Abstract

Hydraulically induced fractures provide a significant fraction of oil supply to the world from unconventional reservoirs due to their high permeability. However, these fractures might choke because of the deposition of organic and in-organic particles. Among organic particles, asphaltene deposition severely reduces reservoir permeability causing an exponential drop in production. In this work, a simulator is developed that predicts the performance of fractured reservoirs by solving the fluid flow governing equations for matrix and fractures. These flow equations were then incorporated with asphaltene deposition equations. Primarily, a numerical model is developed to predict the rate of asphaltene deposition and fracture choking in a radial geometry. It is found that asphaltene deposition could partially or completely choke fractures. Finally, the results are compared with the experimental data and determined various factors affecting fracture choking. From the detailed analysis, it is found that fracture choking is a few percent, but it increases with long production time. The sensitivity analysis was performed to investigate the effect of different influential parameters on permeability alteration of fractured reservoirs by asphaltene deposition. These parameters include fracture-to-matrix permeability ratio, production time, and asphaltene concentration. It is observed that, low fracture-to-matrix permeability ratio has a negligible effect on permeability of a reservoir. The developed model assumes negligible gravity and capillary forces. However, these forces might increase fracture choking in unconventional fractured reservoirs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fractured reservoirs are characterized with low-transmissibility and high storativity matrix, and high-transmissibility and low-storativity fractures’ network (Economides et al. 2013; Civan 2016a). Consequently, these reservoirs represent the extreme case of geological/reservoir heterogeneity. Due to constant pressure depletion in the fractures’ network, the low-permeability matrix re-charges the fractures with oil and the latter provides the necessary conduit for oil flow from the matrix to the wellbore (Civan 2016a). A substantial amount of the world’s oil production comes from these unconventional fractured reservoirs. Moreover, recently low-permeability oil shale has received a lot of attention from both the oil industry and the academia because of its hydrocarbon potentials. Therefore, it is essential to understand the mechanism of oil flow through hydraulically fractured unconventional reservoirs to better predict oil recovery from these reservoirs with complex fracture network at field-scale (Crandall et al. 2010; Khurshid et al. 2019).

Different parameters and processes could affect the flow of hydrocarbons in such complex systems, and consequently control the amount of oil recovery, sweep efficiency, and formation damage (Civan 2016a). Depending on the reservoir fluids present in these reservoirs, the fractures might have a positive or a negative effect on production and recovery factor. In cases when a single-phase oil is present, the fractures would have a positive effect on ultimate reservoir recovery through facilitating the fluid flow from the matrix to the wellbore. The latter results in an excellent sweep efficiency and well performance. Nevertheless, if the oil is produced below the bubble point pressure, the fracture might cause bypassing of oil by the free gas. This results in an early gas breakthrough in the producers and might decrease oil recovery (Economides et al. 2013). Therefore, the determination of different fracture properties in a reservoir is important for proper production planning. A number of tools and techniques were developed for fracture assessment including X-ray tomography, borehole imaging, light transmission, and confocal scanning techniques (Crandall et al. 2010). All these techniques help in determining fracture complexities including their orientation, length, width, and height.

There are two approaches to characterize/model a fracture; fracture design and flow through a fracture (Geertsma and De Klerk 1969). The fracture design requires information about the reservoir rock properties, fracturing fluid properties, direction and magnitude of tectonic, and reservoir/in situ stresses. Different fracture propagation models such as Khristinaovic–Geertsma-de Klerk (KGD) and Perkins–Kem–Nordgren (PKN) use these properties and stresses to predict fracture growth (Perkins and Kern 1961). Similarly, for fluid flow through fractures a number of mathematical models have been developed with different approaches. Goddin Jr. et al. (1966) proposed an approach that is based on cross-flow in layers. Warren and Root (1963) and Kazemi et al. (1976) proposed dual-porosity models. These models are based on matrix–fracture transfer terms. However, when studied at reservoir-scale, this approach is computationally expensive. This is due to the computation to flow through hundreds or even thousands of fractures, which takes a lot of computing time and storage. Detournay (2004) used a simple geometry by incorporating the extension of cracks with high-pressure fluid. On the other hand, Ingham et al. (2006) considered a composite set of channel with perpendicular orientation to the wellbore. Moreover, Rozhko et al. (2007) used simplified crack model to determine different mechanisms, i.e. change of reservoir stresses, pore pressure, and the saturations of different phases. Therefore, the simulator developed in this study considers fluid flow through fractures by representing fractures as parallel walls and incorporating the typical governing equations.

