMCs. J Manuf Process 23:249–257

Barzani MM, Farahany S, Songmene V (2017) Machinability characteristics thermal and mechanical properties of Al–Mg2Si in situ composite with bismuth. Measurement 110:263–274

Jiang R, Xinfa C, Renwei GE, Wenhu W, Guodong S (2018) Influence of TiB2 particles on machinability and machining parameter optimization of TiB2/Al MMCs. Chin J Aeronaut 31:187–196

Udayakumar T, Raja K, Abhijit AT, Sathiya P (2013) Experimental investigation on mechanical and metallurgical properties of super duplex stainless steel joints using friction welding process. J Manuf Process 15:558–571

Wu Z (2015) Empirical modeling for processing parameter’s effects on coating properties in plasma spraying process. J Manuf Process 19:1–13

Moses JJ, Dinaharan I, Sekhar SJ (2016) Predicting the influence of process parameters on tensile strength of AA6061/TiC aluminum matrix composites produced using stir casting. Trans Nonferrous Met Soc China 26:1498–1511

Palanivel R, Laubscher RF, Dinaharan I, Murugan N (2016) Tensile strength prediction of dissimilar friction stir-welded AA6351–AA5083 using artificial neural network technique. J Braz Soc Mech Sci Eng 38:1647–1657

Arokiadass R, Palaniradja K, Alagumoorthi N (2011) Prediction of flank wear in end milling of particulate metal matrix composite-RSM approach. Int J Appl Eng Res 6:559–569

Lakshmi S, Lu L, Gupta M (1998) In situ preparation of TiB2 reinforced Al based composites. J Mater Process Technol 73:160–166

Lu L, Lai MO, Chen FL (1997) Al-4 wt% Cu composite reinforced with in situ TiB2 particles. Acta Mater 45:4297–4309

Montgomery DG (2001) Design and analysis of experiments. Wiley, Hoboken

Box GEP, Hunter WH, Hunter JS (1978) Statistics for experiments. Wiley, New York

Kannan S, Kishawy HA, Deiab I (2009) Cutting forces and TEM analysis of the generated surface during machining metal matrix composites. J Mater Process Technol 209:2260–2269

Rajan HM, Ramabalan S, Dinaharan I, Vijay SJ (2013) Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites. Mater Des 44:438–445

Acknowledgements

The authors are grateful to Centre for Research in Design and Manufacturing Engineering (CRDM) at Karunya University and The South India Textile Research Association (SITRA) for providing the facilities to carry out this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva, Ph.D.

Rights and permissions

About this article

Cite this article

Pugazhenthi, A., Dinaharan, I., Kanagaraj, G. et al. Predicting the effect of machining parameters on turning characteristics of AA7075/TiB2 in situ aluminum matrix composites using empirical relationships. J Braz. Soc. Mech. Sci. Eng. 40, 555 (2018). https://doi.org/10.1007/s40430-018-1480-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1480-2