Abstract

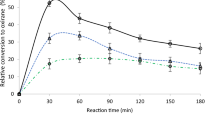

Epoxidation of oleic acid from vegetable oil has become popular due to the high demand for environmentally friendly epoxides from vegetable oils nowadays. This study aims to investigate the synthesis of epoxidized hybrid oleic acid from waste palm cooking oil and palm oil via in situ peracid mechanism. The novel method using hybrid raw material which is palm oil and waste palm cooking oil was introduced in this study in the epoxidation with performic acid in the presence of sulfuric acid as a homogeneous catalyst. Based on ideal process parameters, the maximum conversion to oxirane can be up to 65% using the optimum process parameter with a temperature of 75℃ and sulfuric acid act as catalyst. A mathematical model was developed by using the numerical integration Runge Kutta 4th Order method. The results showed that there was good agreement between the simulation and experimental data, which validates the kinetic model.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Marriam F, Irshad A, Umer I, Arslan M (2023) Vegetable oils as bio-based precursors for epoxies. Sustain Chem Pharm 31:100935. https://doi.org/10.1016/j.scp.2022.100935

Wu Y, Chen Z, Wang Y, Xu X (2022) Kinetic Studies and Reaction Network in the Epoxidation of Styrene Catalyzed by the Temperature-Controlled Phase-Transfer Catalyst [(C18H37) 2 (CH3) 2N] 7 [PW11O39]. Ind Eng Chem Res 61(30):10747–10755

Singh I, Samal SK, Mohanty S, Nayak SK (2020) Recent Advancement in Plant Oil Derived Polyol-Based Polyurethane Foam for Future Perspective: A Review. Eur J Lipid Sci Technol 122(3):1–23. https://doi.org/10.1002/ejlt.201900225

Wai PT, Jiang P, Shen Y, Zhang P, Gu Q, Leng Y (2019) Catalytic developments in the epoxidation of vegetable oils and the analysis methods of epoxidized products. RSC Adv 9(65):38119–38136. https://doi.org/10.1039/c9ra05943a

Amri MR, Al-Edrus SSO, Guan CT, Yasin FM, Hua LS (2021) Jatropha Oil as a Substituent for Palm Oil in Biobased Polyurethane. Int J Polym Sci 3:2021. https://doi.org/10.1155/2021/6655936

Irinislimane R, Belhaneche-Bensemra N (2021) Optimisation of Operatory Conditions for Synthesis of Sunflower Oil Biobased Polyols Using Design of Experiments and Spectroscopic Methods. J Polym Environ 29(3):851–858. https://doi.org/10.1007/s10924-020-01917-2

Azmi IS, Ozir TAZT, Rasib IM, Nurherdiana SD, Jalil MJ (2022) Synergistic epoxidation of palm oleic acid using a hybrid oxygen carrier solution. Biomass Convers Biorefinery 0123456789:1–8. https://doi.org/10.1007/s13399-022-03325-z

Feng S, Jiang P, Zhang P, Lu M, Cui Z, Pan J, Pan L (2023) Synthesis and evaluation of epoxidized vegetable oleic acid as a novel environmental benign plasticizer for polyvinyl chloride. J Appl Polym Sci 140(3):e53331

Dinda S, Veeram NSR, Adusumalli RB (2016) Production of bio-epoxide and bio-adhesive from non-edible oil. Korean J Chem Eng 33(10):2915–2922. https://doi.org/10.1007/s11814-016-0136-0

Azmi IS, Hadi A, Jalil MJ (2022) Eco‐friendly polyol through in situ hydroxylation from epoxidation of palm oleic acid via heterogeneous catalyst. Biofuels, Bioprod and Bioref 1:1–18

Silviana S, Anggoro DD, Kumoro AC (2017) Waste Cooking Oil Utilisation as Bio-plasticiser through Epoxidation using Inorganic Acids as Homogeneous Catalysts. Chem Eng Trans 56:1861–1866. https://doi.org/10.3303/CET1756311

Samidin S, Salimon J (2014) Synthesis and physicochemical properties of epoxidized Tmp trioleate by in situ method. In AIP Conf Proc (Vol. 1614, No. 1, pp. 351–357). American Institute of Physics

Pérez JE, Haagenson DM, Pryor SW, Ulven CA, Wiesenborn DP (2009) Production and characterization of epoxidized canola oil. Trans ASABE 52(4):1289–1297

Borugadda VB, Goud VV (2014) Synthesis of waste cooking oil epoxide as a bio-lubricant base stock: characterization and optimization study. J Bioprocess Eng Biorefinery 3(1):57–72

