Abstract

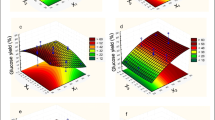

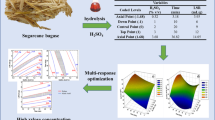

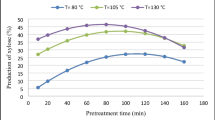

Hydrothermal pretreatment (HP) of two by-products of sugarcane, bagasse (SB) and straw (SS), was optimized to produce xylooligosaccharides (XOS). A central composite rotational design (CCRD) in conjunction with response surface methodology was used to optimize the conditions for maximum XOS production. The developed mathematical models were statistically adequate to predict xylan conversion to XOS, and the by-products were promising for the production of XOS. For both by-products, the mass load in the optimal experiments was of 10%. The xylan conversion to XOS was 24.8% for SB and 45.3% for SS, XOS yield of 53.3 and 96 mg.g−1, respectively. The SB produced more XOS with a greater degree of polymerization than SS. Sugarcane by-products are important in the production of XOS, which may be a valuable commercial product. Furthermore, cellulose and lignin-enriched solids recovered following the optimized HP conditions can be fractionated to obtain other bioproducts of commercial interest.

Similar content being viewed by others

Abbreviations

- HPLC:

-

High-performance liquid chromatography system

- C18 :

-

Reverse phase column HYPERSIL C18

- SB:

-

Sugarcane bagasse

- SS:

-

Sugarcane straw

- XOS:

-

Xylooligosaccharides

- HP:

-

Hydrothermal pretreatment

- X1 :

-

Xylose

- X2 :

-

Xylobiose

- X3 :

-

Xylotriose

- X4 :

-

Xylotetraose

- X5 :

-

Xylopentaose

- X6 :

-

Xylohexaose

- X7 :

-

Xyloheptaose

- X8 :

-

Xylooctaose

- X9 :

-

Xylonanose

- X6 :

-

Oligosaccharides with more than six repetitive units

- log R 0 :

-

Severity factor

- CCRD:

-

Central composite rotational design

- HH:

-

Hemicellulosic hydrolysate

- NaOH:

-

Sodium hydroxide

References

del Río JC, Lino AG, Colodette JL et al (2015) Differences in the chemical structure of the lignins from sugarcane bagasse and straw. Biomass Bioenerg 81:322–338. https://doi.org/10.1016/j.biombioe.2015.07.006

CONAB (2020) Análise Mensal Cana-de-açúcar Abril/maio de 2020. file:///C:/Users/lidia/Downloads/Cana-de-acucarZ-ZAnaliseZMensalZ-ZAbrilZ-Z2020.pdf. Accessed 14 Jun 2020

Szczerbowski D, Pitarelo AP, Zandoná Filho A, Ramos LP (2014) Sugarcane biomass for biorefineries: comparative composition of carbohydrate and non-carbohydrate components of bagasse and straw. Carbohydr Polym 114:95–101. https://doi.org/10.1016/j.carbpol.2014.07.052

de Freitas C, Carmona E, Brienzo M (2019) Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioact Carbohydrates Diet Fibre 18:100184. https://doi.org/10.1016/j.bcdf.2019.100184

Samanta AK, Jayapal N, Jayaram C et al (2015) Xylooligosaccharides as prebiotics from agricultural by-products: production and applications. Bioact Carbohydrates Diet Fibre 5:62–71. https://doi.org/10.1016/j.bcdf.2014.12.003

Carvalho AFA, de Neto PO, da Silva DF, Pastore GM (2013) Xylo-oligosaccharides from lignocellulosic materials: chemical structure, health benefits and production by chemical and enzymatic hydrolysis. Food Res Int 51:75–85. https://doi.org/10.1016/j.foodres.2012.11.021

Singh RD, Banerjee J, Arora A (2015) Prebiotic potential of oligosaccharides: a focus on xylan derived oligosaccharides. Bioact Carbohydrates Diet Fibre 5:19–30. https://doi.org/10.1016/j.bcdf.2014.11.003

Santibáñez L, Henríquez C, Corro-Tejeda R, et al (2021) Xylooligosaccharides from lignocellulosic biomass: a comprehensive review. Carbohydr Polym 251https://doi.org/10.1016/j.carbpol.2020.117118

Amorim C, Silvério SC, Prather KLJ, Rodrigues LR (2019) From lignocellulosic residues to market: production and commercial potential of xylooligosaccharides. Biotechnol Adv 37:107397. https://doi.org/10.1016/j.biotechadv.2019.05.003

Xiao L-P, Song G-Y, Sun R-C (2017) Effect of hydrothermal processing on hemicellulose structure. In: Ruiz HA, Thomsen MH, Trajano HL (eds) Hydrothermal Processing in Biorefineries, 1st edn. Springer International Publishing AG, Cham, p 524

