Abstract

Grain refinement is an important possibility to enhance the mechanical properties such as strength, ductility and toughness of aluminium weld metal. In this study, grain refinement was achieved through the addition of commercial grain refiner Al Ti5B1 to gas tungsten arc weld metal of the aluminium alloys 1050A (Al 99.5) and 5083 (Al Mg4.5Mn0.7). The grain refiner additions led to a significant reduction of the weld metal mean grain size (Alloy 1050A, 86 %; Alloy 5083, 44 %) with a change in grain shape from columnar to equiaxed. Tensile tests showed for Alloy 5083 that the weld metal's ductility can be increased through grain refinement. No improvement in weld metal strength (i.e. yield strength and ultimate tensile strength) was observed. Furthermore, tear tests with notched specimens revealed that the resistance against initiation and propagation of cracks in the weld metal can be enhanced through grain refinement. The toughness was observed to increase clearly by grain refinement in weld metal of commercial pure Al (Alloy 1050A). In Alloy 5083 weld metal, the toughness was not improved through grain refinement, likely because of a semi-continuous network of brittle intermetallic phases that facilitate crack propagation.

Similar content being viewed by others

References

Roos E, Maile K (2002) Werkstoffkunde für Ingenieure, Materials Science for Engineers, 1st edn. Springer, Berlin, in German

Hall EO (1951) The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc B 64:747–752

Petch NJ (1953) The cleavage strength of polycrystals. J Iron Steel Inst 174:25–28

Cottrell AH (1958) Theory of brittle fracture in steel and similar metals. Trans Metall Soc AIME 212(2):192–203

Li JCM (1963) Petch relation and grain boundary sources. Trans Metall Soc AIME 227:239–247

Rösler J, Harders H, Bäker M (2006) Mechanisches Verhalten der Werkstoffe, Mechanical Behaviour of Materials, 2nd edn. Teubner, Stuttgart, in German

Tiryakioğlu M, Staley JT (2003) Physical metallurgy and the effect of alloying additions in aluminum alloys. In: Handbook of aluminum, vol 1, 1st edn. Marcel Dekker, New York, pp 81–209

Hansen N (1977) The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall 25(8):863–869

Embury JD, Lloyd DJ, Ramachandran TR (1989) Strengthening mechanisms in aluminum alloys. In: Vasudevan AK, Doherty RD (eds) Treatise on materials science and technology, vol 31. Academic Press, Boston, pp 579–601

Lloyd DJ (1980) Deformation of fine-grained aluminium alloys. Met Sci 14(5):193–198

Embury JD (1996) Strengthening mechanisms in Al alloys—an overview of natural limits and engineering possibilities. Mater Sci Forum 217–222:57–70

Hornbogen E, Warlimont H (2006) Metalle-Struktur und Eigenschaften der Metalle und Legierungen, metals—structure and properties of metals and alloys, 5th edn. Springer, Berlin, in German

Gottstein G (1998) Physikalische Grundlagen der Materialkunde, Fundamentals of Physics in Materials Science, 1st edn. Springer, Berlin, in German

Phillips VA, Swain AJ, Eborall R (1952) Yield-point phenomena and stretcher-strain markings in aluminium-magnesium alloys. J Inst Met 81:625–647

Staley JT, Sanders RE (2003) Property prediction. In: Handbook of aluminum, first edition, vol. 2. Marcel Dekker, New York, pp. 319–342

Carreker RP, Hibbard WR (1957) Tensile deformation of aluminum as a function of temperature. strain rate, and grain size. Trans Metall Soc AIME 209:1157–1163

Staley JT (1976) Microstructure and toughness of high-strength aluminum alloys. Journal of ASTM International, Spec Tech Publ (STP) 605:71–103

Hornbogen E, Starke EA (1993) Theory assisted design of high strength low alloy aluminum. Acta Metall Mater 41(1):1–16

Kaufman JG (2001) Fracture resistance of aluminum alloys: notch toughness, tear resistance and fracture toughness, 1st edn. ASM International, Materials Park

Jata KV, Starke EA (1986) Fatigue crack growth and fracture toughness behavior of an Al-Li-Cu alloy. Metall Trans A 17(1):1011–1026

