Abstract

Waste cooking oil (WCO) is of increasing interest as an inexpensive feedstock to produce biodegradable plastic, poly(3-hydroxybutyrate) [P(3HB)]. In the present study, palm oil-based WCO (PO-WCO) was obtained from nine different locations. Palm oil-based fresh cooking oil (PO-FCO) and PO-WCO were characterised via proximate and physicochemical analysis, prior to being used as carbon sources for the biosynthesis of P(3HB) using Cupriavidus necator H16. It was shown that the free fatty acid, peroxide value, and saturated compounds in all batches of PO-WCO were higher compared to those in the PO-FCO. The cells produced 60–80 wt% P(3HB) with dry cell weight of 14–17 g/L. The weight average molecular weight \((M_{\mathrm{w}})\) was found to be \(1.8 \times 10^{6}\) Da with a polydispersity \((M_{\mathrm{w}}/M_{\mathrm{n}})\) of 2.7 when PO-WCO was used as the carbon source. The PO-WCO was found to be suitable to be used as a sustainable carbon source for cell growth and P(3HB) biosynthesis.

Similar content being viewed by others

Change history

21 March 2018

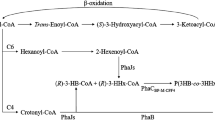

The original version of this article unfortunately contained a mistake. The presentation of Fig. 3 was incorrect. The corrected figure is given below.

21 March 2018

The original version of this article unfortunately contained a mistake. The presentation of Fig.?3 was incorrect. The corrected figure is given below.

21 March 2018

The original version of this article unfortunately contained a mistake. The presentation of Fig.?3 was incorrect. The corrected figure is given below.

References

Doi, Y.: Microbial Polyesters. VCH Publishers, Hoboken (1990)

Loo, C.Y.; Sudesh, K.: Polyhydroxyalkanoates: bio-based microbial plastics and their properties. MPJ 2(2), 31–57 (2007)

Park, D.H.; Kim, B.S.: Production of poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by Ralstonia eutropha from soybean oil. New Biotechnol. 28(6), 719–724 (2011)

Sudesh, K.; Doi, Y.: Molecular design and biosynthesis of biodegradable polyesters. Polym. Adv. Technol. 11, 865–872 (2000)

Rao, U.; Sridhar, R.; Sehgal, P.K.: Biosynthesis and biocompatibility of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) produced by Cupriavidus necator from spent palm oil. Biochem. Eng. J. 49, 13–20 (2010)

Sudesh, K.; Bhubalan, K.; Chuah, J.; Kek, Y.K.; Kamilah, H.; Sridewi, N.; Lee, Y.F.: Synthesis of polyhydroxyalkanoate from palm oil and some new applications. Appl. Microbiol. Biotechnol. 89, 1373–1386 (2011)

Riedel, S.L.; Bader, J.; Brigham, C.J.; Budde, C.F.; Yusof, Z.Z.; Rha, C.; Sinskey, A.J.: Production of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) by Ralstonia eutropha in high cell density palm oil fermentations. Biotechnol. Bioeng. 109, 74–83 (2012)

Taniguchi, I.; Kagotani, K.; Kimura, Y.: Microbial production of poly(hydroxyalkanoate)s from waste edible oils. Green Chem. 5, 545–548 (2003). https://doi.org/10.1039/b304800b

Brigham, C.J.; Sinskey, A.J.: Applications of polyhydroxyalkanoates in the medical industry. Int. J. Biotechnol. Wellness. Ind. 1, 53–60 (2012)

Lutke-Eversloh, T.; Fischer, A.; Remminghorst, U.; Kawada, J.; Marchessault, R.H.; Bogershausen, A.; Kalwei, M.; Eckert, H.; Reichelt, R.; Liu, S.J.; Steinbüchel, A.: Biosynthesis of novel thermoplastic polythioesters by engineered Escherichia coli. Appl. Microbiol. Biotechnol. 98, 1469–1483 (2002)

Anderson, A.J.; Dawes, E.A.: Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol. Rev. 54(4), 450–472 (1990)

Doi, Y.; Kitamura, S.; Abe, H.: Microbial synthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Macromolecules 28, 4822–4828 (1995)

Bhuwal, A.K.; Singh, G.; Aggarwal, N.K.; Goyal, V.; Yadav, A.: Isolation and screening of polyhydroxyalkanoates producing bacteria from pulp, paper, and cardboard industry wastes. Int. J. Biomater. 2013, 1–10 (2013)

