Abstract

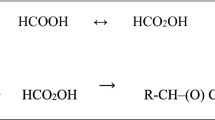

The gradual depletion of fossil fuel reserves and the sharp rise in the cost of fossil fuels have generated a frenzy of activities in the quest to search for renewable source-based alternatives. Epoxides are an intermediate product that can be converted into value-added polymers. In the industry, epoxidation of vegetable oils is most frequently carried out with performic and peracetic acids. The aim of this study is to investigate the influence of the type of oxygen carrier (formic acid, acetic acid, and hybrid solution of formic and acetic acid) on the epoxidation of palm oleic acid. The peracids were formed in situ in this study. Based on the results, the highest relative conversion to oxirane (RCO) is achieved using formic acid, with a value of 82% at a reaction time of 25 min. Interestingly, a high RCO (82%) can also be achieved by using a hybrid solution of formic and acetic acid at a molar ratio of 1:1. The use of a hybrid oxygen carrier solution can help minimize the use of formic acid, which would create a strong acidic environment. In addition, the kinetic model is capable of predicting the reaction kinetics of the epoxidation process since the simulation results show good agreement with the experimental data, particularly for a formic acid/acetic acid molar ratio of 0.5:1.0.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Sardon H, Mecerreyes D, Basterretxea A, Avérous L, Jehanno C (2021) From lab to market: current strategies for the production of biobased polyols. ACS Sustain. Chem Eng 9(32):10664–10677. https://doi.org/10.1021/acssuschemeng.1c02361

Azmi IS, Jalil MJ, Hadi A (2022) Epoxidation of unsaturated fatty acid–based palm oil via peracid mechanism as an intermediate product. Biomass Convers Biorefin 1–9. https://doi.org/10.1007/s13399-022-02862-x

Saurabh T, Patnaik M, Bhagt SL, Renge VC (2011) Epoxidation of vegetable oils: a review. Int J Adv Eng Technol 2(4):491–501

Arniza MZ et al (2015) Synthesis of transesterified palm olein-based polyol and rigid polyurethanes from this polyol, JAOCS. J Am Oil Chem Soc 92(2):243–255. https://doi.org/10.1007/s11746-015-2592-9

González-Benjumea A et al (2021) High epoxidation yields of vegetable oil hydrolyzates and methyl esters by selected fungal peroxygenases. Front Bioeng Biotechnol 8:1–12. https://doi.org/10.3389/fbioe.2020.605854

Performik A, Hong LK, Yusop RM, Salih N, Salimon J (2015) Optimization of the in situ epoxidation of linoleic acid of Jatropha curcas oil with performic acid. Malaysian J Anal Sci 19(1):144–154

Bashiri S, Ghobadian B, DehghaniSoufi M, Gorjian S (2021) Chemical modification of sunflower waste cooking oil for biolubricant production through epoxidation reaction. Mater Sci Energy Technol 4:119–127. https://doi.org/10.1016/j.mset.2021.03.001

Nugrahani RA, Redjeki AS, Mentari Y, Jannah M, Wibowo TY (2017) Study effect of temperature and reaction kinetics model selection epoxidation against rice bran oil methyl ester with catalyst Amberlite Ir-120. ARPN J Eng Appl Sci 12(13):3947–3952

Budiyati E, Rochmadi R, Budiman A, Budhijanto B (2020) Studies on epoxidation of tung oil with hydrogen peroxide catalyzed by sulfuric acid. Bull Chem React Eng Catal 15(3):674–686. https://doi.org/10.9767/BCREC.15.3.8243.674-686

Allauddin S, Somisetti V, Ravinder T, Rao BVSK, Narayan R, Raju KVSN (2016) One-pot synthesis and physicochemical properties of high functionality soy polyols and their polyurethane-urea coatings. Ind Crops Prod 85:361–371. https://doi.org/10.1016/j.indcrop.2015.12.087

Xia W, Budge SM, Lumsden MD (2016) 1H-NMR characterization of epoxides derived from polyunsaturated fatty acids, JAOCS. J Am Oil Chem Soc 93(4):467–478. https://doi.org/10.1007/s11746-016-2800-2

Nwosu-Obieogu K, Aguele F, Chiemenem L (2020) Optimization on rubber seed oil epoxidation process parameters using response surface methodology. Iran J Chem Chem Eng 40(5):1575–1583

Kurańska M, Niemiec M (2020) Cleaner production of epoxidized cooking oil using a heterogeneous catalyst. Catalysts 10(11):1–13. https://doi.org/10.3390/catal10111261

