Abstract

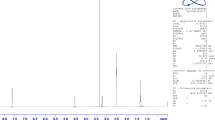

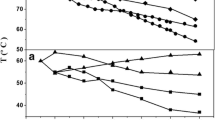

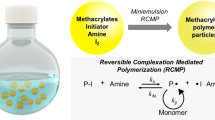

The first example of N-tetradecyl-N-methyl-2-pyrrolidonium was synthesized by using bromide as both an ionic liquid and a surfactant in ionic liquid-based microemulsion polymerization of methyl methacrylate under atom transfer radical polymerization at activator generated electron transfer conditions. The polymerization was carried out at room temperature using copper (II) chloride (CuCl2)/hexamethylene tetramine (HMTA) as a catalyst and CCl4 as an initiator in the absence of surfactant. Ascorbic acid was used as reducing agent. A pseudoternary phase diagram was constructed at 25 °C using the water titration method in the presence and absence of hexadecyltrimethylammonium bromide (CTAB). Kinetics experimental results showed that the polymerization proceeded in a controlled/‘living’ process as evidenced by a linear increase of molecular weights of polymers with monomer conversion with a relatively narrow polydispersity (<1.35) in all cases and M n,GPC values of the resulting polymer were in excellent agreement with the theoretical values M n,th. The polymerization rate increased with the amount of surfactant. However, the polydispersity became broader. The polymerization rate increased with the amount of ligand and decreased with the amount of monomer. In this system, particles of nanoscale (33–51 nm) were prepared. The average particle diameter was found to be affected by the amount of surfactant. The AGET-ATRP of MMA retained the characteristic of living polymerization when the ionic liquid C14MPnBr and catalyst complex were recovered and reused. Living nature of the polymerization was confirmed by the successful homo chain extension experiment. The resultant PMMA was characterized by 1H NMR spectroscopy and gel permeation chromatography techniques.

Similar content being viewed by others

References

Solomon DH, Rizzardo E, Cacioli P (1986) Polymerization process and polymers produced thereby. US Patent 4581429 A

Georges MK, Veregin RPN, Kazmaier PM, Hamer GK (1993) Narrow molecular weight resins by a free-radical polymerization process. Macromolecules 26:2987–2988

Kato M, Kamigaito M, Sawamoto M, Higashimura T (1995) Polymerization of methyl methacrylate with the carbon tetrachloride/dichlorotris-(triphenylphosphine)ruthenium(II)/methylaluminum bis(2,6-di-tert-butylphenoxide) initiating system: possibility of living radical polymerization. Macromolecules 28:1721–1723

Wang JS, Matyjaszewski K (1995) Controlled/”living” radical polymerization. Atom transfer radical polymerization in the presence of transition-metal complexes. J Am Chem Soc 117:5614–5615

Chiefari J, Chong YK, Ercole F, Krstina J, Jeffery J, Le TPT, Mayadunne RTA, Meijs GF, Moad CL, Moad G, Rizzardo E, Thang SH (1998) Living free-radical polymerization by reversible addition–fragmentation chain transfer: the RAFT process. Macromolecules 31:5559–5562

Destarac M, Charmot D, Franck X, Zard SZ (2000) Dithiocarbamates as universal reversible addition-fragmentation chain transfer agents. Macromol Rapid Comm 21:1035–1039

Wang GX, Lu M, Li J, Liu LC, Luo BP, Wu H, Zhong M (2013) Copolymerization of styrene and methyl methacrylate mediated by iron wire/N, N, N′, N′-tetramethyl-1,2-ethanediamine as catalyst in the presence of air. Iran Polym J 22:109–116

Ashaduzzaman M, Kunitake M (2013) Poly(methylmethacrylate)-block-poly(N-hydroxyethylacrylamide) diblock copolymers: direct ATRP synthesis and characterization. Iran Polym J 22:493–499

Konkolewicz D, Magenau AJD, Averick SE, Simakova A, He HK, Matyjaszewski K (2012) ICAR ATRP with ppm Cu catalyst in water. Macromolecules 45:4461–4468

Wang Y, Soerensen N, Zhong MJ, Schroeder H, Buback M, Matyjaszewski K (2013) Improving the “livingness” of ATRP by reducing Cu catalyst concentration. Macromolecules 46:683–691

