Abstract

The indiscriminate consumption of antibiotics and their introduction into the environment have caused global concerns. Typically, following consumption, these compounds are introduced into the environment after incomplete metabolism, and a large portion of them are impossible to remove using conventional wastewater treatment systems. The main aim of this study was to determine the feasibility of using a TiO2/UV-C nanophotocatalyst doped with trivalent iron for the removal of amoxicillin from aquatic solutions. The nanophotocatalyst was prepared and characterized by SEM, XRD, EDX, DRS, and photoluminescence spectrum. The influences of different parameters, including nanocatalyst concentration (30–90 mg/L), initial concentration of amoxicillin (10–45 mg/L), and pH (3–11) at different time intervals (30–120 min) on antibiotic removal efficiency were investigated. Antibiotic concentration was measured with an HPLC device. All experiments were replicated three times according to the Standard Methods for the Examination of Water and Wastewater, 20th edition. Data were analyzed using SPSS 19 and the ANOVA statistical test. Optimal conditions for removing amoxicillin from a synthetic solution were as follows: pH 11, initial concentration of antibiotic = 10 mg/L, nanocatalyst = 90 mg/L, and contact time = 120 min. The optimal conditions were also used to remove amoxicillin from Dana Pharmaceutical Company wastewater. The removal efficiencies of antibiotic for synthetic and pharmaceutical wastewater were 99.14 and 88.92%, respectively. According to the results, the nanophotocatalyst TiO2/UV-C may be used for the removal of significant amounts of amoxicillin from pharmaceutical wastewater.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

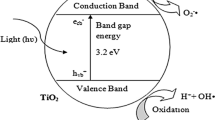

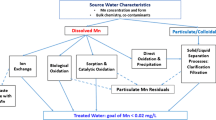

Antibiotics are important anti-bacterial medications used to treat human and animal diseases (Kümmerer 2009). However, the consumption of antibiotics leads to these compounds being introduced into the environment after incomplete metabolism, and they are not removable in conventional wastewater treatment systems (Nasuhoglu et al. 2012). These compounds enter the environment through various means, such as wastewater from the pharmaceutical industry, hospitals, and from human and animal waste deposits (Elmolla and Chaudhuri 2011). Following digestion and metabolism in the body, the residue of these compounds, together with their metabolites, is introduced into the environment through human urine and stool deposits (Zhang et al. 2008, 2010). As emerging contaminants, antibiotics and related antibiotic resistance genes (ARGs) have received increasing attention because of their potential impact on human health and the ecosystem (Chen et al. 2016). The spread of antibiotic-resistant microorganisms in the environment is globally recognized as an important public health issue, and there are concerns on our future ability to treat infectious diseases (Laport et al. 2016). Compounds such as antibiotics influence the microbial population of a wastewater system. Inhibition of wastewater bacteria affects the degradation of organic compounds. For example, nitrification is an important step in removing ammonia in water and wastewater treatments. The second and very sensitive stage is that of oxidation from nitrite to nitrate. Inhibition of this stage under uncontrolled conditions might result in the accumulation of nitrogen compounds in industrial wastewater and the formation of a toxic form of nitrogen (Kümmerer 2009). There are various methods available for removing pharmaceutical compounds, including absorption by active carbon, reverse osmosis, air stripping, and biological methods. However, contaminants are not removed by such methods; rather, they are just transferred from one phase to another (Daghrir et al. 2012; Elmolla and Chaudhuri 2010a). Advanced oxidation methods (AOPs) such as UV/ZnO, UV/TiO2, and UV/H2O2 are useful. In such methods, hydroxyl radicals are used for the oxidation of resistant compounds, and it converts them into the harmless products H2O and CO2 (Klavarioti et al. 2009). One of these processes is nanophotocatalysis (Gad-Allah et al. 2011; Hapeshi et al. 2010). Nanophotocatalytic systems are able to oxidize antibiotics and convert them into by-products that are less toxic for microorganisms or even harmless compounds (Giraldo et al. 2010). TiO2, thanks to its high photocatalytic activity, non-toxicity, stability in aquatic solutions, and relatively low cost, is considered an efficient substitute over other methods (Haque and Muneer 2007). Amoxicillin is a semisynthetic, broad-spectrum medication widely used to treat common human infections. It is a β-lactam antibiotic that has the molecular form of C16H19N3O5S and the molecular weight of 365.4 g/mol. Its antimicrobial activity is related to the beta lactam ring system in its structure. It inhibits interactions between linear peptidoglycan chains, resulting in the inhibition of bacterial cellular wall synthesis (Pouretedal and Sadegh 2014; Tian et al. 2005). Malakootian et al. and Benacherine et al. studied the removal of pharmaceutical compounds and organic and inorganic pollutants from aqueous solutions by adsorption processes and photocatalytic methods (el mehdi Benacherine et al. 2017; Malakootian et al. 2014, 2016a, b, c; Malakootian and Mansuri 2015; Momenzadeh et al. 2015). In their research conducted in Colombia, Giraldo et al. (2010) used a photocatalytic system with TiO2 and achieved desirable results for removing the antibiotic oxolinic acid (Giraldo et al. 2010). Dimitrakopoulou et al. (2012) investigated the effects of TiO2/UV-A on amoxicillin in Greece, and their results determined this method to be acceptable (Dimitrakopoulou et al. 2012). Moreira et al. (2015) used fast mineralization and detoxification of amoxicillin and diclofenac by photocatalytic ozonation and applied these methods on urban wastewater. Their results determined these methods to be acceptable (Moreira et al. 2015) Numerous studies have reported the removal of antibiotics by advanced oxidation, but to date, no study has been done on the application of Fe+3–TiO2/UV-C for removing amoxicillin.

