Abstract

The first stage of ethylene decomposition followed by second stage of temperature-programmed surface reduction (H2-TPSR) to produce higher hydrocarbons at different temperatures over silica-supported iridium catalysts has been investigated. The catalysts for the two stepwise reactions are characterized by X-ray diffraction, Raman and Fourier transformed infrared spectroscopies, temperature-programmed reduction, and mass spectroscopy. These studies reveal that ethylene decomposition at low temperatures (≤673 K) in the first stage produces mainly C1 hydrocarbon moieties on the Ir surface via dissociative adsorption, the sequential hydrogenation in the second stage will give arise to CH4. The surface polymerization of C1 to higher hydrocarbon species and metathesis reactions under these temperatures are also clearly evident. When ethylene is decomposed at 773–973 K, stable graphitic carbon deposits with poor propensity for hydrogenation are obtained. Interestingly, water formed from surface dehydroxylation on silica can produce a significant quantity of CO/H2 with these carbons during the H2-TPSR at elevated temperature.

Similar content being viewed by others

Introduction

The dependence on oil over last century is expected to be gradually offset in this century by an increasing dependence on natural gas (the main constituent of which is methane). Much attention has therefore been paid to methane conversion to more commercially useful chemicals [1]. However, direct CH4 conversion into condensable chemicals such as oxygenates (methanol, formaldehyde) or higher hydrocarbons pose key technical challenges [2, 3]. It was demonstrated that higher hydrocarbons can be formed from methane by a two-stage procedure, namely catalytic deposition of carbonaceous species, followed by Fischer–Tropsch like hydrogenation. They were operated at different reaction temperatures and conditions in order to overcome thermodynamic limitations [4, 5]. Similar processes have also been reported using other light alkanes [6]. It is interesting to extend this fundamental research to ethylene molecule, which is one of the key petrochemicals. It is expected that the use of ethylene, an unsaturated hydrocarbon can facilitate the first stage of carbonaceous deposition process hence enabling their surface coupling to higher hydrocarbons in the second stage. It is noted from previous research that a significant quantity of propylene was selectively formed when ethylene was in contact with cobalt catalyst at elevated temperature [7]. Similar results could also be obtained over Ru catalyst under defined reaction conditions, suggesting the possibility of obtaining selective higher hydrocarbon products [8]. The homologation of ethylene on metal surfaces, more often, was reported in the presence of H2 [9]. The use of two-step sequence is expected to be more favorable to maximize the hydrocarbon chain length than those of co-feeding C2H4 and H2 [10], which should be systematically explored.

It is well known that the metal–carbon bond strength is crucial to determine the type of carbonaceous deposit produced during the low-temperature two-step CH4 conversion [1]. Conceivably, the stepwise conversion of C2H4 may also inherit this feature of methane homologation. Compared to other group VIII noble metals, Ir catalysts are scarcely studied. However, due to its characteristic properties, the C2H4 activation and the sequential hydrogenation on Ir surface are expected to give different activities and selectivities.

In this paper, a systematic study of the two-step C2H4 conversion sequence was therefore performed over iridium-supported catalysts which were then characterized by different techniques. Preliminary results reveal that the type of carbonaceous deposits from ethylene decomposition and the nature of hydrocarbons synthesized during the temperature-programmed reduction (H2-TPR) on Ir surfaces are strongly dependent on the temperature of C2H4 decomposition used. As a result, a mechanism for the stepwise C2H4 conversion is hereby proposed.

Experimental

Catalyst preparation

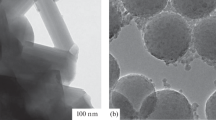

The 10 % Ir/SiO2 catalyst (10 % stands for the nominal loading weight of Ir in catalyst) was prepared by an impregnation method. Typically, 107.54 mg IrCl3 (of 99.99 % purity, supplied from Johnson Matthey) was dissolved in 30 mL deionized water, and then 0.50 g silica gel (99+ % purity, supplied from Aldrich Chemical Company Inc.) was added as the carrier. After stirring at room temperature for 2 h, the water in the solution was evaporated at 353 K. The light yellow sample thus obtained was further dried at 353 K overnight. The product was then calcined in air at 873 K for 3 h, and sequentially treated under a H2 flowing stream at 573 K for 3 h, yielding the 10 % Ir/SiO2 catalyst.