Nese A, Li YC, Sheiko SS, Matyjaszewski K (2012) Synthesis of molecular bottlebrushes by atom transfer radical polymerization with ppm amounts of Cu catalyst. ACS Macro Lett 1:991–994

Wang GX, Lu M, Hou ZH, Li J, Zhong M, Wu H (2013) Controlled/living copolymerization of styrene and acrylamide in DMF with Fe/TMEDA complex as catalyst. Polym Chem 51:2919–2924

Zhu G, Zhang L, Zhang Z, Zhu J, Tu Y, Cheng Z, Zhu X (2011) Iron-mediated ICAR ATRP of methyl methacrylate. Macromolecules 44:3233–3239

Qin J, Cheng Z, Zhang L, Zhang Z, Zhu J, Zhu X (2011) A highly efficient iron-mediated AGET ATRP of methyl methacrylate using Fe(0) powder as the reducing agent. Macromol Chem Phys 212:999–1006

Bicak N, Gazi M, Tunca U, Kucukkaya I (2004) Utility of atom transfer radical polymerization for the preparation of poly(methyl methacrylate) beads in an aqueous suspension. J Polym Sci Polym Chem 42:1362–1366

Min K, Matyjaszewski K (2009) Atom transfer radical polymerization in aqueous dispersed media. Cent Eur J Chem 7:657–674

Min K, Gao H, Matyjaszewski K (2006) Development of an ab initio emulsion atom transfer radical polymerization: from microemulsion to emulsion. J Am Chem Soc 128:10521–10526

Okubo M, Minami H, Zhou J (2004) Preparation of block copolymer by atom transfer radical seeded emulsion polymerization. Colloid Polym Sci 282:747–752

Bombalski L, Min K, Dong H, Tang C, Matyjaszewski K (2007) Preparation of well-defined hybrid materials by ATRP in miniemulsion. Macromolecules 40:7429–7432

Min K, Matyjaszewski K (2005) Atom transfer radical polymerization in microemulsion. Macromolecules 38:8131–8134

Moniruzzaman M, Kamiya N, Goto M (2009) Biocatalysis in water-in-ionic liquid microemulsions: a case study with horseradish peroxidase. Langmuir 25:977–982

Zhao M, Zheng L, Bai X, Li N, Yu L (2009) Fabrication of silica nanoparticles and hollow spheres using ionic liquid microemulsion droplets as templates. Colloid Surface A 346:229–236

Zhang G, Zhou H, Hu J, Liu M, Kuang Y (2009) Pd nanoparticles catalyzed ligand-free Heck reaction in ionic liquid microemulsion. Green Chem 11:1428–1432

Wang G, Lu M, Wu H (2012) Preparation of poly(methyl methacrylate) by ATRP using initiators for continuous activator regeneration (ICAR) in ionic liquid/microemulsions. Polymer 53:1093–1097

Behera K, Dahiya P, Pandey S (2007) Effect of added ionic liquid on aqueous triton X-100 micelles. J Colloid Interf Sci 307:235–245

Lü H, An X, Shen W (2008) Critical behavior of a microemulsion with an ionic liquid. J Chem Eng Data 53:727–731

Rabe C, Koetz J (2010) CTAB-based microemulsions with ionic liquids. Colloid Surface A 354:261–267

Pavlidis IV, Gournis D, Papadopoulos GK, Stamatis H (2009) Lipases in water-in-ionic liquid microemulsions: structural and activity studies. J Mol Catal B Enzym 60:50–56

Zhang HB, Zhou XH, Dong JF, Zhang GY, Wang CX (2007) A novel family of green ionic liquids with surface activities. Sci China Ser B 50:238–242

Gannu R, Rao YM (2012) Formulation optimization and evaluation of microemulsion based transdermal therapeutic system for nitrendipine. J Disper Sci Technol 33:223–233

Zhou Y, Qiu L, Deng Z, Texter J, Yan F (2011) Low-temperature AGET ATRP of methyl methacrylate in ionic liquid-based microemulsions. Macromolecules 44:7948–7955

Ando T, Kamigaito M, Sawamoto M (1998) Silyl enol ethers: end-capping agents for living radical polymerization of methyl methacrylate with ruthenium complex. Macromolecules 31:6708–6711

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, B. Investigation of AGET-ATRP of methyl methacrylate in surface-active ionic liquid microemulsions. Iran Polym J 23, 87–92 (2014). https://doi.org/10.1007/s13726-013-0203-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-013-0203-x