Chanasit, W.; Hodgson, B.; Sudesh, K.; Umsakul, K.: Efficient production of polyhydroxyalkanoates (PHAs) from Pseudomonas mendocina PSU using a biodiesel liquid waste (BLW) as the sole carbon source. Biosci. Biotechnol. Biochem. 80(7), 1440–1450 (2016)

Gomaa, E.Z.: Production of polyhydroxyalkanoates (PHAs) by Bacillus subtilis and Escherichia coli grown on cane molasses fortified with ethanol. Braz. Arch. Biol. Technol. 57(1), 145–154 (2014)

Sudesh, K.; Abe, H.: Practical Guide to Microbial Polyhydroxyalkanoates. Smithers Rapra, Shrewsbury (2010)

Altaee, N.; El-Hiti, G.A.; Fahdil, A.; Sudesh, K.; Yousif, E.: Screening and evaluation of poly(3-hydroxybutyrate) with Rhodococcus equi using different carbon sources. Arab. J. Sci. Eng. 41, 1–11 (2016). https://doi.org/10.1007/s13369-016-2327-8

Lee, S.Y.; Choi, J.; Wong, H.H.: Recent advances in polyhydroxyalakanoate production by bacterial fermentation: mini-review. Int. J. Biol. Macromol. 25, 31–36 (1999)

Song, J.H.; Jeon, C.O.; Choi, M.H.; Yoon, S.C.; Park, W.: Polyhydroxyalkanoate (PHA) production using waste vegetable oil by Pseudomonas sp. Strain DR2. J. Microbiol. Biotechnol. 18(8), 1408–1415 (2008)

Liu, F.; Li, W.; Ridgway, D.; Gu, T.: Production of poly-ß-hydroxybutyrate on molasses by recombinant Escherichia coli. Biotechnol. Lett. 20, 345–348 (1998)

Akaraonye, E.; Keshavarz, T.; Roy, I.: Production of polyhydroxyalkanoates: the future green materials of choice. J. Chem. Technol. Biotechnol. 85, 732–743 (2010)

Kulkarni, M.G.; Dalai, A.K.: Waste cooking oil-an economical source for biodiesel: a review. Ind. Eng. Chem. Res. 45, 2901–2913 (2006)

UN: Economic and social commission for Western Asia wastewater treatment technologies: a general review. In: United Nations (ed.). Distr. General E/ESCWA/SDPD (2003)

Kahar, P.; Tsuge, T.; Taguchi, K.; Doi, Y.: High yield production of polyhydroxyalkanoates from soybean oil by Ralstonia eutropha and its recombinant strain. Polym. Degrad. Stabil. 83, 79–86 (2004)

Verlinden, R.A.J.; Hill, D.J.; Kenward, M.A.; Williams, C.D.; Seget, Z.P.; Radecka, I.K.: Production of polyhydroxyalkanoates from waste frying oil by Cupriavidus necator. AMB Express 1, 1–8 (2011)

AOAC: Official Methods of Analysis of AOAC International, 17th edn. AOAC International, USA (2000)

Dieffenbacher, A.; Pocklington, W.D.: Standard Methods for the Analysis of Oils, Fats and Derivatives. Blackwell Scientific Publications, Oxford (1992)

Mondello, L.; Tranchida, P.Q.; Dugo, P.; Dugo, G.: Rapid, micro-scale preparation and very fast gas chromatographic separation of cod liver oil fatty acid methyl esters. J. Pharm. Biomed. Anal. 41, 1566–1570 (2006)

Kilcawley, K.N.; Wilkinson, M.G.; Fox, P.F.: Determination of key enzyme activities in commercial peptidase and lipase preparations from microbial or animal sources. Enzyme Microb. Technol. 31, 310–320 (2002)

Budde, C.F.; Riedel, S.L.; Hübner, F.; Risch, S.; Popović, M.K.; Rha, C.; Sinskey, A.J.: Growth and polyhydroxybutyrate production by Ralstonia eutropha in emulsified plant oil medium. Appl. Microbiol. Biotechnol. 89, 1611–1619 (2011)

McDowell, E.M.; Trump, B.F.: Histologic fixatives suitable for diagnostic light and electron microscopy. Arch. Pathol. Lab. Med. 100, 405–414 (1976)

Cortinas, L.; Villaverde, C.; Galobart, J.; Baucells, M.D.; Codony, R.; Barroeta, A.C.: Fatty acid content in chicken thigh and breast as affected by dietary polyunsaturation level. Poult. Sci. 83, 1155–1164 (2004)

de Almeida, J.C.; Perassolo, M.S.; Camargo, J.L.; Bragagnolo, N.; Gross, J.L.: Fatty acid composition and cholesterol content of beef and chicken meat in Southern Brazil. Braz. J. Pharm. Sci. 42, 109–117 (2006)

