Abstract

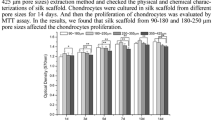

For successful tissue engineering of articular cartilage, a scaffold with mechanical properties that match those of natural cartilage as closely as possible is needed. In the present study, we prepared a fibrous silk fibroin (SF)/poly(L-lactic acid) (PLLA) scaffold via electrospinning and investigated the morphological, mechanical, and degradation properties of the scaffolds fabricated using different electrospinning conditions, including collection distance, working voltage, and the SF:PLLA mass ratio. In addition, in vitro cell-scaffold interactions were evaluated in terms of chondrocyte adhesion to the scaffolds as well as the cytotoxicity and cytocompatibility of the scaffolds. The optimum electrospinning conditions for generating a fibrous SF/PLLA scaffold with the best surface morphology (ordered alignment and suitable diameter) and tensile strength (~1.5 MPa) were a collection distance of 20 cm, a working voltage of 15 kV, and a SF:PLLA mass ratio of S50P50. The degradation rate of the SF/PLLA scaffolds was found to be determined by the SF:PLLA mass ratio, and it could be increased by reducing the PLLA proportion. Furthermore, chondrocytes spread well on the fibrous SF/PLLA scaffolds and secreted extracellular matrix, indicating good adhesion to the scaffold. The cytotoxicity of SF/PLLA scaffold extract to chondrocytes over 24 and 48 h in culture was low, indicating that the SF/PLLA scaffolds are biocompatible. Chondrocytes grew well on the SF/PLLA scaffold after 1, 3, 5, and 7 days of direct contact, indicating the good cytocompatibility of the scaffold. These results demonstrate that the fibrous SF/PLLA scaffold represents a promising composite material for use in cartilage tissue engineering.

Similar content being viewed by others

References

Klein J. Chemistry. Repair or replacement—a joint perspective. Science 2009;323:47–48.

Zhang HY, Blunt L, Jiang XQ, Brown L, Barrans S, Zhao Y. Femoral stem wear in cemented total hip replacement. Proc Inst Mech Eng H 2008;222:583–592.

Dowson D. Bio-tribology. Faraday Discuss 2012;156:9–30;discussion 87-103.

Liao Y, Pourzal R, Wimmer MA, Jacobs JJ, Fischer A, Marks LD. Graphitic tribological layers in metal-on-metal hip replacements. Science 2011;334:1687–1690.

Zhang H, Brown LT, Blunt LA, Jiang X, Barrans SM. Understanding initiation and propagation of fretting wear on the femoral stem in total hip replacement. Wear 2009;266:566–569.

Zhang HY, Blunt LA, Jiang XQ, Fleming LT, Barrans SM. The influence of bone cement type on production of fretting wear on the femoral stem surface:a preliminary study. Clin Biomech (Bristol, Avon) 2012;27:666–672.

Mäkelä KT, Matilainen M, Pulkkinen P, Fenstad AM, Havelin LI, Engesaeter L, et al. Countrywise results of total hip replacement. An analysis of 438,733 hips based on the Nordic Arthroplasty Register Association Database. Acta Orthop 2014;85:107–116.

Zhang HY, Luo JB, Zhou M, Zhang Y, Huang YL. Biotribological properties at the stem-cement interface lubricated with different media. J Mech Behav Biomed Mater 2013;20:209–216.

Zhang H, Brown LT, Blunt LA, Barrans SM. Influence of femoral stem surface finish on the apparent static shear strength at the stem-cement interface. J Mech Behav Biomed Mater 2008;1:96–104.

Zhang H, Zhang S, Luo J, Liu Y, Qian S, Liang F, et al. Investigation of protein adsorption mechanism and biotribological properties at simulated stem-cement interface. J Tribol 2013;135:032301.

Kuo CK, Li WJ, Mauck RL, Tuan RS. Cartilage tissue engineering:its potential and uses. Curr Opin Rheumatol 2006;18:64–73.

Ma PX. Scaffolds for tissue fabrication. Mater Today 2004;7:30–40.

Patterson J, Martino MM, Hubbell JA. Biomimetic materials in tissue engineering. Mater Today 2010;13:14–22.

Niu X, Fan Y, Liu X, Li X, Li P, Wang J, et al. Repair of bone defect in femoral condyle using microencapsulated chitosan, nanohydroxyapatite/ collagen and poly(L-lactide)-based microsphere-scaffold delivery system. Artif Organs 2011;35:E119–E128.

Shive MS, Anderson JM. Biodegradation and biocompatibility of PLA and PLGA microspheres. Adv Drug Deliv Rev 1997;28:5–24.

Ki CS, Park SY, Kim HJ, Jung HM, Woo KM, Lee JW, et al. Development of 3-D nanofibrous fibroin scaffold with high porosity by electrospinning:implications for bone regeneration. Biotechnol Lett 2008;30:405–410.

Mauney JR, Nguyen T, Gillen K, Kirker-Head C, Gimble JM, Kaplan DL. Engineering adipose-like tissue in vitro and in vivo utilizing human bone marrow and adipose-derived mesenchymal stem cells with silk fibroin 3D scaffolds. Biomaterials 2007;28:5280–5290.

Park SY, Ki CS, Park YH, Jung HM, Woo KM, Kim HJ. Electrospun silk fibroin scaffolds with macropores for bone regeneration:an in vitro and in vivo study. Tissue Eng Part A 2010;16:1271–1279.

