Abstract

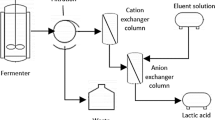

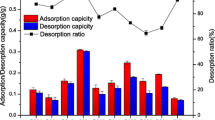

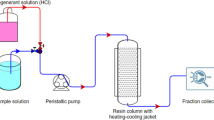

Extractive fermentation with 155.8 g/L initial glucose and 364 g of anion exchange resin yielded a 1.2-fold increase in total lactate produced and a 5.9-fold increase in productivity compared with standard batch fermentation at the same glucose concentration. The addition of resin also served as a pH control strategy. Elution of the resin-bound lactate using 1 M HCl at 0.1 bed volume/min resulted in complete recovery of lactate. Further extraction of the eluted lactate and lactate in fermentation broth was conducted with reactive extraction using trioctylamine in octanol. The extraction also provided partial purification of the product, as protein from fermentation broth did not migrate to the extracted solution with the lactate. The recovery of lactate was up to 70 % of the total lactate produced.

Similar content being viewed by others

References

Abdel-Rahman M.A., Tashiro Y., Sonomoto K.: Recent advances in lactic acid production by microbial fermentation processes. Biotechnol. Adv. 31, 877–902 (2013)

Martinez F.A.C., Balciunas E.M., Salgado J.M., González J.M.D., Converti A., Oliveira R.P.d.S.: Lactic acid properties, applications and production: a review. Trends Food Sci. Technol. 30, 70–83 (2013)

Wee Y.-J., Kim J.-N., Ryu H.-W.: Biotechnological production of lactic acid and its recent applications. Food Technol. Biotechnol. 44, 163–172 (2006)

Datta R., Henry M.: Lactic acid: recent advances in products, processes and technologies—a review. J. Chem. Technol. Biotechnol. 81, 1119–1129 (2006)

Datta R., Tsai S.P., Bonsignore P., Moon S.H., Frank J.R.: Technology and economic potential of poly(lactic acid) and lactic acid derivatives. FEMS Microbiol. Rev. 16, 221–231 (1995)

Groot W.J., Borén T.: Life cycle assessment of the manufacture of lactide and PLA biopolymers from sugarcane in Thailand. Int. J. Life Cycle Assess. 15, 970–984 (2010)

López-Garzón C.S., Straathof A.J.J.: Recovery of carboxylic acids produced by fermentation. Biotechnol. Adv. 32(5), 873–904 (2014)

Joglekar H.G., Rahman I., Babu S., Kulkarni B.D., Joshi A.: Comparative assessment of downstream processing options for lactic acid. Sep. Purif. Technol. 52, 1–17 (2006)

Pal P., Sikder J., Roy S., Giorno L.: Process intensification in lactic acid production: a review of membrane based processes. Chem. Eng. Process. 48, 1549–1559 (2009)

Boonmee M., Leksawasdi N., Bridge W., Rogers P.L.: Batch and continuous culture of Lactococcus lactis NZ133: experimental data and model development. Biochem. Eng. J. 14, 127–135 (2003)

Wang C., Li Q., Wang D., Xing J.: Improving the lactic acid production of Actinobacillus succinogenes by using a novel fermentation and separation integration system. Process Biochem. 49(8), 1245–1250 (2014)

Boontawan P., Kanchanathawee S., Boontawan A.: Extractive fermentation of L-(+)-lactic acid by Pediococcus pentosaceus using electrodeionization (EDI) technique. Biochem. Eng. J. 54, 192–199 (2011)

Wasewar K.L., Yawalkar A.A., Moulijn J.A., Pangarkar V.G.: Fermentation of glucose to lactic acid coupled with reactive extraction: a review. Ind. Eng. Chem. Res. 43, 5969–5982 (2004)

Gao M.-T., Shimamura T., Ishida N., Nagamori E., Takahashi H., Umenoto S., Omasa T., Ohtake H.: Extractive lactic acid fermentation with tri-n-decylamine as the extractant. Enzyme Microb. Technol. 44, 350–354 (2009)

Ye K., Jin S., Shimizu K.: Performance improvement of lactic acid fermentation by multistage extractive fermentation. J. Ferment. Bioeng. 81, 240–246 (1996)

Lu Z., Wei M., Yu L.: Enhancement of pilot scale production of L(+)-lactic acid by fermentation coupled with separation using membrane reactor. Process Biochem. 47, 410–415 (2012)

Zhang Y., Chen X., Qi B., Luo J., Shen F., Su Y., Khan R., Wan Y.: Improving lactic acid productivity from wheat straw hydrolysates by membrane integrated repeated batch fermentation under non-sterilized conditions. Bioresour. Technol. 163, 160–166 (2014)