The current research purposed to evaluate the application of titanium dioxide-doped particles (Fe+3–TiO2) with the help of the sol–gel method and together with UV-C rays for the removal of amoxicillin from aquatic environments, to determine the optimal conditions for maximum removal efficiency, and then to apply those optimal conditions to a real wastewater sample from the pharmaceutical industry.

Materials and methods

This fundamental-applied research was conducted in 2015 (1394) at the Research Center of the Environmental Health Engineering at Kerman University of Medical Sciences and the Environmental Health Group at Shiraz University of Medical Sciences. The removal of amoxicillin was examined using Fe+3–TiO2/UV-C nanophotocatalysis. Tests were done to determine the impact of pH, initial concentration of amoxicillin, concentration of the Fe+3–TiO2 nanocatalyst, and reaction time on the extent of antibiotic removal in an aquatic environment. The number of samples was determined based on the number of investigated parameters. Their range was specified by the one-factor-at-a-time (OFAT) method of change. The sum of levels was considered for the variables of interest; tests were done on 114 samples with three replications and a control sample. Running OFAT experiments is a sequential learning process. The use of OFAT designs allows investigators to determine more rapidly whether a factor has any effect. Researchers continually receive information from each run rather than having to wait until the entire experiment is completed. They can monitor and react to data more rapidly than when using orthogonal fractional factorial designs. To obtain optimal conditions for the removal of contaminants and reduce the costs of research, this method was used (Qu and Wu 2005). The sol–gel method was used to prepare the Fe+3–TiO2 nanocatalyst powder (Nasseri et al. 2011). In the first step, ferrous nitrate was dissolved in half of the propanol (121.77 mL) and mixed completely. After 15 min, 121.77 mL of propanol was mixed with 62.77 mL of titanium tetraisopropoxide (TTIP), and then the mixture was added very slowly to the former solution over 75 min to form the sol. Deionized distilled water (8.33 mL) was added to the solution as well. Thirty minutes after the propanol was added to the TTIP, the pH was adjusted to 3 using nitric acid. All processes were carried out in mixing mode using a homogenizer. The resultant solution was placed on the magnetic mixer for 24 h to form a jelly. This was put in the oven at 80 °C for 10 h to evaporate the alcohol. To activate the catalyst, the jelly was placed in the oven at 500 ± 50 °C for 2 h. The activated catalyst was put in a desiccator until it was cool. Finally, the catalyst was powdered (Nasseri et al. 2011). The mean diameter of the nanocatalyst particle and its appearance were investigated with scanning electron microscopy (SEM). XRD, EDX, DRS, and the photoluminescence spectrum for the catalyst were determined.

