Abstract

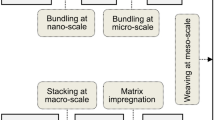

A state of art on characterization of Kevlar fibers and Kevlar fiber reinforced polymer (KFRP) composites is presented to enunciate the limits of further researches in regard of its applicability with the optimized design in today’s high-tech era. A proper characterization is very important for enhancing material properties in various applications such as defense, industrial, marine and aerospace. In this review work, research works performed on the mechanical impact and deformation behavior of Kevlar fiber and KFRP composites have been focused. Kevlar fibers possess high fracture toughness and high strength to weight ratio, of high-performance reinforcement in polymer textile composites. Researchers using different modeling approaches such as homogeneous isotropic and orthotropic material model along with the effect of different parameters as fabric weaving pattern, matrix material, and composite fabrication techniques, working and loading conditions are discussed in detail. Due to anisotropic nature of Kevlar fibers; KFRP composites have high ratio of longitudinal tensile to compression strength whereas the compression strength is considerably found to increase after fiber surface treatment. The purpose of this study is to provide the reader with an overview of different strategies applied with the experimental and numerical investigations of high strength Kevlar fibers and KFRP composites at micro/meso/macroscale.

Similar content being viewed by others

Abbreviations

- k :

-

Thermal conductivity

- T :

-

Temperature

- \(\dot{\varepsilon }\) :

-

Strain rate

- E :

-

Young’s Modulus

- σ max :

-

Peak stress

- \(\varepsilon_{\text{f}}\) :

-

Strain-at-peak stress

- V :

-

Impact velocity

- u trans :

-

Travel speed of Euler transverse wave

- ɛ :

-

Strain by longitudinal deformation wave

- U :

-

Platen displacement

- F :

-

Transverse compressive load

- E 1 :

-

Young’s modulus in 1–2 plane of transverse isotropy

- E 3 :

-

Longitudinal Young’s modulus in the fiber direction

- Ʋ 12 :

-

Poisson’s ratio in plane of transverse isotropy

- r :

-

Single fiber radius

- 2b:

-

Fiber contact width

- 2w:

-

Compressed fiber width

References

Priyanka P, Dixit A, Mali HS (2017) High-strength hybrid textile composites with carbon, Kevlar, and E-glass fibers for impact-resistant structures. Mech Compos Mater 53:685–704

Dixit A, Mali HS (2013) Modeling techniques for predicting the mechanical properties of woven-fabric textile composites: a review. Mech Compos Mater 49:1–20

Sahu NP, Khande DK, Patel GC, Bohidar SK, Sen PK (2014) Study on aramid fibre and comparison with other composite materials. Int J Innov Res Sci Technol 1:303–306

Rao Y, Waddon AJ, Farris RJ (2001) The evolution of structure and properties in poly(p-phenylene terephthalamide) fibers. Polymer 42:5925–5935

McAllister QP, Gillespie JW, Van Landingham MR (2012) Evaluation of the three-dimensional properties of Kevlar across length scales. J Mater Res 27:1824–1837

Sikkema DJ, Northolt MG, Pourdeyhimi B (2003) Assessment of new high-performance fibers for advanced applications. MRS Bull 28:579–584

Reprinted from Kevlar In Wikipedia. https://en.wikipedia.org/wiki/Kevlar. Copyright @ Wikipedia®. All rights reserved). Accessed 5 June 2018

McAllister QP, Gillespie JW Jr, Van Landingham MR (2013) The influence of surface microstructure on the scratch characteristics of Kevlar fibers. J Mater Sci 48:1292–1302

Grujicic M, Bell WC, Arakere G, He T, Xie X, Cheeseman BA (2010) Development of a meso-scale material model for ballistic fabric and its use in flexible-armor protection systems. J Mater Eng Perform 19:22–39

Cheng M, Chen W, Weerasooriya T (2004) Experimental investigation of the transverse mechanical properties of a single Kevlar KM2 fiber. Int J Solids Struct 41:6215–6232

Raja SN, Basu S, Limaye AM, Anderson TJ, Hyland CM, Lin L, Alivisatos AP, Ritchie RO (2015) Strain-dependent dynamic mechanical properties of Kevlar to failure: structural correlations and comparisons to other polymers. Mater Today Commun 2:33–37

