Abstract

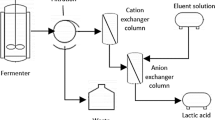

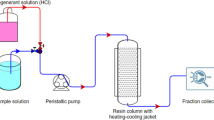

Lactic acid fermentation is an end product inhibited reaction. In situ separation of lactic acid from fermentation broth using ion exchange resins was investigated and compared with conventional fermentation system. Amberlite resin (IRA-400, Cl−) was used to separate lactic acid from fermentation broth and pH was controlled online with an automatic pH controller. The effect of process variables on lactic acid production by Lactobacillus casei in whey permeate was studied. The maximum productivity was obtained at pH = 6.1, T = 37 °C and impeller speed = 200 rpm. The maximum concentration of lactic acid at optimum condition was found to be 37.4 g/L after 38 h of fermentation using in situ separation system. The productivity of in situ separation system was five times increased in comparison with conventional system.

Similar content being viewed by others

References

Ataei SA, Sh Dolatshahi (2005) Isolation and determination of the most appropriate microbial strain and fermentation condition for single cell protein production from whey. J Res Health Sci 5:54–58

Barrera DA (1993) Synthesis and characterization of a novel biodegradable polymer Poly (lactic acid-Co-lysine). DAI-B 54(6):3096–3099

Dunn RL, English JP, Strobel JD, Cowsar DR, Tice TR (1988) Preparation and evaluation of lactide/glycolide co polymers for drug delivery. In: Migliaresi C (ed) Polymers in medicine III. Elsevier, Amsterdam, pp 149–159

Faith WL (1993) Encyclopedia of chemical technology. Interscience Pub, Dublin, pp 576–577

Gonzalez MI, Alvarez S, Riera F, Alvarez R (2007) Economic evaluation of an integrated process for lactic acid production from ultrafiltered whey. J Food Eng 80:553–561

Hatzini KDG, Wang HY (1992) Extractive fermentation systems for organic acids production. Can J Chem Eng 70:543–552

Holland SJ, Tighe BJ, Gould PL (1986) Polymers for biodegradable medical devices I. The potential of polymers as controlled macromolecular release system. J Control release 4:155–160

Huang H, Yang ST, Ramey DE (2004) A hollow-fiber membrane extraction process for recovery and separation of lactic acid from aqueous solution. Appl Biochem Biotechnol 114:671–688

Jarvinen M, Mylikoski L, Keiski R, Sohlo J (2000) Separation of lactic acid from fermentation broth by reactive extraction. Bioseparation 9:163–166

Krischke W, Schroder M, Trosch W (1991) Continuous production of L-lactic acid from whey permiate by immobilized Lactobacillus casei subsp. casei. Appl Microbiol Biotechnol 34:573–578

Lewis D (1990) Biodegradable polymers and drug delivery systems. Derkker, Newyork, pp 203–208

Lipinsky ES, sinclair RG (1986) Is lactic acid a commodity chemical? Chem Eng Prog 82:26–32

Matsumoto M, Kondo K (1998) Fermentation of lactic acid combined with solvent extraction or membrane separation containing a mobile carrier. Recent Res Dev Ferment Bioeng 1:241–252

Nolan-Itu Pty Ltd (2002) Prepared in association with Excel Pals Australia. Biodegradable plastic Developments and Environmental

Pirt SJ (1985) Effect of chemical inhibition and activation of growth. Principles of microbe and cell cultivation. Blackwell Scientific Publications, Oxford, pp 170–185

Roucourt A, Girard D, Prigent Y (1989) Continuous lactic acid fermentation with cell recycled by ultrafiltration and lactate separation by electrodialysis: model identification. Appl Environ Microbiol 30:528–534

Roukas T, Kotzekidou P (1991) Production of lactic acid from deprotonized whey by Coimoblized Lactobacillus casei and Lactococcus lactic cells. Enzyme Microb Technol 13:33–38

Thang VH, Koschuh W (2004) Desalination of high salt content mixture by two-stage electrodialysis as the first step of separation valuable substances from grass silage. Desalination 162:343–353

The American type culture collection (ATCC) (1993)

Thimmaiah SR (2004) Standard methods of biochemical analysis. Kalyani publishers, New Delhi, India, pp 49–57

Tong Y, Hirata M, Takanashi H, Hano T, Kubota F, Goto M, Nakashio F, Matsumoto M (1998) Extraction of lactic acid from fermented broth with microporous hollow fiber membranes. J Memb Sci 143:81–91

Vaccari G, Gonzalez-vara A, Gampi AL, Dosi E, Brigid P, Matteuzzi D (1993) Fermentative Production of l Lactic acid by Lactobacillus casei DSM 20011 and product recovery using ion exchange resin. Appl Microbiol Biotecnol 40:23–27

Wang HY (1983) Integrating biochemical separation and purification steps in fermentation Process. Ann NY Acad Sci 413:313–321

Wardel JM, King CJ (1978) Solvent equilibria for extraction of carboxilic acid from water. J Chem Eng Data 23:144–150

Acknowledgment

We thank Razi institute for providing Lactobacillus casei and Bacillus subtillis strains.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ataei, S.A., Vasheghani-Farahani, E. In situ separation of lactic acid from fermentation broth using ion exchange resins. J Ind Microbiol Biotechnol 35, 1229–1233 (2008). https://doi.org/10.1007/s10295-008-0418-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0418-6