Abstract

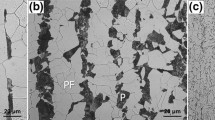

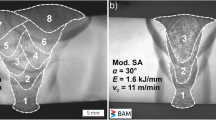

The implant test was used to study the heat-affected zone (HAZ) hydrogen-induced cracking (HIC) susceptibility of a recently developed blast-resistant steel BlastAlloy 160 (BA-160) and two existing naval steels, HY-100 and HSLA-100. It was found that the coarse-grained HAZ (CGHAZ) is the most susceptible to HIC in the entire HAZ. Therefore, phase transformation behavior in the CGHAZ was investigated and continuous cooling transformation (CCT) diagrams for the CGHAZ of the three steels were developed. The new BA-160 steel was compared with the current steels HY-100 and HSLA-100 with respect to inherent resistance to HIC and sensitivity to diffusible hydrogen level based on the implant test results. Fracture surfaces of the implant specimens were also studied, which supports the implant test results when comparing the three steels. Different performance of the three steels is a result of the formation of different microstructures in the CGHAZ. In addition, the effect of welding parameters on reducing HIC tendency of BA-160 was studied using the implant test, providing recommendations for welding BA-160 when HIC is a big concern.

Similar content being viewed by others

References

Montemarano TW, Sack BP, Gudas JP, Vassilaros MG, Vanderveldt HH (1986) High strength low alloy steels in naval construction. J Ship Prod 2(3):145–162

Czyryca EJ (1993) Advances in high strength steel technology for naval hull construction. Key Eng Mater 84–85:491–520

Vassilaros MG, Czyryca EJ (1993) The development of high-strength, cooling-rate insensitive ultra-low-carbon steel weld metals. Key Eng Mater 84–85:587–601

Czyryca EJ, Link RE, Wong RJ, Aylor DA, Montemarano TW, Gudas JP (1990) Development and certification of HSLA-100 steel for naval ship construction. Nav Eng J 102(3):63–82

Isheim D, Gagliano MS, Fine ME, Seidman DN (2006) Interfacial segregation at Cu-rich precipitates in a high-strength low-carbon steel studied on a sub-nanometer scale. Acta Mater 54:841–849

Kolli RP, Seidman DN (2008) The temporal evolution of the decomposition of a concentrated multicomponent Fe-Cu-based steel. Acta Mater 56:2073–2088

Vaynman S, Isheim D, Kolli RP, Bhat SP, Seidman DN, Fine ME (2008) High-strength low-carbon ferritic steel containing Cu-Fe-Ni-Al-Mn precipitates. Metall Mater Trans A 39:363–373

Hunter AH, Farren JD, Dupont JN, Seidman DN (2013) An atom-probe tomographic study of arc welds in a multi-component high strength low alloy steels. Metall Mater Trans A 44:1741–1759

Farren JD, Hunter AH, Dupont JN, Seidman DN, Robino CV, Kozeschnik E (2012) Microstructural evolution and mechanical properties of fusion welds in an iron-copper-based multicomponent steel. Metall Mater Trans A 43:4155–4170

Caron JL, Babu SS, Lippold JC (2011) Welding-induced microstructure evolution of a Cu-bearing high-strength blast-resistant steel. Metall Mater Trans A 42:4015–4031

Caron JL, Babu SS, Lippold JC (2011) Weldability evaluation of a Cu-bearing high-strength blast-resistant steel. Metall Mater Trans A 42:4032–4044

Yu X, Caron JL, Babu SS, Lippold JC, Isheim D, Seidman DN (2010) Characterization of microstructural strengthening in the heat-affected zone of a blast-resistant naval steel. Acta Mater 58:5596–5609

Saha A, Olson GB (2007) Computer-aided design of transformation toughened blast resistant naval hull steels: part I. J Comput Aided Mater Des 14:177–200

Saha A, Jung J, Olson GB (2007) Prototype evaluation of transformation toughened blast resistant naval hull steels: part II. J Comput Aided Mater Des 14:201–233

Devletian JH, Fichtelberg ND (2001) Controlling hydrogen cracking in shipbuilding. Weld J 80(11):46–52

Rowe MD, Nelson TW, Lippold JC (1999) Hydrogen-induced cracking along the fusion boundary of dissimilar metal welds. Weld J 78(2):31s–37s

