Abstract

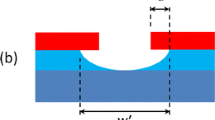

Microfibers with groove structure enable the guided culture of diverse cells. For the fabrication of grooved microfibers, microchannel with a few microscale groove structure needs to be fabricated using complicated photolithography processes. In this study, a novel method to fabricate a round channel embedded microfluidic device for generating continuous grooved microfibers is introduced. The surface tension of PDMS prepolymer was used to construct the round channels and groove patterned structures in the microfluidic device. The self-organized multidroplet structures were utilized to engrave the groove on the microfiber without any complex procedure. Using the device, the groove patterned (ca.10 μm of pattern size) microfiber was successfully fabricated. Microfibers were continuously produced without clogging and the diameters of the grooved microfibers were varied with the flow rate. For the test of usability for cell alignment, fibers were coated with laminin and the neuro-progenitor cells from prenatal rat were seeded on the prepared grooved fibers and cultured. The guided growth of neuronal cells on the fiber was observed through the immunostaining with neurofilament.

Similar content being viewed by others

References

MS Bae, SI Jeong, SE Kim, et al., Nanofiber scaffold for tissue regeneration using electrospinning method, Tissue Eng Regen Med, 5, 2 (2008).

SH Yun, Y-J Kim, OK Kwon, et al., Fabrication and characterization of biodegradable nanofiber containing gelatin. Tissue Eng Regen Med, 5, 4–6 (2008).

YK Seo, JK Park, and SY Kwon, Effect of Collagen-GAG on the Anterior Cruciate Ligament Regeneration of Rabbit, Tissue Eng Regen Med, 7, 5 (2010).

G Orive, SK Tam, JL Pedraz, et al., Biocompatibility of alginatepoly-l-lysine microcapsules for cell therapy.Biomaterials, 27, 20 (2006).

R Langer, New methods of drug delivery,Science, 249, 4976 (1990).

AS Hoffman, Hydrogels for biomedical applications, Advanced drug delivery reviews, 54, 1 (2002).

E Kang, GS Jeong, YY Choi, et al., Digitally tunable physicochemical coding of material composition and topography in continuous microfibres, Nature Materials, 10, 11 (2011).

E Kang, YY Choi, SK Chae, et al., Microfluidic Spinning of Flat Alginate Fibers with Grooves for Cell-Aligning Scaffolds, Advanced Materials, 24, 31 (2012).

Y Zheng, H Bai, Z Huang, et al., Directional water collection on wetted spider silk.Nature, 463, 7281 (2010).

H Bai, J Ju, Y Zheng, et al., Functional Fibers with Unique Wettability Inspired by Spider Silks, Advanced Materials, 24, 20 (2012).

TA Blackledge and CY Hayashi, Silken toolkits: biomechanics of silk fibers spun by the orb web spider Argiope argentata (Fabricius 1775), Journal of Experimental Biology, 209, 13 (2006).

Y Zheng, H Bai, Z Huang, et al., Directional water collection on wetted spider silk, Nature, 463, 7281 (2010).

GA Silva, C Czeisler, KL Niece, et al., Selective differentiation of neural progenitor cells by high-epitope density nanofibers, Science, 303, 5662 (2004).

S-K Chae, E Kang, A Khademhosseini, et al., Micro/Nanometerscale Fiber with Highly Ordered Structures by Mimicking the Spinning Process of Silkworm, Advanced Materials, 25, 22 (2013).

WJ Jeong, JY Kim, J Choo, et al., Continuous fabrication of biocatalyst immobilized microparticles using photopolymerization and immiscible liquids in microfluidic systems, Langmuir, 21, 9 (2005).

JK Nunes, K Sadlej, JI Tam, et al., Control of the length of microfibers, Lab on a Chip, 12, 13 (2012).

E Kang, SJ Shin, KH Lee, et al., Novel PDMS cylindrical channels that generate coaxial flow, and application to fabrication of microfibers and particles, Lab Chip, 10, 14 (2010).

Y Jun, MJ Kim, YH Hwang, et al., Microfluidics-generated pancreatic islet microfibers for enhanced immunoprotection, Biomaterials, 34, 33 (2013).

K Lee, C Kim, KS Shin, et al., Fabrication of round channels using the surface tension of PDMS and its application to a 3D serpentine mixer, Journal of Micromechanics and Microengineering, 17, 8 (2007).

SH Lee, HN Kim, and KY Suh, Use of directly molded poly (methyl methacrylate) channels for microfluidic applications, Lab Chip, 10, 23 (2010).

GS Jeong, Y Jun, JH Song, et al., Meniscus induced self organization of multiple deep concave wells in a microchannel for embryoid bodies generation, Lab Chip, 12, 1 (2012).

GS Jeong, JH Song, AR Kang, et al., Surface Tension-Mediated, Concave-Microwell Arrays for Large-Scale, Simultaneous Production of Homogeneously Sized Embryoid Bodies, Advanced Healthcare Materials, 2, 1 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeong, G.S., Lee, SH. Microfluidic spinning of grooved microfiber for guided neuronal cell culture using surface tension mediated grooved round channel. Tissue Eng Regen Med 11, 291–296 (2014). https://doi.org/10.1007/s13770-014-0046-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13770-014-0046-3