Abstract

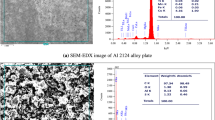

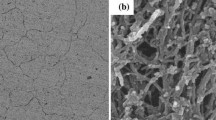

Al 2124 composites are used in aerospace and automotive applications. Foreseeing its applications, it is necessary to examine the properties of Al 2124-reinforced graphene oxide (GO) synthesized by using friction stir processing (FSP). Enhanced properties of metal matrix composites (MMC) are highly dependent on the selection of processing parameters in FSP. Graphene oxide-reinforced MMC were fabricated using processing variants of tool geometry, tool rotation speed, tool transverse speed and quantity of GO using Taguchi L9 orthogonal array. The processing variants were optimized using desirability functional analysis (DFA) by considering multiple characteristic performance involving tensile strength and hardness. From the achieved results, optimal parameters have been identified through the highest value of composite desirability (\(d_G\)) acquired from DFA. Through Taguchi analysis, it was found that tool geometry had the least significance contrary to other factors. The predicted data closely matches the experimental results. Analysis of variance showed that the quantity of GO contributes significantly contrary to other factors. Optical microscopy and scanning electron microscopy (SEM) for the confirmation test showed homogeneous dispersion of a few-layer GO stacks throughout the metal matrix, while fracture studies using SEM showed small dimples indicating plastic deformation capability of Al 2124/GO composite. Besides, almost all fabricated composites were defect-free and also showed homogeneous dispersion of few-layer GO stack in the metal matrix.

Similar content being viewed by others

References

Boyer, R.: Aircraft materials. In: Buschow, K.H.J.; Cahn, R.W.; Flemings, M.C.; Ilschner, B.; Kramer, E.J.; Mahajan, S.; Veyssière, P. (eds.) Encyclopedia of Materials: Science and Technology, pp. 66–73. Elsevier, Oxford (2001). https://doi.org/10.1016/B0-08-043152-6/00013-9

Kaufman, J.G.: Aluminum Alloys, vol. 4. Wiley, New York (2002). https://doi.org/10.1002/9780470172551.ch4

Smaga, M.; Walther, F.; Eifler, D.: Monotonic and cyclic deformation behaviour of the SiC particle-reinforced aluminium matrix composite AMC225xe. Adv. Eng. Mater. 12(4), 262–268 (2010). https://doi.org/10.1002/adem.200900345

Stojanović, B.; Ivanović, L.: Application of aluminium hybrid composites in automotive industry. Tehnicki Vjesnik 22(1), 247–251 (2015). https://doi.org/10.17559/TV-20130905094303

Falsafi, J.; Rosochowska, M.; Jadhav, P.; Tricker, D.: Lower cost automotive piston from 2124/SiC/25p metal-matrix composite. SAE Int. J. Eng. 10(4), 1984–1992 (2017). https://doi.org/10.4271/2017-01-1048

Karamış, M.B.; Alper Cerit, A.; Selçuk, B.; Nair, F.: The effects of different ceramics size and volume fraction on wear behavior of al matrix composites (for automobile cam material). Wear 289, 73–81 (2012). https://doi.org/10.1016/j.wear.2012.04.012

von Hehl, A.; Krug, P.: Aluminum and Aluminum Alloys, vol. 2, pp. 49–112. Wiley (2013). https://doi.org/10.1002/9783527649846.ch2

Boswell, B.; Islam, M.N.; Pramanik, A.: Optimum parameters for machining metal matrix composite. In: Yang, G.-C., Ao, S.-I., Gelman, L. (eds.) Transactions on Engineering Technologies, pp. 43–57. Springer, Dordrecht (2014). https://doi.org/10.1007/978-94-017-8832-8_4

Avouris, P.; Dimitrakopoulos, C.: Graphene: synthesis and applications. Mater. Today 15(3), 86–97 (2012). https://doi.org/10.1016/S1369-7021(12)70044-5

Caffo, M.; Merlo, L.; Daniele, M.O.: Graphene science handbook applications and industrialization. In: Aofkhazraei, M., Ali, N., Milne, W.I., Ozkan, C.S. (eds.) Biomedical Applications of Graphene, 1st edn, pp. 41–56. CRC Press, Boca Raton (2016)

Jiang, L.; Fan, G.; Li, Z.; Kai, X.; Zhang, D.; Chen, Z.; Humphries, S.; Heness, G.; Yeung, W.Y.: An approach to the uniform dispersion of a high volume fraction of carbon nanotubes in aluminum powder. Carbon 49(6), 1965–1971 (2011). https://doi.org/10.1016/j.carbon.2011.01.021

Luo, H.; Sui, Y.; Qi, J.; Meng, Q.; Wei, F.; He, Y.: Mechanical enhancement of copper matrix composites with homogeneously dispersed graphene modified by silver nanoparticles. J. Alloys Compd. 729, 293–302 (2017). https://doi.org/10.1016/j.jallcom.2017.09.102