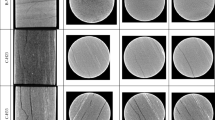

On the other hand, it has been observed that the flow through fractures is not so simple, but rather too complex. Thus, it is crucial to perform detailed studies to determine different flow related problems in fractured reservoirs. After detailed analysis of experimental and field observations, it has been perceived that pressure depletion and the related reservoir fluid change might cause various technical difficulties. These difficulties include, but not limited to, fracture choking, organic deposition, decreased flow rate, increased water-cut, water-coning and fingering, and mobility control issues both in the porous and fractured media. The experimental results of Zekri and Shedid (2004) showed that high concentration of asphaltene plugs the reservoir pores and decreases the permeability. Moreover, in fractured reservoirs under production, pressure drop and solvent/chemical injection might increase asphaltene deposition on the face/walls of the fracture leading to fracture gap reduction and choking (Farzaneh et al. 2010). Soulgani et al. (2011) showed that the deposition of asphaltene decreases fracture width, total fluid flow path, and fluid pressure, and increases fluid velocity. Asphaltene deposition is cumbersome formation damage problem as it occurs in the rock pores as well as the production facilities, which leads to major technical obstacles for oil productivity (Juyal et al. 2013). Pathak et al. (2012) stated that the asphaltene deposition is greater for light paraffinic oils than for heavy ones. Similarly, Telmadarreie and Trivedi (2017) observed the significant adverse effect of fracture permeability reduction by asphaltene as shown in Fig. 1a, b.

Illustrations of asphaltene deposition and subsequent fracture choking from glass micromodel experiments (Telmadarreie and Trivedi 2017)

Therefore, the goal of this study is to develop a model that not only considers fluid flow through a matrix and fractures, but also asphaltene deposition in these fractures and the consequent fracture choking. To achieve this objective, a simulator is developed using MATLAB commuting program and the derived equations were solved with finite difference method to model asphaltene deposition in fractured reservoirs. The derived model can serve as a useful and efficient tool in providing an insight into permeability impairments in fractured reservoirs. Sensitivity analyses are performed as well on influential parameters including fracture-to-matrix permeability ratio, production time, and asphaltene concentration in reservoir fluid. The latter helps to control or minimize fracture choking with the deposition of asphaltene in matrix and fractures.

Fracture choking mechanism

After a certain pressure drop and depletion, the reservoir fluid composition might change (Schlumberger 2018). This change decreases the area of fluid flow in the fractures causing flow impediment. This flow impediment is mainly caused by the deposition of asphaltene in the fracture. This asphaltene deposition will occur in the following stages (Fig. 2a):

-

1.

Precipitation This is the first stage of asphaltene deposition where the pressure drop prompts the appearance of asphaltene fines/flocs in the reservoir with possible alteration of the oil viscosity. The amount of precipitation depends on factors such as pressure, temperature, and molar fraction of asphaltene by weight in the solution.

-

2.

Flocculation This is second stage in which the fines formed during precipitation aggregate together, creating large particles known as flocs. This stage might cause significant change in the reservoir fluid composition with pronounced change in fluid density.

-

3.

Deposition In this stage, the created flocs exchange between the reservoir fluid and the reservoir rock surface. These flocs might adsorb on the reservoir rock fracture surface or inside the porous media leading to its nucleation and growth as shown in Fig. 2a. The asphaltene nucleation is the process in which the small molecules of asphaltene are arranged in a characteristic pattern and form a site where additional particles deposits and the asphaltene grows. However, during deposition, nucleation, and asphaltene growth processes, some of the asphaltene flocs might desorb. This desorption occurs when the drag forces exceeds the attractive forces between asphaltene particles (Poulichet and Garbin 2015). Moreover, depending upon the size of asphaltene flocs, the fractures or pores might be plugged with asphaltene and the surface area of the asphaltene would grow. Therefore, asphaltene deposition in fractures might reduce average fracture width and pore radius (Fig. 2a).

-

4.

Fracture choking and formation damage This is the last stage in fractured reservoirs where the deposition of asphaltene leads to reduction in fracture permeability and its flow area as shown in Fig. 2b. The asphaltene deposition can also initiate a change of reservoir wettability from water wet to oil wet. This change might cause a further reduction of oil recovery and sweep efficiency (Lee and Lee 2019).

