Abstract

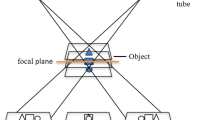

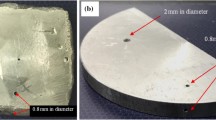

In situ crack detection in the mushy zone and the solid weld of a gas tungsten arc (GTA) weld using X-ray imaging during welding is a new research area for NDT inspection. Usually, NDT flaw detection is done after the complete solidification of the weld seam. In this paper, we present the use of real-time radiography with a minifocus X-ray source (YXLON X-ray tube Y.TU 225-D04) and a 75 μm pixel size digital detector array (Dexela 1512) for the acquisition of 2D radiographic images by a sequence of exposures with time intervals of 80 ms for hot crack detection during single pass bead-on-plate GTA welding of 3 mm thick plates of aluminium alloy AlMgSi (6060). An analysis of the crack distribution in the weld sample is conducted from the acquired 2D radiographs and its corresponding 3D volumetric reconstruction achieved by linear coplanar digital laminography. This in situ approach opens new possibilities in the field of hot crack research by having the direct information of both the crack initiation and growth and its correlation to the welding parameters.

Similar content being viewed by others

References

Kannengießer T, Bollinghaus T (2014) Hot cracking test—an overview of present technologies and application. Weld World Springer 58(3):397–421

Ewert U, Zscherpel U, Heyne K, Jechow M, Bavendiek K (2012) Image quality in digital industrial radiography. Mater Eval 70(8):955–964, 10p

Helfen L et al (2011) On the implementation of computed laminography using synchrotron radiation. Rev Sci Instrum 82(6):063702

Gondrom S, Schropfer S (1999) Digital computed laminography and tomosynthesis- functional principles and industrial applications. International Symposium on Computerized Tomography for Industrial Applications and Image Processing in Radiology, Berlin, Germany Proceedings BB 67-CD published by DGZfP

Ewert U, Jaenisch G-R, Zscherpel U, Osterloh K, Redmer B (2013) Chapter “Industrial radiology” in “Handbook of technical diagnostics”. Springer, p 221–247

Thiessenhusen KU, Ewert U, Redmer B, Bavendiek K (2011) Geometric corrections in coplanar translational Laminography, DIR 2011, Conference proceedings, Berlin

Isee! Professional website (http://www.vision-in-x.com/en/home.html)

ImageJ website (http://imagej.nih.gov/ij/)

VGStudio website (http://www.volumegraphics.com)

Schempp P, Cross CE, Pittner A, Rethmeier M (2013) Influence of grain size on mechanical properties of aluminium GTA weld metal. Weld World 57(3):293–304

Ghosh A et al (2011) Assessment of heat affected zone of submerged arc welding process through digital image processing. Procedia Eng 10:2782–2785

Redmer B, Robbel J, Ewert U, Vengrinovich VV (2002) Mechanised weld inspection by tomographic computer-aided radiometry (TomoCAR). Insight 44(9):564–567

Acknowledgments

The authors want to thank K.U. Thiessenhusen, C. Bellon, M. Grunwald, D. Walter, A. Deresch and M. Tschaikner of Division 8.3 Radiological Methods, A. Hannemann of Division 9.4 Weld Mechanics and D. Stock, M. Richter and K. Scheideck of Division 9.3 Welding Technology of Bundesanstalt für Materialforschung und-prüfung (BAM) for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission V - NDT and Quality Assurance of Welded Products

Rights and permissions

About this article

Cite this article

Boateng, F.T., Ewert, U., Kannengiesser, T. et al. Real-time radiography for observation of crack growth during GTA welding. Weld World 60, 931–937 (2016). https://doi.org/10.1007/s40194-016-0351-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0351-7