Ranganathan S, Tebbe J, Wiemann LO, Sieber V (2016) Optimization of the lipase mediated epoxidation of monoterpenes using the design of experiments—Taguchi method. Process Biochem 51(10):1479–1485. https://doi.org/10.1016/j.procbio.2016.07.005

Campanella A, Baltanás MA, Capel-Sánchez MC, Campos-Martín JM, Fierro JLG (2004) Soybean oil epoxidation with hydrogen peroxide using an amorphous Ti/SiO2 catalyst. Green Chem 6(7):330–334. https://doi.org/10.1039/b404975f

Singh I, Samal SK, Mohanty S, Nayak SK (2020) Recent advancement in plant oil derived polyol-based polyurethane foam for future perspective: a review. Eur J Lipid Sci Technol 122(3):1–23. https://doi.org/10.1002/ejlt.201900225

Jalil MJ, Hadi A, Azmi IS (2021) Catalytic epoxidation of palm oleic acid using in situ generated performic acid — optimization and kinetic studies. Mater Chem Phys 270:124754. https://doi.org/10.1016/j.matchemphys.2021.124754

Ismail KN et al (2021) High yield dihydroxystearic acid (DHSA) based on kinetic model from epoxidized palm oil. Kem u Ind 70(1–2):23–28. https://doi.org/10.15255/kui.2020.016

Jalil MJ (2019) Optimization of palm oleic acid epoxidation via in situ generated performic acid using Taguchi orthogonal array design and the study of reaction kinetics. Smart Sci 7(4):252–259. https://doi.org/10.1080/23080477.2019.1663392

Jumain M, Intan J, Azmi S, Hadi A, Farhan A, Yamin M (2022) In situ hydrolysis of epoxidized oleic acid by catalytic epoxidation — peracids mechanism. J Polym Res 29(3):1–12. https://doi.org/10.1007/s10965-022-02944-4

Kushairi A et al (2019) Oil palm economic performance in Malaysia and R&D progress in 2018. J Oil Palm Res 31(2):165–194. https://doi.org/10.21894/jopr.2019.0026

Benaniba MT, Belhaneche-bensemra N, Gelbard G (2007) Kinetics of tungsten-catalyzed sunflower oil epoxidation studied by 1H NMR. Eur J Lipid Sci Technol 109(12):1186–1193. https://doi.org/10.1002/ejlt.200700114

Azmi IS, Bakar MHA, Raofuddin DNA, Habri HH, Azmi MHM, Jalil MJ (2022) Synthesis and kinetic model of oleic acid-based epoxides by in situ peracid mechanism. Kemija u industriji: Časopis kemičara i kemijskih inženjera Hrvatske 71(3–4):209–214

Chou T, Chang J (2007) Acetic acid as an oxygen carrier between two phases for epoxidation of oleic acid. Chem Eng Commun 41(1):253–266. https://doi.org/10.1080/00986448608911722

BeltránOsuna AA, Boyacá Mendivelso LA (2010) Two-phase kinetic model for epoxidation of soybean oil. Ing e Investig. 30(2):188–196

Ifa L, Syarif T, Sabara Z, Nurjannah N, Munira M, Aryani F (2018) Study on the kinetics of epoxidation reaction of RBD palm olein. IOP Conf Ser Earth Environ Sci 175(1):012035. https://doi.org/10.1088/1755-1315/175/1/012035

Campanella A, Baltanás MA (2005) Degradation of the oxirane ring of epoxidized vegetable oils in liquid-liquid systems: I Hydrolysis and attack by H2O2. Latin Am Appl Res 35(3):205–210

Gan LH, Goh SH, Ooi KS (1992) Kinetic studies of epoxidation and oxirane cleavage of palm olein methyl esters. J Am Oil Chem Soc 69(4):347–351

Funding

The author would like to thank Universiti Teknologi MARA for the financial support with RMI file no: 600-RMC/GIP 5/3 (097/2022).

Author information

Authors and Affiliations

Contributions

Intan Suhada Azmi: data curation and writing — original draft.

Tunku Arif Zafri Tunku Ozir: data curation and writing.

Ismail Md. Rasib: data curation.

Silvana Dwi Nurherdiana: writing and methodology.

Mohd Jumain Jalil: conceptualization, investigation, and methodology.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azmi, I.S., Ozir, T.A.Z.T., Rasib, I.M. et al. Synergistic epoxidation of palm oleic acid using a hybrid oxygen carrier solution. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03325-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03325-z