Asphaltene deposition and formation damage model

The flow of fluid through fractured reservoirs is contributed by both matrix and fractures, as mentioned above. Usually, the fractures have high permeability and thus, they increase fluid production. However, in some cases when the resistance offered by the fracture is high, then it is important to consider the flow of fluid through the porous/matrix. The fluid flow through porous media is modeled by the famous Darcy’s law, which describes the flow through a media under a certain pressure gradient (Eq. 1).

where Q is the rate of fluid flow through porous media in volume per unit time, k is permeability in milli-Darcy, A is the cross-sectional in m2, μ is the fluid viscosity in cP, and \(\frac{{{\text{d}}p}}{{{\text{d}}r}}\) shows the change in pressure per radial distance from the wellbore. For fluid flow through the fractured part of the reservoir, Navier–Stokes equation is solved by Sarkar et al. (2004) through presenting fractures as parallel plates. However, their cubic solution is applicable only for highly fractured reservoirs and they ignored the effect of gravity on fluid flow through fracture.

where Q is rate of fluid flow through fracture in volume per unit time, w is fracture width in meter, A is the cross-sectional area in m2, h is height in m, and μ is the fluid viscosity in cP.

Regarding, asphaltene deposition in fractured and porous media, it is observed that reservoir pressure drops with the production of hydrocarbons. This pressure drop might change/disturb the equilibrium of oil–water–gas interface with definite change in pressure, temperature, and reservoir fluids composition. The change in one or all of these parameters can cause a wettability transformation and separation of solid, liquid, and gas. These processes might cause the deposition of asphaltene in fractures and pores of the reservoir. Field engineers and scientists have performed a number of experiments and developed different mathematical models to describe asphaltene deposition (Gruesbeck and Collins 1982; Wang and Civan 2001; Civan 2016b; Khurshid et al. 2019; Lee and Lee 2019). Therefore, when oil is produced from a reservoir, its flow in the presence of asphaltene is described by the following continuity equation as given in “Appendix”.

where S is saturation in fraction, ρ is density in kg/m3, X is asphaltene concentration, ϕ is porosity in fraction, v is fluid flow in m/s, w is mole concentration, V is deposited concentration, and t is time in s. Subscripts a, o, l, g, as, and asp refer to oil, liquid, gas, aqueous, asphaltene, and suspended asphaltene, respectively.

It is observed that asphaltene deposition in fractures/porous media might plug pore-throat and damage the formation by reducing its porosity and permeability. Thus, decreasing overall well performance and its flow capacity. To simulate asphaltene deposition, Gruesbeck and Collins (1982) developed a model for single-phase flow and observed that asphaltene deposition is controlled by its physical and chemical properties, and concentration in the reservoir fluid. Wang and Civan (2001) modified their model and showed that asphaltene deposition is based on its concentration, depositional properties, and its trapping mechanism in fractures, vugs, and reservoir pores. They mentioned that asphaltene concentration, liquid saturation, and liquid superficial velocity are the important parameters and derived the following equation:

where Gas is the volume fraction of deposited asphaltene, γ is plugging coefficient, Sl is saturation of liquid, αas is coefficient of asphaltene surface deposition, Xas is asphaltene concentration in liquid phase, βas is entrainment rate coefficient for asphaltene, vl is the interstitial velocity, and vcr.l is the critical interstitial velocity for the liquid phase.

Asphaltene due to its infusibility (decomposition after heating and leaving behind carbon residue) is regarded as the most difficult and severe problem in fluid flow dynamics. Whenever it deposits on the rock surface, it changes reservoir wettability reducing recovery and sweep efficiency. Soulgani et al. (2011) mentioned that asphaltene deposition on a surface is controlled by two mechanisms. These mechanisms are mass transfer and chemical reactions for flocs appearance, precipitation, and deposition of asphaltene. They performed a number of experiments and observed that asphaltene deposition decreased with an increase in injected fluid velocity, and this phenomenon indicates that mass transfer is not the controlling mechanism. Moreover, it is also observed that heat transfer coefficient decreases at a higher rate with increasing temperature and thus asphaltene deposition increased. It shows that asphaltene deposition on a surface is controlled by temperature and thus chemical reaction is the dominant mechanism. A number of models were investigated (Gruesbeck and Collins 1982; Wang and Civan 2001; Khurshid and Choe 2015; Civan 2016b; Gharbi et al. 2017; Khurshid and Choe 2018; Lee and Lee 2019). However, in this study our interest is to model the deposition of asphaltene due to chemical interactions of injected fluid and oil. Therefore, the asphaltene deposition model is used to determine asphaltene deposition in Eq. 5 and it is combined with Eq. 4 to formulate the net volume fraction of asphaltene deposition that will occur in the reservoir. Table 1 presents the values for different coefficient for asphaltene deposition.