Lazzeri L, Cascone MG, Danti S, Serino LP, Moscato S, Bernardini N. Gelatine/PLLA sponge-like scaffolds:morphological and biological characterization. J Mater Sci Mater Med 2007;18:1399–1405.

Kundu B, Rajkhowa R, Kundu SC, Wang X. Silk fibroin biomaterials for tissue regenerations. Adv Drug Deliv Rev 2013;65:457–470.

Ehler E, Jayasinghe SN. Cell electrospinning cardiac patches for tissue engineering the heart. Analyst 2014;139:4449–4452.

Wang S, Zhang Y, Wang H, Dong Z. Preparation, characterization and biocompatibility of electrospinning heparin-modified silk fibroin nanofibers. Int J Biol Macromol 2011;48:345–353.

Garrigues NW, Little D, Sanchez-Adams J, Ruch DS, Guilak F. Electrospun cartilage-derived matrix scaffolds for cartilage tissue engineering. J Biomed Mater Res A 2014;102:3998–4008.

Kijenska E, Prabhakaran MP, Swieszkowski W, Kurzydlowski KJ, Ramakrishna S. Electrospun bio-composite P(LLA-CL)/collagen I/collagen III scaffolds for nerve tissue engineering. J Biomed Mater Res B Appl Biomater 2012;100:1093–1102.

Puppi D, Piras AM, Chiellini F, Chiellini E, Martins A, Leonor IB, et al. Optimized electro-and wet-spinning techniques for the production of polymeric fibrous scaffolds loaded with bisphosphonate and hydroxyapatite. J Tissue Eng Regen Med 2011;5:253–263.

Vatankhah E, Prabhakaran MP, Semnani D, Razavi S, Morshed M, Ramakrishna S. Electrospun tecophilic/gelatin nanofibers with potential for small diameter blood vessel tissue engineering. Biopolymers 2014;101:1165–1180.

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 2003;63:2223–2253.

Ma G, Fang D, Liu Y, Zhu X, Nie J. Electrospun sodium alginate/ poly(ethylene oxide) core-shell nanofibers scaffolds potential for tissue engineering applications. Carbohyd Polym 2012;87:737–743.

Kai D, Prabhakaran MP, Jin G, Ramakrishna S. Guided orientation of cardiomyocytes on electrospun aligned nanofibers for cardiac tissue engineering. J Biomed Mater Res B 2011;98:379–386.

USP. USP 24. Rockville, MD:United States Pharmacopeial Convention, Inc;2000. p.1943.

He X, Fu W, Feng B, Wang H, Liu Z, Yin M, et al. Electrospun collagenpoly( L-lactic acid-co-e-caprolactone) membranes for cartilage tissue engineering. Regen Med 2013;8:425–436.

Brown L, Zhang H, Blunt L, Barrans S. Reproduction of fretting wear at the stem-cement interface in total hip replacement. Proc Inst Mech Eng H 2007221:963–971.

Wang Y, Kim HJ, Vunjak-Novakovic G, Kaplan DL. Stem cell-based tissue engineering with silk biomaterials. Biomaterials 2006;27:6064–6082.

Zhang HY, Brown L, Barrans S, Blunt L, Jiang XQ. Investigation of relative micromotion at the stem-cement interface in total hip replacement. Proc Inst Mech Eng H 2009;223:955–964.

Zhang H, Brown L, Blunt L, Jiang X, Barrans S. The contribution of the micropores in bone cement surface to generation of femoral stem wear in total hip replacement. Tribol Int 2011;44:1476–1482.

Huey DJ, Hu JC, Athanasiou KA. Unlike bone, cartilage regeneration remains elusive. Science 2012;338:917–921.

Frenot A, Chronakis IS. Polymer nanofibers assembled by electrospinning. Curr Opin Colloid Interface Sci 2003;8:64–75.

Kumbar SG, James R, Nukavarapu SP, Laurencin CT. Electrospun nanofiber scaffolds:engineering soft tissues. Biomed Mater 2008;3:034002.

Sung HJ, Meredith C, Johnson C, Galis ZS. The effect of scaffold degradation rate on three-dimensional cell growth and angiogenesis. Biomaterials 2004;25:5735–5742.

Sionkowska A. Current research on the blends of natural and synthetic polymers as new biomaterials:review. Prog Polym Sci 2011;36:1254–1276.

Torricelli P, Gioffrè M, Fiorani A, Panzavolta S, Gualandi C, Fini M, et al. Co-electrospun gelatin-poly(L-lactic acid) scaffolds:modulation of mechanical properties and chondrocyte response as a function of composition. Mater Sci Eng C Mater Biol Appl 2014;36:130–138.

Slepicka P, Kasalkova NS, Siegel J, Kolska Z, Bacakova L, Svorcik V. Nanostructured and functionalized surfaces for cytocompatibility improvement and bactericidal action. Biotechnol Adv 2015;53(6 Pt 2):1120–1129.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, W., Li, Z., Zheng, L. et al. Electrospun fibrous silk fibroin/poly(L-lactic acid) scaffold for cartilage tissue engineering. Tissue Eng Regen Med 13, 516–526 (2016). https://doi.org/10.1007/s13770-016-9099-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13770-016-9099-9