Abstract

Portland cement has been suggested as an effective stabilization (physico-chemical) method for hazardous waste. This research explored the immobilization of metals in various mixtures of Portland cement and fly ash waste sampled from coal power plant in the province of Lodz, central Poland. The stabilization of fly ash in Portland cement was investigated under a wide range of pH conditions (3–12). Leachability tests were used to determine the efficiency of the encapsulation by studying the dissolution of alkaline metals (sodium, potassium) and alkaline earth metals (calcium, magnesium). The lowest value of leached metals was obtained for ratio of ash to cement of 1:10 in a case of sodium and calcium, while ratio 1.5 gave the lowest leached effects for potassium and magnesium. The high effectiveness of solidification/stabilization process was gained in high pH values (9–11).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Solidification/stabilization (S/S) is one of the physical–chemical pre-landfill treatment processes that can be used for fly ash, which requires a special utilization as the hazardous waste listed in the European Catalogue on Hazardous Waste (EPA, Environmental Protection Agency 2002) with the code 10.01.02. The fly ash originates from coal as the inorganic thermal waste from power station and it is estimated in millions tons per year which is significant for environment. The coal deposits often contain impurities such as radioactive elements in ores which can be also found in fly ash after the combustion process (Zielinski and Finkelman 1997).

The solidification/stabilization (S/S) process can be used to encapsulate the wastes by adsorption (Wu et al. 2012; Wang et al. 2009), hydration (Poon et al. 2003) or precipitation reactions with cement and water (Gitari et al. 2010). The results of these interactions are the stabled forms of waste which are non-hazardous or less hazardous than raw material (Zheng et al. 2010; Maschio et al. 2011; Colangelo et al. 2012). It is important to optimize the S/S process parameters to have adequate resistance of the end products to aggressive agents that can appear in the environment i.e. acid groundwater or rainfall (Pandey and Singh 2010). Before the landfill, which is the most popular constituent of waste storage, the environmental characterization is required on crushed mortar samples according to the European standard procedure including in Council Decision 2003/33/EC (2003). The pH dependence test is the best to characterize the general leaching behaviour of elements in cement-based products and it is a tool in a creation of different exposure scenarios (Aubert et al. 2007; Cetin et al. 2012).

Various pH of a soil structure that influences the natural biodiversity has its origin in leachability of collected waste. Monitoring of the end product behaviour in different pH solutions allows optimizing its storage condition. Decreasing percolation of the contaminants from the final products can be also achieved by the establishment of the proper proportion of binder and immobilized waste (Liang et al. 2008). According to the Council Decision 2003/33/EC (2003), establishing criteria and procedures for the acceptance of waste at landfill pursuant, most of the scientific interests focus on the heavy metals (Dermatas and Meng 2003; Shim et al. 2005). Nevertheless, the results obtained for alkaline metals and alkaline earth metals like Na, K, Ca and Mg create a significant part of the completed risk assessment scenario. The participation of these metals in the waste and binder mixture decides about the final chemical properties of the products as well as the stabilization of utilized waste.

The scope of the study was to investigate the final product stabilization consisting of the Portland cement and fly ash sampled from the electrical power plant, Belchatov, Lodz Province, Poland. The aim was realized by the fly ash/cement ratio optimization to create the most stable product, as well as finding the correlation to the immobilization of chosen alkaline metals and alkaline earth metals in various pH solutions.

Materials and methods

Experiments

The Municipal solid waste incinerator fly ash (FA), which came from the electrical power plant Belchatov was used in the experiments. A regular portland cement (PC) I 42.5 R of Cement Lafarge S.A. Poland was used as the binder.

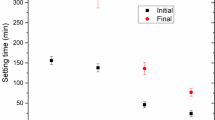

The mortar samples 2 × 2 × 1.5 cm3 were prepared for analysis. The water/mortar ratio was 0.5. The samples were cured for 72 h at 25 °C.

Five series (A–E) of the samples were prepared and subjected to identical exposure and testing. The stabilized waste contained different loadings of fly ash: 10 wt%, 20 wt%, 40 wt%, 50 wt% and 60 wt%. These correspond to the fly ash/cement ratio: A—0.1; B—0.25; C—0.67; D—1.00; E—1.50.