where Zas is the mass of asphaltene deposition per unit area on rock surface (kg/m2), K is reaction rate coefficient (kg/ms)2, Xas is concentration of asphaltene, E is activation energy in J/mol, R is universal gas constant in J/mol K, T is reservoir temperature in K, and v is fluid velocity in m/s. The various tuning parameters are flow rate of injected fluid, asphaltene concentration, its surface deposition, plugging and entrainment coefficients. These parameters were adjusted until the simulated conditions represent typical reservoir conditions.

The parameters that were carefully monitored and were modified to characterize reservoir conditions are concentration of asphaltene, reservoir porosity and permeability, and production time. The different parameters used in this study are given in Table 1. Therefore, after the deposition of asphaltene, the surface area of the fractures and pores will be modified in different regions. This deposition will decrease the reservoir permeability in the neighborhood of the production well. This change in permeability is shown by the following equations to determine the average change in porosity and permeability of the reservoir (Khurshid et al. 2018):

where k is reservoir permeability, ϕ is reservoir porosity, and superscript e represents the exponent with values of 3, 5, and 12 representing clean formations, anhydrite precipitation, and for coreflooding experiments showing the technical time scale for anhydrite dissolution and precipitation, respectively. It should be noted that an e value of 3 was used in this work and subscript i represents the initial stage.

However, the fracture permeability is independent of the matrix porosity. Hence, the reduction in fracture permeability was determined by calculating the amount of asphaltene deposition. The fracture will choke due to asphaltene precipitation, flocculation, and deposition leading to reduction in its conductivity. This fracture conductivity/permeability reduction will decrease pressure and fluid flow through the fracture. Therefore, the pressure drop and skin through the fracture is given by Eqs. 8 and 9, respectively (Economides et al. 2013).

where Δp is pressure drop in psi, n is conversion factor, B is formation volume factor in bbl/STB, q is flow rate in STB/day, μ is viscosity in cP, k is permeability in m2, h is the height in m, s is skin factor, and x is fracture half-length in m. It should be noted that subscripts c and f denote choked and fracture, respectively. It is important to mention that the asphaltene will deposit inside the fracture, thus it will affect only the pressure drop caused by fluid flow through the fracture. Figure 3 shows the flowchart for asphaltene deposition and fracture choking.

In this study, the finite difference method was used to solve the developed model. The results of simulation work was used to develop a reliable term for the deposition of asphaltene on a surface. The surface deposition model presented in this work was utilized to improve the modeling of asphaltene deposition in porous media. Equation 4 that shows the kinetic deposition of asphaltene is modified by introducing the new term for surface deposition. The resulting model was used to compare the results of coreflooding for asphaltene deposition. This study utilized radial geometry for fluid flow and asphaltene deposition in fracture and matrix. The grid refinement was done to capture the physics of the problem, the number of grid/cells were varied, where 10 cells resulted in least numerical error. In this model, cells number 10 and 1 represent the point of production and the reservoir limit/boundary, respectively. Moreover, cells number 9 are 10 represent the fracture half-length with permeability 10 times that of the matrix represented by cells number 1 through 8 (Fig. 4).

The radial geometry was selected because it is computationally stable and efficient, requiring less numerical effort as compared to other geometries. Moreover, it mimics the reservoir configuration in a practical manner. Regarding asphaltene deposition in this geometry, it is observed that the area affected by asphaltene depends on the properties of crude oil and asphaltene, and the point of asphaltene deposition. The asphaltene may deposit in the fracture and pores, i.e., on either side surfaces, or top/bottom, and in worst case, in the throats of both fracture and pore. The deposition of asphaltene in pore throat is considered the most problematic because the throat is the narrowest point and they are the main oil pathways for connecting fractures and matrix to the wellbore as shown in Fig. 2b. It is important to mention that asphaltene amount and distribution control the flow and capillary pressure behavior of the whole reservoir.

