Abstract

α-Fe2O3 nanoparticles were synthesized using Tabebuia aurea leaf extract by a facile approach. The signature peaks for Fe and O in the EDX spectrum verified the formation of Fe2O3 nanoparticles. Cuboidal-shaped nanoparticles were observed in the FE-SEM image. In the XRD pattern, it was observed that the peaks belong to α-Fe2O3 nanoparticles. These particles were pure and crystalline with an average particle size of 25.69 nm. The signals at 538 and 494 cm−1 in the FTIR image confirmed the formation of hematite nanoparticles. BET analysis showed a comparatively greater surface area (31.03 m2/g) than the commercial α-Fe2O3 nanoparticles, and the pores were mesoporous. XPS analysis confirmed the existence of α-Fe2O3 by showing the specific oxidation states for iron and oxygen at 710.34 and 529.67 eV, respectively. The saturation magnetization value of 13.97 emu/g confirmed the superparamagnetic nature. The TGA, which determined the thermal stability of the nanoparticles, reported a total weight loss of 12.75%. Hence, the highly crystalline, pure, mesoporous, superparamagnetic α-Fe2O3 nanoparticles with high surface area synthesized using T. aurea leaf extract can be potentially applied in diverse fields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanotechnology is the field of technology that deals with the study, application, and manufacture of materials on a nanoscopic scale, often between 1 and 100 nm. The key characteristics of these particles are their large surface to volume ratio that is responsible for their extensive usage in medicinal, optical, biotechnological, microbiological, electronics, environmental, and other branches of engineering and materials science (Dihom et al. 2022).

Iron oxide nanoparticles (IONPs) possess exceptional features like strong catalytic properties, excellent adsorption capacity, reactivity, mechanical properties, biocompatibility, and chemical and thermal stability (Vinayagam et al. 2020). The use of IONPs-based nanomaterials has been widely studied because of their novel properties such as small size, large surface area, magnetic property, and functionality (Singh 2022). IONPs are categorized as magnetite (Fe3O4), maghemite (γ-Fe2O3), hematite (α-Fe2O3) and goethite (FeO(OH)) (Dave and Chopda 2014). Among them, α-Fe2O3 is more thermally and chemically stable and is used widely as nanocatalysts, photocatalysts, and nano adsorbents in environmental remediation (Thakur et al. 2022).

IONPs are synthesized using several methods, among which physical and chemical methods are the most common (Gottimukkala et al. 2017). The synthesis of IONPs requires certain strong chemicals that are necessarily reducing agents, which can lead to a severe impact on the environment. Hence, it is very essential to look for a reliable, efficient, and ecological method for the synthesis of nanoparticles (Al-Buriahi et al. 2022). The method adopted should be economically reasonable, sustainable, and cheap. Also, the availability of raw materials and natural resources are the factors that have to be given extreme importance while choosing a method (Saif et al. 2016).

Recently, researchers are developing methods that are effective, reliable, and pose minimal or zero impact on the environment. Various organisms such as algae, yeast, plants, and parts of plants act as the source to produce stable and well-functioning nanoparticles (Kamaruzaman 2022). However, biomass-based synthesis is expensive and consumes more time (Mukherjee et al. 2006).

Unlike the biomass-based process, the green synthesis based on plant extract is rapid, inexpensive, and simple (Hernandez 2022). Specific metabolites of plants such as proteins, phenolic compounds, alkaloids, polyphenols, terpenoids, acids, and sugars play an essential part in reducing metallic ions and yielding nanomaterials (Makarov et al. 2014). These metabolites also stabilize nanoparticles by capping them. The increase in the reports on the production of nanomaterials based on plant extracts indicates that this approach is particularly prevalent (Yadav et al. 2018).

Few recent literatures on the plant-based preparation of α-Fe2O3 nanoparticles have been published, such as those with Ficus carica dried fruit extract (Aksu Demirezen et al. 2019), Citrus reticulum peels extract (Ali et al. 2017), Sida cordifolia extract (Naga et al. 2018), Carica papaya leaf extract (Hossen et al. 2020), fruit extract of Cornelian cherry (Rostamizadeh et al. 2020), Salvadoro persica extract (Miri et al. 2020), Rhus punjabensis extract (Naz et al. 2019), and orange peel extract (Bashir and Ali 2020).