Wilfong RE, Zimmerman J (1977) Strength and durability characteristics of Kevlar aramid fiber. J Appl Polym Sci Appl Polym Symp 31:1–21

Nirbhay M, Misra RK, Dixit A (2015) Finite-element analysis of jute-and coir-fiber reinforced hybrid composite multipanel plates. Mech Compos Mater 51:505–520

Reed RP, Golda M (1994) Cryogenic properties of unidirectional composites. Cryogenics 34:909–928

Duband L, Hui L, Lange A (1993) Thermal isolation of large loads at low temperature using Kevlar rope. Cryogenics 33:643–647

Yang HH (1993) Kevlar aramid fiber, 2nd edn. Wiley, New York

Hearle JW (2001) High-performance fibres. The Textile Institute, Woodhead Publishing Limited, Cambridge

Hufenbach W, Kroll L, Tager O, Zhou B (2005) Material-adapted design of textile-reinforced composite structures with optimized vibro-acoustic and damping properties including shear effects. Mech Compos Mater 41:195–204

Yushanov SP, Bogdanovich AE (2000) Fiber waviness in textile composites and its stochastic modeling. Mech Compos Mater 36:297–318

Cheeseman BA, Bogetti TA (2003) Ballistic impact into fabric and compliant composite laminates. Compos Struct 61:161–173

Lim CT, Shim VP, Ng YH (2003) Finite-element modeling of the ballistic impact of fabric armor. Int J Impact Eng 28:13–31

Cheng M, Chen W, Weerasooriya T (2005) Mechanical properties of Kevlar® KM2 single fiber. J Eng Mater Technol 127:197–203

Sanborn B, Weerasooriya T (2014) Quantifying damage at multiple loading rates to Kevlar KM2 fibers due to weaving, finishing, and pre-twist. Int J Impact Eng 71:50–59

Bencomo-Cisneros JA, Tejeda-Ochoa A, García-Estrada JA, Herrera-Ramírez CA, Hurtado-Macías A, Martínez-Sánchez R, Herrera-Ramírez JM (2012) Characterization of Kevlar-29 fibers by tensile tests and nanoindentation. J Alloy Compound 536:456–459

McAllister QP, Gillespie JW, VanLandingham MR (2012) Nonlinear indentation of fibers. J Mater Res 27:197–213

Sebastian MS, Unnikrishnan KC, Narayanan S (2008) Viscoelastic properties of Kevlar-29 fabric tape strength member. Mech Mater 40:949–960

Dixit A, Mali HS, Misra RK (2015) Investigation of the thermomechanical behavior of a 2 × 2 twill weave fabric advanced textile composite. Mech Compos Mater 51:253–264

Bersani A, Canonica L, Cariello M, Cereseto R, Di Domizio S, Pallavicini M (2013) Long term elongation of Kevlar-49 single fiber at low temperature. Cryogenics 54:50–53

Ventura G, Martelli V (2009) Very low temperature thermal conductivity of Kevlar-49. Cryogenics 49:376–377

Ventura G, Barucci M, Gottardi E, Peroni I (2000) Low temperature thermal conductivity of Kevlar. Cryogenics 40:489–491

Ventura G, Martelli V (2009) Thermal conductivity of Kevlar-49 between 7 and 290K. Cryogenics 49:735–737

Wang Y, Xia Y (1998) The effects of strain rate on the mechanical behavior of Kevlar fibre bundles: an experimental and theoretical study. Compos Part A Appl Sci Manuf 29:1411–1415

Xu F, Fan W, Zhang Y, Gao Y, Jia Z, Qiu Y, Hui D (2017) Modification of tensile, wear and interfacial properties of Kevlar fibers under cryogenic treatment. Compos Part B Eng 116:398–405

Lin JS (2002) Effect of surface modification by bromination and metalation on Kevlar fibre-epoxy adhesion. Eur Polym J 38:79–86

Wang H, Xie H, Hu Z, Wu D, Chen P (2012) The influence of UV radiation and moisture on the mechanical properties and micro-structure of single Kevlar fiber using optical methods. Polym Degrad Stabil 97:1755–1761