Fracture choking observations and validation

Modeling of asphaltene deposition is difficult and complex, as it depends on the reservoir rock properties, composition of formation water and oil, reservoir thermodynamic conditions, and flow rate of the injected fluids. To validate the numerical model, the most accepted way is to validate the numerical/simulation results with experimental data. In this study, our simulation results were compared with the experimental work performed by Soulgani et al. (2011). This work was selected as the researchers used asphaltene in their coreflooding experiment and measured its effect on formation damage. The details of the core sample used in the simulation runs is given in Table 1.

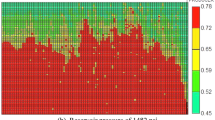

After performing the simulation run for injecting fluid at 2.76 × 10−9 m3/s, the simulation results were compared with the experimental data as shown in Fig. 5. The latter figure presents a good match between experimental and simulation results. From the results, it can be observed that the asphaltene deposition has adverse effects on formation permeability at 80 °C. The simulation indicates that thermal reactions, resulted in a decrease in the rock porosity and permeability. This is supported by Fig. 5, which shows that with the increase in pore volume, the permeability ratio of initial to altered permeability decreases, which indicates a formation damage. Further explanation on the asphaltene deposition will be provided in the results and discussion section. It is also evident from the figure that the formation permeability decrease by 45%. This decrease is expected to have a pronounced negative impact on oil production from a reservoir. It is worth highlighting that a grid sensitivity analysis was performed where 10 gridblocks were enough to capture the physics and validate the experimental results given by Soulgani et al. (2011) to capture asphaltene deposition in porous media.

Comparison of results with experimental data from Soulgani et al. (2011)

Therefore, the developed simulator results are validated against formation damage experimental data and can be used further to predict the effect of this damage on oil recovery from an oil reservoir. It is worth mentioning that the problem presented and solved in this study is unique as the authors did an extensive literature review and found limited laboratory work conducted on formation damage during asphaltene deposition and the related oil recovery.

Results and discussions

Different factors that might affect asphaltene deposition were analyzed with the derived model and developed simulator. Asphaltene deposition in fractured reservoirs was predicted along with different parameters such as fracture-to-matrix permeability ratio, production time, and asphaltene concentration. The values of these parameters were fixed to represent typical conditions of a reservoir (Table 1). In this study, the simulator was run for a pre-determined period and the different reservoir parameters were modified accordingly. Then, the changes in reservoir permeability were investigated. This section includes a description of asphaltene deposition effect on fracture chocking. Also, sensitivity analysis of different parameters effect on asphaltene deposition in fractures are discussed including fracture-to-matrix permeability (kf/km), production time, and asphaltene concentration. Moreover, a comparison between asphaltene depositions in fractured versus non-fractured reservoirs is presented.

Asphaltene deposition effect on fracture choking

This effect is illustrated in Fig. 6, which shows permeability alteration (k/ki ratio) versus cell numbers with and without asphaltene presence in the crude oil. It can be observed that in the absence of asphaltene, there will be no change in the permeability of both parts of the reservoir: fractured and matrix. However, as soon as asphaltene is present, there will be 40% decrease in fracture permeability when the fracture permeability is 10 times the matrix permeability. In addition, this asphaltene deposition will change the behavior of fluid flow in the reservoir due to changes in the wettability behavior of the reservoir. The overall effect of asphaltene deposition is reduction in the sweep efficiency of oil that leads to the reduction of oil recovery efficiency. Therefore, asphaltene presence can yield severe damage to the reservoir by reducing its porosity and permeability, but more importantly, it damages the fractured part of the reservoir. The latter is much more affected by the “maximum level” of plugging. As also seen from the figure, the asphaltene deposition effect on permeability becomes less pronounced as reservoir limit/boundary is reached. It should be noted that this simulation case represents the base case with input values from Table 1; however, for the next simulation runs, some parameters were modified as will be further indicated below.

Sensitivity analysis

In this section, a sensitivity analysis study was performed in order to investigate the effect of different selected parameters on asphaltene deposition in fractured reservoirs. These parameters include fracture-to-matrix permeability (kf/km), production time, and asphaltene concentration.

