Abstract

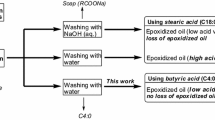

The world consumption of raw materials has shifted from the use of non-renewable materials to renewable materials. Studies on greener epoxidation by using vegetable oils to produce eco-friendly epoxides have also increased. In this study, the epoxidation of oleic acid was carried out by in situ-produced performic acid. The one-factor-at-a-time (OFAT) method was used to optimise the epoxidation process for the maximum production of epoxidised oleic acid with respect to oxirane stability as an intermediate product. The OFAT method showed that the optimum process parameters for production of epoxidised oleic acid to the response of relative conversion to oxirane (RCO) and epoxy ring stability at a longer time with the determination of oxirane oxygen content (OOC) was maximum (82%) under following conditions: (1) stirring speed at 350 rpm, (2) reaction temperature at 100 °C, (3) formic acid/oleic acid molar ratio of 2.0:1, and (4) hydrogen peroxide/oleic acid molar ratio of 2.0:1. Overall, a high yield of epoxidised oleic acid production and epoxy ring stability at a longer reaction time was successfully produced from oleic acid as the main raw material. The results showed a good agreement between the simulation and experimental data, validating the kinetic model.

Similar content being viewed by others

Abbreviations

- FA:

-

Formic acid

- HP:

-

Hydrogen peroxide

- OA:

-

Oleic acid

- EOA:

-

Epoxidised oleic acid

- RCO:

-

Relative conversion to oxirane

- OOC:

-

Oxygen oxirane content

- OFAT:

-

One factor at a time

- PA:

-

Performic acid

References

Meng Y et al (2021) The lord of the chemical rings: catalytic synthesis of important industrial epoxide compounds. Catalysts 11 (7). https://doi.org/10.3390/catal11070765.

Jalil MJ, Hadi A, Azmi IS (2021) Catalytic epoxidation of palm oleic acid using in situ generated performic acid — optimization and kinetic studies. Mater Chem Phys 124754. https://doi.org/10.1016/j.matchemphys.2021.124754.

Turco R, Tesser R, Russo V, Cogliano T, Di Serio M, Santacesaria E (2021) Epoxidation of linseed oil by performic acid produced in situ. Ind Eng Chem Res 60(46):16607–16618. https://doi.org/10.1021/acs.iecr.1c02212

Jalil MJ et al. (2019) Synthesis and physicochemical properties of epoxidized oleic acid-based palm oil. IOP Conf Ser Earth Environ Sci 291(1). https://doi.org/10.1088/1755-1315/291/1/012046.

Minyak P, Olein S, Sebagai, T, Keterbaharuan B, Peroksi A (2014) Preparation of epoxidized palm olein as renewable material by using peroxy acids. Malaysian J Anal Sci 18(3):584-591

Pérez-Sena WY et al (2018) Aminolysis of cyclic-carbonate vegetable oils as a non-isocyanate route for the synthesis of polyurethane: a kinetic and thermal study. Chem Eng J 346(January):271–280. https://doi.org/10.1016/j.cej.2018.04.028

Jalil MJ, Zaini MSM, Yamin AFM, Chang SH (2019) Kinetics of epoxidized oleic acid derived from palm oil by in situ generated performic acid. 68 181–187 https://doi.org/10.15255/KUI.2018.039

Cheong MEIYEE, Aldrin Z, Hasan A, Idris Z (2019) Characterisation of epoxidised trimethylolpropane trioleate : NMR and thermogravimetric analysis 31(March):146–158

Hasmaruddin NS, Tahir SM (2019) Synthesis of waste cooking oil-based polyol via one-pot epoxidation and hydroxylation reaction. Int J Recent Technol Eng 8(1S):382–385

Cai X, Aguilera AF, Leveneur S (2018) Influence of ring-opening reactions on the kinetics of cottonseed oil epoxidation. Int J Chem Kinet 50(10):726–741 1–16. https://doi.org/10.1002/kin.21208.

Jalil MJ (2019) Optimization of palm oleic acid epoxidation via in situ generated performic acid using taguchi orthogonal array design and the study of reaction kinetics. Smart Sci 7(4). https://doi.org/10.1080/23080477.2019.1663392.