Parimala HV, Vijayan K (1993) Effect of thermal exposure on the tensile properties of Kevlar fibres. J Mater Sci Lett 12:99–101

Yue CY, Sui GX, Looi HC (2000) Effects of heat treatment on the mechanical properties of Kevlar-29 fibre. Compos Sci Technol 60:421–427

Cai G, Li D, Fang D, Yu W (2014) A new apparatus to measure the effect of temperature and light on the bending fatigue properties of Kevlar 49 and PBO fibers. Polym Test 40:143–148

Minoshima K, Maekawa Y, Komai K (2000) The influence of vacuum on fracture and fatigue behavior in a single aramid fiber. Int J Fatigue 22:757–765

Tan VBC, Lim CT, Cheong CH (2003) Perforation of high-strength fabric by projectiles of different geometry. Int J Impact Eng 28:207–222

Bazhenov SL, Goncharuk GP, Bobrov AV (2015) Effect of transverse compression on the tensile strength of aramid yarns. Doklady Phys Chem 462:115–117

Smith JC, McCrackin FL, Schiefer HF (1958) Stress-strain relationships in yarns subjected to rapid impact loading. Part V. Wave propagation in long textile yarns impacted transversely. Text Res J 28:288–302

Walker JD, Chocron S (2011) Why impacted yarns break at lower speed than classical theory predicts. J Appl Mech 78:051021

Song B, Park H, Lu WY, Chen W (2011) Transverse impact response of a linear elastic ballistic fiber yarn. J Appl Mech 78:051023

Kim J, McDonough WG, Blair W, Holmes GA (2008) The modified-single fiber test: a methodology for monitoring ballistic performance. J Appl Polym Sci 108:876–886

Raftenberg MN, Scheidler MJ, Moy P (2004) Transverse compression response of a multi-ply Kevlar vest. Army Res Lab Aberdeen Proving Ground Md

Lim J, Zheng JQ, Masters K, Chen WW (2010) Mechanical behavior of A265 single fibers. J Mater Sci 45:652–661

Lim J, Zheng JQ, Masters K, Chen WW (2011) Effects of gage length, loading rates, damage on the strength of PPTA fibers. Int J Impact Eng 38:219–227

Leal AA, Deitzel JM, Gillespie JW Jr (2009) Compressive strength analysis for high performance fibers with different modulus in tension and compression. J Compos Mater 43:661–674

Mamivand M, Liaghat GH (2010) A model for ballistic impact on multi-layer fabric targets. Int J Impact Eng 37:806–812

Wollbrett-Blitz J, Joannès S, Bruant R, Le Clerc C, Romero De La Osa M, Bunsell A, Marcellan A (2016) Multiaxial mechanical behavior of aramid fibers and identification of skin/core structure from single fiber transverse compression testing. J Polym Sci, Part B Polym Phys 54:374–384

Sockalingam S, Bremble R, Gillespie JW, Keefe M (2016) Transverse compression behavior of Kevlar KM2 single fiber. Compos Part A Appl Sci Manuf 81:271–281

Crema LB, Castellani A, Drago U (1989) Damping characteristics of fabric and laminated Kevlar composites. Composites 20:593–596

Ganczakowski HL, Beaumont PW (1989) The behavior of Kevlar fibre-epoxy laminates under static and fatigue loadings. Part I: experimental. Compos Sci Technol 36:299–319

Seretis GV, Kostazos PK, Manolakos DE, Provatidis CG (2015) On the mechanical response of woven para-aramid protection fabrics. Compos Part B Eng 79:67–73

Chu TL, Ha-Minh C, Imad A (2016) A numerical investigation of the influence of yarn mechanical and physical properties on the ballistic impact behavior of a Kevlar KM2® woven fabric. Compos Part B Eng 95:144–154

Sánchez-Gálvez V, Gálvez F, Sancho R, Cendón D (2017) A new analytical model to simulate high-speed impact onto composite materials targets. Int J Impact Eng 108:322–333

Wang JZ, Dillard DA, Ward TC (1992) Temperature and stress effects in the creep of aramid fibers under transient moisture conditions and discussions on the mechanisms. J Polym Sci Part B Polym Phys 30:1391–1400

Deteresa SJ, Allen SR, Farris RJ, Porter RS (1984) Compressive and torsional behaviour of Kevlar 49 fibre. J Mater Sci 19:57–72