Janaki Ram GD, Mitra TK, Shankar V, Sundaresan S (2003) Microstructural refinement through inoculation of type 7020 Al-Zn-Mg alloy welds and its effect on hot cracking and tensile properties. J Mater Process Technol 142(1):174–181

Dev S, Archibald SA, Ravi Dev Kumaar RC, Murty BS, Prasad Rao K (2007) Effect of scandium additions on microstructure and mechanical properties of Al-Zn-Mg alloy welds. Mater Sci Eng, A 467(1–2):132–138

Seshagiri PC, Nair BS, Reddy GM, Rao KS, Bhattacharya SS, Rao KP (2008) Improvement of mechanical properties of aluminium-copper-alloy (AA2219) GTA welds by Sc addition. Sci Technol Weld Join 13(2):146–158

Arata Y, Matsuda F, Mukae S, Katoh M (1973) Effect of weld solidification mode on tensile properties of aluminum weld metal. Trans JWRI 2(2):55–61

Cui GR, Ma ZY, Li SX (2009) The origin of non-uniform microstructure and its effects on the mechanical properties of a friction stir processed Al-Mg alloy. Acta Mater 57(19):5718–5729

Matsuda F, Nakata K, Tsukamoto K, Arai K (1983) Effect of additional element on weld solidification crack susceptibility of Al-Zn-Mg alloy (report II). Trans Join Weld Res Inst 12(2):253–262

Dvornak MJ, Frost RH, Olson DL (1989) The weldability and grain refinement of Al-2.2Li-2.7Cu. Weld J 68(8):327s–335s

Mousavi MG, Cross CE, Grong Ø (1999) Effect of scandium and titanium-boron on grain refinement and hot cracking of aluminium Alloy 7108. Sci Technol Weld Join 4(6):381–388

Schempp P, Cross CE, Schwenk C, Rethmeier M (2012) Influence of Ti and B additions on grain size and weldability of aluminium Alloy 6082. Weld World 56(9–10):95–104

Dvornak MJ, Frost RH, Olson DL (1991) Influence of solidification kinetics on aluminum weld grain refinement. Weld J 70(10):271s–276s

Spittle JA, Cushway AA (1983) Influences of superheat and grain structure on hot-tearing susceptibilities of Al-Cu alloy castings. Met Tech 10(1):6–13

Koteswara Rao SR, Madhusudhana Reddy G, Kamaraj M, Prasad Rao K (2005) Grain refinement through arc manipulation techniques in Al-Cu alloy GTA welds. Mater Sci Eng, A 404(1–2):227–234

Pearce BP, Kerr HW (1981) Grain refinement in magnetically stirred GTA welds of aluminum alloys. Metall Mater Trans B 12(3):479–486

Schempp P, Cross CE, Schwenk C, Rethmeier M (2011) Weld metal grain refinement of aluminium Alloy 5083 through controlled additions of Ti and B. MP Mater Test 53(10):604–609

Schneider W, StJohn DH, Greer AL (2008) Solidification processing of foundry alloys: mechanism of grain refinement of aluminium—almost all you need to know. Proceedings of the 11th International Conference on Aluminium Alloys, Their Physical and Mechanical Properties, Aachen, Germany, vol. 1, pp. 383–392

Cibula A (1949) The mechanism of grain refinement of sand castings in aluminium alloys. J Inst Met 76(4):321, et seqq

Crossley FA, Mondolfo LF (1951) Mechanism of grain refinement in aluminum alloys. J Met 191:1143–1148

McCartney DG (1989) Grain refining of aluminium and its alloys using inoculants. Int Mater Rev 34(5):247–260

Easton M, StJohn D (2005) An analysis of the relationship between grain size, solute content, and the potency and number density of nucleant particles. Metall Mater Trans A 36(7):1911–1920

Bäckerud L, Król E, Tamminen J (1986) Solidification characteristics of aluminium alloys, vol 1, 1st edn. Skanaluminium Universitetsforlaget, Oslo

