Abstract

The study presented in this paper has multiple objectives. First, a simulation model for partially naturally fractured reservoirs under solution gas drive is developed. The model considers the major key parameters controlling fluid flow in the reservoir, including fracture intensity and distribution, instantaneous gas/oil segregation due to vertical capillary continuity, gas/oil gravity drainage, and reinfiltration of the drained oil to the lower matrix. Once the model is well-established, it is used to study the reservoir performance under two recovery processes: primary depletion and gas injection. A detailed investigation of the sensitivity of the ultimate oil recovery to the fracture intensity, oil production rates, and gas injection rates is performed. The findings of this study indicate that the ultimate oil recovery of low-fracture intensity reservoirs subjected to the depletion drive process is insensitive to production rates. However, for moderate- to high-fracture intensity reservoirs and low production rates, the recovery increases with increasing fracture intensity. Conversely, for moderate- to high-fracture intensity reservoirs and high production rates, the recovery is not significantly affected. For the gas injection mechanism, it is found that the ultimate oil recovery is a function of both the fracture intensity and gas injection rate. Furthermore, three fracture intensity ranges are identified: low, medium, and high. For the low- and high-fracture intensity ranges, the recovery increases with increasing gas injection rates and fracture intensity. However, for the medium fracture intensity ranges, the recovery behaves differently. It increases at low gas injection rates and decreases at high injection rates as the fracture intensity increases. New equations relating the cumulative oil production to the production rates, gas injection rates, and fracture intensity are also presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Naturally fractured reservoirs (NFRs) exist in all types of reservoir lithologies, throughout geologic stratigraphic columns worldwide. Firoozabadi (2000) classified fractured reservoirs into three types with respect to fracture pore volume (PV). The first type of fracture PV is infinitesimal in comparison to the matrix PV; thus, most of the hydrocarbon fluids are stored in the matrix pore spaces. The second type of fracture PV could carry from 10 to 20% of the hydrocarbon fluids; nonetheless, the largest hydrocarbon volume is stored within the matrix pore spaces. More than 50% of the hydrocarbon fluids are stored in the third type of fractures. The complex anisotropy and heterogeneity of NFRs make their modeling and characterization extremely challenging. Previous studies of NFRs assume an idealized fully fractured network, which is inconsistent with actual geological structures. Most NFRs are fractured to a certain extent. The fractures have various degrees of aperture and may be entirely closed due to mineralization, which leads to a reservoir that is, effectively partially fractured. An additional complication of the modeling process arises when the fractures are neither confined to limited zones nor uniformly distributed over the entire reservoir. The connectivity of fractures plays a dominant role in the fluid flow in a reservoir. An NFR with spatially random fracture scattering is known as a partially naturally fractured reservoir (PNFR). Fracture intensity (FI) is a key parameter frequently used to describe the spatial heterogeneity in PNFRs (Qasem et al. 2002). Fractures provide the main fluid flow paths from a reservoir toward the production wells. However, under more hydrodynamic flow conditions, the effect of fractures is more dominant especially when they form a connected network. Capillarity, gravity, externally applied pressure gradients, fluid types and rock expansion are specific factors that play dominant roles in controlling the matrix–fracture fluid flow.

The behavior of PNFRs is quite different from that of conventional reservoirs. The fundamental difference between the recovery performances of these two reservoir types is attributed to the large discrepancy among the matrix and fracture capillary pressures (van Golf-Racht 1982; Saidi 1987; Aguilera 1995). Oil recovery of NFRs substantially contributes to the gas/oil gravity drainage phenomenon. The efficiency of this phenomenon is affected by two mechanisms known as reinfiltration and capillary continuity. The instantaneous gas/oil segregation due to vertical capillary continuity and reinfiltration of the drained oil in the lower matrix adversely affects oil recovery (Qasem and Ershaghi 1996). The fluid flow behavior in PNFRs with a gas/oil system presents specific problems due to the partial and irregular vertical capillary continuity of the fractures. Furthermore, due to partial vertical capillary continuity, the shape and effect of secondary gas caps formed in PNFRs are quite different from those in totally fractured reservoirs.

The novelty of this work stems from modeling PNFRs using percolation theory to map the FI of the reservoir. This paper also presents a detailed investigation of the effects of FI on the performance of solution gas drive reservoirs subjected to depletion drive and gas injection processes. Our study demonstrates that gravity drainage, capillary continuity, and FI are key parameters controlling reservoir performance and should be incorporated in the simulation of PNFRs. Furthermore, this study illustrates that the ultimate oil recovery of low-FI reservoirs subjected to the depletion drive process is insensitive to production rate. However, for moderate- to high-FI reservoirs and low production rates, the recovery is significantly affected by the FI and production rate. For example, at a given production rate, the recovery increases with increasing FI. Additionally, at a certain FI, the recovery is higher at lower production rates. On the other hand, for moderate- to high-FI reservoirs and high production rates, the recovery is not significantly affected. For instance, at a given production rate, the recovery decreases as FI increases. Additionally, for a given FI, the recovery decreases as the production rate increases. For the gas injection mechanism, it has been found that the recovery is a function of both FI and gas injection rate. Furthermore, three FI ranges have been identified: low, medium, and high. For the low- and high-FI ranges, the recovery increases with simultaneous increases in the gas injection rate and FI. However, for the medium FI ranges, the recovery increases at low gas injection rates and decreases at high injection rates as FI increases. New equations relating cumulative oil production to production rates, gas injection rates, and FI are also presented.

This paper is organized according to its major objectives as follows: We first review the general concepts governing the simulation models of NFRs and PNFRs and the related research studies. Next, we illustrate the methodology used to develop the PNFR simulation model, providing insight into its major elements. Then, we investigate the various mechanisms that play dominant roles in the oil recovery of solution gas drive reservoirs and the performance of PNFRs under primary depletion and gas injection processes.

Modeling of naturally fractured reservoirs

The Simulation of NFRs is a challenging endeavor from both reservoir delineation and simulation viewpoints. The available NFR models can be classified into two major categories: dual-porosity and dual-permeability models. The former model was initially presented by Barenblatt et al. (1960). In this model, the fractures constitute major fluid flow conduits, and the matrix acts as sinks. Warren and Root (1963) adopted the dual-porosity model to present a well testing technique assuming pseudo-steady state matrix/fracture fluid transfer. Later, Kazemi (1969) presented the first multiphase dual-porosity model using the Warren and Root method. This scheme has been vastly adopted to construct numerical simulators for NFRs (Thomas et al. 1983; Peng et al. 1990). Arana-Ortiz and Rodriguez (1996) presented a semi-implicit reservoir simulation model for NFRs. The equation system created by this methodology is analogous to a fully implicit black oil equation system formulation. The implicitness level of the suggested technique is close to those of implicit pressure and explicit composition/saturation (IMPECS) and fully implicit methods. Thus, semi-implicit reservoir simulation offers an alternate scheme to situations where the IMPECS technique is unrealistic and the fully implicit technique is time consuming.

The dual-porosity model is inadequate in accounting for gravity effects and the associated fluid exchange processes. Many modifications to this model have been proposed to consider the local matrix–fracture and matrix–matrix fluid exchange processes under multiphase flow conditions. The modifications included the gravity segregated model, the subdomain method, and the dual-permeability model (Por et al. 1989; Fung and Collins 1991; Tan and Firoozabadi 1995). Rubin (2007) used finely gridded single-porosity models to predict the performance of gravity drainage in fractured gas caps/gas-invaded regions with and without block-to-block reinfiltration. These models were considered focal solutions in developing the subdomain dual-permeability/dual-continua (SD–DK) model. The adjustment of the standard subdomain model can simulate the gravity drainage fluid flow caused by direct matrix flow and matrix-to-matrix reinfiltration from fractures without using pseudo-functions. De Guevara-Torres et al. (2009) adjusted the conventional dual-porosity model to account for gravity drainage and oil reinfiltration. The model adjustment included fluid interaction expressions between the matrix and the fractures. Triple-porosity models were introduced to model naturally fractured vuggy reservoirs. These models considered the matrix, fracture, and vug porosities (Abdassah and Ershaghi 1986; Ganzer 2003; Camacho et al. 2005). Recently, Bakyani et al. (2018) designed a simulator for fractured dry gas reservoirs using the implicit pressure and explicit saturation method (IMPES). The corresponding computer code can be applied for single-porosity/single-permeability, dual-porosity/single-permeability, and dual-porosity/dual-permeability problems. Capillary effects and Darcy and non-Darcy flow in the fractures and matrix are also considered.