Alexandrov B, Theis K, Streitenberger M, Herold H, Martinek I (2005) Cold cracking in weldments of steel S 690 QT. Weld World 49:64–73

Yurioka N, Suzuki H (1990) Hydrogen assisted cracking in C-Mn and low alloy steel weldments. Int Mater Rev 35(4):217–249

Petch NJ, Stables P (1952) Delayed fracture of metals under static load. Nature 169(4307):842–843

Troiano AR (1960) The role of hydrogen and other interstitials in the mechanical behavior of metals. Trans ASM 52:54–80

Beachem CD (1972) A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall Trans 3:437–451

Kou S (2003) Welding metallurgy. Wiley, New Jersey, pp 410–417

Granjon H (1969) The implants method for studying the weldability of high strength steels. Met Constr Br Weld J 1(11):509–515

Kannengiesser T, Boellinghaus T (2013) Cold cracking tests-an overview of present technologies and applications. Weld World 57(1):3–37

Sawhill JM, Dix AW, Savage WF (1974) Modified implant test for studying delayed cracking. Weld J 53(12):554s–560s

Signes EG, Howe P (1988) Hydrogen-assisted cracking in high-strength pipeline steels. Weld J 67(8):163s–170s

Mayudeeswaran G, Balasubramanian V, Reddy GM (2008) Hydrogen induced cold cracking studies on armour grade high strength, quenched and tempered steel weldments. Inter J Hydrog Energy 33(7):1897–1908

Yue X, Lippold JC, Alexandrov BT, Babu SS (2012) Continuous cooling transformation behavior in the CGHAZ of naval steels. Weld J 91(3):67s–75s

Yue X, Feng XL, Lippold JC (2013) Quantifying heat-affected zone hydrogen-induced cracking in high-strength naval steels. Weld J 92(9):265s–273s

Yue X, Feng XL, Lippold JC (2014) Effect of diffusible hydrogen level on heat-affected zone hydrogen-induced cracking of high-strength steels. Weld World 58(1):101–109

Yue X, Feng XL, Lippold JC (2014) Effect of welding parameters on the heat-affected zone hydrogen-induced cracking tendency of a blast-resistant steel. Weld J 93(3):98s–105s

Easterling K (1992) Introduction to the physical metallurgy of welding. Butterworth-Heinemann, Oxford, pp 12–15

Nawrocki JG, DuPont JN, Robino CV, Marder AR (2001) The postweld heat treatment response of simulated coarse-grained heat-affected zones in a new ferritic steel. Metall Mater Trans A 32:2585–2594

Spanos G, Fonda RW, Vandermeer RA, Matuszeski A (1995) Microstructural changes in HSLA-100 steel thermally cycled to simulate the heat-affected zone during welding. Metall Mater Trans A 26:3277–3293

Yue X, Lippold JC (2013) Evaluation of heat-affected zone hydrogen induced cracking in Navy steels. Weld J 92(1):20s–28s

Yue X, Feng XL, Lippold JC (2013) Strength increase in the coarse-grained heat-affected zone of a high-strength, blast-resistant steel after post-weld heat treatment. Mater Sci Eng A 585:149–154

Bhadeshia HKDH (2001) Bainite in steels: transformations, microstructure and properties. IOM, London, pp 63–75

Dickinson DW, Ries GD (1979) Implant testing of medium to high strength steel—a model for predicting delayed cracking susceptibility. Weld J 59(7):205s–211s

Acknowledgments

The author gratefully acknowledges the financial support of the Office of Naval Research, Award No. N000140811000. Grant Officers: Dr. Julie Christodoulou and Dr. William Mullins. The author would like to thank Johnnie DeLoach, Matthew Sinfield, and Jeffrey Farren with the Naval Surface Warfare Center Carderock Division, West Bethesda, MD for providing the naval steels used in this study. Thanks are extended to Prof Gregory Olson’s research group in Northwestern University for collaboration on this research project and QuesTek Innovations LLC for providing the BA-160 steel. Dejian Liu and Geoffrey Taber are acknowledged for their constructive ideas and assistance with building the implant testing system.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2496, recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding”.

Rights and permissions

About this article

Cite this article

Yue, X. Investigation on heat-affected zone hydrogen-induced cracking of high-strength naval steels using the Granjon implant test. Weld World 59, 77–89 (2015). https://doi.org/10.1007/s40194-014-0181-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0181-4