A photocatalytic reactor was constructed with a volume of 2 L. To evaluate the effects of different parameters on the process of Fe+3–TiO2/UV-C, amoxicillin solutions were prepared at three concentrations of 10, 25, and 45 mg/L. To determine the optimal pH for photocatalytic removal, experiments were performed at three pH levels: acidic (3), neutral (7), and alkaline (11). The pH of the samples was adjusted using ammonium hydroxide 1 N and HCl 1 N. Following pH adjustment, the samples were poured into the reactor. The Fe+3–TiO2 nanocatalyst was added to the antibiotic solution in powder form and exposed to constant ultraviolet radiation. For better mixing of the samples, an adjustable stirrer was used on the reactor. Tests were done at concentrations of 30, 60, and 90% to determine the optimal amount of nanocatalyst. Samples were taken from the reactor at intervals of 30, 60, 90, and 120 min to make determinations for optimal time; a centrifuge of 10,000 rpm was used for 10 min at the end of each experiment to separate the particles. Thereafter, samples were passed through a syringe filter of 0.22 µm. The amount of remaining antibiotic was measured using an HPLC device. Eventually, all experiments were conducted in three replications in the presence of a control sample (Dehghani et al. 2014b; Dimitrakopoulou et al. 2012; Nasseri et al. 2011). The experiments were also done in the absence of the nanocatalyst. Samples of real wastewater were taken from the Dana pharmaceutical factory. Determinations were made for quality and amounts of antibiotic. Optimal removal conditions were applied, removal efficiency was calculated, and comparisons were made with the synthetic solution. Data were analyzed using SPSS software and the ANOVA test.

The amoxicillin removal efficiency was calculated using (Eq. 1):

where C0 and C represent the amoxicillin concentration before and after the titanium catalyst doped with iron (Fe+3–TiO2) process, respectively, and E represents the efficiency.

The specifications of the photochemical reactor are indicated in Fig. 1.

The experiment was conducted in a closed glass reactor with a volume of 2 L facilitated by an incorporated stirrer. The source of radiation was a UV lamp of C Type, 125 W, and 247 nm, protected by a quartz tube 30 cm long and 5 cm in diameter. The entire reactor was protected by aluminum foil to prevent reflection.

Running the HPLC device

To run the HPLC device, amoxicillin standard with a purity of 99% was used. Methanol and deionized water were used as the mobile phase in ratios of 5–95, respectively. The water contained potassium dihydrogen phosphate salt (KH2PO4) 0.05 M. For the mobile phase, pH was 4.5. The utilized column was C18 with 5 µm particles, a length of 250 mm, and an internal diameter of 4.6 mm. Amoxicillin was identified using a UV absorbance detector at the wavelength of 229 nm with an injection volume of 20 mL and flow rate of 0.5 mL/min.

Amoxicillin (purity: 85%) was purchased from Dana Daru Co. for the synthetic sample. Compounds used in the tests were supplied by Merck Co., Germany. For radiation, a UV-C lamp with an intensity of 125 W/m2 and wavelength of 247 nm was purchased from ARDA Co., France. The utilized devices included a centrifuge 3K30 (Sigma, Germany) for separating the nanocatalyst particles from the solution, a balance with an accuracy of 4 decimals (AND HR 200, Japan), and a pH meter (Metrohm 744, Switzerland). Mean diameter of the nanocatalyst particles and their appearance were determined by employing scanning electron microscopy (SEM) (EM3200, KYKY Co. China). To identify and measure amoxicillin, an HPLC device (YL 9100 Waters, USA) was utilized. The structure of the catalyst’s crystal was determined using a D8 Advanced Ray Diffractometer (XRD) (Bruker AXS, Germany). The photoluminescence spectrum and DRS analysis were determined using an Avaspec UV-2550 (Shimadzu, Japan). EDX analysis was determined using a MIRA3TESCAN-XMU (Tescan, Czech Republic).

Results and discussion

Results obtained from the injection of amoxicillin by the HPLC device are shown in Fig. 2 in the form of a chromatogram peak.

SEM was used to characterize the size, shape, and morphology of the nanocatalyst. Figure 3 shows electron microscopy images of the nanocatalyst particles (Fe+3–TiO2).

The XRD patterns of pure TiO2 and Fe3+–TiO2 are illustrated in Fig. 4.

The red lines show the anatase structure, and the blue lines are the rutile structure. Anatase had a greater intensity before the synthesis of TiO2, but rutile had a greater intensity after the doping of TiO2 with iron trivalent. Iron ion peaks were observed in the crystalline structure of titanium dioxide.

The DRS analysis of Fe3+–TiO2 is shown in Fig. 5.

Diffused reflectance spectra of the sample which are illustrated in Fig. 5 show uniform visible light absorption in the entire visible range. To see the radiation effect of the included Fe+3–TiO2 particles, in Fig. 5 the photoluminescence spectra of the sample are included.