Simulation of partially naturally fractured reservoirs

It is well known in the oil industry that most hydrocarbon reservoirs worldwide are naturally fractured. The major concern is whether the fractures are connected in such a way as to form a network for the fluids to flow toward the wellbore. Natural fractures usually occur in clusters oriented in specific directions (Singh et al. 2008). A NFR with a nonuniform distribution of fractures is known as a PNFR (van Golf-Racht 1982; Qasem 1996; Qasem et al. 2008). Most numerical simulation models presume that fractures are uniformly disseminated, which is not an accurate assumption. Thus, there is an urgent need to comprehend the effects of fracture distribution, and hence formation heterogeneity, on reservoir performance. This task requires innovative techniques for modeling and predicting the behavior of PNFRs. In 1996, Qasem (1996) outlined an approach to model partially fractured reservoirs (PFRs). Von Pattay and Ganzer (2001) described the application of dual-continuum methodology into a perpendicular bisector (PEBI) grid-based simulation model for PFRs. They claimed that when the PEBI grid is implemented, various regions in the grid model can be discretely chosen and allocated matrix, fractures, and matrix–fracture exchange parameters on a grid-by-grid basis.

Qasem et al. (2002) used a dual-permeability approach to investigate tracer propagation in PNFRs. They assigned a value of zero porosity to the grid blocks that are not fractured. Under this condition, the permeability of the nonfractured blocks becomes equivalent to the matrix permeability. They called the ratio of the fractured blocks to the total number of blocks the FI. They also inspected the minimum FI at which the fractures become significant to fluid flow. Cui and Kelkar (2005) developed computer software to determine the full-field FI distribution using production data. Qasem et al. (2008) investigated the interaction between viscous and capillary forces and their impacts on the behavior of immiscible flooding of PNFRs.

Salimi and Bruining (2011) presented an upscaling approach for PNFRs using homogenization. In their model, the matrix blocks are linked to the adjacent blocks so that only a portion of the total flow takes place in the matrix domain. Fluid flow in the matrix blocks has a vital impact on PNFR, especially when the connections among the matrix blocks are large. By applying homogenization, an upscaled PNFR model that simultaneously applies dual-porosity/dual-permeability approaches was derived. The resultant fully implicit 3-D numerical model was used to examine recovery processes for various dimensionless characteristic numbers. The upscaled model was proven to be more efficient than the totally fractured reservoir models and the dual-porosity/dual-permeability models.

Wang et al. (2020) used an embedded discrete fracture model (EDFM) to characterize dispersion due to velocity differences in matrix blocks and fractures. Khadivi et al. (2022) used production data, image and temperature logs, and pressure tests results to characterize fracture network patterns and extension across an Iranian field. They also used geomechanical data, 3-D seismic surveys, and drilling and well data to build a 3-D geological structure model. The constructed model was then coupled with an inverted geostress field and used to determine the natural fracture characteristics and distributions (Maerten et al. 2006; Wang and Li 2019).

Recovery processes in naturally fractured reservoirs

The recovery processes of solution gas NFRs are completely different from those of homogenous reservoirs. The difference in recovery is due to gravity contrasts between the two phases and the exposure of matrix to various hydrocarbon saturations in the fracture network. According to Boerrigter et al. (1993), at early production stages, oil is driven out of the matrix into the fracture network by fluid expansion and dissolved gas drive. At later depletion stages, the effective oil driving mechanism is due to gas/oil gravity drainage (Saidi et al. 1979). The efficiency of this process is affected by two mechanisms known as capillary continuity and reinfiltration. Capillary continuity between the matrix blocks has been examined experimentally and numerically by several investigators (Aronofsky et al. 1958; Horie et al. 1990; Schechter and Guo 1996). Reinfiltration is the process of resaturating the lower matrix by the addition of the drained liquid back into the fracture network. This process is significant in gas/oil systems. Thus, instantaneous gas/oil segregation due to vertical capillary continuity and reinfiltration of the drained oil adversely affect the ultimate recovery. In addition to the domination of recovery by gravity drainage and capillary imbibition, molecular diffusion occurs due to significant differences in fluid composition in the matrix and fractures caused by fluid segregation within the fractures.

Aronofsky et al. (1958) presented an exponential relationship of oil recovery by capillary imbibition versus time. Reiss (1976) and van Golf-Racht (1982) examined four distinct zones that could develop during depletion of fractured reservoirs. They classified these zones, starting from the gas/oil to the oil/water contacts as the gas-invaded, gassing, undersaturated, and water-invaded zones. The first three zones involve gas/oil interaction, gas segregation, convection, and fracture-matrix fluid transfer. Capillary and gravity imbibition are the main recovery mechanisms in the water-invaded zone. Convectional mixing due to higher oil density may occur in the gassing zone, when heavy oil moves downward through the fractures where it contacts the lighter oil in the matrix blocks. Stones et al. (1992) presented experimental results exploring the impact of capillary connectivity through horizontal fractures on gravity-induced drainage. Their work illustrated the existence of capillary connectivity in fractured laboratory experiments. The active cross-sectional area of capillary contact along the horizontal fractures was recognized as an important parameter in both vertical drainage and cumulative production. Boerrigter et al. (1993) presented field applications of a prototype fractured reservoir simulator demonstrating its capabilities to model the impacts of capillary contacts and block–block communication or oil reinfiltration in gravity drainage mechanisms.

Sener (1986) introduced the concept of “relative diffusion flux” to describe the controlled diffusion of gas in oil from the fracture to the matrix in dual-porosity/dual-permeability models. Da Silva and Belery (1989) presented a numerical solution for predicting mass transfer due to molecular diffusion. They concluded that molecular diffusion overrides other driving processes, especially in highly fractured reservoirs. Hu et al. (1991) also examined the diffusion impact on the recovery mechanism by nitrogen injection through the top of a core. By numerically simulating the experiment, they concluded that diffusion is important and that the capillary pressure curve should be corrected for variations in interfacial tension caused by compositional effects. Le Gallo et al. (1997) performed numerical simulation of experimental work to determine the incremental recovery caused by mass transfer in NFRs during gas injection. Their results highlighted the existence of different mechanisms affecting matrix–fracture mass transfer. These mechanisms include capillary and diffusion phenomena between the matrix and the fractures. Gabitto (1998) concluded that diffusion by itself cannot justify the magnitude of recovery improvement. This statement does not entirely agree with the results of previous studies by Sener (1986), da Silva and Belery (1989), and Le Romancer et al. (1994).

Hoier and Whitson (2000) presented an analytical study quantifying the prospective changes in oil pressure, volume, and temperature (PVT) properties with depth caused by thermal, chemical, and gravity forces. Li and Horne (2003) proposed a modified empirical/analytical model to calculate oil recovery by free-fall gravity drainage using the Aronofsky et al. (1958) model. Yang et al. (2002) developed several equations to estimate the inflow performance of vertical and horizontal wells using production data from three NFRs. They considered the matrix compaction and inertial flow resistance. Babadagli (2003) conducted experimental studies on four different rock types of NFRs to identify the conditions yielding high ultimate recovery by capillary imbibition of surfactant solutions. Zendehboudi et al. (2009) reported laboratory results of gravity drainage in fractured systems under a controlled liquid production rate. They introduced the concept of the “critical pumping rate”, at which each specific reservoir has a recovery factor equal to the recovery factor for higher rates just before gas breaks through at the bottom of the production well. They concluded that higher pumping rates create more discrepancy between the liquid levels in the fracture network and the matrix, causing early gas breakthrough. They also concluded that if the reservoir is produced at a constant lower than the critical rate, the height difference between the gas/liquid contacts in the matrix and the fracture network remains constant. Lemonnier and Bourbiaux (2010a) determined that water floods and gas floods are the most favorable recovery mechanisms in NFRs. They presented several modeling methods emphasizing the vertical equilibrium concept in NFRs containing fractures/faults at multiple scales. In another paper, Lemonnier and Bourbiaux (2010b) focused on modeling the physical driving mechanisms and the interactions between fractures and matrix.

Yu and Phillips (2014) introduced a distinctive curve to determine different factors required to estimate solution gas production without relying on expensive historical PVT data. Their proposed method was validated by both synthetic and real well data. However, the mathematical and physical fundamentals of this technique were not presented. Kuchuk et al. (2014) presented semianalytical solutions for the rate-transient behavior of vertical wells in NFRs containing finite- and infinite-conductivity fractures, as well as hydraulic fractures. Their solutions were supported by examples of the rate-transient behavior of discretely and continuously fractured reservoirs.

Sofla et al. (2016) conducted experimental and simulation work to examine the gravity drainage and diffusion phenomena and their influence on ultimate oil recovery from NFRs. Their work showed that these phenomena have a significant impact on oil recovery and should be incorporated into simulation programs to obtain accurate results. More recently, Zobeidi et al. (2022) performed a simulation investigation to assess the impact of the gravity drainage process on oil recovery from a highly fractured Iranian reservoir. Their work showed that gravity drainage contributes more than 50% of the oil recovery factor.

Gas injection into naturally fractured reservoirs

Over the years, the gravity-stable gas injection process has been successfully applied to enhance oil recovery from solution gas drive NFRs. Sustaining a gravity-stable driving mechanism is crucial for the success of this process. To achieve optimum recovery, gas must be injected at a low rate and pressure so that gravity displaces the oil.