Tabebuia aurea is an ornamental tree belonging to Tabebuia genus which is common in tropical and subtropical areas. The Caribbean trumpet tree, tree of gold, and silver trumpet tree are common names for T. aurea. They are deciduous trees that have bright yellow flowers and grow to 8 m tall in the dry season. Silver nanoparticles were synthesized using T. aurea leaf extract (Prathibha and Priya 2017). No report on the synthesis of IONPs using T. aurea has been found in the literature. Therefore, the key focus of the current investigation is to synthesize α-Fe2O3 nanoparticles using T. aurea leaf extract and characterize them using various techniques.

Materials and methods

Materials

Analytical-grade chemicals were utilized for all the experimentations and procured from Merck, India. Iron (II) sulfate heptahydrate (FeSO4.7H2O) was used as a precursor and sodium hydroxide was used to maintain the pH of the system. T. aurea plant leaves were collected from Manipal Campus, India.

T.aurea leaf extract (TALE) preparation

The collected T. aurea leaves were thoroughly rinsed with tap water and further with distilled water. They were air dried, made into small pieces, and kept in a plastic cover before any further use. 30 g leaves were added to 1 L distilled water and heated for 1 h at 80 °C. The dark brown filtrate was cooled, named TALE, and stored in a fridge.

Preparation of TA–Fe2O3 nanoparticles

TALE and freshly prepared FeSO4.7H2O were combined in 1:1 volume at room temperature. The mixture completely changed to a dark hue indicating the formation of nanoparticles. After increasing the pH to 13 using 2N NaOH, the contents were incubated at 80 °C for 40 min (Vinayagam et al. 2020). The formation of black color colloidal suspension confirmed the synthesis of TA–Fe2O3NPs, which were extracted subsequently from the solution using a powerful neodymium magnet (Fig. 1). The obtained contents were dried at 100° C for 1d and kept in a vial.

Characterization

The prepared TA–Fe2O3NPs were examined by measuring the absorbance of plant extract and the nanoparticle colloidal suspension by employing a UV–Vis spectrophotometer (SHIMADZU—UV1700). Field emission scanning electron microscope (FE-SEM) (Carl ZEISS, Sigma, Oxford Instruments) was employed to analyze the topological properties of TA–Fe2O3NPs. The porous nature and specific surface area were determined by Brunauer–Emmett and Teller apparatus (Smart Instruments, Mumbai). The X-ray diffraction (Rigaku Miniflex 600) pattern examined the crystallinity. X-ray photoelectron microscopy (PHI 5000 VersaProbe III, Physical cryotonics) analyzed the oxidation state of the components. The vibrating sample magnetometer (VSM 8600 series, Lakeshore cryotonics, USA) analyzed the magnetic property of TA–Fe2O3NPs. For studying chemical bonding in TA–Fe2O3NPs, Fourier transform infrared spectroscopy (FTIR-SHIMADZU-8400S) was employed. The thermal stability of TA–Fe2O3NPs was analyzed using thermogravimetric analysis (TGA55 (0550–0543) equipment) at a temperature range 33–800 °C in an N2 surrounding at 10 °C per min heating rate.

Zero point of charge (ZPC)

The pH needed to provide zero net charge on the surface of the nanoparticles is referred to as zero point of charge (ZPC). The surface charge on the nanoparticles is neutral at ZPC (Qin et al. 2015). The nanoparticle surface is negatively charged at pH > ZPC and vice versa at pH < ZPC. It also describes the pollutant removal potential at different pHs. Anionic pollutants are efficiently removed in acid conditions (pH < ZPC) and cationic pollutants in basic conditions (Tang et al. 2015). As reported in an earlier study, the pH drift method was used to determine ZPC with few modifications (Vinayagam et al. 2020). For the measurement of ZPC, 20 mg of synthesized nanoparticles was taken in 50 mL of 5 mM NaCl with pH ranging from 2 to 12 and incubated at room temperature. The final pH was noted after 48 h of equilibration. Then, ZPC was obtained at the intersection point of the straight line of the initial and final pH.