Ruiz HA, Rodríguez-Jasso RM, Fernandes BD et al (2017) Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: a review. Renew Sustain Energy Rev 21:35–51. https://doi.org/10.1016/j.rser.2012.11.069

Singh A, Rodríguez Jasso RM, Gonzalez-Gloria KD et al (2019) The enzyme biorefinery platform for advanced biofuels production. Bioresour Technol Reports 7:100257. https://doi.org/10.1016/j.biteb.2019.100257

Neto FSPP, Roldán IUM, Galán JPM et al (2020) Model-based optimization of xylooligosaccharides production by hydrothermal pretreatment of Eucalyptus by-product. Ind Crops Prod 154:112707. https://doi.org/10.1016/j.indcrop.2020.112707

Chen J, Yuan Z, Zanuso E, Trajano HL (2017) Response of biomass species to hydrothermal pretreatment. In: Ruiz HA, Thomsen MH, Trajano HL (eds) Hydrothermal Processing in Biorefineries, 1st edn. Springer International Publishing AG, Cham, p 524

Canilha L, Santos VTO, Rocha GJM et al (2011) A study on the pretreatment of a sugarcane bagasse sample with dilute sulfuric acid. J Ind Microbiol Biotechnol 38:1467–1475. https://doi.org/10.1007/s10295-010-0931-2

Masarin F, Gurpilhares DB, Baffa DCF et al (2011) Chemical composition and enzymatic digestibility of sugarcane clones selected for varied lignin content. Biotechnol Biofuels 4:1–10. https://doi.org/10.1186/1754-6834-4-55

Ferraz A, Baeza J, Rodriguez J, Freer J (2000) Estimating the chemical composition of biodegraded pine and eucalyptus wood by DRIFT spectroscopy and multivariate analysis. Bioresour Technol 74:201–212

Da Cruz SH, Nichols NN, Dien BS et al (2012) Hydrothermal pretreatment of sugarcane bagasse using response surface methodology improves digestibility and ethanol production by SSF. J Ind Microbiol Biotechnol 39:439–447. https://doi.org/10.1007/s10295-011-1051-3

Batista G, Souza RBA, Pratto B et al (2019) Effect of severity factor on the hydrothermal pretreatment of sugarcane straw. Bioresour Technol 275:321–327. https://doi.org/10.1016/j.biortech.2018.12.073

Mafei TDT, Neto FSPP, Peixoto G et al (2020) Extraction and characterization of hemicellulose from eucalyptus by-product: assessment of enzymatic hydrolysis to produce xylooligosaccharides. Appl Biochem Biotechnol 190:197–217. https://doi.org/10.1007/s12010-019-03076-0

Liu J, Li M, Luo X et al (2015) Effect of hot-water extraction (HWE) severity on bleached pulp based biorefinery performance of eucalyptus during the HWE-Kraft-ECF bleaching process. Bioresour Technol 181:183–190. https://doi.org/10.1016/j.biortech.2015.01.055

Overend RP, Chornet E, Gascoigne JA (1987) Fractionation of lignocellulosics by steam-aqueous pretreatments. Philos Trans R Soc A Math Phys Eng Sci 321:523–536. https://doi.org/10.1098/rsta.1987.0029

de Souza AP, Leite DCC, Pattathil S et al (2013) Composition and structure of sugarcane cell wall polysaccharides: implications for second-generation bioethanol production. Bioenergy Res 6:564–579. https://doi.org/10.1007/s12155-012-9268-1

Sluiter A, Hames B, Ruiz R, Scarlata C (2008) Determination of sugars, byproducts, and degradation products in liquid fraction process samples. Tech Rep NREL/TP-510–42623

Oliveira FMV, Pinheiro IO, Souto-Maior AM et al (2013) Industrial-scale steam explosion pretreatment of sugarcane straw for enzymatic hydrolysis of cellulose for production of second generation ethanol and value-added products. Bioresour Technol 130:168–173. https://doi.org/10.1016/j.biortech.2012.12.030

Yoon LW, Ang TN, Ngoh GC, Chua ASM (2012) Regression analysis on ionic liquid pretreatment of sugarcane bagasse and assessment of structural changes. Biomass Bioenerg 36:160–169. https://doi.org/10.1016/j.biombioe.2011.10.033

Costa SM, Mazzola PG, Silva JCAR et al (2013) Use of sugar cane straw as a source of cellulose for textile fiber production. Ind Crops Prod 42:189–194. https://doi.org/10.1016/j.indcrop.2012.05.028