Figure 6 presents the Kubelka–Munk plot of the sample for determination of the band gap. The result shows that the band gap of Fe+3–TiO2 particles is 1.535 eV in the visible region.

The EDX spectra of Fe3+–TiO2 are shown in Fig. 7.

The elemental composition of Fe+3–TiO2 was determined by energy-dispersive X-ray analysis. The chemical composition of nanocatalyst particles is iron—8.68 at.%, titanium—40.63 at.%, and oxygen—50.69 at.%; the weight ratios are iron—15.39%, titanium—61.81%, and oxygen—25.77%.

The photoluminescence spectra of Fe3+–TiO2 are shown in Fig. 8.

The photoluminescence spectra of Fe+3–TiO2 show that in the presence of Fe+3–TiO2 particles, radiated light will increase significantly around 380 nm.

The effect of pH on the removal of amoxicillin Fe+3–TiO2/UV-C

The results of investigating the effect of pH on the removal efficiency of amoxicillin by the Fe3+–TiO2/UV-C process and under nanocatalyst-free conditions are shown and compared in Fig. 9.

The efficiency rates for removal of amoxicillin at pH 3, 7, and 11 were 49.51, 55.93, and 75.35%, respectively. In the absence of the nanocatalyst, these values were 44.19, 49.67, and 71.418%, respectively. pH is an important factor that affects removal efficiency of many chemical and biological reactions (Dehghani et al. 2014b). Removal efficiency by nanocatalyst with exposure to UV radiation was reported as 99.14%, while in the absence of the nanocatalyst, it was 86.72%. The greatest removal rate (90 mg/L) reported at pH 11 in the presence of the nanocatalyst was caused by a high concentration of hydroxyl radicals in the solution (p < 0.05) (Hemati Borji et al. 2010). These radicals play an important role in oxidizing organic contaminants (Konstantinou and Albanis 2002). The advanced oxidation process is based on hydroxyl radicals that cause oxidation and the removal of contaminants (Dehghani et al. 2014b; Hemati Borji et al. 2010). The impact of pH on the contaminant molecules, the surface charge of a nanocatalyst, and the mechanism of the degree of production of hydroxyl radicals is important (Saien and Shahrezaei 2012). The hydroxyl radical rapidly reacts with the aromatic ring in the side chain of amoxicillin (Song et al. 2008). The effect of pH on antibiotic degradation can be explained by considering the properties of both catalyst and antibiotics at different pH values. For TiO2, as pH increases, the overall surface charge of TiO2 changes from positive (pKa1 = 2.6) to negative (pKa2 = 9.0) with the point of zero charge being pH 6.4. Ionic amoxicillin species change from a positive charge at acidic pH to a negative charge at alkaline pH. At acidic pH, both TiO2 and amoxicillin are positively charged, and hence, adsorption on the surface of TiO2 is limited. The high degradation of antibiotics at acidic pH compared to that at neutral pH may be due to the hydrolysis of antibiotics. At alkaline pH, both amoxicillin and the TiO2 are negatively charged, and so repulsive forces develop between the catalyst and the antibiotics. The high degradation of antibiotics under alkaline conditions may be due to two facts: the enhancement of hydroxyl radical formation at high pH due to the availability of hydroxyl ions on the TiO2 surface that can easily be oxidized to form hydroxyl radicals and the hydrolysis of the antibiotics due to the instability of the β-lactam ring at high pH values (Elmolla and Chaudhuri 2010b). Mendez-Arriaga et al. (2011) conducted a study in Spain on the application of the UV/TiO2 process for removing fluoxetine. Their results indicated that the photolysis of fluoxetine was only justifiable in an alkaline pH. The UV/TiO2 process resulted in 50% removal of fluoxetine at an initial fluoxetine concentration of 0.11 mM, pH 11, and a duration of 60 min. This is explained by the fact that a higher pH level led to increased absorption of fluoxetine on TiO2 and oxidation of the contaminant by hydroxyl radicals (Mendez-Arriaga et al. 2011). The results of that study are congruent with the results of this research. In Malaysia, Elmolla and Chaudhuri (2010a) studied the photocatalytic removal of the antibiotics amoxicillin, ampicillin, and cloxacillin from aquatic environments. Results showed that the greatest removal rate was obtained at pH 11. It was also reported that at alkaline pH, more hydroxyl ions had become available to the catalyst, producing more hydroxyl radicals and thus oxidizing the antibiotic (Elmolla and Chaudhuri 2010b). The results of that study are consistent with the results of the current research. Malakootian et al. (2017) conducted a study on the application of the UV/Fe+3–TiO2 process for removing metronidazole. Their results indicated that the photodegradation of metronidazole was justifiable in an alkaline pH. The UV/Fe+3–TiO2 process resulted in removal of metronidazole at pH 11 and a duration of 120 min (Malakootian et al. 2017).