Decomposition of C2H4 on the Ir-supported catalyst was performed at ambient pressure as follows: 30 mg 10 % Ir/SiO2 was placed in a vertical quartz tube. A helium flow (10 mL/min) was first used to flush the tube at 313 K for 15 min, removing all the remaining air inside. Pure C2H4 flow (10 mL/min) was then introduced. The temperature was subsequently increased at a rate of 10 K/min to a designated value and kept for 1 h to obtain a 10 % Ir/SiO2-x sample, where x stands for the temperature of C2H4 decomposition. Afterwards, the temperature was decreased to 313 K under the He flow. The solid product was hydrogenated by switching the gas flow to 20 mL/min of 5 % H2–95 % Ar. The temperature was increased gradually to 1,273 K at a rate of 10 K/min.

Catalyst characterization

XRD patterns were acquired on a PANalytical PW3719 diffractometer, using Cu K α radiation (λ = 1.5418 Ǻ) from a generator operating at 40 kV and 30 mA. All Raman spectra were recorded on a Jobin–Yvon spectrometer (Labram 1B) equipped with a microscope using 20 mW He–Ne laser (632.8 nm) in the range of 200 cm−1 up to 3,600 cm−1, by adding four sets of spectra together. The spectral resolution was set at 4.0 cm−1. FTIR spectra were collected on a Nicolet 6700 FTIR spectrometer with a liquid nitrogen-cooled MCT detector. FTIR spectra were obtained by averaging 128 scans at a resolution of 4 cm−1. H2–TPR measurement was performed immediately after the decomposition of C2H4 on the Ir catalysts on a ThermoQuest CE INSTRUMENTS TPDRO1100 equipment, using a 5 % H2–95 % Ar gas mixture in the temperature range of 313–1,273 K. The gaseous products leaving the tubular reactor were also analyzed on line by a HIDEN ANALYTICAL HPR20 mass spectrometer, where the signals of H2, H2O, CO, CO2, and the hydrocarbon species C1 to C6 were detected. The MS signal changes for CO2 and C6 species were not obvious during the whole process, and therefore are not shown in the figures.

Results and discussion

Characterization of the Ir catalysts

The XRD patterns of different 10 % Ir/SiO2 samples are shown in Fig. 1. Diffraction lines due to the metallic Ir were observed at 40.7o, 47.2o, 69.3o, 83.3o, and 88.0o, respectively [11], while silica gave diffraction around 23.5o [12]. There was no obvious change in the intensity or shape of the diffraction peaks before and after the C2H4 decomposition. This indicates that there were strong interactions between Ir nanoparticles (NPs) and the silica support, and the characteristic structure of Ir NPs was not altered by the high-temperature treatment under C2H4 flow over the whole range of the ethylene decomposition temperatures. Furthermore, there was no observable shift in the diffraction peak positions to suggest any lattice expansion of Ir nanocrystal due to carbon atoms inclusion in the crystal interstice as those observed in the case of fcc Pd (C) [13]. Thus, the carbonaceous deposition during the ethylene decomposition appears to take place only on the catalyst surface instead of lattice insertion.

Raman measurement was then performed to explore the type of carbonaceous species produced after the C2H4 decomposition. As seen in Fig. 2, there is no obvious peak found on the surfaces of 10 % Ir/SiO2-x (x = 473, 573, and 673 K) samples, suggesting the absence of less reactive carbons (Cβ) and graphitic carbon deposits (Cγ) previously identified during methane decomposition at these temperatures [5]. Further increasing the temperatures of C2H4 decomposition to 773–973 K resulted in the appearance of the characteristic D and G bands around 1,323 and 1,589 cm−1, respectively of a typical carbonaceous material [14]. Moreover, the ID/IG value decreased on increasing the temperature of C2H4 decomposition, implying the gradual formation of stable graphitic carbons from reactive carbons.