Øyno et al. (1995) conducted laboratory experiments and simulation investigations to examine the effects of injecting nonequilibrium dry gas into fractured core samples. Their work indicated that if the reservoir pressure is increased due to gas injection, compositional effects between the gas in the fracture network and the oil in the matrix will be activated, leading to an increase in oil recovery. Maroufi et al. (2013) conducted an experimental study to investigate the effects of matrix permeability, oil physical properties, and production rate on oil recovery from NFRs. They concluded that vertical oil displacement during gas injection assisted by gravity drainage is one of the most efficient methods of oil recovery.

Saidi (1996) examined the gas injection history of a fractured Iranian reservoir. He observed that oil drainage occurs along a full block-to-block interface without capillary continuity. He concluded that convection/diffusion processes must be included in such an analysis; otherwise, gas movement from the gas cap to the oil zone and the corresponding produced gas/oil ratio (GOR) would be incorrectly replaced by other phenomena. Furthermore, he claimed that repressuring the field by gas injection is the most effective recovery process, wherein the major mechanisms are decreasing the capillary pressure by decreasing the gas/oil interfacial tension and increasing the irreducible oil volume in the region swept by gas and the oil zone. Badakhshan et al. (1998) presented results on the impact of long-term gas cap injection on the recovery of an Iranian NFR. Gas cap injection was used as a pressure conservation scheme and an enhanced recovery method. The results of laboratory and field studies indicated that due to the presence of natural fractures, the gravity drainage process has a dominant impact on production improvement by gas injection in the gas cap. The ratio of the gas injection rate to the oil production rate, the gas cap size, and the presence of active aquifers were identified as crucial factors in reservoir performance. It was also concluded that to obtain the highest efficiency from the gas cap injection operation, gas must be injected in the appropriate location in the reservoir with due attention to the reservoir characteristics, the fracture system position and orientation, and the reservoir capability to produce under natural depletion.

Uleberg and Hoier (2002) presented a compositional model to estimate the miscibility development conditions and to evaluate the gas injection process. It was shown that the minimum miscibility pressure/enrichment (MMP/MME) in NFRs is greater than that in conventional reservoirs. It was further concluded that at pressures less than the fracture system MMP, significant improvements in the oil production rate and recovery are anticipated by nonequilibrium gas injection. It was also shown that a decrease in the gas/oil interfacial tension and inner flow induced by interfacial tension have a dominant role in fluid recovery.

Alan and Sun (2003) investigated the effects of porosity, permeability, mobility ratio, water saturation, wettability, fracture allocation, and driving processes on the selection of reservoir development schemes. Xu and Gupta (2004) examined the effect of the gravity-driven flow in NFRs. Their investigation provided background for comprehensive models that express rock/fluid systems at the microscopic scale with deterministic resolutions. Sahni et al. (2005) presented a modeling approach to evaluate gas injection behavior in NFRs by means of discrete fracture network (DFN) models, wherein stochastic perceptions of fracture arrangements adjusted to accessible reservoir data were used to evaluate the effect of fracture properties on the driving performance. The displacement properties realized from the DFN were then applied to regulate full-field dual-porosity models. The simulations indicated that the displacement efficiency was significantly improved with a higher matrix permeability.

Ringen et al. (2005) conducted experimental and numerical studies to examine the effects of capillary continuity and reservoir repressurization by injecting equilibrium and nonequilibrium gases on oil recovery. Their work showed that vaporization and reduced interfacial tension are key factors in improving oil recovery by both equilibrium and nonequilibrium gas injection. Hoteit and Firoozabadi (2009) presented a coherent model to integrate the physical diffusion of multicomponent mixtures for gas injection mechanisms in NFRs. Their results showed a substantial impact of diffusion on ultimate oil recovery behavior away from the MMP. Yanze and Clemens (2011) investigated the effect of the diffusion of nonmiscible gas injection into NFRs. They illustrated that nonequilibrium gas injection creates a region of reduced oil viscosity for carbon dioxide and methane gases at the gas/oil contact in the matrix. Lemonnier and Bourbiaux (2010a) presented an overview of the key features of gas injection into NFRs. They claimed that gas injection is a compositional recovery mechanism as the injected gas is seldom in complete stability with the in situ oil. Moreover, based on the oil and injected gas PVT properties and on the thermodynamic situations in the reservoir, miscibility of the injected gas with the in situ oil can be attained.

Methodology and reservoir model

The PVT data published by Weinstein et al. (1986) and Killough (1995) were used as the basis for this research. The producing zone has a net sand thickness of 359 ft uniformly divided into 100 layers. The capillary pressure, Pcm, matrix relative permeability, krm, matrix block permeability, km, and block size, Lm, were used as input parameters in the PNFR simulation model. The fracture network mapping was based on a random distribution.

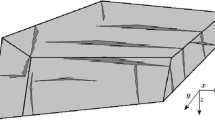

Since gravity drainage is the dominant recovery mechanism, it was important to capture the behavior of gas/oil interactions caused by gravity effects, phase resegregation, and coning phenomena. Thus, a high resolution vertical cross-sectional model was selected to illustrate the oil displacement and the gas penetration profile in the vertical direction. This was established by refining the grid size in the vertical direction. Furthermore, to maintain an appropriate level of heterogeneity in the system, the grid size in the horizontal direction was also refined. Our previous simulation experience (Qasem and Ershaghi 1994; Qasem 1996; Qasem et al. 2002; 2008) indicates that a two-dimensional model representation of PNFR requires a minimum number of grids to statistically and efficiently capture reservoir heterogeneity. Moreover, the two-dimensional model is more appropriate to concentrate on the gravity, phase distribution, and convection effects. Consequently, the constructed simulation model has a total of 10,000 cells distributed as Nx = 100 cells, Ny = 1 cell, and Nz = 100 cells, where Nx, Ny, Nz, are the number of cells in the x, y, and z dimensions, respectively. Notably, it is worth mentioning that for dual-permeability systems the number of cell blocks is double that for single-porosity systems; thus, in our case, the actual number of cells is 20,000 cells. The sizes of the grid cells in the x, y, and z dimensions are 72 ft, 300 ft, and 3.59 ft, respectively.

The matrix–fracture shape factor parameter proposed by Gilman and Kazemi (1983) was adopted in this work to contemplate the matrix-to-fracture flow conductivity within a grid block. The fracture spacing was used to calculate the matrix-to-fracture transfer coefficient, which is an essential building block in NFR simulation and accounts for fluid swelling, gravity drainage, and imbibition. A constant fracture spacing of 4 ft was used in the numerical simulator in all three directions.

Transmissibility is a measure of fracture’s connectivity strength. In the dual-permeability model, the matrix–matrix connectivity is equal to one; however, it could be reduced by multiplying the matrix–matrix transmissibility by a fraction between zero and one, where zero reduces the dual-permeability model to the dual-porosity model. Furthermore, the matrix transmissibility multiplier can be used to modify the interblock matrix-to-matrix flow. To account for the gravity drainage impact due to phase segregation in the vertical direction, a constant transmissibility multiplier of one was assigned to the fracture and matrix PVs.

The matrix porosity of all nonfractured grid blocks was 20.8%, whereas the fracture and matrix porosities of all fractured grid blocks were 1% and 20%, respectively. Modeling highly interconnected fracture systems requires assigning low permeability values to the matrix blocks and high permeability values to the fractures. Thus, a fracture permeability of 1000 md was assigned to all fractured grid blocks in all three directions. The matrix permeability was assumed to be uniform throughout the reservoir. Qasem and Ershaghi (1994; 1996) have shown that matrix permeability variation in the reservoir might yield different simulation outcomes.

To account for the irregular fracture distribution, FI values were used to specify the spatial heterogeneity and to generate various PNFR realizations. To investigate the impact of fracture distribution and reservoir heterogeneity on ultimate recovery, various reservoir realizations were generated for 9 FI values between 0.1 and 0.9. A program to generate a two-dimensional random array of 100 × 100 grids was developed. With a given probability of FI, three data sets, one for each of the matrix porosity, fracture porosity, and fracture permeability were generated.

Recovery performance of solution gas drive reservoirs

The concept of a PNFR is based on percolation theory (Chelidze 1982; Nakaya and Nakamura 2007; Tóth and Vass 2011). Percolation is a fast and reliable methodology that assists in determining the impact of geological disorders found within reservoir formations, a classification that can be associated to the partial presence of natural fractures. The PNFR porous medium is defined as a set of fractures. In our study, percolation is used as an algorithm to solve fracture connectivity and phase transition problems. In 2D reservoir modeling, the percolation threshold at which the formation of the smallest continuous fracture networks for a square lattice occurs is approximately 60%. Thus, any FI less than 60% results in a discontinuous fracture network. Figures 1 and 2 illustrate the effects of several depletion stages on the matrix oil saturation and fluid distribution in reservoirs with FIs of 0.2 and 0.4, respectively. Our PNFR research experience (Qasem et al. 2002; 2008) suggests that for reservoirs with FI less than 20%, the formation of a continuous fracture network is very difficult, indicating that the fractures have an insignificant effect on reservoir performance. This behavior is clear in Fig. 1, where the matrix oil saturation forms continuous plumes resembling those of homogenous reservoirs. Conversely, for 40% FI reservoirs (Fig. 2), the matrix oil saturation is discontinuous and spotty. This behavior reflects the nature of partial depletion of the matrix blocks that are linked to the fracture networks. Both figures (Figs. 1 and 2) show the gas coning phenomenon near the well; however, the gas cone is more pronounced in the 0.4 FI reservoir (Fig. 2) than the 0.2 FI reservoir (Fig. 1) due to the presence of more connected fractures at a FI of 0.4.