Results and discussions

UV–Vis spectra analysis

The nanoparticle formation was established by the black color development after mixing the precursor and the TALE. This black-colored colloidal suspension was subjected to UV spectral studies after multiple dilutions. For both TALE and TA–Fe2O3NPs, a broad absorption band was observed with no specific peaks between 300 and 800 nm, confirming the formation of IONPs as shown in Fig. 2. A similar kind of absorption band was obtained for α-Fe2O3 nanoparticles synthesized from various plant sources such as root extract of Arisaema amurense (Narayanan and Han 2016), Spondias dulcis (Vinayagam et al. 2020), Pheonix dactylifera leaf extract (Laouini 2019), and henna leaf extract (Abid and Kadhim 2020). The band gap for the TA–Fe2O3NPs was calculated as 2.67 eV by Tauc plot (Fig. 2 inset). The value matches with the reported value of 2.6 eV for the synthesis of Fe2O3 by the chemical method (Suman et al. 2020).

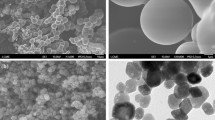

FE-SEM and EDX studies

Figure 3a displays the FE-SEM image of the synthesized TA–Fe2O3NPs. Cuboidal-shaped nanoparticles with irregular morphology were observed which indicated their powdery and porous nature (Swarup Kumar Maji 2012). The average size of 43 nm was determined by Image J software. Many researchers have documented the cuboidal-shaped IONPs using fruit extracts of Hyphaene thebaica (Mohamed et al. 2020) and Tridax leaf extract (Yadav and Fulekar 2018). The elemental nature of nanoparticles was studied using EDX (Fig. 3b). The strong peak of iron and oxygen confirmed the formation of IONPs. The other peaks such as Na, Ca, and Si mainly originated because of the glass specimen used for the analysis (Dash et al. 2019). The carbon peak may be due to the polyphenols in the extract.

XRD analysis

The XRD pattern for the synthesized TA–Fe2O3NPs is shown in Fig. 4. The peaks were obtained at 33.15°, 35.72°, 40.92°, 49.4°, 54.04°, 62.5°, and 64.04° which corresponded to Braggs’s reflections of (104), (110), (113), (024), (116), (214), and (300), respectively (Eldin et al. 2018). This pattern conformed to α-Fe2O3 with the rhombohedral centered hexagonal structure as per JCPDS (No. 33-0664) (Sharifah and Abdul 2014). The lack of other peaks indicated the purity and strong crystallinity of the TA–Fe2O3NPs. Debye–Scherrer equation estimated the crystallite size as 25.69 nm. Many researchers have also reported within this range of size for Fe2O3NPs with a green synthesis approach. 48.19 nm of Fe2O3NPs with rhombohedral structure was synthesized from Raphanus sativus leaf extract (Balu et al. 2020), while 48 nm-sized semi-spherical nanoparticles were synthesized from pomegranate seed extract (Bibi et al. 2019).

BET analysis

The specific surface area of the synthesized TA–Fe2O3NPs was determined by BET analysis to be 31.03 m2/g and pore volume was 0.0339 cc/g. The pore diameter was 4.37 nm, which substantiated the mesoscopic nature, and the particle size was 39 nm. The particle size determined from the BET analysis is consistent with that from XRD and SEM analysis. The synthesized TA–Fe2O3NPs showed better results than other studies. Moreover, the specific surface area of commercially available α-Fe2O3 is 6 m2/g (Ahmmad et al. 2013). This indicates that the specific surface area of the synthesized TA–Fe2O3NPs is five times larger than the commercial one. Besides, the specific surface area observed herein is higher than that reported for other α-Fe2O3 nanoparticles as shown in Table 1. The specific surface area of the nanomaterials is one of the important properties which help in determining the effectiveness of nanoparticles in pollutant removal by adsorption or photocatalytic degradation.

FTIR analysis

Many sharp bands were observed at (cm−1) 3734, 3277, 2357, 1545, 1207, 762 and 494 in the FTIR spectrum (Fig. 5). The signal observed at 2357 cm−1 may be assigned to stretching of the alkyne C≡C or C–H because of aliphatic and aromatic compounds (Aksu Demirezen et al. 2019). It is also attributed to the bending mode of S–N vibration of amino acids present in TALE (Luo et al. 2016). The broadband found in the range from 3000 to 3500 cm−1 in addition to a small signal at 3734 cm−1 was correlated to the vibrations of the OH group in polyphenol TALE. A sharp band at 1545 cm−1 was associated with the C=O stretching, suggesting that the amide region was mainly due to enzymes and proteins that were accountable for reducing metallic ions (Madubuonu et al. 2019).

