Abstract

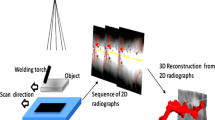

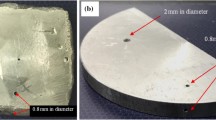

X-ray computed laminography is a depth-resolving non-destructive testing technique well suited for the non-destructive examination of large and flat structures where traditional computed tomography is impractical. This technique provides 3D radiographic imaging and characterization with depth information of welding imperfections in welded components, ensuring component quality meets the standard criteria and safety purposes. Furthermore, determining the welding imperfection’s location in fabrication, in-service and maintenance is crucial for welding repair, resulting in the areas where the repair work needs to be started. This work highlights the characterization of welding imperfections by experimental digital radiography with digital detector array (RT-D with DDA) and coplanar translational laminography (CTL) techniques applied to welded carbon steel plates. A test specimen was tested, specially prepared with artificial planar and volumetric flaws like lack of fusion, clustered porosities and slag inclusions with varying dimensions and the approaches were analyzed. Additionally, a test phantom was fabricated with known geometry features that access the CTL system’s optimal detection accuracy to demonstrate a broad functionality and acceptance of the CTL system for depth information in the plate-like structures. The coplanar translational laminography technique provides advantages for characterizing welding imperfections and testing phantom features with high contrast and acceptable image quality. The result is confirmed by the phased array ultrasonic testing and RT-D with DDA. The exposure conditions, image sensitivity, and quality are analyzed according to ISO 17636-2 to ensure compliance with industry standards in digital radiography.

Similar content being viewed by others

Data Availability

Upon request.

References

Brien, R.L.: Welding Handbook—Welding Science and Technology. American Welding Society, Miami (2001)

Ewert, U., Zscherpel, U., Bavendiek, K.: Replacement of film radiography by digital techniques and enhancement of image quality. NDT.net J. 6, 4516 (2007)

Moreira, E.V., Barbosa Rabello, J.M., Pereira, M.D.S., Lopes, R.T., Zscherpel, U.: Digital radiography using digital detector arrays fulfills critical applications for offshore pipelines. EURASIP J. Adv. Signal Process. (2010). https://doi.org/10.1155/2010/894643

Bavendiek, K., Heike, U., Meade, W.D., Zscherpel, U., Ewert, U.: New digital radiography procedure exceeds film sensitivity considerably in aerospace applications. In: 9th European Conference on NDT (ECNDT 2006), pp. 1–16. NDT, Mayan (2006)

Boateng, F.T., Ewert, U., Kannengiesser, T., Zscherpel, U., Griesche, A., Kromm, A., Hohendorf, S., Redmer, B.: Real-time radiography for observation of crack growth during GTA welding. Weld. World IIW 60(5), 931–937 (2016). https://doi.org/10.1007/s40194-016-0351-7

Van Tiggelen, R.: In search for the third dimension: from radiostereoscopy to three-dimensional imaging. JBR-BTR 85, 266–270 (2002)

Kupsch, A., Trappe, V., Nielow, D., Schumacher, D., Lange, A., Hentschel, M.P., Redmer, B., Ewert, U., Bruno, G.: X-ray laminographic inspection of sandwich shell segments for wind turbine rotor blades. In: 12th European Conference on Non-destructive Testing, pp. 1–8. NDT, Mayan (2018)

Bullinger, O., Schnars, U., Schulting, D., Redmer, B., Tschaikner, M., Ewert, U.: Laminographic inspection of large carbon fibre composite aircraft-structures at airbus. In: 19th World Conference on Non-Destructive Testing, Proceedings, pp. 1–10. NDT, Mayan (2016)

Shen, Y., Morgeneyer, T.F., Garnier, J., Allais, L., Helfen, L., Crépin, J.: Three-dimensional quantitative in situ study of crack initiation and propagation in AA6061 aluminum alloy sheets via synchrotron laminography and finite-element simulations. Acta Mater. 61(7), 2571–2582 (2013). https://doi.org/10.1016/j.actamat.2013.01.035

Moore, T.D., Vanderstraeten, D., Forssell, P.M.: Three-dimensional x-ray laminography as a tool for detection and characterization of BGA package defects. IEEE Trans. Components Packag. Technol. 25(2), 224–229 (2002). https://doi.org/10.1109/TCAPT.2002.1010010

Wakimoto, K., Blunt, J., Carlos, C., Monteiro, P.J.M., Ostertag, C.P., Albert, R.: Digital laminography assessment of the damage in concrete exposed to freezing temperatures. Cem. Concr. Res. 38, 1232–1245 (2008). https://doi.org/10.1016/j.cemconres.2008.05.003

Hamidi, S.H.A., Salleh, K.A.M., Hamzah, A.R., Wahab, M.N., Azaman, N., Ahmad, A.S.: Preliminary study of digital laminography parameters on carbon steel plate. IOP Conf. Ser. Mater. Sci. Eng. (2019). https://doi.org/10.1088/1757-899X/554/1/012007