The effects of FI and maximum allowable oil production rate, qj, on the depletion drive performance of PNFRs were thoroughly investigated in this work. Simulation runs were conducted for nine reservoirs with different FI varying from 0.1 to 0.9 with an increment of 0.1. Eleven different qj values (q1 to q11) were used for each FI, making a total of 99 simulation runs. A production rate of 1500 STB/D, designated as qb, was used as a base case. The first production rate, q1, was the lowest and equal to one-tenth of qb (q1 = 150 STB/D). Conversely, q11 represented the highest production rate and was two times qb (q11 = 3000 STB/D).

Dimensionless variables were used to represent the generated data concisely. The dimensionless variables used in this study are defined as follows:

where qjD and qoD are the dimensionless maximum allowable oil production rate and dimensionless oil production rate, respectively. NpD and pRD are the dimensionless cumulative oil production and dimensionless average reservoir pressure, respectively. qo and qoi are the oil production rate at each depletion stage and initial oil production rate at pi, respectively. N and Np are the initial oil in place and cumulative oil production, respectively. pi and pR are the initial and average reservoir pressures, respectively. N and pi equal 21,379,600 STB and 3660 psi, respectively.

The dimensionless maximum allowable oil production rates input into the simulator, qjD, were assigned values of 0.1, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.4, 1.6, 1.8, and 2.0. A minimum flowing bottomhole pressure, pwf, of 500 psi and a minimum oil production rate of 5 STB/D were used as limiting conditions for each of the 99 simulation runs.

Two sets of characteristic plots were used to represent the generated data in graphical forms. The first set (Figs. 3 through 6) illustrates the behavior of qoD as a function of pRD. Figures 3 and 4 display the performance of qoD with respect to pRD for different qjD and FI inputs. Figures 5 and 6 show the behavior of qoD with respect to pRD for different FI and qj inputs. The second set of characteristic plots (Figs. 8 through 11) displays the performance of NpD as a function of pRD for various qjD and FI inputs, as shown in Figs. 8 and 9, and for different FI and qj, inputs as illustrated in Figs. 10 and 11.

Effects of maximum allowable oil production rate and fracture intensity on oil production

Figures 3 through 6 indicate that the behavior of solution gas drive PNFRs is highly affected by qjD and FI. The behavior of qoD as a function of pRD for various values of qjD and FI is interpreted as follows:

-

Figures 3 through 6 show that each qoD versus pRD curve has two distinct features, a constant production feature and a declining production feature. qoD remains constant at a maximum value of 1 from the beginning of production up to a certain pRD value; then, it starts to steadily decline until the end of the simulation run due to either limiting the flowing bottomhole pressure or the minimum allowable oil production rate, which are set to 500 psi and 5 STB/D, respectively. The duration of the constant qoD period is affected by the maximum allowable oil production rate qj and FI. For a given qj, the constant period increases with increasing FI. Moreover, it has been observed that the constant period is much more prominent for FI between 0.6 and 0.9 as opposed to lower FI. Furthermore, for a given qjD, the slope of the declining qoD part of the curve increases with increasing FI until it becomes asymptotic at low pRD values, indicating a sharp decline in qoD. This behavior is quite evident for a FI higher than 0.5 and a qjD less than 0.8, as displayed in all the curves of Fig. 3.

-

Figures 3 and 4 also indicate that for a given qj, as FI increases from 0.1 to 0.5, the reservoir productivity, qoD, increases at a certain value of pRD. However, for FI higher than 0.5, qoD is not significantly affected. Conversely, for reservoirs with FI between 0.1 and 0.5, a significant gradual decrease in qoD is exhibited with an increasing qjD. As a result, the qoD versus pRD curves are more distinctively separated from each other at a higher qjD and lower pRD. Furthermore, at high values of qjD, qoD declines exponentially as pRD increases, as shown in Fig. 3e and Fig. 4a through Fig. 4f.

-

All the curves in Fig. 5 indicate that the effect of the oil production rate is significant only for reservoirs with FI between 0.1 and 0.5. The curves in Fig. 6 indicate that for FI higher than 0.5, the effect of the production rate is less significant compared to reservoirs with FI less than 0.5; consequently, the qoD curves approach each other, exhibiting asymptotic behavior. Figure 6d illustrates that a reservoir with an FI of 0.9 would produce at the highest oil rate for all the allowable oil production rates investigated.

The above discussion implies that solution gas drive reservoirs with a low-to-moderate FI (0.1 ≤ FI ≤ 0.5) behave differently when compared to reservoirs with an FI higher than 0.5 (0.6 ≤ FI ≤ 0.9). In the remaining sections of this paper, we refer to low-to-moderate FIs and moderate-to-high FIs as the ‘lower FI range’ and ‘upper FI range’, respectively.

The graphical behavior of Figs. 3 through 6 is consistent with the rock properties and fluid flow dynamics in the reservoir. For the lower FI range, the formation of a gas cap is not fully established at early depletion stage due to discontinuity in the fracture network, which impedes gas percolation to the upper structure. Thus, the gas does not effectively enhance oil displacement. For the upper FI range, the fracture network becomes continuous, and the gas easily migrates to the upper structure, which helps maintain the reservoir pressure for longer production times and drives the oil downward toward the producing wells. Furthermore, at a high production rate, the gas coning phenomenon becomes evident, yielding a lower oil recovery. Conversely, at a low production rate, gas coning is not significant, which allows gas percolation to the upper structure. This phenomenon helps delay reservoir pressure decline, driving the oil toward the producing wells and eventually yielding higher oil recovery.

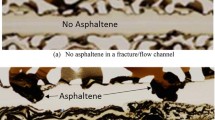

Figure 7a and b illustrates the effect of low production rate on the development of gas phase in low and high fracture intensity reservoirs, respectively. Figure 7a illustrates the effect of low production rate (q = 150 STB/D) on gas saturation of low fracture intensity (FI = 0.3) reservoir. While Fig. 7b shows the effects of the same production rate on gas saturation of high fracture intensity (FI = 0.9) reservoir. It is evident from the two figures that for low-FI reservoirs (Fig. 7a), the gas phase distribution is not uniform due to low fracture connectivity. This phenomenon leads to a fast pressure decline, hence low oil recovery. For high-FI reservoirs (Fig. 7b), the fractures’ connectivity is high which leads to more efficient gas percolation to the top of the structure yielding a continuous uniform gas cap which helps to maintain the reservoir pressure and yields high oil recovery.

Effects of the maximum allowable oil production rate and fracture intensity on the ultimate oil recovery

Figures 8 and 9 illustrate the variation in NpD as a function of pRD when qjD increases from 0.1 to 2 for different FIs. Figures 10 and 11 show the behavior of NpD as FI increases from 0.1 to 0.5 (Fig. 10) and from 0.6 to 0.9 (Fig. 11) for 11 different values of oil production rates.

-

The curves in Figs. 8 and 9 indicate that for lower FI-range reservoirs, NpD exhibits an incremental improvement as FI increases. Moreover, in this range of FIs, NpD is not substantially affected by production rate variations. Conversely, for the upper FI-range reservoirs, NpD is adversely affected by high production rates. As FI increases beyond 0.5, NpD decreases as the production rate increases due to gas coning. Thus, for high-FI reservoirs, the production rate should be carefully monitored to prevent excessive free gas and to minimize the gas coning phenomenon.

At low production rates, qjD≤0.4, the upper FI-range reservoirs exhibit higher oil recovery as FI increases beyond 0.5. Under these conditions of low production rates and high FI, the oil recovery curves are quite separated from each other, as illustrated in Fig. 8a through c. However, at high production rates, qjD≥0.6, the recovery from the upper FI-range reservoirs gradually decreases with increasing oil production rate. The NpD curves plot closer together, indicating that high production rates have a negative impact on NpD (Figs. 8d, e, and 9). Thus, under high production rates, the ultimate oil recovery from upper FI-range reservoirs is lower than that from lower FI-range reservoirs.