Metal leachability measurements of the raw materials and stabilized ash forms after 48-h exposure were carried out according to European Standard method 12457-2 (2002). All the leaching tests were carried out on the samples in duplicate.

Analysis

Fly ash composition

The metal composition of the fly ash was determined by atomic absorption spectrometry using spectrometer GBC 932 Plus (air–acetylene flame) following the European Standard 12457 (2002). The EA 1108 CHNS—O Analyzer Fisons Instrument equipped with autosampler AS 128, GC column SS PQS (2 m) and thermal conductive detector (TCD) was used to measure carbon, hydrogen and sulphur in the fly ash.

Leachability tests

Metal concentrations of water extracts at different pH solutions (3–12) were measured by atomic absorption spectrometer GBC 932 Plus (air–acetylene flame) according to the CEN/TS European Standard 14429 (2005). The results were presented in milligrams per kilogram of sample dry mass (mg/kg d.m.).

XRD analysis

The XRD studies were carried out on powdered samples. The analysis was conducted using a PANanalytical Model X’Pert PRO MPD using Cu Kα radiation source in the 2θ range from 5° to 90° at 40 kV and current 40 mA. The crystalline phases were identified according the International Centre of Diffraction Data—PDF—2.

Data analysis

The effect of chosen metal leachability in stabilized samples of various ratio fly ash/cement in different pH was investigated using a one-way ANOVA analysis with StatistiXL Version 1.8.

Results and discussion

The chemical analyses results of the fly ash (Table 1) showed that silica, calcium and aluminium were the primary constituents found in the waste samples under investigation. These results were confirmed by XRD analysis shown in Fig. 1. These three constituents in oxide form made up approximately 72 % of the total mass of the fly ash composition.

Table 2 shows the potential maximum leachability for studied material. The analysis of the starting materials of fly ash and Portland cement (before encapsulation/mixing) allowed the maximum potential leachability of the studied metals (Na+, K+, Ca2+ and Mg2+) to be investigated. The calculations were based on the analyses of leachability of each of the investigated metals in powder samples for FA and PC.

As shown in Table 2 for three of the investigated elements (Na+, K+, Ca2+), the potential leachability of the starting materials was directly proportional to fly ash addition, while Mg2+ was inversely proportional.

The appropriate choice of binders can decrease the permeability of stabilized waste forms, in which pollutants are physically isolated from aggressive agents (Rendell and Jauberthie 1999). One of the interactions of contaminants with environment and binder is pH-dependent precipitation which involves a fixation mechanism in products (Glasser 1997; Wang et al. 2006). In Fig. 2, the chemical stabilization of alkaline metals (Na+, K+) and alkaline earth metals (Ca2+, Mg2+) are given for cement-bound matrices as the function of pH. The results were observed for stabilized waste with different fly ash loading: 10 wt% (A), 20 wt% (B), 40 wt% (C), 50 wt% (D) and 60 wt% (E).

In a case of Na+, no significant differences were observed between the mixture ratio of cement and fly ash (p value <0.05). The leachability increased at a pH of 11 and reaches its maximum at a pH 12. Such the results were observed for all the analyzed samples. For K+, the lowest concentration of this metal were observed in the samples which consisted of 60 wt% of fly ash and 40 wt% of cement (E) while the highest leachability was in the samples with the lowest loading of fly ash (A). The pH changes did not influence significantly the leachability of K+. Nevertheless, some significant differences in the leachability were observed (p value 0.98) between the different sample series (A–B). The lowest concentration of Ca2+ was observed after leachability test investigations in the stabilized forms included only 10 wt% of fly ash (A). For all the samples, the significant regression was observed at a pH 10 and almost no metal leached was obtained at a pH 12. No significant results of leachability were obtained between the different loadings of fly ash/cement samples in the investigated sample series (p value <0.05). Analyses of Mg leachability gave the lowest concentration of this metal in the samples of 60 wt% loading of fly (A), while the highest concentration of Mg2+ was observed in the 10 wt% loading. For all the samples, pH values in a range of 3–8 do not influence the leachability of Mg2+. In strong alkaline solution the leachability of Mg2+ increased for all the analyzed samples. The various sample series ratio of fly ash/cement did not influence significantly the leachability of this metal, p value <0.05.