The weak bands at 1207 cm−1 are designated for C–CO–C stretching of carboxyl compounds (Pan et al. 2019). The 762 cm−1 signals may be allocated to the C–H bending of aromatic components (Yi et al. 2019). The respective frequencies of the low wavenumbers (< 700 cm−1) originate from the Fe–O vibrations of the iron oxide bond. The bands at 538 and 494 cm−1 corroborated the presence of hematite (Kumar et al. 2014).

XPS analysis

XPS analysis investigated the oxidation state of Fe and O present in TA–Fe2O3NPs. Figure 6 reflects the elementary analysis using XPS spectra. It established the existence of elements such as Fe, O, and C. These results are in line with the EDX analysis. The photoelectron peaks at 529.67 eV indicated the existence of O on the surface of TA–Fe2O3NPs, associated with O–H, O–C, and O=C compounds of TALE. This signal can also be traced to oxygen in α-Fe2O3 (Iacovita et al. 2015). Figure 6 inset shows the C signal at 284.79 eV, which affirmed the presence of the alkyl or aliphatic C in the biomolecules of TALE. Further, the peaks at 710.34 eV and 724.04 eV are signature signals of Fe 2p1/2 and Fe 2p3/2, respectively. The peaks at 710.34 eV are related directly to Fe3+ octahedral species. This confirmed the existence of Fe3+ ions of α-Fe2O3 (Shen et al. 2014). The core levels of Fe 2p and O 1 s were + 3 and −2, respectively, for the oxidation states of iron and oxygen. Hence, it may be concluded that the nanoparticles formed are pure α-Fe2O3 and devoid of other impurities like zero-valent iron and another form of iron oxide.

VSM analysis

VSM analysis provides the magnetic behavior of the synthesized nanoparticles by determining the magnetic parameters such as magnetization, coercivity, and retentivity. Figure 7 provides measurements of magnetic hysteresis performed for TA–Fe2O3NPs at room temperature in an applied magnetic field from −15 kOe to + 15 kOe. The magnetization studies showed that magnetic particle saturation occurs in the higher field due to the nanoscale size of TA–Fe2O3NPs, which was obtained as 43 nm from SEM analysis. Also, an increase in the magnetic force favored particle magnetization (Sebastian et al. 2018). The analysis showed that magnetic saturation was 13.97 emu/g, 23 times higher than the commercial α-Fe2O3 nanoparticles (0.6 emu/g) (Tang et al. 1989). This high magnetization is attributed to the surface disordered spin which is more likely to be oriented in the direction of the external magnetic field that is applied. Hence, it is hypothesized that the nanoparticle core–shell structure causes the elevated magnetic moment of the particles (Karade et al. 2019). TA–Fe2O3NPs were attracted to the strong magnet as seen in the inset of Fig. 7, demonstrating its superparamagnetic property. Moreover, this research shows a higher magnetic saturation value than other published green synthesis literature for α-Fe2O3. The magnetic saturation of α-Fe2O3 synthesized from the root extract of Arisaema amurense was 1.25 emu/g (particle size: 24 nm) (Narayanan and Han 2016), from Salvadora persica aqueous extract 1.8 emu/g (particle size: 50–20 nm) (Miri et al. 2020), and from Gardenia resinifera plant extract 8.5 emu/g (particle size: 5 nm) (Karade et al. 2019).

Zero point of charge (ZPC)

ZPC plays a key role in the analysis of α-Fe2O3 nanoparticle surface properties. It defines the electroneutrality of the nanomaterials and their surface at a particular pH (Lasheen et al. 2014). The graph of the initial vs final pH to estimate ZPC is shown in Fig. 8. The intersection point with the straight line is considered as ZPC and the value was 7.1, which was consistent with α-Fe2O3 nanoparticles synthesized by the precipitation process (Dehbi et al. 2020). The ZPC value of the synthesized TA–Fe2O3NPs revealed that the nanoparticle surface was negatively charged at a solution pH greater than the ZPC and positively charged at pH smaller than the ZPC.