-

The impact of the oil production rate on the ultimate recovery performance of solution gas drive PNFRs is illustrated in Figs. 10 and 11. The curves in Fig. 10a, b show that the recovery from very low-FI reservoirs (FI = 0.1 and 0.2, Fig. 10a, b, respectively) is less dependent on the production rate. However, as FI increases beyond 0.2 (FI ≥ 0.3), the effect of the production rate becomes more dominant. As a result, the NpD curves gradually deviate from each other, as shown in Fig. 10c, through e and Fig. 11, indicating higher oil recoveries at lower production rates (qj < q5). Figure 10e and Fig. 11 also indicate that for a given FI between 0.5 and 0.9, as the production rate increases, the recovery decreases. These figures also demonstrate that as the production rate increases beyond q6, its effect on recovery becomes less significant and causes more harm to the reservoir than good. Consequently, it can be concluded that for high-FI reservoirs, the recovery is significantly improved by low production rates (q1 to q5); conversely, it is adversely affected by high production rates (q6 to q11). This behavior is also evident in Figs. 12 and 13, which illustrate the combined effects of FI and production rate on the recovery. Figure 12 displays the performance of 9 different PNFRs, each subjected to 11 different production rates. It is evident from the figure that the recovery is inversely proportional to the simultaneously increasing values of FI and production rate, i.e., as both FI and production rate increase, the recovery decreases. Conversely, the recovery increases for higher FI and lower production rates. This behavior is also shown in Fig. 13, which indicates that in the upper FI range, the recovery sharply decreases as the production rate increases. Nevertheless, the increase in production rate has minimal effects on recovery at the upper FI range.

-

In general, two major factors enhance the recovery from solution gas drive PNFRs: (i) low production rates and (ii) high FIs. Low production rates allow more efficient gas/oil segregation. Production at a low rate gives more time for the dissolved gas to come out of solution. A high FI implies more fracture connectivity and higher vertical permeability. The combined effects of the two factors allow the liberated gas to easily and rapidly percolate to the top of the structure, form a gas cushion that helps drive the oil to the producing wells, retard the reservoir pressure decline, permit a longer constant production rate period, and consequently improve oil recovery.

The behavior of ultimate recovery, as illustrated in Figs. 12 and 13, is in complete harmony with the reservoir rock properties, fluid PVT properties, and fluid flow phenomena in porous media. Figure 12 indicates that for low-FI reservoirs, the gravity drainage process is less significant, and most production is due to solution gas-induced oil expansion. As FI increases, more vertical fractures are formed in the reservoir, which enhances the vertical permeability; consequently, the gravity drainage process plays a more prevailing role in recovery improvement. For reservoirs with FIs between 0.1 and 0.2 (0.1≤FI≤0.2), the fluid flow is dominated by the matrix permeability. Hence, gravity drainage is not significant; consequently, the production rate does not significantly affect recovery.

For highly fractured reservoirs with FI between 0.6 and 0.9 (0.6≤FI≤0.9) the production rate is low, the gas/oil interface in the fractures moves at the same speed as the matrix gas/oil interface, allowing an efficient gravity drainage process. Thus, to take full advantage of the gravity drainage mechanism, it is vital to produce at a low rate to allow the gas/oil contact in the reservoir to move uniformly and give more time for the gas to percolate to the upper structure and for the oil to infiltrate to the bottom structure.

Conversely, for 0.6≤FI≤0.9 and high production rates, the gas/oil interface in the fractures moves faster than that in the matrix, resulting in early free gas breakthrough, which causes excessive pressure decline and eventually leaves a large volume of bypassed oil in the matrix blocks. Moreover, high production rates result in gas coning around the producing wells, which impedes production.

Figure 13 indicates that for low-FI reservoirs, the recovery is less sensitive to the flow rate due to the weak gravity drainage process. In such cases, the recovery is mainly dependent on viscous and capillary forces. Conversely, for high-FI reservoirs (0.6≤FI≤0.9), gravity drainage is a dominant force in the recovery process due to the formation of high-permeability vertical fractures. Moreover, the recovery is very sensitive to the production rate, which controls the movement of the gas/oil interface in the fracture.

According to these observations, the behavior of PNFRs subjected to solution gas drive can be summarized based on the combined effects of FI and production rate as follows:

-

0.1 ≤ FI ≤ 0.3 and 0.1 ≤ qjD ≤ 2: In these ranges, the ultimate oil recovery is not sensitive to the production rate and remains almost constant.

-

0.3 ≤ FI ≤ 0.9 and 0.1 ≤ qjD ≤ 0.8: In these ranges, the ultimate oil recovery is significantly affected by FI and production rate. For a given production rate, the oil recovery increases with increasing FI. Additionally, at a certain FI, the ultimate recovery is higher at lower production rates.

-

0.3 ≤ FI ≤ 0.9 and 0.8 ≤ qjD ≤ 2: In these ranges, the ultimate oil recovery is not significantly affected. For a given production rate, the recovery decreases as FI increases. Additionally, for a given FI, the recovery decreases as the production rate increases.

Ultimate oil recovery correlations by depletion drive mechanism

Correlations for determining NpD as a function of FI and qjD were established by fitting the 3-D surface in the generated oil recovery data. The simulated ultimate oil recovery data were clustered into three sets based on the reservoir performance under the various ranges of FI and oil production rates investigated in this work. Dimensionless oil recovery correlations in the form of a surface-fit polynomial equation were determined for each data set as follows:

-

0.1 ≤ FI ≤ 0.3 and 0.1 ≤ qjD ≤ 2

$$N_{pD} = a + b(FI) + c(FI)^{2} + d(FI)^{3} + \frac{e}{{q_{jD} }}\, + \frac{f}{{(q_{jD} )^{2} }} + \frac{g}{{(q_{jD} )^{3} }} + h\,\left( {\frac{FI}{{q_{jD} }}} \right) + i\,\frac{FI}{{(q_{jD} )^{2} }} + j\,\frac{{(FI)^{2} }}{{q_{jD} }}$$(5) -

0.3 ≤ FI ≤ 0.9 and 0.1 ≤ qjD ≤ 0.8

$$N_{pD} = a + \frac{b\,}{{FI}} + \frac{c}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + e\ln q_{jD} + f(\ln q_{jD} )^{2} + g(\ln q_{jD} )^{3} + h\left( {\frac{{\ln q_{jD} }}{FI}} \right) + i\,\frac{{(\ln q_{jD} )^{2} }}{FI} + j\frac{{\ln q_{jD} }}{{\left( {FI} \right)^{2} }}$$(6) -

0.3 ≤ FI ≤ 0.9 and 0.8 ≤ qjD ≤ 2

$$N_{pD} = a + \frac{b\,}{{FI}} + \frac{c}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + \frac{e}{{q_{jD} }} + \frac{f}{{(q_{jD} )^{2} }} + \frac{g}{{(q_{jD} )^{3} }} + \frac{h}{{(FI)(q_{jD} )}} + \frac{i}{{(FI)(q_{jD} )^{2} }} + \frac{j}{{(FI)^{2} (q_{jD} )}}$$(7)

The coefficients a through j of the three equations are given in Table 1. The fitting correlation coefficients of Eqs. (5), (6), and (7) are 99.6%, 99.7%, and 99.1%, respectively.

Recovery performance by gas injection

The recovery performance of PNFRs by gas injection was also investigated in this work. Extensive simulation runs were performed to explore the influence of FI and gas injection rate, qing, on ultimate recovery. The simulation runs were conducted for 9 reservoirs with different FI. Each run was performed at 15 different qing values. A base qing value designated qingB was set to 1.0 MMSCF/D. This rate is equivalent to injecting 0.001647 PV/year of gas at the average initial reservoir pressure. The 15 qing values (\(q_{1}\) to \(q_{15}\)) were defined with respect to qingB. q1 represents the smallest gas injection rate; it was set to be one-fourth of qingB (q1 = 0.25qingB). q15 represents the highest injection rate; it was set to be 15 times qingB (q15 = 15qingB). The dimensionless gas injection rate, qingD, was used to represent the generated data concisely. qingD is defined as:

Accordingly, the qingD values corresponding to the 15 injection rates were: 0.25, 0.5, 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 7.5, 10, 12.5, and 15. A maximum limiting pwf value of 10,000 psi and minimum oil rate of 5 STB/D were applied to each of the 135 simulated cases.

For each simulation run, NpD was noted at three gas injection stages. These stages corresponded to when the PV of the cumulative injected gas, Gi, was equal to 0.25 PV, 0.5 PV, and 0.75 PV, at an average initial reservoir pressure of 3660 psi. The generated NpD data were presented in two sets of characteristic plots for each Gi stage. The first set is displayed in Fig. 14, where NpD is illustrated as a function of qingD for 9 different FIs. The second set is shown in Fig. 15, where NpD is plotted as a function of FI for 14 different values of qingD.

Effects of fracture intensity and gas injection rate on reservoir performance

The curves in Fig. 14 indicate that for a given FI, NpD decreases with increasing qingD or increasing qing. This behavior is applicable to all \(G_{{\text{i}}}\) values. It is also clear that the impact of qingD is much more influential in its lower range (0.5 ≤ qingD ≤ 5) than in its upper range (5 ≤ qingD ≤ 15). This observation is valid for FI higher than 0.2. Even though each reservoir with a given FI exhibits a unique behavior at various gas injection rates, the curves of Fig. 14 indicate that there are three FI ranges that affect oil recovery.