Liu, X.; Li, J.; Sha, J.; Liu, E.; Li, Q.; He, C.; Shi, C.; Zhao, N.: In-situ synthesis of graphene nanosheets coated copper for preparing reinforced aluminum matrix composites. Mater. Sci. Eng. A 709(August 2017), 65–71 (2018). https://doi.org/10.1016/j.msea.2017.10.030

Liu, G.; Zhao, N.; Shi, C.; Liu, E.; He, F.; Ma, L.; Li, Q.; Li, J.; He, C.: In-situ synthesis of graphene decorated with nickel nanoparticles for fabricating reinforced 6061Al matrix composites. Mater. Sci. Eng. A 699, 185–193 (2017). https://doi.org/10.1016/j.msea.2017.05.084

Chen, Y.; Zhang, X.; Liu, E.; He, C.; Han, Y.; Li, Q.; Nash, P.; Zhao, N.: Fabrication of three-dimensional graphene/Cu composite by in-situ CVD and its strengthening mechanism. J. Alloys Compd. 688, 69–76 (2016). https://doi.org/10.1016/j.jallcom.2016.07.160

Li, D.; Ye, Y.; Liao, X.; Qin, Q.H.: A novel method for preparing and characterizing graphene nanoplatelets/aluminum nanocomposites. Nano Res. 11(3), 1642–1650 (2018). https://doi.org/10.1007/s12274-017-1779-9

Fadavi Boostani, A.; Tahamtan, S.; Jiang, Z.Y.; Wei, D.; Yazdani, S.; Azari Khosroshahi, R.; Taherzadeh Mousavian, R.; Xu, J.; Zhang, X.; Gong, D.: Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos. Part A Appl. Sci. Manuf. 68, 155–163 (2015). https://doi.org/10.1016/j.compositesa.2014.10.010

El-Ghazaly, A.; Anis, G.; Salem, H.G.: Effect of graphene addition on the mechanical and tribological behavior of nanostructured AA2124 self-lubricating metal matrix composite. Compos. Part A Appl. Sci. Manuf. 95, 325–336 (2017). https://doi.org/10.1016/j.compositesa.2017.02.006

Narimani, M.; Lotfi, B.; Sadeghian, Z.: Investigating the microstructure and mechanical properties of Al-TiB\(_2\) composite fabricated by friction stir processing (FSP). Mater. Sci. Eng. A 673, 436–442 (2016). https://doi.org/10.1016/j.msea.2016.07.086

Asadi, P.; Faraji, G.; Besharati, M.K.: Producing of AZ91/SiC composite by friction stir processing (FSP). Int. J. Adv. Manuf. Technol. 51(1), 247–260 (2010). https://doi.org/10.1007/s00170-010-2600-z

Huang, G.; Wu, J.; Hou, W.; Shen, Y.: Microstructure, mechanical properties and strengthening mechanism of titanium particle reinforced aluminum matrix composites produced by submerged friction stir processing. Mater. Sci. Eng. A 734, 353–363 (2018). https://doi.org/10.1016/j.msea.2018.08.015

Sahraeinejad, S.; Izadi, H.; Haghshenas, M.; Gerlich, A.P.: Fabrication of metal matrix composites by friction stir processing with different particles and processing parameters. Mater. Sci. Eng. A 626, 505–513 (2015). https://doi.org/10.1016/j.msea.2014.12.077

Bauri, R.; Yadav, D.; Kumar, C.N.S.; Ram, G.D.J.: Optimized process parameters for fabricating metal particles reinforced 5083 Al composite by friction stir processing. Data Brief 5, 309–313 (2015). https://doi.org/10.1016/j.dib.2015.09.006

Rashad, M.; Pan, F.; Tang, A.; Asif, M.; She, J.; Gou, J.; Mao, J.; Hu, H.: Development of magnesium-graphene nanoplatelets composite. J. Compos. Mater. 49(3), 285–293 (2015). https://doi.org/10.1177/0021998313518360

Puviyarasan, M.; Senthil Kumar, V.S.: An experimental investigation for multi-response optimization of friction stir process parameters during fabrication of AA6061/B\(_4\)Cp composites. Arab. J. Sci. Eng. 40(6), 1733–1741 (2015). https://doi.org/10.1007/s13369-015-1654-5

Eftekharinia, H.; Amadeh, A.A.; Khodabandeh, A.; Paidar, M.: Microstructure and wear behavior of AA6061/SiC surface composite fabricated via friction stir processing with different pins and passes. Rare Met. 39(4), 429–435 (2020). https://doi.org/10.1007/s12598-016-0691-x

Elangovan, K.; Balasubramanian, V.: Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng. A 459(1), 7–18 (2007). https://doi.org/10.1016/j.msea.2006.12.124

Elangovan, K.; Balasubramanian, V.: Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in aa6061 aluminium alloy. Mater. Des. 29(2), 362–373 (2008). https://doi.org/10.1016/j.matdes.2007.01.030

Elangovan, K.; Balasubramanian, V.; Valliappan, M.: Influences of tool pin profile and axial force on the formation of friction stir processing zone in AA6061 aluminium alloy. Int. J. Adv. Manuf. Technol. 38, 285–295 (2007). https://doi.org/10.1007/s00170-007-1100-2