TGA

TGA measures the changes in the mass of nanoparticles as a function of temperature (or time) under a regulated environment to estimate thermal stability. The TGA plot of synthesized IONPs revealed a high rate of weight loss up to the temperature of 385 °C and it stabilized further (Fig. 9). In the initial phase, a minimal amount of weight loss, i.e., 2.34%, was detected within the temperature ranges of 33–100 °C. A similar amount of weight loss (2.5%) was observed for α-Fe2O3 synthesized using Cyperus rotundus rhizome extract (Basavegowda et al. 2017). This was because of the evaporation of surface-bound water and the volatile content present in TA–Fe2O3NPs (Akshay et al. 2020). From 100 to 400 °C, a significant weight loss of about 11.22% was observed. This could be attributed to the destruction of the surrounding phyto-compounds of TA–Fe2O3NPs (Narayanan and Han 2016). Further, from 400 to 800 °C, a gradual decrement (1.5%) was obtained due to adsorbed oxygen species (Basavegowda et al. 2017). At this temperature range, α-Fe2O3 nanoparticles synthesized utilizing Spondias dulcis leaf extract showed a 7% loss (Vinayagam et al. 2020). Finally, it was shown that the residual weight of TA–Fe2O3NPs at 750 °C was 87.26% of the initial weight.

Plausible mechanism of TA–Fe2O3NPs synthesis

The plant extracts contain a range of biomolecules which are responsible for the reduction and stabilization of nanoparticles as reported by many researchers. The present study’s FTIR findings clearly demonstrate that proteins and polyphenols are present, which are responsible for the synthesis. These compounds reduce Fe2+ to Fe0 which is followed by metal core–shell oxidation, wherein Fe0 is oxidized to Fe3+ as explained in the literature (Aksu Demirezen et al. 2019).

Conclusion

α-Fe2O3 nanoparticles were effectively prepared using T. aurea leaf extract by a green synthesis approach without the use of any toxic chemicals. The adopted method proved to be easy and inexpensive. The synthesized TA–Fe2O3NPs were characterized by various techniques to analyze their size, morphology, surface functional group, and magnetic behavior. The synthesized nanoparticles were cuboidal in shape, pure, crystalline, and thermally stable with a mean diameter of 43 nm, and a specific surface area of 31.03 m2/g. They were more strongly magnetic than commercially available α-Fe2O3 nanoparticles with magnetic saturation of 13.97 emu/g. The synthesized TA-Fe2O3NPs can be used in various fields such as environmental remediation, biomedical application, and construction.

Data availability

Data will be made available on request.

References

Abid MA, Kadhim DA (202) Novel comparison of iron oxide nanoparticle preparation by mixing iron chloride with henna leaf extract with and without applied pulsed laser ablation for methylene blue degradation. J Environ Chem Eng 8(5):104138. doi: https://doi.org/10.1016/j.jece.2020.104138.

Abolhasani Zadeh F et al (2022) Drug delivery and anticancer activity of biosynthesised mesoporous Fe2O3 nanoparticles. IET Nanobiotechnol 16(3):85–91. https://doi.org/10.1049/nbt2.12080

Ahmmad B, Leonard K, Islam S, Kurawaki J (2013) Green synthesis of mesoporous hematite (a-Fe2O3) nanoparticles and their photocatalytic activity. Adv Powder Technol 24(1):160–167. https://doi.org/10.1016/j.apt.2012.04.005

Akshay VR, Vasundhara M, Muthu A (2020) Biosynthesis of multiphase iron nanoparticles using Syzygium aromaticum and their magnetic properties. Colloids Surf A Physicochem Eng Asp. https://doi.org/10.1016/j.colsurfa.2020.125241

Aksu Demirezen D, Yıldız YŞ, Yılmaz Ş, Demirezen Yılmaz D (2019) Green synthesis and characterization of iron oxide nanoparticles using Ficus carica (common fig) dried fruit extract. J Biosci Bioeng 127(2):241–245. https://doi.org/10.1016/j.jbiosc.2018.07.024

Al-Buriahi AK, Al-shaibani MM, Mohamed RMSR, Al-Gheethi AA, Sharma A, Ismail N (2022) Ciprofloxacin removal from non-clinical environment: a critical review of current methods and future trend prospects. J Water Process Eng 47:102725. https://doi.org/10.1016/J.JWPE.2022.102725