-

0.1 ≤ FI ≤ 0.3: In this range, NpD is sensitive to injection rate as well as FI. For a given injection rate, NpD increases as FI increases. This behavior applies to all injection rates investigated.

-

0.3 ≤ FI ≤ 0.6: In this range, NpD behaves differently at the lower and upper ranges of the injection rate. At the lower injection rate range, (0.5 ≤ qingD ≤ 5), NpD increases with increasing FI, while at the upper injection rate range, (5 ≤ qingD ≤ 15), NpD decreases with increasing FI.

-

0.6 ≤ FI ≤ 0.9: In this range, NpD increases with FI. Furthermore, NpD decreases as qingD increases. At very high rates, the curves plot very close together.

The second set of characteristic curves is displayed in Fig. 15. This figure also exhibits three distinct patterns of oil recovery in the three FI ranges.

-

0.1 ≤ FI ≤ 0.3: In this range, NpD shows an increasing trend with increasing FI. At FI = 0.1, the oil recovery is approximately 10% for injection rates between 7.5 and 15 (7.5 ≤ qingD ≤ 15), while for injection rates lower than 7.5, the oil recovery varies between 20 and 33%. As FI increases, the difference in oil recoveries by different injection rates decreases to a minimum at FI = 0.3.

-

0.3 ≤ FI ≤ 0.6: In this range, NpD exhibits conflicting behavior at the lower and upper injection rate ranges. At the lower injection rate range, (0.5 ≤ qingD ≤ 5), NpD increases as FI increases, while at the upper injection rate range, (5 ≤ qingD ≤ 15), NpD decreases as FI increases.

-

0.6 ≤ FI ≤ 0.9: In this range, NpD increases as FI increases. This observation is applicable to all injection rates.

The above observations can be explained in terms of the reservoir phenomenon. In general, PNFRs are very sensitive to gas injection because in these reservoirs, gas channeling is a very dominant phenomenon. This is due to preferential gas flow in the fracture network. The extreme contrast in permeability between the fractures and the matrix causes the gas to flow in the fracture network, bypassing the large oil volume trapped in the low-permeability matrix blocks. Therefore, the gas injection process in fractured reservoirs is not efficient in high-FI reservoirs, in contrast to low-FI reservoirs, where the gas displaces the oil from the matrix.

Ultimate oil recovery correlations for the gas injection process

Correlations for determining NpD by the gas injection process as a function of FI and qingD were also established. The generated data were clustered into three sets based on the reservoir performance with respect to FI and qingD. Dimensionless oil recovery correlations were determined for each of the data sets. Three correlations were established for each of the three injection cases corresponding to 0.25PV, 0.5PV, and 0.75PV of cumulative gas injected.

Correlations for the case of G i = 0.25PV

-

0.1 ≤ FI ≤ 0.3 and 0.5 ≤ qingD ≤ 15

$$N_{pD} = a + \frac{b\,}{{FI}} + \frac{c\,}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + eq_{ingD} + f(q_{ingD} )^{2} + g(q_{ingD} )^{3} + h\,\left( {\frac{{q_{ingD} }}{FI}} \right) + i\frac{{(q_{ingD} )^{2} }}{FI} + j\,\frac{{q_{ingD} }}{{(FI)^{2} }}$$(9) -

0.3 ≤ FI ≤ 0.6 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + \frac{b\,}{{FI}} + \frac{c\,}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + e\,\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h\,\left( {\frac{{\ln q_{ingD} }}{FI}} \right) \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i\frac{{(\ln q_{ingD} )^{2} }}{FI} + j\,\frac{{\ln q_{ingD} }}{{(FI)^{2} }} \hfill \\ \end{gathered}$$(10) -

0.6 ≤ FI ≤ 0.9 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + \frac{b\,}{{FI}} + \frac{c\,}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + e\,\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h\,\left( {\frac{{\ln q_{ingD} }}{FI}} \right) \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i\frac{{(\ln q_{ingD} )^{2} }}{FI} + j\,\frac{{\ln q_{ingD} }}{{(FI)^{2} }} \hfill \\ \end{gathered}$$(11)

The coefficients a through j of the three equations are presented in Table 2. The fitting correlation coefficients of Eqs. (9), (10), and (11) are 95.4%, 99.4%, and 99.99%, respectively.

Correlations for the case of G i = 0.5PV

-

0.1 ≤ FI ≤ 0.3 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + b(FI) + c(FI)^{2} + d(FI)^{3} + e\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h(FI)\ln q_{ingD} \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i(FI)(\ln q_{ingD} )^{2} + j(FI)^{2} \ln q_{ingD} \hfill \\ \end{gathered}$$(12) -

0.3 ≤ FI ≤ 0.6 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + b(FI) + c(FI)^{2} + d(FI)^{3} + e\,\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h(FI)\ln q_{ingD} \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i(FI)(\ln q_{ingD} )^{2} + j\,(FI)^{2} \ln q_{ingD} \hfill \\ \end{gathered}$$(13) -

0.6 ≤ FI ≤ 0.9 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + b\ln FI + c(\ln FI)^{2} + d(\ln FI)^{3} + e\,\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h(\ln FI)q_{ingD} \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i(\ln FI)(\ln q_{ingD} )^{2} + j\,(\ln FI)^{2} \ln q_{ingD} \hfill \\ \end{gathered}$$(14)

The coefficients a through j of the three equations are presented in Table 3. The fitting correlation coefficients of Eqs. (12), (13), and (14) are 97.5%, 99.7%, and 99.98%, respectively.

Correlations for the case of G i = 0.75PV

-

0.1 ≤ FI ≤ 0.3 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + \frac{b\,}{{FI}} + \frac{c\,}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + e\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h\left( {\frac{{\ln q_{ingD} }}{FI}} \right) \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i\frac{{(\ln q_{ingD} )^{2} }}{FI} + j\,\frac{{\ln q_{ingD} }}{{(FI)^{2} }} \hfill \\ \end{gathered}$$(15) -

0.3 ≤ FI ≤ 0.6 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + \frac{b\,}{{FI}} + \frac{c\,}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + e\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h\left( {\frac{{\ln q_{ingD} }}{FI}} \right) \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i\frac{{(\ln q_{ingD} )^{2} }}{FI} + j\,\frac{{\ln q_{ingD} }}{{(FI)^{2} }} \hfill \\ \end{gathered}$$(16) -

0.6 ≤ FI ≤ 0.9 and 0.5 ≤ qingD ≤ 15

$$\begin{gathered} N_{pD} = a + \frac{b\,}{{FI}} + \frac{c\,}{{(FI)^{2} }} + \frac{d}{{(FI)^{3} }} + e\ln q_{ingD} + f(\ln q_{ingD} )^{2} + g(\ln q_{ingD} )^{3} + h\left( {\frac{{\ln q_{ingD} }}{FI}} \right) \hfill \\ \,\,\,\,\,\,\,\,\,\,\,\,\,\,\, + i\frac{{(\ln q_{ingD} )^{2} }}{FI} + j\,\frac{{\ln q_{ingD} }}{{(FI)^{2} }} \hfill \\ \end{gathered}$$(17)

The coefficients a through j of the three equations are presented in Table 4. The fitting correlation coefficients of Eqs. (15), (16), and (17) are 98.6%, 99.7%, and 99.98%, respectively.

Validation of the methodology and proposed equations

Figure 15 is used to illustrate the validity of the methodology and accuracy of the proposed equations. The curves in Fig. 15 indicate that as the injection rate (qiD) decreases, the recovery (NpD) increases. This behavior is applicable to all gas injection pore volumes used in this study. To confirm this conclusion, we calculated NpD using Eqs. (9, 10, and 11) for qiD = 0.25. The generated data points are displayed in open circles in Fig. 16. The plotted points show that as the injection rate decreases the recovery (NpD) indeed increases. This conclusion agrees with all other curves displayed in the figure which show similar behavior. Furthermore, we used Eqs. (9, 10, and 11) to calculate NpD for qiD = 0.5. The calculated data points are also plotted in Fig. 16 in open triangles and connected in dashed line. The figure shows that the calculated data superimpose on the simulated data indicating that the equations presented in this work highly reproduce the simulated data.

Conclusions

This paper presented, for the first time, the implementation of percolation theory to model solution gas drive partially naturally fractured reservoirs (PNFR) and investigates the recovery performance of these reservoirs under depletion drive and gas injection processes. The recovery behavior was examined with respect to the dimensionless oil production rate and dimensionless cumulative oil production versus dimensionless average reservoir pressure. This study covered fractured reservoirs with 9 different fracture intensities (FI). Each reservoir was subjected to a wide range of oil production rates, including the minimum to the maximum allowable rates. The results of this investigation demonstrate that the recovery performance of PNFRs subjected to both driving mechanisms is affected by the composite effects of FI, maximum allowable oil production rate, and gas injection rate. The following conclusions summarize this work.

-

1.