Ganczakowski HL, Beaumont PW (1990) The behaviour of Kevlar fibre-epoxy laminates under static and fatigue loadings. Part II: Modelling. Compos Sci Technol 37:371–392

Zhu D, Soranakom C, Mobasher B, Rajan SD (2011) Experimental study and modeling of single yarn pull-out behavior of Kevlar® 49 fabric. Compos Part A Appl Sci Manuf 42:868–879

Dong Z, Sun CT (2009) Testing and modeling of yarn pull-out in plain woven Kevlar fabrics. Compos Part A Appl Sci Manuf 40:1863–1869

Bilisik K (2011) Properties of yarn pull-out in para-aramid fabric structure and analysis by statistical model. Compos Part A Appl Sci Manuf 42:1930–1942

Nilakantan G, Gillespie JW (2013) Yarn pull-out behavior of plain woven Kevlar fabrics: effect of yarn sizing, pullout rate, and fabric pre-tension. Compos Struct 101:215–224

Zhu D, Mobasher B, Vaidya A, Rajan SD (2013) Mechanical behaviors of Kevlar 49 fabric subjected to uniaxial, biaxial tension and in-plane large shear deformation. Compos Sci Technol 74:121–130

Greenwood JH, Rose PG (1974) Compressive behaviour of Kevlar 49 fibres and composites. J Mater Sci 9:1809–1814

Xuezhong Z, Yudong H, Tianyu W, Lijiang H (2007) Influence of oligomeric silsesquioxane coating treatment on interfacial properties of CF/PAA composites. Front Mater Sci China 1:40–48

de Lange PJ, Akker PG, Mäder E, Gao SL, Prasithphol W, Young RJ (2007) Controlled interfacial adhesion of Twaron® aramid fibres in composites by the finish formulation. Compos Sci Technol 67:2027–2035

Leal AA, Deitzel JM, McKnight SH, Gillespie JW (2009) Interfacial behavior of high performance organic fibers. Polymer 50:1228–1235

Jang BZ (1992) Control of interfacial adhesion in continuous carbon and Kevlar fiber reinforced polymer composites. Compos Sci Technol 44:333–349

Kotaki M, Hamada H (1997) Effect of interfacial properties and weave structure on mode I interlaminar fracture behaviour of glass satin woven fabric composites. Compos Part A Appl Sci Manuf 28:257–266

Krawczak P, Pabiot J (1995) Fracture mechanics applied to glass fibre/epoxy matrix interface characterization. J Compos Mater 29:2230–2253

Varelidis PC, Papakostopoulos DG, Pandazis CI, Papaspyrides CD (2000) Polyamide coated Kevlar™ fabric in epoxy resin: mechanical properties and moisture absorption studies. Compos Part A Appl Sci Manuf 31:549–558

Lin TK, Wu SJ, Lai JG, Shyu SS (2000) The effect of chemical treatment on reinforcement/matrix interaction in Kevlar-fiber/bismaleimide composites. Compos Sci Technol 60:1873–1878

Su M, Gu A, Liang G, Yuan L (2011) The effect of oxygen-plasma treatment on Kevlar fibers and the properties of Kevlar fibers/bismaleimide composites. Appl Surf Sci 257:3158–3167

Fei S, Dong XH (2010) Numerical study of resin transfer molding (RTM) curing process. Front Mater Sci 4:217–224

Pearson A, Naguib HE (2017) Novel polyurethane elastomeric composites reinforced with alumina, aramid, and poly(p-phenylene-2, 6-benzobisoxazole) short fibers, development and characterization of the thermal and dynamic mechanical properties. Compos Part B Eng 122:192–201

Ha-Minh C, Imad A, Kanit T, Boussu F (2013) Numerical analysis of a ballistic impact on textile fabric. Int J Mech Sci 69:32–39

Song J, Yang W, Liu X, Zhang W, Zhang Y (2016) ASA/graphite/carbon black composites with improved EMI SE, conductivity and heat resistance properties. Iran Polym J 25:111–118

Roylance D, Wang SS (1979) Penetration mechanics of textile structures. Massachusetts Institute of Technology, Cambridge