Ali HR, Nassar HN, El-gendy NS (2017) Environmental effects green synthesis of α-Fe2O3 using Citrus reticulum peels extract and water decontamination from different organic pollutants. Energy Sources Part A Recovery, Utilization Environ Effects. https://doi.org/10.1080/15567036.2017.1336818

Balu P IV, Asharani DT (2020) Catalytic degradation of hazardous textile dyes by iron oxide nanoparticles prepared from Raphanus sativus leaves’ extract: a greener approach. J Mater Sci Mater Electron 31(13):10669–10676. https://doi.org/10.1007/s10854-020-03616-z

Basavegowda N, Mishra K, Lee YR (2017) Synthesis, characterization, and catalytic applications of hematite (α-Fe2O3) nanoparticles as reusable nanocatalyst. Adv Nat Sci Nanosci Nanotechnol. https://doi.org/10.1088/2043-6254/aa6885

Bashir M, Ali S (2020) Green synthesis of Fe2O3 nanoparticles from orange peel extract and a study of its antibacterial activity. J Korean Phys Soc 76(9):848–854. https://doi.org/10.3938/jkps.76.848

Bibi I et al (2019) Green synthesis of iron oxide nanoparticles using pomegranate seeds extract and photocatalytic activity evaluation for the degradation of textile dye. J Market Res 8(6):6115–6124. https://doi.org/10.1016/j.jmrt.2019.10.006

Dash A, Ahmed MT, Selvaraj R (2019) Mesoporous magnetite nanoparticles synthesis using the Peltophorum pterocarpum pod extract, their antibacterial efficacy against pathogens and ability to remove a pollutant dye. J Mol Struct 1178:268–273. https://doi.org/10.1016/j.molstruc.2018.10.042

Dave PN, Chopda LV (2014) Application of iron oxide nanomaterials for the removal of heavy metals. J Nanotechnol. https://doi.org/10.1155/2014/398569

de Menezes AS et al (2007) Sintering of nanoparticles of α-Fe2O3 using gelatin. J Non Cryst Solids 353(11–12):1091–1094. https://doi.org/10.1016/j.jnoncrysol.2006.12.022

Dehbi A, Dehmani Y, Omari H, Lammini A, Elazhari K, Abdallaoui A (2020) Hematite iron oxide nanoparticles (α-Fe2O3): synthesis and modelling adsorption of malachite green. J Environ Chem Eng 8(1):103394. https://doi.org/10.1016/j.jece.2019.103394

Dihom HR, Al-Shaibani MM, Radin Mohamed RMS, Al-Gheethi AA, Sharma A, Khamidun MH (2022) Photocatalytic degradation of disperse azo dyes in textile wastewater using green zinc oxide nanoparticles synthesized in plant extract: a critical review. J Water Process Eng 47:102705. https://doi.org/10.1016/J.JWPE.2022.102705

Eldin D, Zhang C, El-didamony H, Yingnan L, Daniel T, Hussain A (2019) Results in physics improved size, morphology and crystallinity of hematite (α-Fe2O3) nanoparticles synthesized via the precipitation route using ferric sulfate precursor. Results Phys 12:1253–1261. https://doi.org/10.1016/j.rinp.2019.01.005

Gottimukkala KSV, Harika RP, Zamare D (2017) Green synthesis of iron nanoparticles using green tea leaves extract. J Nanomed Biotherapeutic Discov 7(1):1–4. https://doi.org/10.4172/2155-983x.1000151

Hernandez P et al (2022) Development and applications of Ru and Ce based iron oxides as photocatalysts. Mater Lett 313:131720. https://doi.org/10.1016/J.MATLET.2022.131720

Hossen S et al (2020) Heliyon green synthesis of iron oxide nanoparticle using Carica papaya leaf extract: application for photocatalytic degradation of remazol yellow RR dye and antibacterial activity. Heliyon 6:e04603. https://doi.org/10.1016/j.heliyon.2020.e04603

Iacovita C et al (2015) Polyethylene glycol-mediated synthesis of cubic iron oxide nanoparticles with high heating power. Nanoscale Res Lett. https://doi.org/10.1186/s11671-015-1091-0

Kamaruzaman NH et al (2022) Applicability of bio-synthesized nanoparticles in fungal secondary metabolites products and plant extracts for eliminating antibiotic-resistant bacteria risks in non-clinical environments. Environ Res 209:112831. https://doi.org/10.1016/J.ENVRES.2022.112831

