Abstract

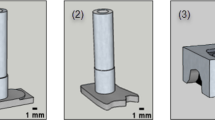

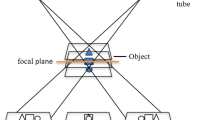

This paper describes the use of X-ray computed tomography (XCT) to inspect the internal defects of industrial Aluminum alloys die-casting, to justify the adequateness of super sealant resins in filling tiny holes, and to reduce the casting porosity of metals by the impregnation process. High-resolution 2D slice images were generated by a microfocus X-ray CT system with direct conversion Cadmium Telluride (CdTe) flat panel detector (FPD). Moreover, we were able to visualize the internal defects of the two different shapes of casting objects. The gray-value contrasts of the CT images were excellent to distinguish the resin material in the alloy samples after impregnation treatment. Furthermore, to determine the dimensions of internal defects, virtual sectioning was carried out to view the cross-section of the metal samples and dimensions of internal defects. Dual-energy X-ray computed tomography (DXCT) was used with an energy differentiation type 64-pixel linear array photon-counting line sensor for the material characterization. The impregnated resin part inside the castings defects was verified based on the effective atomic number with a 2.92% low error margin. Hence, this will be a useful qualitative and quantitative advancement to rapid and detailed non-destructive analysis within the die-casting industries in improving the quality of the impregnation process.

Similar content being viewed by others

References

Engelberger JF (1980) Die casting applications. Robotics in practice. Springer, Boston

Casarotto F, Franke AJ, Franke R (2012) 6—High-pressure die-cast (HPDC) aluminium alloys for automotive applications. In: Rowe J (ed) Advanced materials in automotive engineering. Woodhead Publishing, Sawston, pp 109–149. https://doi.org/10.1533/9780857095466.109

Benedyk JC (2010) Aluminium alloys for lightweight automotive structures, a volume in Woodhead Publishing series in composite science and engineering, materials, design and manufacturing for lightweight vehicles, pp 79–113

Kaufman JG (2000) Introduction to aluminum alloys and tempers. ASM International, United States

Fiorese E, Bonollo F, Timelli G et al (2015) Inter Metalcast 9:55. https://doi.org/10.1007/BF03355602

Kanno T (1997) An Introduction to die casting technology. Nikkan-kogyo-sinbunsha, Tokyo, pp 227–247

American Society for Testing of Materials ASTM E1742/E1742M, “Standard Practice for Radiography Examination”, Annual book of ASTM standards 2011 (03.03)

Bossi RH, Georgeson GE (1992) Computed tomography analysis of castings, Boeing Defense and Space Group Seattle WA Aerospace and Electronics Div

Baruchel J, Buffiere JY, Maire E, Merie P. and Peix (eds) G (2000). X-ray tomography in material science, 204; Hermes Paris Science publication, France

Salvo L, Cloetens P, Maire E, Zabler S, Blandin JJ, Buffiere JY et al (2003) X-ray micro-tomography an attractive characterization technique in materials science. Nucl Instrum Meth Phys Res B 200:273–286

Kastner J, Heim D, Salaberger D, Sauerwein Ch, Simon M (2006) Advanced applications of computed tomography by combination of different methods. In: Proceedings of 9th European Conference on Non-destructive Testing, Berlin. September 25–29, 2006

Kastner J (2008) editor. Proceedings Industrielle Computertomografietagung; Wels, Austria, 26–27 February 2008

Reinhart C (2008) Industrial computer tomography—A universal inspection tool. In: 17th world conference on nondestructive testing. 25–28 Oct 2008, Shanghai, China

Ohno Y, Torikoshi M, Tsunoo T, Hyodo K (2005) Dual-energy x-ray CT with CdTe array and its extension. Nucl Instrum Methods Phys Res, Sect A 548:72–77. https://doi.org/10.1016/j.nima.2005.03.069

Torikoshi M, Tsunoo T, Endo M, Noda K, Kumada M, Yamada S, Soga F, Hyodo K (2001) Design of synchrotron light source and its beamline dedicated to dual-energy x-ray computed tomography. J Biomed Opt 6(3):371–377

Kastner J, Harrer B, Degischer HP (2011) High resolution cone beam X-ray computed tomography of 3D-microstructures of cast Al-alloys. Mater Charact 62:99–107

Kan K, Imura Y, Morii H, Kobayashi K, Minemura T, Aoki T (2013) Application of photon-counting X-ray computed tomography to aluminum-casting inspection. World J Nucl Sci Technol 3:106–108

Du Plessis A, Rossouw P (2015) X-ray computed tomography of a titanium aerospace investment casting. Case Stud Nondestruct Test Eval. https://doi.org/10.1016/j.csndt.2015.03.001

Lauritsch G, Haerer WH (1998) A theoretical framework for filtered backprojection in tomosynthesis. Proc SPIE 3338:1127–1137

Jackson DF, Hawkes DJ (1981) X-ray attenuation coefficients of elements and mixtures. Phys Rep 70(3):169–233

Hawkes DJ, Jackson DF (1980) An accurate parametrisation of the x-ray attenuation coefficient. Phys Med Biol 25(6):1167–1171

Zou W, Nakashima T, Onishi Y, Koike A, Shinomiya B, Morii H, Neo Y, Mimura H, Aoki T (2008) Atomic number and electron density measurement using a conventional X-Ray tube and a CdTe detector. Jpn J Appl Phys 47(9):7317–7323

Acknowledgements

We wish to thank Koji Kobayashi for his technical support to the impregnation process. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AB and HM carried out the experiment. AB wrote the manuscript with support from KK. AK and TA helped supervise the project. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bandara, A., Kan, K., Morii, H. et al. X-ray computed tomography to investigate industrial cast Al-alloys. Prod. Eng. Res. Devel. 14, 147–156 (2020). https://doi.org/10.1007/s11740-019-00946-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-019-00946-8