Ávila PF, Forte MBS, Goldbeck R (2018) Evaluation of the chemical composition of a mixture of sugarcane bagasse and straw after different pretreatments and their effects on commercial enzyme combinations for the production of fermentable sugars. Biomass Bioenerg 116:180–188. https://doi.org/10.1016/j.biombioe.2018.06.015

do Espírito Santo MC, Cardoso EB, Guimaraes FEG et al (2019) Multifaceted characterization of sugarcane bagasse under different steam explosion severity conditions leading to distinct enzymatic hydrolysis yields. Ind Crops Prod 139:111542. https://doi.org/10.1016/j.indcrop.2019.111542

Rocha GJM, Gonçalves AR, Oliveira BR et al (2012) Steam explosion pretreatment reproduction and alkaline delignification reactions performed on a pilot scale with sugarcane bagasse for bioethanol production. Ind Crops Prod 35:274–279. https://doi.org/10.1016/j.indcrop.2011.07.010

Candido RG, Mori NR, Gonçalves AR (2019) Sugarcane straw as feedstock for 2G ethanol: evaluation of pretreatments and enzymatic hydrolysis. Ind Crops Prod 142:111845. https://doi.org/10.1016/j.indcrop.2019.111845

Ek M, Gellerstedt G, Heriksson G (2009) Wood chemistry and wood biotechnology, v1, Pulp and Paper Chemistry and Technology, 2nd ed. Walter de Gruyter, Berlin

Rocha GJM, Silva VFN, Martín C et al (2013) Effect of xylan and lignin removal by hydrothermal pretreatment on enzymatic conversion of sugarcane bagasse cellulose for second generation ethanol production. Sugar Tech 15:390–398. https://doi.org/10.1007/s12355-013-0218-9

Chen H, Liu J, Chang X et al (2017) A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Process Technol 160:196–206. https://doi.org/10.1016/j.fuproc.2016.12.007

Rasmussen H, Sørensen HR, Meyer AS (2014) Formation of degradation compounds from lignocellulosic biomass in the biorefinery: Sugar reaction mechanisms. Carbohydr Res 385:45–57. https://doi.org/10.1016/j.carres.2013.08.029

Hongdan Z, Shaohua X, Shubin W (2013) Enhancement of enzymatic saccharification of sugarcane bagasse by liquid hot water pretreatment. Bioresour Technol 143:391–396. https://doi.org/10.1016/j.biortech.2013.05.103

Zhang X, Zhang W, Lei F et al (2020) Coproduction of xylooligosaccharides and fermentable sugars from sugarcane bagasse by seawater hydrothermal pretreatment. Bioresour Technol 309:123385. https://doi.org/10.1016/j.biortech.2020.123385

dos Santos Rocha MSR, Pratto B, de Sousa R et al (2017) A kinetic model for hydrothermal pretreatment of sugarcane straw. Bioresour Technol 228:176–185. https://doi.org/10.1016/j.biortech.2016.12.087

Brenelli LB, Figueiredo FL, Damasio A, et al (2020) An integrated approach to obtain xylo-oligosaccharides from sugarcane straw: from lab to pilot scale. Bioresour Technol 123637https://doi.org/10.1016/j.biortech.2020.123637

Calado V, Montgomery DC (2003) Planejamento de experimentos usando o Statistica, 1st edn. E-papers Serviços Editoriais Ltda, Rio de Janeiro

de Carvalho DM, Sevastyanova O, Penna LS et al (2015) Assessment of chemical transformations in eucalyptus, sugarcane bagasse and straw during hydrothermal, dilute acid, and alkaline pretreatments. Ind Crops Prod 73:118–126. https://doi.org/10.1016/j.indcrop.2015.04.021

Zhang W, You Y, Lei F et al (2018) Acetyl-assisted autohydrolysis of sugarcane bagasse for the production of xylo-oligosaccharides without additional chemicals. Bioresour Technol 265:387–393. https://doi.org/10.1016/j.biortech.2018.06.039

Funding

São Paulo State Research Support Foundation (FAPESP, contract number 2018/06241–3) funded this work. Coordination of Improvement of Higher Education Personnel (CAPES) funded the doctoral scholarship of Lídia Manfrin Dias.

Author information

Authors and Affiliations

Contributions

LMD and FN performed HP in SB and SS and chemically characterized the recovered liquid and solid fractions. LMD, FN, MB, SCO, and FM participated in the design of the experiments, data interpretation, and mathematical modeling. LMD, FN, SCO, MB, and FM participated in reviewing the manuscript and data interpretation. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors read and approved the final manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dias, L.M., Neto, F.S.P.P., Brienzo, M. et al. Experimental design, modeling, and optimization of production of xylooligosaccharides by hydrothermal pretreatment of sugarcane bagasse and straw. Biomass Conv. Bioref. 13, 12777–12794 (2023). https://doi.org/10.1007/s13399-021-02151-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02151-z