Duan Y, Keefe M, Bogetti TA, Cheeseman BA (2005) Modeling the role of friction during ballistic impact of a high-strength plain-weave fabric. Compos Struct 68:331–337

Duan Y, Keefe M, Bogetti TA, Cheeseman BA, Powers B (2006) A numerical investigation of the influence of friction on energy absorption by a high-strength fabric subjected to ballistic impact. Int J Impact Eng 32:1299–1312

Bandaru AK, Chavan VV, Ahmad S, Alagirusamy R, Bhatnagar N (2016) Ballistic impact response of Kevlar® reinforced thermoplastic composite armors. Int J Impact Eng 89:1–13

Bandaru AK, Sachan Y, Ahmad S, Alagirusamy R, Bhatnagar N (2017) On the mechanical response of 2D plain woven and 3D angle-interlock fabrics. Compos Part B Eng 118:135–148

Sapozhnikov S, Kudryavtsev O (2015) Modeling of thermoplastic composites used in protective structures. Mech Compos Mater 51:419–426

Bresciani LM, Manes A, Ruggiero A, Iannitti G, Giglio M (2016) Experimental tests and numerical modelling of ballistic impacts against Kevlar 29 plain-woven fabrics with an epoxy matrix: macro-homogeneous and meso-heterogeneous approaches. Compos Part B Eng 88:114–130

Bandaru AK, Ahmad S, Bhatnagar N (2017) Ballistic performance of hybrid thermoplastic composite armors reinforced with Kevlar and basalt fabrics. Compos Part A Appl Sci Manuf 97:151–165

Bandaru AK, Ahmad S (2017) Ballistic impact behaviour of thermoplastic Kevlar composites: parametric studies. Proc Eng 173:355–362

Carrillo JG, Gamboa RA, Flores-Johnson EA, Gonzalez-Chi PI (2012) Ballistic performance of thermoplastic composite laminates made from aramid woven fabric and polypropylene matrix. Polym Test 1:512–519

Bhatnagar A, Arvidson B (2006) Lightweight ballistic composites: military and law-enforcement applications. CRC Press, New York, pp 272–304

Zaera R (2011) Ballistic impacts on polymer matrix composites, composite armor, personal armor. In: Impact engineering of composite structures. Springer, Vienna

Chu CK, Chen YL (2010) Ballistic-proof effects of various woven constructions. Fibre Text East Eur 18:63–67

Sorrentino L, Bellini C, Corrado A, Polini W, Aricò R (2014) Ballistic performance evaluation of composite laminates in Kevlar 29. Proc Eng 88:255–262

Walker JD (2001) Ballistic limit of fabrics with resin. In: InTB46, Proceedings of the 19th international symposium on ballistics, Interlaken, Switzerland, pp 7–11

Hazell PJ, Appleby-Thomas G (2009) A study on the energy dissipation of several different CFRP-based targets completely penetrated by a high velocity projectile. Compos Struct 91:103–109

Grujicic M, Pandurangan B, Koudela KL, Cheeseman BA (2006) A computational analysis of the ballistic performance of light-weight hybrid composite armors. Appl Surf Sci 253:730–745

Woo SC, Kim TW (2014) High-strain-rate impact in Kevlar-woven composites and fracture analysis using acoustic emission. Compos Part B Eng 60:125–136

Gorham DA (1989) Specimen inertia in high strain-rate compression. J Phys D Appl Phys 22:1888–1893

Ramesh KT (2008) High rates and impact experiments. Springer handbook of experimental solid mechanics. Springer, New York, pp 929–960

Kapoor R, Pangeni L, Bandaru AK, Ahmad S, Bhatnagar N (2016) High strain rate compression response of woven Kevlar reinforced polypropylene composites. Compos Part B Eng 89:374–382

Bandaru AK, Chavan VV, Ahmad S, Alagirusamy R, Bhatnagar N (2016) Low velocity impact response of 2D and 3D Kevlar/polypropylene composites. Int J Impact Eng 93:136–143

Chouhan H, Singh D, Parmar V, Kalyanasundaram D, Bhatnagar N (2016) Laser machining of Kevlar fiber reinforced laminates–effect of polyetherimide versus polypropylene matrix. Compos Sci Technol 134:267–274