FTIR spectra were collected in order to identify the existence of hydrocarbon species on the catalysts. However, no absorption band was attributable to any of the vibration modes of CH x for all the samples in Fig. 3. This means that all the above CH x fragments may have been reacted or decomposed quickly at high temperature with their surface concentrations below the detection limit. Similar results were also reported by Solymosi and co-workers [15], where in situ measurements or sudden cooling of the sample in a continuous CH4 + H2 flow to 200 K did not produce detectable IR peaks. Nevertheless, it is noted that the intensity of band around 3,379 cm−1, which is characteristic of –OH groups on the silica surface [16] was decreased with the increasing C2H4 decomposition temperature, especially at temperatures above 673 K. Similar trend was also observed for the band at around 1,631 cm−1, which can be attributed to the scissoring mode of H2O molecules [17]. All these results suggest the loss of H2O and –OH groups from the catalyst surface at high temperatures.

It is reported that temperature-programmed reduction (TPR) can separate various types of carbon residing on the metal surface [6]. Thus, H2–TPR spectra related to the hydrogenation of surface carbons over various catalysts were collected in this work and displayed in Fig. 4. First, negative peaks at the programming temperatures below 373 K were observed for all samples, which can be attributed to the release of hydrogen from Ir NPs similar to those cases of other group VIII noble metals [13]. In addition, there were some reduction peaks detected at the temperature range of 373–923 K. In the case of 10 % Ir/SiO2-473, two peaks centered at 547 and 674 K, respectively, corresponded to the hydrogenation of at least two different carbonaceous species on the catalyst surface. When increasing the temperature of C2H4 decomposition up to 573 K, reduction peaks appeared to shift to higher temperatures. Furthermore, the intensity of the reduction peak increased drastically, suggesting an increase in the amount of reactive carbonaceous species on the Ir surfaces during the higher temperature decomposition. Further increasing the decomposition temperature to 673 K, the reduction peak on 10 % Ir/SiO2-673 shifted toward further higher temperature but the intensity this time decreased suggesting that the reactive carbonaceous species were somehow converted to less reactive forms that could not be easily hydrogenated. This trend was maintained as the temperature of C2H4 decomposition increased from 773 to 973 K. Interestingly, new but distinctive negative peaks at high temperatures, indicative of hydrogen gas evolution could be observed and their intensities increased at increasing C2H4 decomposition temperature.