The surface adsorption of metal ions on the stabilized forms of fly ash and cement, as well as the presence of salt forms and dissociated ions in the solution were pH dependent. Some formation of metal complexes and precipitation of metal salts occurred as the ultimate result of pH changes (Valls and Vazquez 2000; Galiano et al. 2010; Batchelor 2006).

The aqueous phase presented in the pore structure of cement-based waste forms was alkaline which influenced the precipitation of insoluble compounds (Li et al. 2001; Glasser and Zhang 2001). The amount of hydrated phases did not influence on the high pH of pore fluids (Glasser 1993) and this effect was a result of continued retention of metallic contaminants in a waste form.

The leachability of alkaline and alkaline earth metal ions from the stabilized waste forms and the adsorption into the nanoporous of these forms surfaces influenced the calcium silicate hydrate (C–S–H) gels. The C–S–H gels have been known as the naturally existed geological forms characterized of a high persistence for a long time (Tiruta-Barna et al. 2004). These gels have been a part of cement chemistry and were created during the solidification process. Their properties were directly depended on the mortar composition (Hong and Glasser 1999). The surface charge of C–S–H has been about zero when the calcium silicon (Ca/Si) ratio was about 1.2 (Maschio et al. 2011; Glasser 1993).

Based on the fly ash and cement composition Table 1, the Ca/Si ratio was calculated in different mortar samples that corresponded to the different fly ash loading: 10 wt% (A), 20 wt% (B), 40 wt% (C), 50 wt% (D) and 60 wt% (E). According to the waste included in the samples, the Ca/Si ratio were: A—2.7, B—2.2, C—1.5, D—1.2 and E—1.0. For these calculations, the neutral charge of the C–S–H gel was expected for the samples with the 50 wt% loading of fly ash (D). In the samples A, B and C where the calcium dominated C–S–H gel had a positive surface charge and anions may occur while silicon-rich C–S–H gel (samples E) adsorbed cations. Nevertheless, the obtained results generally divided the analyzed metals for two groups. To the first one belonged Na and Ca, where the high concentration of these metals was observed in the fly ash loading of 60 wt% (E). To the second group, K and Mg belonged and high amount of the fly ash in the mortar sample (E) decreased these metals’ concentration in the solution.

The properties of the S/S waste especially near surface area depended on the aggressive reagents’ attack including pH changes and caused the degradation of stabilized waste forms. Chemical immobilization of pollutants in S/S process depended also on the crystalline phase of binder matrix (Zheng et al. 2010). Portland cement used in the study contained about 1 wt% of Na2O and K2O, which afforded the high hydroxide ions concentration in pH 12 and suppressed the calcium solubility. Portlandite which dominated in the PC composition buffered the surface pore solution during the alkali metals leaching. It minimized the chemical interactions between the contaminants and surface of the stabilized waste (Shi and Fernandez-Jimenez 2006). This effect was observed for both of the alkali earth metals whose solubility significantly decreased in the highest value of pH solution.

Table 3 has compiled the percentage yield of solidification process of FA and PC as the binder. The analyzed samples with various loading of FA (A–E) were processed by different pH solutions to estimate the durability of metals’ immobilization in stabled waste forms. In a case of alkali metals, the best results of encapsulation were obtained for the samples with 60 wt% loading of FA (E) in pH 9, while the most effective adsorption for alkali earth metals was obtained in pH 12 for the samples with 20 wt% loading of FA. Nevertheless, the high values of solidification for Ca2+ and Mg2+ in the samples with 60 wt% loading of FA were also observed. Most of the Table 3 results maintained the high yield of immobilization effects in the alkaline solutions, which should be taken for the further consideration of the stabilized waste risk assessment scenario in environment.