Yang CC, Ngo T, Tran P (2015) Influences of weaving architectures on the impact resistance of multi-layer fabrics. Mater Des 85:282–295

Manes A, Bresciani LM, Giglio M (2014) Ballistic performance of multi-layered fabric composite plates impacted by different 7.62 mm calibre projectiles. Proc Eng 88:208–215

Mittelman A, Roman I (1990) Tensile properties of real unidirectional Kevlar/epoxy composites. Composites 21:63–69

Guoqi Z, Goldsmith W, Dharan CH (1992) Penetration of laminated Kevlar by projectiles—I. Experimental investigation. Int J Solid Struct 29:399–420

Park SJ, Seo MK, Ma TJ, Lee DR (2002) Effect of chemical treatment of Kevlar fibers on mechanical interfacial properties of composites. J Colloid Interf Sci 252:249–255

Sun D, Chen X (2012) Plasma modification of Kevlar fabrics for ballistic applications. Text Res J 82:1928–1934

Lee YS, Wetzel ED, Wagner NJ (2003) The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J Mater Sci 38:2825–2833

Park Y, Kim Y, Baluch AH, Kim CG (2014) Empirical study of the high velocity impact energy absorption characteristics of shear thickening fluid (STF) impregnated Kevlar fabric. Int J Impact Eng 72:67–74

Majumdar A, Butola BS, Srivastava A (2014) Development of soft composite materials with improved impact resistance using Kevlar fabric and nano-silica based shear thickening fluid. Mater Des 54:295–300

Srivastava A, Majumdar A, Butola BS (2011) Improving the impact resistance performance of Kevlar fabrics using silica based shear thickening fluid. Mater Sci Eng A 529:224–229

Chouhan H, Asija N, Gebremeskel SA, Bhatnagar N (2017) Effect of specimen thickness on high strain rate properties of Kevlar/polypropylene composite. Proc Eng 173:694–701

Cao S, Chen Q, Wang Y, Xuan S, Jiang W, Gong X (2017) High strain-rate dynamic mechanical properties of Kevlar fabrics impregnated with shear thickening fluid. Compos Part A Appl Sci Manuf 100:161–169

Lee BW, Kim CG (2012) Computational analysis of shear thickening fluid impregnated fabrics subjected to ballistic impacts. Adv Compos Mater 21:177–192

Tham CY, Tan VB, Lee HP (2008) Ballistic impact of a KEVLAR® helmet: experiment and simulations. Int J Impact Eng 35:304–318

Pereira JM, Revilock DM Jr (2009) Ballistic impact response of Kevlar 49 and Zylon under conditions representing jet engine fan containment. J Aerospace Eng 22:240–248

Safri SN, Sultan MT, Yidris N, Mustapha F (2014) Low velocity and high velocity impact test on composite materials–a review. Int J Eng Sci 3:50–60

Abrate S (2007) Ballistic impact on composites. In: 16th international conference on composite materials

El-baky MAA (2018) Impact performance of hybrid laminated composites with statistical analysis. Iran Polym J 27:445–459

Sikarwar RS, Rajput NS, Velmurugan R, Naik S (2017) FE Analysis of impact on Kevlar/epoxy laminates with different orientations and thicknesses. Mater Today Proc 4:2599–2607

Bandaru AK, Patel S, Sachan Y, Ahmad S, Alagirusamy R, Bhatnagar N (2016) Mechanical characterization of 3D angle-interlock Kevlar/basalt reinforced polypropylene composites. Polym Test 55:238–246

Nirbhay M, Dixit A, Mishra RK, Mali HS (2014) Tensile test simulation of CFRP test specimen using finite element. Proc Mater Sci 5:267–273

Dixit A, Mali HS, Mishra RK (2014) Finite element (FE) shear modeling of woven fabric textile composite. Proc Mater Sci 6:1344–1350

Dixit A, Mali HS, Mishra RK (2014) A micromechanical unit cell model of 2x2 Twill woven fabric textile composite for multi scale analysis. J Inst Eng India Ser E 95:1–9

Dixit A, Mali HS, Mishra RK (2013) Unit cell model of woven fabric textile composite for multiscale analysis. Proc Eng 68:352–358