The ultimate recovery performance of depletion drive PNFRs is a function of FI and oil production rate. The results illustrate that reservoirs with moderate-to-high FIs yield higher oil recovery when operated at low oil production rates.

-

2.

The performance of PNFRs under the gas injection process behaves differently for various FI ranges. The ultimate recovery increases as FI increases in the lower and upper ranges for all injection rates. In the middle FI range, the ultimate recovery is a function of the gas injection rate. As FI increases, the ultimate recovery increases at low injection rates and decreases at high gas injection rates.

-

3.

Correlations in the form of surface-fit polynomial equations were established by fitting the simulated data by a 3-D surface. The presented correlations accurately predict the ultimate recovery for the depletion drive and the gas injection processes.

References

Abdassah D, Ershaghi I (1986) Triple porosity systems for representing naturally fractured reservoirs. SPE Form Eval 1:113–127. https://doi.org/10.2118/13409-PA

Aguilera R (1995) Naturally fractured reservoirs. 2nd edn, Pennwell Corp, Tulsa, OK. ISBN-13: 978–0878141227

Alan J, Sun SQ (2003) Controls on recovery factor in fractured reservoirs: lessons learned from 100 fractured fields. In: Proceedings SPE annual technical conference and exhibition. Denver, CO. https://doi.org/10.2118/84590-MS

Arana-Ortiz VH, Rodriguez F (1996) A semi-implicit formulation for compositional simulation of fractured reservoirs. In: Proceedings SPE latin America/Caribbean petroleum engineering conference. Port-of-Spain, Trinidad. https://doi.org/10.2118/36108-MS

Aronofsky JS, Masse L, Natanson SG (1958) A model for the mechanism of oil recovery from the porous matrix due to water invasion in fractured reservoirs. Trans AIME 213:17–19. https://doi.org/10.2118/932-G

Babadagli T (2003) Analysis of oil recovery by spontaneous imbibition of surfactant solution. In: Proceedings SPE international asia pacific improved oil recovery conference. Kuala Lumpur, Malaysia. https://doi.org/10.2118/84866-MS

Badakhshan A, Golshan H, Musavi-Nezhad HR, Sobbi FA (1998) The impact of gas injection on the oil recovery of a giant naturally fractured carbonate reservoir. J Can Pet Technol 37:22–29. https://doi.org/10.2118/98-12-01

Bakyani AE, Taghizadeh A, Sarvestani AN, Esmaeilzadeh F, Mowla D (2018) Three-dimensional and two-phase numerical simulation of fractured dry gas reservoirs. J Pet Explor Prod Technol 8:1425–1441. https://doi.org/10.1007/s13202-017-0423-2

Barenblatt GI, Zheltov IP, Kochina IN (1960) Basic concepts in the theory of seepage in the homogeneous liquids in fissured rocks (strata). J Appl Math Mech 24:1286–1303. https://doi.org/10.1016/0021-8928(60)90107-6

Boerrigter PM, van de Leemput BLEC, Pieters J, Wit K, Ypma JGJ (1993) Fractured reservoir simulation: case studies. In: Proceedings SPE middle east oil technical conference and exhibition. Manama, Bahrain. https://doi.org/10.2118/25615-MS

Camacho-Velazquez R, Vasquez-Cruz M, Castrejon-Aivar R, Arana-Ortiz V (2005) Pressure-transient and decline-curve behavior in naturally fractured vuggy carbonate reservoirs. SPE Form Eval 8:95–112. https://doi.org/10.2118/77689-PA

Chelidze TL (1982) Percolation and fracture. Phys Earth Planet 28(2):93–101. https://doi.org/10.1016/0031-9201(82)90075-9

Cui H, Kelkar M (2005) Automatic history matching of naturally fractured reservoirs and a case study. In: Proceedings SPE Western Regional Meeting. Irvine, CA. https://doi.org/10.2118/94037-MS

de Guevara-Torres JEL, de la Garza FR, Galindo-Nava A (2009) Gravity-drainage and oil-reinfiltration modeling in naturally fractured reservoir simulation. SPE Res Eval Eng 12:380–389. https://doi.org/10.2118/108681-PA

Firoozabadi A (2000) Recovery mechanisms in fractured reservoirs and field performance. J Can Pet Technol 39:13–17. https://doi.org/10.2118/00-11-DAS

Fung LSK, Collins DA (1991) An evaluation of the improved dual porosity model for the simulation of gravity effects in naturally fractured reservoirs. J Can Pet Technol. https://doi.org/10.2118/91-03-06

Gabitto FJ (1998) Matrix-fracture mass transfer. In: Proceedings SPE improved oil recovery symposium. Tulsa, OK. https://doi.org/10.2118/39702-MS

Gallo Le Y, Le Romancer JF, Bourbiaux B, Fernandes G (1997) Mass transfer in fractured reservoirs during gas injection: experimental and numerical modeling. In: Proceedings SPE annual technical conference and exhibition. San Antonio, TX. https://doi.org/10.2118/38924-MS

Ganzer LJ (2003) Simulating fractured reservoirs using adaptive dual continuum. In: Proceedings SPE/DOE improved oil recovery symposium. Tulsa, OK. https://doi.org/10.2118/75233-MS

Gilman J, Kazemi H (1983) Improvements in simulation of naturally fractured reservoirs. SPE J 23:695–707. https://doi.org/10.2118/10511-PA

Hoier L, Whitson CH (2000) Compositional grading–theory and practice. In: Proceedings SPE annual technical conference and exhibition. Dallas, TX. https://doi.org/10.2118/63085-MS

Horie T, Firoozabadi A, Ishimoto K (1990) Laboratory studies of capillary interaction in fracture/matrix systems. SPE Res Eng 5:353–360. https://doi.org/10.2118/18282-PA

Hoteit H, Firoozabadi A (2009) Numerical modeling of diffusion in fractured media for gas-injection and recycling schemes. SPE J 14:323–337. https://doi.org/10.2118/103292-PA

Hu H, Whitson CH, Yuandiang Q (1991) A study of recovery mechanisms in a nitrogen diffusion experiment. In: Proceedings SPE european symposium on improved oil recovery. Stavanger, Norway. https://doi.org/10.2118/21893-MS

Kazemi H (1969) Pressure transient analysis of naturally fractured reservoirs with uniform fracture distribution. SPE J 9:451–462. https://doi.org/10.2118/2156-A

Khadivi K, Alinaghi M, Dehghani S, Soltani M, Hassani H, Mosavi SC, Shiralipour M, Fardin H, Sanjari S, Partovi M (2022) Integrated fracture characterization of Asmari reservoir in Haftkel field. J Pet Explor Prod Technol 12:1867–1887. https://doi.org/10.1007/s13202-021-01435-4

Killough JE (1995) Ninth SPE comparative solution project: a reexamination of black-oil simulation. In: Proceedings SPE reservoir simulation symposium. San Antonio, TX. https://doi.org/10.2118/29110-MS

Kuchuk F, Biryukov D, Fitzpatrick T (2014) Rate transient and decline curve analyses for continuously (dual-porosity) and discretely naturally fractured reservoirs. In: Proceedings SPE annual technical conference and exhibition. Amsterdam, The Netherlands. https://doi.org/10.2118/170698-MS

Lemonnier P, Bourbiaux B (2010a) Simulation of naturally fractured reservoirs. State of the art. Part 1–physical mechanisms and simulator formulation. Oil Gas Sci Technol Rev IFP 65:239–262. https://doi.org/10.2516/ogst/2009066

Lemonnier P, Bourbiaux B (2010b) Simulation of naturally fractured reservoirs. State of the art. Part 2–matrix-fracture transfers and typical features of numerical studies. Oil Gas Sci Technol Rev IFP 65:263–286. https://doi.org/10.2516/ogst/2009067

Li K, Horne RN (2003) Prediction of oil production by gravity drainage. In: Proceedings SPE annual technical conference and exhibition. Denver, CO. https://doi.org/10.2118/84184-MS

Maerten L, Gillespie P, Daniel JM (2006) Three-dimensional geomechanical modeling for constraint of subseismic fault simulation. AAPG Bull 90(9):1337–1358. https://doi.org/10.1306/03130605148

Maroufi P, Ayatollahi Sh, Rahmanifard H, Jahanmiri A, Riazi M (2013) Experimental investigation of secondary and tertiary oil recovery from fractured porous media. J Pet Explor Prod Technol 3:179–188. https://doi.org/10.1007/s13202-013-0054-1

Nakaya S, Nakamura K (2007) Percolation conditions in fractured hard rocks: a numerical approach using the three-dimensional binary fractal fracture network (3D-BFFN) model. J Geophys Res 112(B12203):1–15. https://doi.org/10.1029/2006JB004670

Øyno L, Uleberg K, Whitson C (1995) Dry gas injection in fractured chalk reservoirs – an experimental approach. In: International symposium of the society of core analysts. San Francisco, CA. https://jgmaas.com/SCA/1995/SCA1995-27.pdf