Sharma, V.; Prakash, U.; Kumar, B.V.M.: Surface composites by friction stir processing: a review. J. Mater. Process. Technol. 224, 117–134 (2015). https://doi.org/10.1016/j.jmatprotec.2015.04.019

Shunmugasundaram, M.; Nagarajan, S.M.; Reddy, Y.; Chaurasiya, P.K.; Kumar, A.; Rajak, U.: An experimental study and joining parameters optimization of friction stir weld butt joint by Taguchi approach to maximize the mechanical properties. Arab. J. Sci. Eng. (2021). https://doi.org/10.1007/s13369-021-06352-6

Pinar, A.M.: Optimization of process parameters with minimum surface roughness in the pocket machining of AA5083 aluminum alloy via Taguchi method. Arab. J. Sci. Eng. 38(3), 705–714 (2013). https://doi.org/10.1007/s13369-012-0372-5

Sivaiah, P.; Chakradhar, D.: Modeling and optimization of sustainable manufacturing process in machining of 17–4 ph stainless steel. Measurement 134, 142–152 (2019). https://doi.org/10.1016/j.measurement.2018.10.067

Balamugundan, B.; Karthikeyan, L.; Senthilkumar, V.S.: Multi characteristics optimization during milling of friction stir processed glass fiber reinforced plastic composites. Proc. Eng. 38, 1276–1285 (2012). https://doi.org/10.1016/j.proeng.2012.06.157

Kondaiah, V.V.; Pavanteja, P.; Afzal Khan, P.; Anannd Kumar, S.; Dumpala, R.; Ratna Sunil, B.: Microstructure, hardness and wear behavior of AZ31 Mg alloy-fly ash composites produced by friction stir processing. Mater. Today Proc. 4(6), 6671–6677 (2017). https://doi.org/10.1016/j.matpr.2017.06.441

Sharma, S.; Handa, A.; Singh, S.S.; Verma, D.: Influence of tool rotation speeds on mechanical and morphological properties of friction stir processed nano hybrid composite of MWCNT-graphene-AZ31 magnesium. J. Magn. Alloys 7(3), 487–500 (2019). https://doi.org/10.1016/j.jma.2019.07.001

Simar, A.; Avettand-Fènoël, M.-N.: 7. In: Estrin, Y., Bréchet, Y., Dunlop, J., Fratzl, P. (eds.) Friction Stir Processing for Architectured Materials, pp. 195–229. Springer, New York (2019). https://doi.org/10.1007/978-3-030-11942-3_7

Komarasamy, M.; Kumar, N.; Tang, Z.; Mishra, R.S.; Liaw, P.K.: Effect of microstructure on the deformation mechanism of friction stir-processed Al\(_{0.1}\)CoCrFeNi high entropy alloy. Mater. Res. Lett. 3(1), 30–34 (2015). https://doi.org/10.1080/21663831.2014.958586

Krishnan, K.N.: On the formation of onion rings in friction stir welds. Mater. Sci. Eng. A 327(2), 246–251 (2002). https://doi.org/10.1016/S0921-5093(01)01474-5

Bahrami, M.; Besharati Givi, M.K.; Dehghani, K.; Parvin, N.: On the role of pin geometry in microstructure and mechanical properties of aa7075/sic nano-composite fabricated by friction stir welding technique. Mater. Des. 53, 519–527 (2014). https://doi.org/10.1016/j.matdes.2013.07.049

Kavimani, V.; Prakash, K.S.; Thankachan, T.: Influence of machining parameters on wire electrical discharge machining performance of reduced graphene oxide/magnesium composite and its surface integrity characteristics. Compos. B Eng. 167, 621–630 (2019). https://doi.org/10.1016/j.compositesb.2019.03.031

Sharma, A.; Sharma, V.M.; Sahoo, B.; Pal, S.K.; Paul, J.: Effect of multiple micro channel reinforcement filling strategy on Al6061-graphene nanocomposite fabricated through friction stir processing. J. Manuf. Process. 37, 53–70 (2019). https://doi.org/10.1016/j.jmapro.2018.11.009

Sharma, A.; Sharma, V.M.; Paul, J.: A comparative study on microstructural evolution and surface properties of graphene/cnt reinforced al6061-sic hybrid surface composite fabricated via friction stir processing. Trans. Nonferrous Met. Soc. China 29(10), 2005–2026 (2019). https://doi.org/10.1016/S1003-6326(19)65108-3

Rathee, S.; Maheshwari, S.; Siddiquee, A.N.; Srivastava, M.: A review of recent progress in solid state fabrication of composites and functionally graded systems via friction stir processing. Crit. Rev. Solid State Mater. Sci. 43(4), 334–366 (2018). https://doi.org/10.1080/10408436.2017.1358146

Funding

This study was not funded by any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aafaq, A.A., Jailani, H.S. Multi-response Optimization of Process Parameters in Fabricating Al 2124/GO Metal Matrix Composite by Friction Stir Processing. Arab J Sci Eng 48, 3647–3664 (2023). https://doi.org/10.1007/s13369-022-07247-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07247-w