Rule, D.C.; Broughton, K.S.; Shellito, S.M.; Maiorano, G.: Comparison of muscle fatty acid profiles and cholesterol concentrations of bison, beef, cattle, elk, and chicken. J. Anim. Sci. 80, 1202–1211 (2002)

Mittelbach, M.; Enzelsberger, H.: Transesterification of heated rapeseed oil for extending diesel fuel. J. Am. Oil Chem. Soc. 76(5), 545–550 (1999)

Nawar, W.W.: Chemical changes in lipids produced by thermal processing. J. Chem. Ed. 61(4), 299–302 (1984)

Knothe, G.; Dunn, R.O.: Dependence of oil stability index of fatty compounds on their structure and concentration and presence of metals. J. Am. Oil Chem. Soc. 80(10), 1021–1026 (2003)

Siddique, B.M.; Ahmad, A.; Ibrahim, M.H.; Hena, S.; Rafatullah, M.; Omar, A.K.M.: Physico-chemical properties of blends of palm olein with other vegetable oils. Grasas Aceites (2010). https://doi.org/10.3989/gya.010710

Lertsathapornsuk, V.; Pairintra, R.; Aryusuk, K.; Krisnangkura, K.: Microwave assisted in continuous biodiesel production from waste frying palm oil and its performance in a 100 kW diesel generator. Fuel Process. Technol. 89(12), 1330–1336 (2008)

Tan, C.P.; Che Man, Y.B.: Differential scanning calorimetric analysis of palm oil, palm oil based products and coconut oil: effects of scanning rate variation. Food Chem. 76, 89–102 (2002)

Ong, A.S.H.; Goh, S.H.: Palm oil: a healthful and cost-effective dietary component. Food Nutr. Bull. 23(1), 11–22 (2002)

Martino, L.; Cruz, M.V.; Scoma, A.; Freitas, F.; Bertin, L.; Scandola, M.; Reis, M.A.M.: Recovery of amorphous polyhydroxybutyrate granules from Cupriavidus necator cells grown on used cooking oil. Int. J. Biol. Macromol. 71, 117–123 (2014)

Obruca, S.; Marova, I.; Snajdar, O.; Mravcova, L.; Svoboda, Z.: Production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Cupriavidus necator from waste rapeseed oil using propanol as a precursor of 3-hydroxyvalerate. Biotechnol. Lett. 32, 1925–1932 (2010)

Cruz, M.V.; Freitas, F.; Paiva, A.; Mano, F.; Dionı’sio, M.; Ramos, A.M.; Reis, M.A.M.: Valorization of fatty acids-containing wastes and byproducts into short- and medium-chain length polyhydroxyalkanoates. New Biotechnol. 33, 206–215 (2015)

Nawar, W.W.: Chemical changes in lipids produced by thermal processing. J. Chem. Ed. 61(4), 299–302 (1984)

Oliveira, F.C.; Dias, M.L.; Castilho, L.R.; Freire, D.M.G.: Characterization of poly(3-hydroxybutyrate) produced by Cupriavidus necator in solid-state fermentation. Bioresour. Technol. 98, 633–638 (2007)

Motasemi, F.; Ani, F.N.: The production of biodiesel from waste cooking oil using microwave irradiation. J. Mek. 32, 61–72 (2011)

Arroyo, R.; Cuesta, C.; Sanchez-Montero, J.M.; Sanchez-Muniz, F.J.: High performance size exclusion chromatography of palm olein used for frying. Eur. J. Lipid Sci. Technol 97, 292–296 (1995)

Tsuge, T.: Metabolic improvements and use of inexpensive carbon sources in microbial production of polyhydroxyalkanoates. J. Biosci. Bioeng. 94(6), 579–584 (2002)

Acknowledgements

The authors thank the community of Teluk Bahang, Penang, Malaysia, for contributing the PO-WCO used in this study. This study was funded in parts by the Division of Industry and Community Network and Short-Term Research Grants (304/Pbiologi/6311070) from Universiti Sains Malaysia (USM). H. Kamilah acknowledges USM Fellowship during the period of the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kamilah, H., Al-Gheethi, A., Yang, T.A. et al. The Use of Palm Oil-Based Waste Cooking Oil to Enhance the Production of Polyhydroxybutyrate [P(3HB)] by Cupriavidus necator H16 Strain. Arab J Sci Eng 43, 3453–3463 (2018). https://doi.org/10.1007/s13369-018-3118-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3118-1