Fracture-to-matrix permeability effect

The effect of fracture-to-matrix permeability (kf/km) on permeability alteration with radial distance from the wellbore is depicted in Fig. 7. Asphaltene concentration, reservoir temperature, and fluid flow rate were held constant. However, the fracture-to-matrix permeability ratio was changed by a factor of 10, 100 and 1000, respectively. It is evident from Fig. 7 that the permeability contrast scenarios for all of these three values are affected by asphaltene deposition within the fractured portion of the reservoir. It is also observed that all of these scenarios have the same amount of permeability decrease that is 10 percent. Consequently, fracture-to-matrix permeability has insignificant effect on asphaltene deposition in this fractured reservoir model.

Production time effect

In order to investigate the effect of the period of oil production on asphaltene deposition, two simulation runs were performed for 1 and 10 years. The results are depicted in Fig. 8. The reservoir parameters were kept constant with fracture permeability 10 times the matrix permeability, matrix porosity at 20%, asphaltene concentration at 5.3% by weight. It is evident from the figure that the asphaltene deposition will cause a permanent formation damage phenomenon in the reservoir especially in the fractured part of the reservoir near the wellbore. By the end of 10 years, the fracture will be completely choked with asphaltene. Therefore, after long period of oil production, the asphaltene deposition issue will become more critical. With asphaltene precipitation and deposition, the oil will lose the heavy components and consequently, its viscosity in the reservoir is expected to decrease, which might lead affect oil mobility (Ghanavati et al. 2013).

Asphaltene concentration effect

The effect of asphaltene concentration on the k/ki ratio versus cell number is presented in Fig. 9. The results show that asphaltene concentration in reservoir fluid has a severe effect on the fractured reservoir performance. With the increase of asphaltene concentration, the fracture permeability will decrease by many folds. At 5.3% concentration, the fracture permeability decreases by 40% after 1 year of production. When asphaltene concentration was doubled to 10.6%, the fractured permeability decreased by 60% for the same period of injection. Such a reduction in fracture permeability could drastically decrease oil production from fractured reservoirs. These findings of asphaltene deposition in fractured reservoirs are consistent with the experimental findings of Zekri and Shedid (2004). The authors performed experiments on fractured cores with crude oil containing 0.1, 0.2, and 0.4 percent asphaltene by weight. They found that the increase in asphaltene concentration causes an increase in formation damage because of the high amount of asphaltene deposition that might plug or choke the fracture by decreasing its permeability.

Fractured versus non-fractured reservoirs

In this case, simulation runs were performed in order to compare the performance of fractured and non-fractured reservoirs in the presence of asphaltene deposition. Figure 10 shows the effect of pressure drop in fractured and non-fractured (matrix) reservoirs. It can be observed that the non-fractured reservoir has higher pressure drop than the fractured one. The pressure drop in fractured reservoir is 96 psi, while in the non-fractured is 142 psi at the constant production rate of 600 STB/day with similar fluid properties. Details analysis showed that matrix reservoirs have high pressure drop because of low permeability and radial flow regime in the near wellbore region. However, in fractured reservoirs there is less pressure drop because of high permeability and linear flow. It is worth mentioning that the pressure drop data is consistent in both fractured and non-fractured models for cell numbers 1–8. This is because in both models these cells represent a matrix; however, the difference starts in cells 9 and 10 because these represent a fracture in the fractured model and a matrix in the non-fractured model.

The effect of permeability reduction in fractured and non-fractured reservoirs due to asphaltene deposition is shown in Fig. 11. It is evident from this figure that the decrease of permeability due to asphaltene deposition in non-fractured reservoir is 60% while in fractured reservoirs is 20%. However, the effect of asphaltene deposition is more detrimental in fractured reservoirs, because the fractures are the only pathways in these reservoirs. Once asphaltene deposits in these fractures, they will be choked, and hydrocarbon production will decrease exponentially. In addition, asphaltene deposition will narrow down the fracture width and the fracture will become bottlenecked. Once the fracture has bottlenecked, the fracture length will reduce and it will make the whole reservoir bottlenecked. Thus, these processes will decrease wellbore flowing pressure, reducing well productivity, and reservoir recovery efficiency significantly.

Summary and conclusions

During fluid production from fractured unconventional reservoirs, the reservoir fluid equilibrium is disturbed and it might cause the appearance and creation of asphaltene fines. These fines form flocs that after deposition could decrease fractures permeability in the wellbore vicinity. In this work, a numerical model was developed and successfully used to determine the effect of asphaltene deposition on permeability of fractured reservoirs. The main findings of this work can be summarized as follows:

-

The developed model showed that asphaltene deposition could cause partial or complete fracture choking in unconventional reservoirs.