Karade VC et al (2019) A green approach for the synthesis of α-Fe2O3 nanoparticles from Gardenia resinifera plant and it’s in vitro hyperthermia application. Heliyon. https://doi.org/10.1016/j.heliyon.2019.e02044

Kumar B, Smita K, Cumbal L, Debut A (2014) Biogenic synthesis of iron oxide nanoparticles for 2-arylbenzimidazole fabrication. J Saudi Chem Soc 18(4):364–369. https://doi.org/10.1016/j.jscs.2014.01.003

Laouini SE (2019) Green synthesis of iron nanoparticules using leaf extract from Phoenix dactylifera L. J Fundam Appl Sci 2019(2):978–993. https://doi.org/10.4314/jfas.v11i2.28

Lasheen MR, El-Sherif IY, Sabry DY, El-Wakeel ST, El-Shahat MF (2014) Removal and recovery of Cr (VI) by magnetite nanoparticles. Desalt Water Treat 52(34–36):6464–6473. https://doi.org/10.1080/19443994.2013.822158

Luo Y et al (2016) Facile crystal-structure-controlled synthesis of iron oxides for adsorbents and anode materials of lithium batteries. Mater Chem Phys 170:239–245. https://doi.org/10.1016/j.matchemphys.2015.12.044

Madubuonu N et al (2019) Biosynthesis of iron oxide nanoparticles via a composite of Psidium guavaja-Moringa oleifera and their antibacterial and photocatalytic study. J Photochem Photobiol B 199:111601. https://doi.org/10.1016/j.jphotobiol.2019.111601

Makarov VV, Love AJ, Sinitsyna OV, Makarova SS, Yaminsky IV (2014) Green nanotechnologies : synthesis of metal nanoparticles using plants. Acta Naturae 6(20):35–44

Miri A, Khatami M, Sarani M (2020) Biosynthesis, magnetic and cytotoxic studies of hematite nanoparticles. J Inorg Organomet Polym Mater 30(3):767–774. https://doi.org/10.1007/s10904-019-01245-6

Mohamed HEA et al (2020) Bio-redox potential of Hyphaene thebaica in bio-fabrication of ultrafine maghemite phase iron oxide nanoparticles (Fe2O3 NPs) for therapeutic applications. Mater Sci Eng C 112:110890. https://doi.org/10.1016/j.msec.2020.110890

Mukherjee P, Mandal D, Bolander ME, Mukhopadhyay D, Sarkar G (2006) The use of microorganisms for the formation of metal nanoparticles and their application. Appl Microbiol Biotechnol 69(5):485–492

Naga P, Kumar V, Ummey S, Kalyani L (2019) Heliyon antibacterial efficacy of green synthesized α-Fe2O3 nanoparticles using Sida cordifolia plant extract. Heliyon 5:e02765. https://doi.org/10.1016/j.heliyon.2019.e02765

Narayanan KB, Han SS (2016) One-pot green synthesis of hematite (α-Fe2O3) nanoparticles by ultrasonic irradiation and their in vitro cytotoxicity on human keratinocytes CRL-2310. J Clust Sci 27(5):1763–1775. https://doi.org/10.1007/s10876-016-1040-9

Naz S et al (2019) Green synthesis of hematite (a-Fe2O3) nanoparticles using Rhus punjabensis extract and their biomedical prospect in pathogenic diseases and cancer. J Mol Struct 1185:1–7. https://doi.org/10.1016/j.molstruc.2019.02.088

Pan Z, Lin Y, Sarkar B, Owens G, Chen Z (2019) Green synthesis of iron nanoparticles using red peanut skin extract: synthesis mechanism, characterization and effect of conditions on chromium removal. J Colloid Interface Sci 558:106–114. https://doi.org/10.1016/j.jcis.2019.09.106

Prathibha BS, Priya KS (2017) Green synthesis of silver nanoparticles using Tabebuia aurea leaf extract. IOSR J Appl Chem 10(06):23–29. https://doi.org/10.9790/5736-1006012329

Qin GHX, Liu F, Wang G (2015) Adsorption of humic acid from aqueous solution by hematite: effects of pH and ionic strength. Environ Earth Sci 73(8):4011–4017