Reactions are schematically shown from (Eqs. 2–13) (Sood et al. 2015):

Effect of initial concentration of amoxicillin in its removal under the Fe+3–TiO2/UV-C process

The results obtained from investigating the effect of initial concentration of amoxicillin on its removal efficiency by the Fe+3–TiO2/UV-C process and under nanocatalyst-free conditions are shown and compared in Fig. 10.

The removal efficiency rates of amoxicillin in the Fe+3–TiO2/UV-C process at concentrations of 10, 25, and 45 mg/L were 69.62, 69.17, and 57.44%, respectively. In the absence of a nanocatalyst, the values were 63.706, 63.0126, and 48.948%, respectively. Based on the obtained results, the efficiency of amoxicillin removal using a nanocatalyst under exposure to UV radiation reached 99.14%, and in the absence of a nanocatalyst was 86.72%, suggesting that the application of nanocatalysts in the presence of UV radiation achieved a greater removal efficiency than did UV radiation alone. At various antibiotic concentrations, the highest removal rate under optimal conditions was 99.14% achieved for an antibiotic concentration of 10 mg/L, where the initial concentration of antibiotic was inversely related to the level of photocatalytic removal (p < 0.05). In the photocatalytic process, concentrations of produced radicals were equal in all samples. Samples of amoxicillin at lower concentrations with the same amount of hydroxyl radicals had a greater possibility of removal than did samples with a higher concentration of antibiotic. Other studies by Dehghani et al. (2014b) in Iran for the photocatalytic removal of penicillin-G and Nasseri et al. (2011) for the photocatalytic removal of phenol indicated that removal efficiency was developed under a lower initial concentration of contaminant. The concentrations of the produced radicals were equal across all solutions in the photocatalytic process, and the solution with a concentration lower than that of the contaminant with the same amount of hydroxyl radicals had a higher removal efficiency than did a higher concentration solution. These results are congruent with those of the current research. In China, Zhang et al. (2008) revealed that the removal of acetaminophen from an aquatic solution was approximately 95% after 100 min with the concurrent use of TiO2 and UV radiation. The initial concentration of acetaminophen affected removal efficiency, whereas initial concentration and efficiency were inversely related. This was because the concentrations of the produced radicals were the same for all samples. Samples with lower concentrations and the same amount of hydroxyl radicals had a greater removal potential compared with samples with higher concentrations (Zhang et al. 2008); these results are in accordance with the results of the current research.

Effect of the amount of Fe3+–TiO2 nanocatalyst in removing amoxicillin using the Fe3+–TiO2/UV-C method

Results obtained from investigating the effect of loading the Fe+3–TiO2 nanocatalyst on the removal of amoxicillin are illustrated in Fig. 11.

The removal efficiency of amoxicillin at 30, 60, and 90 mg/L of the nanocatalyst concentrations was determined to be 59.42, 61.92, and 63.52%, respectively. Titanium dioxide has the potential to be applied in the decomposition of many organic pollutants because of its optical and electrical properties, low cost, chemical stability, and nontoxicity. Numerous methods are available for the preparation of photocatalysts. Among them, sol–gel methods are interesting (Sohrabi and Akhlaghian 2016). The mechanism of photocatalytic removal is based on the production of active and reactive radicals such as ·OH. Titanium dioxide is the most commonly used semiconductor photocatalyst for removing contaminants from water or air. Despite the above-mentioned advantages, this compound also has some disadvantages; for example, it makes less effective use of photons in comparison with samples doped with other elements; there is a relatively high velocity of the recombination of electrons and pores generated by light and activity at wavelengths below 400 nm. To improve the photocatalytic efficiency of TiO2, to develop its effective absorption of light on a visible light range, and to prevent the recombination of electrons and pores, the process has been modified using various operations. Among such modifications is TiO2 doping with metal and nonmetal ions. Because of the semi-full electron arrangements and the close proximity of the ion radius to the ion radius of Ti4+, metal ions are easily replaced throughout the TiO2 network, causing increased photocatalytic activity within the visible light range. Fe3+ ions in the TiO2 network develop a surface trap for electrons and pores created out of radiation. By decreasing the recombination of developed electrons and pores, it then enhances quantum efficiency and photocatalytic activity. Fe3+ is known as an effective and remarkable enriching factor (Nasseri et al. 2011). Trivial amounts of enriching iron have a positive influence in enhancing the photocatalytic activity of Fe3+–TiO2 (Sun et al. 2009). Titanium dioxide has three crystalline phases (anatase, rutile, and brukite). The combination of rutile and anatase structures has more activity (Kazuhito et al. 2005). Some researchers have studied the photocatalytic activity of TiO2 in the visible light region. It can only make use of 3–5% of the solar spectrum that reaches the earth because of its large band gap. It is essential to produce visible light-responsive TiO2 not only to use the visible light, but also to reduce the recombination of photogenerated electrons and holes (Baghapour et al. 2016).