-

Sensitivity analysis was performed on permeability alteration of fractured reservoirs by asphaltene deposition through considering various parameters and found three influential parameters; fracture-to-matrix permeability ratio, production time, and asphaltene concentration.

-

Long production time and high asphaltene concentration have adverse effect on fracture permeability while matrix permeability was not much affected.

-

Fracture-to-matrix ratio has a negligible effect on the simulated fractured reservoir model.

-

Fractured reservoirs experience less damage compared to non-fractured ones; however, the damage effect is more detrimental in them where fractures are the main conduits for oil flow.

Abbreviations

- A :

-

Reservoir area (m2)

- B :

-

Formation volume factor (res-bbl/STB)

- d :

-

Asphaltene deposition rate

- E :

-

Activation energy (J/mol)

- f :

-

Fracture width (m)

- G :

-

Deposition rate of asphaltene

- h :

-

Height (m)

- k :

-

Reservoir permeability (m2)

- K :

-

Reaction rate coefficient

- n :

-

Conversion factor

- P :

-

Reservoir pressure (psi)

- q :

-

Flow rate (STB/day)

- Q :

-

Fluid flow rate (m3 per unit time)

- R :

-

Gas constant (J/mol K)

- s :

-

Skin factor

- S :

-

Saturation (%)

- t :

-

Time (h)

- T :

-

Reservoir temperature (K)

- v :

-

Fluid flow rate (kg/h)

- V :

-

Volume (m3)

- w :

-

Width of fracture (m)

- x :

-

Fracture half-length (m)

- X :

-

Concentration

- Z :

-

Rate of asphaltene deposition on fracture face

- μ :

-

Reservoir fluid viscosity (cP)

- ρ :

-

Density (kg/m3)

- ϕ :

-

Porosity (%)

- γ :

-

Plugging coefficient

- α :

-

Asphaltene surface deposition coefficient

- β :

-

Asphaltene Entrainment rate coefficient

- a:

-

Aqueous

- as:

-

Asphaltene

- asp:

-

Suspended asphaltene

- c:

-

Choked

- cr:

-

Critical

- f:

-

Fracture

- g:

-

Gas

- i:

-

Initial

- l:

-

Liquid

- o:

-

Oil

References

Civan F (2016a) Reservoir formation damage fundamentals, modeling, assessment, and mitigation, 3rd edn. Gulf Publishing Company, Houston

Civan F (2016b) Modified formulations of particle deposition and removal kinetics in saturated. Transp Porous Med 111(2):381–410

Crandall D, Ahmadi G, Smith HD (2010) Computational modeling of fluid flow through a fracture in permeable rock. Transp Porous Med 84(2):493–510

Detournay E (2004) Propagation regimes of fluid driven fractures in impermeable rocks. Int J Geomech 4(1):34–45

Economides MJ, Hill AD, Economides CE, Zhu D (2013) Petroleum production systems, 2nd edn. Pearson Inc., New Jersey

Farzaneh SA, Kharrat R, Ghazanfari MH (2010) Experimental study of solvent flooding to heavy oil in fractured five-spot micro-models: the role of fracture geometrical characteristics. J Can Pet Technol 49(3):36–43

Geertsma J, De Klerk F (1969) A rapid method of predicting width and extent of hydraulically induced fractures. J Pet Technol 21(12):1571–1581

Ghanavati M, Shojaei MJ, Ramazani AS (2013) Effects of asphaltene content and temperature on viscosity of iranian heavy crude oil: experimental and modeling study. Energy Fuels 27:7127–7232

Gharbi K, Benyounes K, Khodja M (2017) Removal and prevention of asphaltene deposition during oil production: a literature review. J Petrol Sci Eng 158(11):351–360

Goddin CS Jr., Craig FF Jr., Wilkes JO, Tek MR (1966) A numerical study of waterflood performance in a stratified system with crossflow. J Pet Technol 18(6):765–771

Gruesbeck C, Collins RE (1982) Entrainment of deposition of fine particles in porous media. SPE J 22(6):847–856

Ingham DB, Al-Hadhrami AK, Elliott L, Wen X (2006) Fluid flows through some geological discontinuities. J Appl Mech 73(1):34–40

Juyal P, McKenna AM, Fan T, Cao T, Rueda-Velasquez RI, Fitzsimmons JE, Yen A, Rodgers RP, Wang J, Buckley JS, Gray MR, Allenson SJ, Creek J (2013) Joint industrial case study for asphaltene deposition. Energy Fuels 27(4):1899–1908

