Abstract

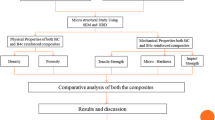

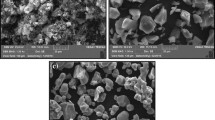

A study was conducted to produce and characterize composites consisting of AA5052 reinforced with Al2TiO5 using the bottom pouring stir-casting method. The weight percentages (wt%) of the five distinct AA5052 compositions were 0, 1, 2, 3 and 3.5. To evaluate the density, porosity, microstructure, tensile strength, microhardness and sliding wear, a central composite response surface methodology (RSM) technique was used. The density of the composites gradually increased from the initial matrix as Al2TiO5 particles were added in small amounts. Microstructural analysis of the AA5052 and Al2TiO5 composites revealed that the Al2TiO5 particles in the matrix alloy were finely dispersed. The reinforced composite specimens demonstrated an improvement in microhardness and tensile strength of 28.15 and 14.26%, respectively, over the as-cast specimens. To investigate the effects of load, reinforcement weight percentage and sliding distance on composite specimens, a total of 16 experimental runs were conducted using RSM. The wear rate and coefficient of friction of the composites were found to be most affected by the applied wear load and the weight percentage of Al2TiO5. The wear specimens’ fracture surfaces displayed a combination of ploughing and abrasive processes.

Similar content being viewed by others

References

Garg P, Jamwal A, Kumar D, Sadasivuni K K, Hussain C M and Gupta P 2019 J. Mat. Res. Tech. 8 4924

Kumar N, Gautam G, Gautam R K, Mohan A and Mohan S 2016 Tribol. Int. 97 313

Baek S, Song J, Lee H C, Park S, Song K H, Lee S et al 2022 Mater. Sci. Eng. 833 142378

Jojith R, Sam M and Radhika N 2022 Mater. Sci. Eng. A 25 100999

Zheng K, Politis D J, Wang L and Lin J 2018 Int. J. Lightwt. Mater. Manuf. 1 55

Kumaravelu P and Kandasamy J 2023 Eng. Fail Anal. 146 107139

Dinesh Kumar P K and Solomon D G 2023 Mater. Today Comm. 37 106978

Uday K N and Rajamurugan G 2022 Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 236 4904

Chelladurai S J S, Kumar S S, Venugopal N, Ray A P, Manjunath T C and Gnanasekaran S 2021 Mater. Today. Proc. 37 908

Sharifi H, Ostovan K, Tayebi M and Rajaee A 2017 Tribol. Int. 116 244

Gautam G, Kumar N, Mohan A, Gautam R K and Mohan S 2016 Metal. Mater. Trans. A Phys. Metal. Mater. Sci. 47 4709

Jain V K S and Muthukumaran S 2019 Metall. Mater. Trans. A Phys. Metal. Mater. Sci. 50 2933

Samal P, Vundavilli P R, Meher A and Mahapatra M M 2019 J. Compos. Mater. 53 4323

Samal P, Vundavilli P R, Meher A and Mahapatra M M 2022 Proc. Inst. Mech. Eng. Part E 236 254

Kumar N, Gautam R K, Mohan S, Kumar N, Gautam R K and Mohan S 2015 Tribol. Ind. 37 244

Gautam G and Mohan A 2016 J. Tribol. 138 2

Shiva Kumar G N and Rajamurugan G 2023 Mater. Lett. 353 135289

Menachery N, Thomas S, Deepanraj B and Senthilkumar N 2023 Appl. Nanosci. 13 4075

Ravindranath V M, Basavarajappa G S and Suresh R 2016 IOP Conf. Ser. Mater. Sci. Eng. 149 012103

Senthilraj K, Uday K N and Rajamurugan G 2022 SAE Techn. Pap. 5 1585

Senthilraj K and Rajamurugan G 2023 Mater. Lett. 338 134085

Sadhu K K, Mandal N and Sahoo R R 2023 J. Manuf. Process. 91 10

Sivanesh Prabhu M, Elaya Perumal A, Arulvel S and Franklin Issac R 2019 Measurement (Lond) 142 10

Uygunolu T, Brostow W and Gunes I 2015 Polimeros 25 271

Chotěborský R, Hrabě P, Müller M, Válek R, Savková J and Jirka M 2009 Res. Agri. Eng. 55 149

Zhai W, Bai L, Zhou R, Fan X, Kang G, Liu Y et al 2021 Adv. Sci. 8 1

Bhuvaneswari V, Rajeshkumar L and NimelSworna Ross K 2021 J. Mater. Res. Tech. 15 2802

Kumar R, Jha K, Sharma S, Kumar V, Li C, Eldin E M T et al 2022 Heliyon 8 9

Sharma P, Khanduja D and Sharma S 2016 J. Mater. Res. Tech. 5 29

Diler E A and Ipek R 2013 Compos. B Eng. 50 371

Hariharasakthisudhan P, Jose S and Manisekar K 2019 J. Mater. Res. Tech. 8 275

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Senthilraj, K., Rajamurugan, G. Mechanical and tribological behaviour of Al2TiO5 particle-reinforced AA5052 composite. Bull Mater Sci 47, 95 (2024). https://doi.org/10.1007/s12034-024-03186-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-024-03186-4