Sikder J., Chakraborty S., Pal P., Drioli E., Bhattacharjee C.: Purification of lactic acid from microfiltrate fermentation broth by cross-flow nanofiltration. Biochem. Eng. J. 69, 130–137 (2012)

Min-tian G., Hirata M., Koide M., Takanashi H., Hano T.: Production of L-lactic acid by electrodialysis fermentation (EDF). Process Biochem. 39, 1903–1907 (2004)

Wang X., Wang Y., Zhang X., Feng H., Xu T.: In-situ combination of fermentation and electrodialysis with bipolar membranes for the production of lactic acid: continuous operation. Bioresour. Technol. 147, 442–448 (2013)

Boonmee M., Leksawasdi N., Bridge W., Rogers P.L.: Electrodialysis for lactate removal in the production of the dairy starter culture Lactococcus lactis NZ133. Int. J. Food Sci. Technol. 42, 567–572 (2007)

Ataei S.A., Vasheghani-Farahani E.: In situ separation of lactic acid from fermentation broth using ion exchange resins. J. Ind. Microbiol. Biotechnol. 35, 1229–1233 (2008)

Jianlong W., Xianghua W., Ding Z.: Production of citric acid from molasses integrated with in-situ product separation by ion-exchange resin adsorption. Bioresour. Technol. 75, 231–234 (2000)

Van’t Hul J.S., Gibbons W.R.: Neutralization/recovery of lactic acid from Lactococcus lactis: effects on biomass, lactic acid, and nisin production. World J. Microbiol. Biotechnol. 13, 527–532 (1997)

Yu P.-L., Dunn N.W., Kim W.S.: Lactate removal by anionic-exchange resin improves nisin production by Lactococcus lactis. Biotechnol. Lett. 24, 59–64 (2002)

Liu B., Hui J., Cheng Y-Q., Zhang X.: Extractive fermentation for enhanced production of thailandepsin A from Burkholderia thailandensis E264 using polyaromatic adsorbent resin Diaion HP-20. J. Ind. Microbiol. Biotechnol. 39, 767–776 (2012)

Phillips T., Chase M., Wagner S., Renzi C., Powell M., DeAngelo J., Michels P.: Use of in situ solid-phase adsorption in microbial natural product fermentation development. J. Ind. Microbiol. Biotechnol. 40, 411–425 (2013)

Jianlong W., Ping L., Ding Z.: Extractive fermentation of lactic acid by immobilized Lactobacillus casei using ion-exchange resin. Biotechnol. Tech. 8, 905–908 (1994)

John R.P., Nampoothiri K.M., Pandey A.: L(+)-Lactic acid recovery from cassava bagasse based fermented medium using anion exchange resins. Braz. Arch. Biol. Technol. 51, 1241–1248 (2008)

Moldes A.B., Alonso J.L., Parajó J.C.: Recovery of lactic acid from simultaneous saccharification and fermentation media using anion exchange resins. Bioprocess Biosyst. Eng. 25, 357–363 (2003)

Raya-Tonetti G., Córdoba P., Bruno-Bárcena J., Sin͂eriz F., Perotti N.: Fluidized bed ion exchange for improving purification of lactic acid from fermentation. Biotechnol. Tech. 13, 201–205 (1999)

Hong Y.K., Hong W.L., Han D.H.: Application of reactive extraction to recovery of carboxylic acids. Biotechnol. Bioprocess Eng. 6, 386–394 (2001)

Yankov D., Molinier J., Albet J., Malmary G., Kyuchoukov G.: Lactic acid extraction from aqueous solutions with tri-n-octylamine dissolved in decanol and dodecane. Biochem. Eng. J. 21, 63–71 (2004)

Krzyzaniak A., Schuur B., de Hann A.B.: Equilibrium studies on lactic acid extraction with N,N-didodecylpyridin-4-amine (DDAP) extractant. Chem. Eng. Sci. 109, 236–243 (2014)

Uslu H., Kıbaşlar Ş.İ.: Effect of temperature and initial acid concentration on the reactive extraction of carboxylic acids. J. Chem. Eng. Data 58, 1822–1826 (2013)

Heyberger A., Procházka J., Volaufova E.: Extraction of citric acid with tertiary amine—third-phase formation. Chem. Eng. Sci. 53, 515–521 (1998)

Wasewar K.L.: Reactive extraction: an intensifying approach for carboxylic acid separation. Int. J. Chem. Eng. Appl. 3, 249–255 (2012)

Harington T., Hossain Md.M.: Extraction of lactic acid into sunflower oil and its recovery into an aqueous solution. Desalination 218, 287–296 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boonmee, M., Cotano, O., Amnuaypanich, S. et al. Improved Lactic Acid Production by In Situ Removal of Lactic Acid During Fermentation and a Proposed Scheme for Its Recovery. Arab J Sci Eng 41, 2067–2075 (2016). https://doi.org/10.1007/s13369-015-1824-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-015-1824-5