Deyhle, H., Towsyfyan, H., Biguri, A., Mavrogordato, M., Boardman, R., Blumensath, T.: Spatial resolution of a laboratory based X-ray cone-beam laminography scanning system for various trajectories. NDT E Int. 111(102222), 2020 (2020). https://doi.org/10.1016/j.ndteint.2020.102222

Fisher, S.L., Holmes, D.J., Jørgensen, J.S., Gajjar, P., Behnsen, J., Lionheart, W.R.B., Withers, P.J.: Laminography in the lab: Imaging planar objects using a conventional x-ray CT scanner. Meas. Sci. Technol. (2019). https://doi.org/10.1088/1361-6501/aafcae

O’Brien, N., Mavrogordato, M., Boardman, R., Sinclair, I., Hawker, S., Blumensath, T.: Comparing cone beam laminographic system trajectories for composite NDT. Case Stud. Nondestruct. Test. Eval. 6, 56–61 (2016). https://doi.org/10.1016/j.csndt.2016.05.004

Kurfiss, M., Streckenbach, G.: Digital Laminography and Computed Tomography with 600 kV for Aerospace Applications. International symposium on NDT in Aerospace, Berlin (2012)

Yang, Y., Li, L., Chen, Z.: A review of geometric calibration for different 3-D X-ray imaging systems. Nucl. Sci. Tech. 27(76), 1–11 (2016). https://doi.org/10.1007/s41365-016-0073-y

Thiessenhusen, K.U., Ewert, U., Redmer, B., Bavendiek, K.: Geometric corrections in coplanar translational laminography. In: International Symposium on Digital Industrial Radiology and Computed Tomography, pp. 1–8. NDT, Mayan (2011)

O’Brien, N.S., Boardman, R.P., Sinclair, I., Blumensath, T.: Recent advances in X-ray cone-beam computed laminography. J. Xray. Sci. Technol. 24(5), 691–707 (2016). https://doi.org/10.3233/XST-160581

Zhou, J., Maisl, M., Reiter, H., Arnold, W.: Computed laminography for materials testing. Appl. Phys. Lett. 68(24), 3500–3502 (1996). https://doi.org/10.1063/1.115771

Silva, W., Lopes, R., Zscherpel, U., Meinel, D., Ewert, U.: X-ray imaging techniques for inspection of composite pipelines. Micron 145, 103033 (2021). https://doi.org/10.1016/j.micron.2021.103033

Ou, Y.X.D., Schumacher, D., Zscherpel, U.: Dual-energy materials characterization methods for laminography image enhancement based on photon counting detector. J. Instrum. 14(P02018), 1–11 (2019). https://doi.org/10.1088/1748-0221/14/02/P02018

Ewert, U., Fuchs, T.: Progress in digital industrial radiology Part II: computed tomography (CT). Nondestruct. Test. Diagnostics 2, 7–14 (2017). https://doi.org/10.26357/BNiD.2017.018

Varex (Perkin Elmer): Flat panel X-ray detectors. https://www.perkinelmer.com/PDFs/downloads/SPC-NDT-Detectors-012163A_01.pdf.

Ewert, U., Thiessenhusen, K., Deresch, A.: Reconstruction methods for coplanar translational laminography applications. In: Digital Industrial Radiology and Computed Tomography DIR 2015, pp. 1–21. NDT, Mayen (2015)

ISO 17636-2; Part 2: X- and gamma-ray techniques with digital detectors, (2013)

Hanif, S., Hamidi, A., Muad, A.M., Anuar, K., Salleh, M.: Development of a manipulator system for X-ray imaging laminography. J. Electr. Eng. 20(2), 117–120 (2021)

Acknowledgements

Institutional Fund Projects funded this research work under grant IFPIP_2006-135-1443. Therefore, the authors gratefully acknowledge the technical and financial support from the Ministry of Education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Funding

Institutional Fund Projects funded this research work under grant IFPIP_2006-135-1443.

Author information

Authors and Affiliations

Contributions

The manuscript was authored by SH and KA and reviewed by all authors. All shown figures are part of the laminography work performed at the Malaysian Nuclear Agency, funded by the Institutional Fund Projects under grant IFPIP_2006-135-1443, the Ministry of Education and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Corresponding author

Ethics declarations

Competing interests

Not Applicable.

Ethical Approval

Yes.

Informed Consent

Yes.

Consent for Publication

Yes.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghandourah, E.E., Hamidi, S.H.A., Mohd Salleh, K.A. et al. Evaluation of Welding Imperfections with X-ray Computed Laminography for NDT Inspection of Carbon Steel Plates. J Nondestruct Eval 42, 77 (2023). https://doi.org/10.1007/s10921-023-00989-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-023-00989-z