Hesse W (2008) Aluminium-Schlüssel, Aluminium Handbook, 2nd edn. Aluminium, Düsseldorf, in German

ASTM E 112–96 (1996) Standard test methods for determining average grain size, Standard USA

ASTM B 871–01 (2001) Standard test method for tear testing of aluminum alloy products, Standard USA

Shi Y, Zhong F, Li X, Gong S, Chen L (2007) Effect of laser beam welding on tear toughness of a 1420 aluminum alloy thin sheet. Mater Sci Eng, A 465(1–2):153–159

Pirondi A, Fersini D (2009) Simulation of ductile crack growth in thin panels using the crack tip opening angle. Eng Fract Mech 76(1):88–100

Schempp P, Tang Z, Cross CE, Pittner A, Seefeld TM (June 2012) Rethmeier: influence of base metal and solidification parameters on grain refinement in aluminum weld metal due to inoculation. Proceedings of the 9th International Trends in Welding Research Conference, Chicago, USA

Dvornak MJ, Frost RH, Olson DL (1990) Effects of grain refinement of aluminum weldability. In: Weldability of materials, ASM International, Materials Park, Ohio, 1990, pp. 289–295

Schempp P, Cross CE, Pittner A, Rethmeier M (2013) Influence of solute content and solidification parameters on grain refinement of aluminum weld metal. Metall Trans A (in press)

Easton MA, StJohn DH (2001) A model of grain refinement incorporating alloy constitution and potency of heterogeneous nucleant particles. Acta Mater 49(10):1867–1878

Schloz JD (2010) Fundamentals of grain refining aluminum alloys. Light Met Age 4:30–37

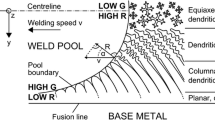

Schempp P, Cross CE, Pittner A, Rethmeier M (2013) Solidification of GTA aluminium weld metal: part I—grain morphology and nucleant particles. Mater Sci Eng A (in press)

Maxwell I, Hellawell A (1975) A simple model for grain refinement during solidification. Acta Metall 23(2):229–237

Turchin AN, Zuijderwijk M, Pool J, Eskin DG, Katgerman L (2007) Feathery grain growth during solidification under forced flow conditions. Acta Mater 55(11):3795–3801

Zhu H, Kumai S, Sato A (2004) Tear toughness evaluation of aluminum alloy castings using a small-size specimen. Proceedings of the 9th International Conference on Aluminium Alloys, Brisbane, Australia, pp. 1160–1166

Poklyatsky AG (2011) Resistance of welds on thin-sheet aluminium alloys to initiation and propagation of service cracks. The Paton Welding Journal, no. 10, pp. 5–9

Czechowski M (2005) Low-cycle fatigue of friction stir welded Al–Mg alloys. J Mater Process Technol 164–165:1001–1006

Mondolfo LF (1976) Aluminum alloys: structure and properties, 1st edn. Butterworths, London

Acknowledgments

The authors are grateful to H. Hayen (formerly working for Aluminium-Bau Jonuscheit GmbH, Germany) and P. Gudde from KBM Affilips B.V., Netherlands, for the very kind donation of plates of Alloy 5083 (Alijo) and grain refiner (KBM Affilips). They also would like to thank M. Babiker (tensile and tear testing), M. Cassau (tear testing), D. Bettge and S. Bohraus (SEM analysis), G. Oder (WDS analysis), M. Marten and N. Stojkic (metallography and hardness testing), H. Strehlau (ICP-OES chemical analysis), D. Köhler (casting of ingots), W. Großmann (machining of inserts) and S. Brauser (strain measurement) for their great support at BAM. The authors are very thankful to the Research Association on Welding and Allied Processes of the DVS for their support and to the Program for Funding of Industrial Research and Technology (IGF) of the German Federal Ministry of Economics and Technology for funding the research project 16.242N.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2345 recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding”.

Rights and permissions

About this article

Cite this article

Schempp, P., Cross, C.E., Häcker, R. et al. Influence of grain size on mechanical properties of aluminium GTA weld metal. Weld World 57, 293–304 (2013). https://doi.org/10.1007/s40194-013-0026-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0026-6