Pattay von PW, Ganzer LJ (2001) Reservoir simulation model for fractured and partially fractured reservoirs based on PEBI grids. In: Proceedings SPE reservoir simulation symposium. Houston, TX. https://doi.org/10.2118/66384-MS

Peng CP, Yanosik JL, Stephenson RE (1990) A generalized compositional model for naturally fractured reservoirs. SPE Res Eng 5:221–226. https://doi.org/10.2118/16340-PA

Por GJ, Boerrigter P, Maas JG, de Vries A (1989) A fractured reservoir simulator capable of modeling block-block interaction. In: Proceedings SPE annual technical conference and exhibition. San Antonio, TX. https://doi.org/10.2118/19807-MS

Qasem FH, Gharbi R, Mir MI (2002) Tracer response in partially fractured reservoirs. J Pet Sci Technol 20:915–938. https://doi.org/10.1081/LFT-120003686

Qasem F, Nashawi IS, Gharbi R, Mir MI (2008) Recovery performance of partially fractured reservoirs by capillary imbibition. J Pet Sci Eng 60:39–50. https://doi.org/10.1016/j.petrol.2007.05.008

Qasem F, Ershaghi I (1994) Optimizing gas injection into naturally fractured reservoirs. In: Proceedings SPE III Latin American/Caribbean petroleum engineering conference. Buenos Aires, Argentina https://doi.org/10.2118/26979-MS

Qasem FH, Ershaghi I (1996) A look at issues related to stochastic representation of naturally fractured reservoirs. In: Proceedings SPE international petroleum conference and exhibition. Villahermosa, Mexico https://doi.org/10.2118/35293-MS

Qasem FH (1996) Performance and recovery prediction in heterogeneous naturally fractured reservoirs under the solution gas drive process. Dissertation. University of Southern California, USA.

Reiss LH (1976) The reservoir engineering aspects of fractured formations. Editions Technip, Paris, France

Ringen, JK, Haugse V, Høier L, Berge LI, Reed J (2005) Experimental and numerical studies of gas injection in fractured carbonates: pressure and compositional effects. In: International symposium of the society of core analysts. Toronto, Canada. https://jgmaas.com/SCA/2005/SCA2005-13.pdf

Romancer Le JFX, Defives DF, Fernandes G (1994) Mechanism of oil recovery by gas diffusion in fractured reservoir in presence of water. In: Proceedings SPE ninth symposium on improved oil recovery. Tulsa, OK. https://doi.org/10.2118/27746-MS

Rubin B (2007) Simulating gravity drainage and reinfiltration with a subdomain-dual-permeability hybrid fracture model. In: Proceedings SPE reservoir simulation symposium. Houston, TX. https://doi.org/10.2118/106191-MS

Sahni A, Bakenov R, Kaveh D, Narr W, Dull D (2005) Evaluating gas-injection performance in fractured reservoirs using discrete fracture network models. In: International Petroleum Technology Conference. Doha, Qatar. https://doi.org/10.2523/IPTC-10631-ABSTRACT

Saidi AM (1987) Reservoir engineering of fractured reservoirs: fundamental and practical aspects. Total edn press, Paris, France

Saidi AM, Tehrani DH, Wit K (1979) Mathematical simulation of fractured reservoir performance based on physical model experiments. In: Proceedings tenth world petroleum congress vol. 3. Bucharest, Romania. WPC-18227

Saidi AM (1996) Twenty years of gas injection history into well-fractured Haft Kel field (Iran). In: Proceedings SPE Annual Petroleum Conference and Exhibition. Villahermosa, Mexico. https://doi.org/10.2118/35309-MS

Salimi H, Bruining J (2011) Upscaling in partially fractured oil reservoirs using homogenization. SPE J 16:273–293. https://doi.org/10.2118/125559-PA

Schechter DS, Guo B (1996) Mathematical modeling of gravity drainage after gas injection into fractured reservoirs. In: Proceedings SPE/DOE permian basin oil gas recovery conference. Midland, TX. https://doi.org/10.2118/35170-MS

Sener I (1986) Relative diffusion flux: a practical concept for characterizing fracture to matrix gas transfer - application to fractured reservoir model. In: Proceedings SPE annual technical conference and exhibition. New Orleans, LA. https://doi.org/10.2118/15522-MS

da Silva FV, Belery P (1989) Molecular diffusion in naturally fractured reservoirs; a decisive recovery mechanism. In: Proceedings SPE annual technical conference and exhibition. San Antonio, TX. https://doi.org/10.2118/19672-MS

Singh SK, Abu-Habbiel H, Khan B, Akbar M, Etchecopar A, Montaron B (2008) Mapping fracture corridors in naturally fractured reservoirs: an example from Middle East carbonates. First Break 26:109–113. https://doi.org/10.3997/1365-2397.26.1119.27999

Sofla SJD, Pouladi B, Sharifi M, Shabankareian B, Moraveji MK (2016) Experimental and simulation study of gas diffusion effect during gas injection into naturally fractured reservoirs. J Nat Gas Sci Eng 33:438–447. https://doi.org/10.1016/j.jngse.2016.05.035

Stones EJ, Zimmerman SA, Chien CV, Marsden SS (1992) The effect of capillary connectivity across horizontal fractures on gravity drainage from fractured porous media. In: Proceedings SPE Annual technical conference and exhibition. Washington, DC. https://doi.org/10.2118/24920-MS

Tan JCT, Firoozabadi A (1995) Dual-porosity simulation incorporating reinfiltration and capillary continuity concepts. In: Proceedings SPE reservoir simulation symposium. San Antonio, TX. https://doi.org/10.2118/29113-MS

Thomas LK, Dixon TN, Pierson RG (1983) Fractured reservoir simulation. SPE J 23:42–54. https://doi.org/10.2118/9305-PA

Tóth TM, Vass I (2011) Relationship between the geometric parameters of rock fractures, the size of percolation clusters and REV. Math Geosci 43(1):75–97. https://doi.org/10.1007/s11004-010-9315-4

Uleberg K, Hoier L (2002) Miscible gas injection in fractured reservoirs. In: Proceedings SPE improved oil recovery symposium. Tulsa, OK. https://doi.org/10.2118/75136-MS

van Golf-Racht TD (1982) Fundamentals of reservoir engineering. Elsevier, Amsterdam, The Netherlands

Wang C, Li S (2019) The effect of fractures on gas injection in Hailar oilfield. J Pet Explor Prod Technol 9:409–416. https://doi.org/10.1007/s13202-018-0475-y

Wang D, Zhang X, Zhang J, Cheng L (2020) A simulation study on the effect of the dispersion on the process of enhanced oil recovery. IOP Conf Ser Earth Environ Sci. https://doi.org/10.1088/1755-1315/675/1/012204

Warren JE, Root PJ (1963) The behavior of naturally fractured reservoirs. SPE J 3:245–255. https://doi.org/10.2118/426-PA

Weinstein HG, Chappelear JE, Nolen JS (1986) Second comparative solution project: a three-phase coning study. J Pet Technol 38(03):345–353. https://doi.org/10.2118/10489-PA

Xu Q, Gupta A (2004) Modeling of gravity-drainage in naturally fractured reservoirs using flow in angular capillary tubes. In: Proceedings SPE international petroleum conference. Puebla Pue, Mexico. https://doi.org/10.2118/92009-MS

Yang D, Gu Y, Zhang Q (2002) Determination of production operation methods in naturally fractured reservoirs. J Can Pet Technol 41:54–61. https://doi.org/10.2118/02-12-03

Yanze Y, Clemens T (2011) The role of diffusion for non-miscible gas injection into a fractured reservoir. In: Proceedings SPE Annual Conference and Exhibition. Vienna, Austria. https://doi.org/10.2118/02-12-03

Yu S, Phillips C (2014) A new methodology to forecast solution gas production in tight oil reservoirs. In: Proceedings SPE unconventional resources conference. Calgary, Canada. https://doi.org/10.2118/171580-MS

Zendehboudi S, Mohammadzadeh O, Chatzis I (2009) Experimental study of controlled gravity drainage in fractured porous media. In: Proceedings Canadian international petroleum conference. Calgary, Alberta, Canada. https://doi.org/10.2118/2009-186

Zobeidi K, Mohammad-Shafie M, Ganjeh-Ghazvini M (2022) The effect of gravity drainage mechanism on oil recovery by reservoir simulation; a case study in an Iranian highly fractured reservoir. J Pet Explor Prod Technol 12:1633–1647. https://doi.org/10.1007/s13202-021-01430-9

Acknowledgements

The authors express their appreciation to the Kuwait Foundation for the Advancement of Sciences (KFAS) for financially supporting this work through a research Grant (2011-1504-02).

Funding

This study was funded by the Kuwait Foundation for the Advancement of Sciences (KFAS) through a research grant 2011-1504-02.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Qasem, F.H., Nashawi, I.S. Simulation and performance prediction of partially naturally fractured reservoirs under solution gas drive primary recovery and gas injection processes. J Petrol Explor Prod Technol 14, 1259–1282 (2024). https://doi.org/10.1007/s13202-024-01764-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-024-01764-0