Cai C, Thua P, Gua F (2008) Studies on the kinetics of in situ epoxidation of vegetable oils. Eur J Lipid Sci Technol 110(4):341–346. https://doi.org/10.1002/ejlt.200700104

Moreno D, Velasco M, Malagón-Romero D (2020) Production of polyurethanes from used vegetable oil-based polyols. Chem Eng Trans 79(January):337–342. https://doi.org/10.3303/CET2079057

Azmi IS, Mustafa MR, MohdZalman NIS, HaqeemNorazlan MD, Jalil MJ (2023) Synthesis of bio-polyol from epoxidized palm oleic acid by homogeneous catalyst. J Elastomers Plast 55(2):303–315

Phimsen S et al (2017) Epoxidation of methyl oleate in a TiO2 coated-wall capillary microreactor. Chem Eng J 314:594–599. https://doi.org/10.1016/j.cej.2016.12.017

Arniza MZ et al (2015) “Synthesis of transesterified palm olein-based Polyol and rigid polyurethanes from this polyol”, JAOCS. J Am Oil Chem Soc 92(2):243–255. https://doi.org/10.1007/s11746-015-2592-9

Azmi IS, Bakar MHA, Raofuddin DNA, Habri HH, Azmi MHM, Jalil MJ (2022) Synthesis and kinetic model of oleic acid-based epoxides by in situ peracid mechanism. Kemija u industriji: Časopis kemičara i kemijskih inženjera Hrvatske 71(3-4):209–214

Cai X, Zheng JL, Aguilera AF, Vernières‐Hassimi L, Tolvanen P, Salmi T, Leveneur S (2018) Influence of ringopening reactions on the kinetics of cottonseed oil epoxidation. Int J Chem Kinet 50(10):726–741

Borugadda VB, Goud VV (2014) Epoxidation of castor oil fatty acid methyl esters (COFAME) as a lubricant base stock using heterogeneous ion-exchange resin (IR-120) as a catalyst. Energy Procedia 54(0361):75–84. https://doi.org/10.1016/j.egypro.2014.07.249

De Souza FM, Sulaiman MR, Gupta RK (2021) Materials and Chemistry of Polyurethanes. ACS Symp Ser 1399:1–36. https://doi.org/10.1021/bk-2021-1399.ch001

Patil SS, Jena HM (2019) Synthesis of Epoxidized Citrullus lanatus Seed Oil: Experimental Investigation and Statistical Optimization. Arab J Sci Eng 44(12):9965–9976. https://doi.org/10.1007/s13369-019-04077-1

Mohd Nor N, Salih N, Salimon J (2021) Optimization of the ring opening of epoxidized palm oil using d-optimal design. Asian J Chem 33(1):67–75. https://doi.org/10.14233/ajchem.2021.22938

Allauddin S, Somisetti V, Ravinder T, Rao BVSK, Narayan R, Raju KVSN (2016) One-pot synthesis and physicochemical properties of high functionality soy polyols and their polyurethane-Urea coatings. Ind Crops Prod 85:361–371. https://doi.org/10.1016/j.indcrop.2015.12.087

Coman AE et al (2021) Synthesis and characterization of renewable polyurethane foams using different biobased polyols from olive oil. Eur Polym J 149:110363. https://doi.org/10.1016/j.eurpolymj.2021.110363

Mungroo R, Goud VV, Naik SN, Dalai AK (2011) Utilization of green seed canola oil for in situ epoxidation. Eur J Lipid Sci Technol 113(6):768–774

Ogunjobi JK, Farmer TJ, Clark JH, McElroy CR (2023) Synthesis, Characterization, and Physicochemical Performance of Nonionic Surfactants via PEG Modification of Epoxides of Alkyl Oleate Esters. ACS Sustain Chem Eng 11(5):1857–1866

Azmi IS, Jalil MJ, Hadi A (2022) Epoxidation of unsaturated fatty acid–based palm oil via peracid mechanism as an intermediate product. Biomass Convers Biorefin 1(1):1–9

Acknowledgements

The author would like to thank Universiti Teknologi MARA for financially supporting with: RMI file no: 600-TNCPI/PBT 5/3 (016/2022) and 600-TNCPI/PBT 5/3 (005/2022).

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Mohd Zulkipli Ab Kadir: Writing and experiment work.

Aivenny Stacey Motiyus: Data curation.

Intan Suhada Azmi: Data curation.

Mohd Jumain Jalil: conceptualization and methodology.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kadir, M.Z.A., Motiyus, A.S., Azmi, I.S. et al. In situ epoxidation of oleic acid derived from hybrid oleic acid from waste palm cooking oil & palm oil via homogenous catalyst. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04306-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04306-6