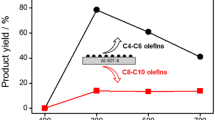

To better understand the compounds produced in the hydrogenation process, temperature-programmed surface reduction monitored by mass spectroscopy, TPSR–MS technique has been applied in this work. Compared with other physical methods such as electron energy loss spectroscopy (EELS) and Auger electron spectroscopy (AES), this technique is powerful for studying carbon deposits on surface [18]. The measurement can be performed more easily and the carbonaceous intermediates can be identified indirectly. As shown in Fig. 5, detection of positive hydrogen peak at low temperature (<373 K) due to the release of H2 was confirmed for all samples, which are consistent with the observation of the negative peaks in the H2–TPR profiles. Over 10 % Ir/SiO2-473, two broad CH4 peaks were detected accompanying the inverted H2 consumption profile at the same temperatures. This suggests that the catalyst surface must be covered with reactive carbonaceous species during ethylene decomposition at the first stage for the gaseous CH4 production under hydrogen at the second stage. In addition, small amounts of higher hydrocarbons of C2–C4 species were clearly produced, suggesting a degree of surface polymerization of adsorbed hydrocarbon species akin to those of Fischer–Tropsch catalysis. The quantities of gaseous higher hydrocarbons produced were higher from the same sample at the decomposition temperature of 573 K, implying a higher level of surface coverage of the reactive carbonaceous species. Interestingly, we also noted that the production of gaseous ethylene and butylene molecules were always associated with the decrease in propylene concentration. This indicates the favorable propylene metathesis reaction (2C3H6 → C2H4 + C4H8) on the Ir surface. CH4 and C2 compounds appeared to be the predominant products than C3+ alkanes/olefins over our Ir catalyst which is different from the reported Ni and Pt catalysts [10]. Further increasing the decomposition temperature at and above 673 K in the first step rendered the consumption of H2 much reduced together with the decrease in CH4 signal. In addition, the signals for C2–C5 compounds were attenuated to zero. This strongly indicates the fundamental change in the nature of carbonaceous species deposited on the Ir surface at the higher ethylene decomposition temperatures. In the case of 10 % Ir/SiO2-773, CH4 signal arose only at around 850 K. Also, a broad peak assigned to H2 appeared above 923 K during the temperature-programmed heating. For 10 % Ir/SiO2-873, the signal for H2 at high temperature further increased with a clear decrease in H2O concentration. At the decomposition temperature of 973 K, a similar observation of increase in H2 signal together with the reduction of H2O signal was noted, but in this case, production of gaseous CO molecules was detected.

Mechanistic issues

With reference to the above studies and previous research, this short paper demonstrates that when C2H4 decomposition takes place at 473 K, its dissociative adsorption leads to the formation of hydrocarbon CH x species on the Ir surfaces. These species can then be readily hydrogenated into gaseous CH4 in the second step. As the decomposition temperature reaches 573 K, CH x groups on the catalyst surface can assemble to ethylidyne- or vinylidene-like surface species similar to those surface reactions reported by Bond et al. and Goodman et al. [6, 18]. Their presence can be clearly reflected by the TPSR–MS results, where both gaseous CH4 and C2 compounds were detected upon hydrogenation (Fig. 5). In addition, surface C1 polymerization and metathesis reactions clearly took place at ≤573 K on the Ir surface, resulting in the formation of a range of higher hydrocarbons. But, the gaseous hydrocarbon distribution formed appears to be quite different from that reported on Ni and Pt catalysts [10]. Stepwise C2H4 adsorption can produce surface ethylidyne, ethynyl, and carbon and hydrogen atoms on the metallic Ir and their surface interactions (i.e. metathesis) at different rates as compared to other metal surfaces [6]. We thus believe that both the iridium–carbon bond strength and the silica support must play some important roles during this process. More detailed studies on these aspects are currently in progress. Nevertheless, these hydrocarbon species are not stable at higher temperatures and can be transformed or decomposed into more stable graphitic carbon deposits. Interestingly, despite their reluctance for hydrogenation these carbons can react readily with H2O produced from the dehydroxylation reaction on the catalyst surface via steam gasification [19] to form H2/CO in the second step at elevated temperature.

Conclusion

A two-step non-oxidative C2H4 conversion is carried out over silica-supported iridium catalysts. XRD patterns reveal that there is no obvious lattice expansion of the Ir nanocrystal after the C2H4 decomposition over a whole temperature range, indicative of the purely surface deposition of carbonaceous species on the supported catalyst with no inclusion of sub-layer carbon atoms. Raman, FTIR, TPR, and TPSR–MS studies reveal that methyl and higher hydrocarbons like species (CH x and C n H y ) are formed on the Ir surface at relative low ethylene decomposition temperatures (≤673 K). These lead to the formation of methane and higher hydrocarbons via surface hydrogenation, polymerization and metathesis reactions in the second hydrogenation stage. In contrast, much less reactive graphitic carbons are formed at higher ethylene decomposition temperatures (>673 K), which can give rise to H2/CO via steam gasification in the second step.