Rostamizadeh E, Iranbakhsh A, Majd A, Arbabian S, Mehregan I (2020) Green synthesis of Fe2O3 nanoparticles using fruit extract of Cornus mas L. and its growth—promoting roles in Barley. J Nanostructure Chem. https://doi.org/10.1007/s40097-020-00335-z

Rufus A, Sreeju N, Philip D (2016) Synthesis of biogenic hematite (α-Fe2O3) nanoparticles for antibacterial and nanofluid applications. RSC Adv 6(96):94206–94217. https://doi.org/10.1039/c6ra20240c

Saif S, Tahir A, Chen Y (2016) Green synthesis of iron nanoparticles and their environmental applications and implications. Nanomaterials 6(11):1–26. https://doi.org/10.3390/nano6110209

Sebastian A, Nangia A, Prasad MNV (2019) Cadmium and sodium adsorption properties of magnetite nanoparticles synthesized from Hevea brasiliensis Muell. Arg. bark: relevance in amelioration of metal stress in rice. J Hazard Mater 371:261–272. https://doi.org/10.1016/j.jhazmat.2019.03.021

Sharifah MA, Abdul B (2014) Green synthesis of a -Fe2O3 nanoparticles for photocatalytic application. J Mater Sci Mater Electron. https://doi.org/10.1007/s10854-014-2058-0

Shen S et al (2014) Surface engineered doping of hematite nanorod arrays for improved photoelectrochemical water splitting. Sci Rep 4:1–9. https://doi.org/10.1038/srep06627

Singh H et al (2022) Ultrasonically assisted solvohydrothermal synthesis of nanocrystalline Zn-Ni ferrite advanced material for EMI shielding. J Alloys Compd 906:164199. https://doi.org/10.1016/J.JALLCOM.2022.164199

Suman S, Chahal AK, Kumar P (2020) “Zn doped α-Fe2O3: an efficient material for UV driven photocatalysis and electrical conductivity. Crystals (basel). https://doi.org/10.3390/cryst10040273

Swarup Kumar M, Nillohit M (2012) Synthesis, characterization and photocatalytic activity of α-Fe2O3 nanoparticles. Polyhedron 33:145–149

Tang ZX et al (1989) Magnetic properties of aerosol synthesized iron oxide particles. J Magn Magn Mater 80:285–289

Tang L et al (2015) Rapid adsorption of 2,4-dichlorophenoxyacetic acid by iron oxide nanoparticles-doped carboxylic ordered mesoporous carbon. J Colloid Interface Sci 445:1–8. https://doi.org/10.1016/j.jcis.2014.12.074

Thakur A, Kumar A, Kaya S, Vo DVN, Sharma A (2022) Suppressing inhibitory compounds by nanomaterials for highly efficient biofuel production: a review. Fuel 312:122934. https://doi.org/10.1016/J.FUEL.2021.122934

Vinayagam R, Pai S, Varadavenkatesan T (2020) Structural characterization of green synthesized α-Fe2O3 nanoparticles using the leaf extract of Spondias dulcis. Surfaces Interfaces 20:1–9. https://doi.org/10.1016/j.surfin.2020.100618

Yadav VK, Fulekar MH (2018) Biogenic synthesis of maghemite nanoparticles (γ-Fe2O3) using tridax leaf extract and its application for removal of fly ash heavy metals (Pb, Cd). Mater Today Proc 5(9):20704–20710. https://doi.org/10.1016/j.matpr.2018.06.454

Yadav P, Manjunath H, Selvaraj R (2018) Antibacterial and dye degradation potential of zero-valent silver nanoparticles synthesised using the leaf extract of Spondias dulcis. IET Nanobiotechnol. https://doi.org/10.1049/iet-nbt.2018.5058

Yi Y, Tu G, Tsang PE, Xiao S, Fang Z (2019) Green synthesis of iron-based nanoparticles from extracts of nephrolepis auriculata and applications for Cr(VI) removal. Mater Lett 234:388–391. https://doi.org/10.1016/j.matlet.2018.09.137

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sridevi, H., Bhat, M.R., Kumar, P.S. et al. Structural characterization of cuboidal α-Fe2O3 nanoparticles synthesized by a facile approach. Appl Nanosci 13, 5605–5613 (2023). https://doi.org/10.1007/s13204-023-02780-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-023-02780-y