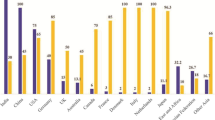

Fly ashes and their disposal has been a current issue affecting the global environment (Iyer and Scott 2001) including Lodz Province, which is an important agglomeration in central Poland with a population of 2.6 million inhabitants. In 2009, 13,732.4 tons of wastes were created in this region where 5,074.8 tons came from the thermal processes of power plants (PIEP, Provincial Inspectorate for Environmental Protection of Lodz 2010).

Exposure to the environment has had significant effects on waste chemical landfill storage and the acidity was one of the parameters deciding this (Otero-Rey et al. 2005). It has been important to monitor the pH of the landfill wastes and optimize the process parameters to slow the chemical reactions between the environment and immobilized pollutants.

Conclusion

The fly ash waste management has been an important issue in the worldwide environment therefore, their proper collection and disposal have been important as they can directly impact the health risks.

Landfilling as the most popular form of waste disposal in Central and Eastern Europe should focus on the effectiveness of solidification and stabilization (S/S) processes of the wastes before their storage.

The proper composition of the waste mixture and a binder should be held in the planning of S/S process to obtain the most stable forms of the immobilized contaminants. In the experiments made under this work, the stabilization effects were characterized by the leachability tests. The lowest concentrations for the analyzed metals in the solutions were obtained for 10 wt% loading of fly ash (FA) samples in a case of Na+ and Ca2+, while the 60 wt% loading of FA samples gave the low leached effects for K+ and Mg2+.

The low changes of the pH range should be provided during the storage process of the stable wastes to limit the leachability of the pollutants to the environment. For alkaline and alkaline earth metals studied under this work, the high value of pH (9–11) should be retained to give the most effective yield of S/S process.

With the results obtained in these studies the most optimized composition of the FA/PC mortar should consist of FA 60 wt% loading and landfill storage of the stabilized waste should not exceed the pH range of 9–11 to hold the most effective encapsulation of contaminants.

References

Aubert JE, Husson B, Sarramone N (2007) Utilization of municipal solid waste incineration (MSWI) fly ash in blended cement. Part 2. Mechanical strength of mortars and environmental impact. J Hazard Mat 146(1–2):12–19

Batchelor B (2006) Overview of waste stabilization with cement. Waste Manag 26(7):689–698

CEN/TS European Standard 14429 (2005) Characterization of waste—leaching behaviour tests—influence of pH on leaching with initial acid/base addition

Cetin B, Aydilek AH, Li L (2012) Experimental and numerical analysis of metal leaching from fly ash-amended highway bases. Waste Manag. doi:10.1016/j.wasman.2011.12.012

Colangelo F, Cioffi R, Montagnaro F, Santoro L (2012) Soluble salt removal from MSWI fly ash and its stabilization for safer disposal and recovery as road basement material. Waste Manag. doi:10.1016/j.wasman.2011.12.013

Council Decision 2003/33/EC (2003) Establishing criteria and procedures for the acceptance of waste at landfill pursuant to Article 16 of an Annex II to Directive 1999/31/EC

Dermatas D, Meng X (2003) Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng Geolog 70(3–4):377–394

EPA, Environmental Protection Agency (2002) European waste catalogue and hazardous waste list, Ireland

European Standard 12457 (2002) Characterization of waste—leaching—compliance test for leaching of granular waste materials and sludge—Part 4

Galiano YL, Fernandez Pereira C, Vale J (2010) Stabilization/solidification of a municipal solid waste incineration residue using fly ash-based geopolymers. J Haz Mat 185(1):373–381

Gitari WM, Petrik LF, Key DL, Okujeni C (2010) Partitioning of major and trace inorganic contaminants in fly ash acid mine drainage derived solid residues. Int J Environ Sci Tech 7(3):519–534

Glasser FP (1993) Chemistry of cement solidified waste forms. In: Spencer RD (ed) Chemistry and microstructure of solidified waste form, vol 1. Lewis publishers, New York

Glasser FP (1997) Fundamental aspects of cement solidification and stabilization. J Haz Mat 52(2–3):151–170

Glasser FP, Zhang L (2001) High-performance cements matrices based on calcium sulfoaluminate–belite compositions. Cem Concr Res 31(12):1881–1886