References

Bradford MCJ (2000) Two-step methane conversion to higher hydrocarbons: comment on the relevance of metal-carbon bond strength. J Catal 189:238

Ross JRH, van Keulen ANJ, Hegarty MES, Seshan K (1996) The catalytic conversion of natural gas to useful products. Catal Today 30:196

Soulivong D, Copéret C, Thivolle-Cazat J, Basset JM, Maunders BM, Pardy RBA, Sunley GJ (2004) Cross-metathesis of propane and methane: a catalytic reaction of CC bond cleavage of a higher alkane by methane. Angew Chem Int Ed 43:5366

Belgued M, Pareja P, Amariglio A, Amariglico H (1991) Conversion of methane into higher hydrocarbons on platinum. Nature 352:789

Koerts T, van Santen RA (1991) A low temperature reaction sequence for methane conversion. J Am Chem Soc 113:1281

Bond GC (1997) The role of carbon deposits in metal-catalysed reactions of hydrocarbons. Appl Catal A Gen 149:3

Suzuki T (2007) Selective ethene homologation reaction on silica supported cobalt catalyst. React Kinet Catal Lett 90:61

Suzuki T (2004) Homologation of ethylene without metathesis on silica supported ruthenium catalyst. React Kinet Catal Lett 81:327

Suzuki T, Hirai T, Hayashi S (1991) Enhancement of the ethylene conversion to propylene on reduced molybdena silica catalyst in the presence of hydrogen. Int J Hydrogen Energy 16:345

Lefort L, Amariglio A, Amariglio H (1994) Oligomerization of ethylene on platinum by a two-step reaction sequence. Catal Lett 29:125

Silvennoinen RJ, Jylhä OJT, Lindblad M, Österholm H, Krause AOI (2007) Supported iridium catalysts prepared by atomic layer deposition: effect of reduction and calcination on activity in toluene hydrogenation. Catal Lett 114:135

Yang HW, Tang DL, Lu XN, Yuan YZ (2009) Superior performance of gold supported on titanium-containing hexagonal mesoporous molecular sieves for gas-phase epoxidation of propylene with use of H2 and O2. J Phys Chem C 113:8186

Chan CWA, Xie Y, Cailuo N, Yu KMK, Cookson J, Bishop P, Tsang SC (2011) Palladium with interstitial carbon atoms as a catalyst for ultraselective hydrogenation in the liquid phase. Chem Commun 47:7971

Demir-Cakan R, Baccile N, Antonietti M, Titirici MM (2009) Carboxylate-rich carbonaceous materials via one-step hydrothermal carbonization of glucose in the presence of acrylic acid. Chem Mater 21:484

Solymosi F, Erdöhelyi A, Cserényi J (1992) A comparative study on the activation and reactions of CH4 on supported metals. Catal Lett 16:399

Mrityunjoy K, Vijayakumar PS, Prasad BLV, Gupta SS (2010) Synthesis and characterization of poly-L-lysine-grafted silica nanoparticles synthesized via NCA polymerization and click chemistry. Langmuir 26:5772

Yu XP, Chu W, Wang N (2011) Hydrogen production by ethanol steam reforming on NiCuMgAl catalysts derived from hydrotalcite-like precursors. Catal Lett 141:1228

Choudhary TV, Goodman DW (2002) Methane activation on ruthenium: the nature of the surface intermediates. Top Catal 20:35

Choudhary TV, Goodman DW (2000) CO-free production of hydrogen via stepwise steam reforming of methane. J Catal 192:316

Acknowledgments

This work was supported by the EPSRC and the authors wish to thank China Scholarships Council for a studentship to H. Yang.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Yang, H., Tsang, S.C.E. Transformation of ethylene to higher hydrocarbons on silica-supported Ir catalysts: the nature of carbonaceous deposits. Appl Petrochem Res 2, 85–91 (2012). https://doi.org/10.1007/s13203-012-0009-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-012-0009-3