Kazemi H, Merrill LS, Porterfield KL, Zeman PR (1976) Numerical simulation of water–oil flow in naturally fractured reservoirs. SPE J 16(6):317–326

Khurshid I, Choe J (2015) Analysis of asphaltene deposition, carbonate precipitation, and their cementation in depleted reservoirs during CO2 injection. Greenh Gas Sci Technol 5(5):1–11

Khurshid I, Choe J (2018) An analytical model for dissolution of deposited asphaltene during CO2 injection from porous media. Int J Oil Gas Coal Technol 18(3/4):338–352

Khurshid I, Al-Attar H, Alraeesi AR (2018) Modeling cementation in porous media during waterflooding: asphaltene deposition, formation dissolution and their cementation. J Petrol Sci Eng 161:359–367

Khurshid I, Al-Shalabi EW, Al-Attar H, Al-Neaimi A (2019) Characterization of formation damage and fracture choking in hydraulically induced fractured reservoirs due to asphaltene deposition. Paper SPE 198628, SPE Gas & Oil Technology Showcase and Conference, Dubai, UAE

Lee JH, Lee KS (2019) Investigation of asphaltene-derived formation damage and nano-confinement on the performance of CO2 huff-n-puff in shale oil reservoirs. J Pet Sci Eng 182:10634

Pathak V, Babadagli T, Edmunds N (2012) Mechanics of heavy-oil and bitumen recovery by hot solvent injection. SPE Reserv Eval Eng 15:182–194

Perkins TK, Kern LR (1961) Widths of hydraulic fractures. J Pet Technol 13(9):937–949

Poulichet V, Garbin V (2015) Ultrafast desorption of colloidal particles from fluid interfaces. Proc Natl Acad Sci USA 112(19):5932–5937

Rozhko AY, Podladchikov Y, Renard F (2007) Failure of patterns caused by localized rise in pore-fluid overpressure and effective strength of rocks. Geophys Rev Lett 34(22):1–5

Sarkar S, Toksoz MN, Burns DR (2004) Fluid flow modeling in fractures. Massachusetts Institute of Technology, Earth Resources Laboratory, Cambridge

Schlumberger (2018) ECLIPSE reservoir simulation software: technical description, 1st edn. Schlumberger

Soulgani SB, Tohidi B, Ahmadi JM, Rashtchian D (2011) Modeling formation damage due to asphaltene deposition in the porous media. Energy Fuels 25(2):753–761

Telmadarreie A, Trivedi J (2017) Dynamic behavior of asphaltene deposition and distribution pattern in fractured porous media during hydrocarbon solvent injection: pore-level observations. Energy Fuels 31(9):907–9079

Wang S, Civan F (2001) Productivity decline of vertical and horizontal wells by apshaltene depsotion in petroleum reservoirs. In: Paper SPE 64991, SPE international symposium on oilfield chemistry, Houston, Texas, USA

Warren JE, Root PJ (1963) The behavior of naturally fractured reservoirs. SPE J 3(3):245–255

Zekri AY, Shedid AS (2004) The effect of fracture characteristics on reduction of permeability by asphaltene precipitation in carbonate formation. J Pet Sci Eng 42(2–4):171–182

Acknowledgements

The authors wish to acknowledge Khalifa University of Science and Technology for the support and encouragements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The flow characteristics of oil, gas, and aqueous phases are described by the following continuity equations for different phases:

The summation of Eqs. (10) to (12) gives:

If we neglect the diffusion, then the above equations for the various phases can be written as:

If it is assumed that the injection rate is constant, then Eq. (14) is rewritten as:

Thus, the equation of mass balance for the asphaltene deposition during production is

where S is saturation in fraction, ρ is density in kg/m3, X is asphaltene concentration, ϕ is porosity in fraction, v is fluid flow in m/s, w is mole concentration, V is deposited concentration, and t is time in s. Subscripts a, o, l, g, as, and asp refer to oil, liquid, gas, aqueous, asphaltene, and suspended asphaltene, respectively.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khurshid, I., AlShalabi, E.W., Al-Attar, H. et al. Analysis of formation damage and fracture choking in hydraulically induced fractured reservoirs due to asphaltene deposition. J Petrol Explor Prod Technol 10, 3377–3387 (2020). https://doi.org/10.1007/s13202-020-00910-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00910-8