Hong S-Y, Glasser FP (1999) Alkali binding in cement pastes. Part I. The C–S–H chase. Cem Concr Res 29(12):1893–1903

Iyer RS, Scott JA (2001) Power station fly ash—a review of value-added utilization outside of the construction industry. Res Conserv Rec 31(3):217–228

Li XD, Poon CS, Sun H, Lo IMC, Kirk DW (2001) Heavy metals speciation and leaching behaviours in cement based solidified/stabilized waste materials. J Haz Mat 82(3):215–230

Liang S, Jiang J, Zhang Y, Xu X (2008) Leaching characteristics of heavy metals during cement stabilization of fly ash from municipal solid waste incinerators. Front Environ Sci Engin China 2(3):358–363

Maschio S, Tonello G, Piani L, Furlani E (2011) Fly and bottom ashes from biomass combustion as cement replacing components in mortars production: rheological behaviour of the pastes and materials compression strength. Chemosphere 85(4):666–671

Otero-Rey JR, Mato-Fernandez MJ, Moreda-Pineiro J, Alonso-Rodrıguez E, Muniategui-Lorenzo S, Lopez-Mahıa P, Prada-Rodriguez D (2005) Influence of several experimental parameters on As and Se leaching from coal fly ash samples. Analyt Chim Acta 531(2):299–305

Pandey VC, Singh N (2010) Impact of fly ash incorporation in soil systems. Agric Ecosyst Environ 136(1–2):16–27

PIEP, Provincial Inspectorate for Environmental Protection of Lodz (2010) Wastes, In: Report about environmental condition in Lodz Province, Ed. AGRI s.c., Wroclaw, 94–210

Poon CS, Qiao XC, Lin ZS (2003) Pozzolanic properties of reject fly ash in blended cement pastes. Cem Concr Res 33(11):1857–1865

Rendell F, Jauberthie R (1999) The deterioration of mortar in sulphate environments. Cem Build Mat 13(6):321–327

Shi C, Fernandez-Jimenez A (2006) Stabilization/solidification of hazardous and radioactive wastes with alkali-activated cements. J Haz Mat B 137(3):1656–1663

Shim Y-S, Rhee Y-S, Lee W-K (2005) Comparison of leaching characteristics of heavy metals from bottom and fly ashes in Korea and Japan. Waste Manag 25(5):473–480

Tiruta-Barna L, Imyim A, Barna R (2004) Long-term prediction of the leaching behavior of pollutants from solidified waste. Adv Environ Res 8(3–4):697–711

Valls S, Vazquez E (2000) Stabilisation and solidification of sewage sludges with Portland cement. Cem Concr Res 30(10):1671–1678

Wang J, Ban H, Teng X, Wang H, Ladwig K (2006) Impacts of pH and ammonia on the leaching of Cu(II) and Cd(II) from coal fly ash. Chemosphere 64(11):1892–1898

Wang C, Li J, Sun X, Wang L, Sun X (2009) Evaluation of zeolites synthesized from fly ash as potential adsorbents for wastewater containing heavy metals. J Environ Sci 21(1):127–136

Wu K, Shi H, De Schutter G, Guo X, Ye G (2012) Preparation of alinite cement from municipal solid waste incineration fly Ash. Cem Concr Com 34(3):322–327

Zheng L, Wang W, Shi Y (2010) The effects of alkaline dose and Si/Al ratio on the immobilization of heavy metals in municipal solid waste incineration fly ash-based geopolymer. Chemosphere 79(6):665–671

Zielinski R, Finkelman RB (1997) Radioactive elements in coal and fly ash: abundance, forms and environmental significance, US Geological Survey Fact Sheet FS-163-97, http://pubs.usgs.gov/fs/1997/0163/report.pdf

Acknowledgments

The author would like to express the gratitude to Lafarge Cement S.A. in Poland for providing the Portland cement CEM I 42.5 R samples with their characteristics.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Sobiecka, E. Investigating the chemical stabilization of hazardous waste material (fly ash) encapsulated in Portland cement. Int. J. Environ. Sci. Technol. 10, 1219–1224 (2013). https://doi.org/10.1007/s13762-012-0172-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-012-0172-1