Ilgin P, Ozay O (2017) Novel stimuli-responsive hydrogels derived from morpholine: synthesis, characterization and absorption uptake of textile azo dye. Iran Polym J 26:391–404

Khan SM, Gull N, Munawar MA, Zia S, Anjum F, Iqbal MS, Butt MTZ (2016) Polyphenylene sulphide/carbon fiber composites: study on their thermal, mechanical and microscopic properties. Iran Polym J 25:475–485

Dixit A, Mishra RK, Mali HS (2015) Finite element analysis of quasi-static indentation of woven fabric textile composites using different nose shape indenters. Mater Sci Eng Tecknol 46:1014–1028

Dixit A, Mishra RK, Mali HS (2014) Compression modeling of plain weave textile fabric using finite elements. Mater Sci Eng Tecknol 45:600–610

Najafi M, Khalili SMR, Eslami-Farsani R (2014) Hybridization effect of basalt and carbon fibers on impact and flexural properties of phenolic composites. Iran Polym J 23:767–773

Erol O, Powers BM, Keefe M (2017) Effects of weave architecture and mesoscale material properties on the macroscale mechanical response of advanced woven fabrics. Compos Part A Appl Sci Manuf 101:554–566

Sockalingam S, Gillespie JW, Keefe M (2014) On the transverse compression response of Kevlar KM2 using fiber-level finite element model. Int J Solid Struct 51:2504–2517

Sockalingam S, Gillespie JW, Keefe M (2015) Dynamic modeling of Kevlar KM2 single fiber subjected to transverse impact. Int J Solid Struct 67:297–310

Nilakantan G (2013) Filament-level modeling of Kevlar KM2 yarns for ballistic impact studies. Compos Struct 104:1–13

Del Sorbo P, Girardot J, Dau F, Iordanoff I (2018) Numerical investigations on a yarn structure at the microscale towards scale transition. Compos Struct 183:489–498

Wang Y, Miao Y, Swenson D, Cheeseman BA, Yen CF, LaMattina B (2010) Digital element approach for simulating impact and penetration of textiles. Int J Impact Eng 37:552–560

López-Gálvez H, Rodriguez-Millán M, Feito N, Miguelez H (2016) A method for inter-yarn friction coefficient calculation for plain wave of aramid fibers. Mech Res Commun 74:52–56

Wang Y, Chen X, Young R, Kinloch I (2016) Finite element analysis of effect of inter-yarn friction on ballistic impact response of woven fabrics. Compos Struct 135:8–16

Zhu D, Vaidya A, Mobasher B, Rajan SD (2014) Finite element modeling of ballistic impact on multi-layer Kevlar 49 fabrics. Compos Part B 56:254–262

Shen Y, Meir AJ, Cao Y, Adanur A (2015) Finite element analysis of monofilament woven fabrics under uniaxial tension. J Text Inst 106:90–100

Espadas-Escalante JJ, van Dijk NP, Isaksson P (2017) A study on the influence of boundary conditions in computational homogenization of periodic structures with application to woven composites. Compos Struct 160:529–537

Yilbas BS, Akhtar SS (2012) Laser cutting of Kevlar laminates and thermal stress formed at cutting sections. Optics Lasers Eng 50:204–209

Talib ARA, Ramadhan AA, Mohd Rafie AS, Zahari R (2013) Influence of cut-out hole on multi-layer Kevlar-29/epoxy composite laminated plates. Mater Des 43:89–98

Russelle A, Naganambi N (2014) Numerical investigation of bonded repair for TDS of helicopter and characterization of Kevlar/epoxy composite patch. Proc Mater Sci 5:204–211

Palta E, Hongbing F, Weggel DC (2018) Finite element analysis of the advanced combat helmet under various ballistic impacts. Int J Impact Eng 112:125–143

Bandaru AK, Ahmad S (2016) Modeling of progressive damage for composites under ballistic impact. Compos Part B Eng 93:75–87

Acknowledgements

This study is supported by DRDO ARMREB, Govt. of India under Grant No: ARMREB/MAA/2019/213 and TEQIP-III.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Priyanka, P., Dixit, A. & Mali, H.S. High strength Kevlar fiber reinforced advanced textile composites. Iran Polym J 28, 621–638 (2019). https://doi.org/10.1007/s13726-019-00721-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-019-00721-7