Jalil MJ, Hadi A, Mora N, Chang SH, Yamin AFM, Zaini MSM (2019) Kinetika epoksidirane oleinske kiseline dobivene iz palmina ulja in situ proizvedenom permravljom kiselinom Kinetics of epoxidized oleic acid derived from palm oil by in situ generated performic acid. Kem u Ind 68(56):181–187. https://doi.org/10.15255/kui.2018.039

Prasad KS, Rao CS, Rao DN (2012) Study on factors effecting weld pool geometry of pulsed current micro plasma arc welded AISI 304L austenitic stainless steel sheets using statistical approach. J Miner Mater Charact Eng 11(08):790–799. https://doi.org/10.4236/jmmce.2012.118068

Kurańska M, Niemiec M (2020) Cleaner production of epoxidized cooking oil using a heterogeneous catalyst. Catalysts 10(11):1–13. https://doi.org/10.3390/catal10111261

Patil H, Waghmare J (2013) Catalyst for epoxidation of oils: a review. Discovery 3(7):10–14

Mohd Yunus MZ, Jamaludin SK, Abd Karim SF, Abd Gani A, Sauki A (2018) Catalytic efficiency of titanium dioxide (TiO2) and zeolite ZSM-5 catalysts in the in-situ epoxidation of palm olein. IOP Conf Ser Mater Sci Eng 358:(1). https://doi.org/10.1088/1757-899X/358/1/012070.

Nim B, Sreearunothai P, Petchsuk A, Opaprakasit, P (2018) Preparation of TiO2-loaded electrospun fibers of polylactide/poly(vinylpyrrolidone) blends for use as catalysts in epoxidation of unsaturated oils. J Nanoparticle Res 20:(4) https://doi.org/10.1007/s11051-018-4199-1.

Young C (2016) Studies on the synthesis and characterization of epoxidized soybean oil studies on the synthesis and characterization of title: studies on the characterization of epoxidized soybean oil epoxidized soybean oil authors, no. October 2017.

Hong LK, Yusop RM, Salih N, Salimon J (2015) Optimization of the in situ epoxidation of linoleic acid of jatropha curcas oil with performic acid. Malaysian J Anal Sci 19(1):144–154

Milchert E, Malarczyk-Matusiak K, Musik M (2016) Technological aspects of vegetable oils epoxidation in the presence of ion exchange resins: a review. Polish J Chem Technol 18(3):128–133. https://doi.org/10.1515/pjct-2016-0059

Sinadinović-Fišer S, Janković M, Borota O (2012) Epoxidation of castor oil with peracetic acid formed in situ in the presence of an ion exchange resin. Chem Eng Process Process Intensif 62:106–113. https://doi.org/10.1016/j.cep.2012.08.005

Goud VV, Dinda S, Patwardhan AV, Pradhan NC (2010) Epoxidation of Jatropha ( Jatropha curcas ) oil by peroxyacids. Asia-Pacific J Chem Eng 5(2):346–354. https://doi.org/10.1002/apj.285

JW. & Sons (1993) Chemical reaction engineering, Fourth edi. University of Michigan

Meshram PD, Patil HV, Puri RG (2017) Producing phosphate-polyols by ring-opening hydrolysis of wild safflower oil epoxides 10(10):206–215

Piccolo D (2016) Epoxidation of soybean oil by conventional and non-conventional methods, Master Degree Thesis

Performik A, Hong LK, Yusop RM, Salih N, Salimon J (2015) Optimization of the in situ epoxidation of linoleic acid of Jatropha curcas oil with performic acid. Malaysian J Anal Sci 19(1):144–154

Fong MNF, Salimon J (2012) Epoxidation of palm kernel oil fatty acid. J Sci Technol 4(2):87–98

Acknowledgements

The author would like to thank Universiti Teknologi MARA with RMI file no. 600-TNCPI/PBT 5/3 (016/2022)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azmi, I.S., Jalil, M.J. & Hadi, A. Epoxidation of unsaturated fatty acid–based palm oil via peracid mechanism as an intermediate product. Biomass Conv. Bioref. 14, 7847–7855 (2024). https://doi.org/10.1007/s13399-022-02862-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02862-x