According to the current results, the greatest amoxicillin removal efficiency was 99.14% for 90 mg/L of nanocatalyst. A direct relation was determined between concentration of nanocatalyst and extent of removal (p < 0.05). With an increased nanocatalyst concentration, there were an increased number of absorbed photons that increased active sites throughout the nanocatalyst (Zhou et al. 2005). Higher concentrations of nanocatalyst up to 90 mg/L led to the increased efficiency of contaminant removal (Hoseini et al. 2013; Mahvi et al. 2009; Yang et al. 2008). The extent of removal declined at higher concentrations of nanocatalyst. This is explained by the accumulation of TiO2 particles and the decrease in the number of superficial active sites of the nanocatalyst and increased turbidity and light dispersion at high concentrations (Thakur et al. 2010). A study conducted by Dehghani et al. (2014a) in Iran demonstrated that increased concentrations of Fe3+–TiO2 nanocatalyst resulted in the increased efficiency of penicillin-G removal. This was due to the enumeration of absorbed photons in the number of active sites of the nanocatalyst that resulted in an increased number of hydroxyl radicals (Dehghani et al. 2014b); these results support the results of the current research. The results obtained by Evgenidou et al. (2007) in their 2007 study in Greece for removing prometrin photocatalytically from an aquatic environment indicated that the application of TiO2 was very effective and dramatically increased the reaction rate; this result was attributed to the increased production of hydroxyl radicals. The results obtained by Mantzavinos et al. demonstrated that complete amoxicillin degradation and 93% mineralization were achieved after 25 and 90 min of reaction, respectively, at 10 mg/L amoxicillin and 250 mg/L titanium dioxide using UV-A/TiO2 photocatalysis. The current study showed that 91.43–99.14% amoxicillin removal was obtained at an initial antibiotic concentration of 10 and 90 mg/L of catalyst at 90–120 min contact time using Fe+3–TiO2/UV-C. The results obtained by Reyes et al., in Mexico in 2016 for the removal of As(III) under visible radiation and Fe-doped TiO2 and its potential application on the treatment of As-contaminated groundwater indicated that favorable outcomes could be achieved in the photocatalytic oxidation reaction of As(III) by using a small doping amount of Fe (1.0 wt%) in TiO2 powder (Garza-Arévalo et al. 2016). Therefore, titanium dioxide doped with trivalent iron can increase the efficiency of amoxicillin removal and save on catalyst consumption (Dimitrakopoulou et al. 2012). Trace amounts of iron enrichment had positive effects on increasing Fe3+–TiO2 photocatalytic activity.

Influence of applying UV radiation in removing amoxicillin using the Fe3+–TiO2/UV-C method

Applying UV radiation with the nanocatalyst developed the removal efficiency of amoxicillin up to 99.14%. At lower concentrations of amoxicillin, removal efficiency was determined as suitable (p < 0.05), because the UV rays caused an increased number of active sites on the catalyst surface. The results of Sun et al. in Korea in 2009 for the photolysis and photocatalysis of Triclosan using TiO2 demonstrated that removal efficiency for photolysis and photocatalysis cases at similar times was 75 and 82%, respectively, showing the greater efficiency of photocatalysis. This result was attributed to active sites on the catalyst surface (Son et al. 2009). Their results were congruent with the results of the current research. In Japan, Nahar et al. (2006) reported that the photocatalytic removal of phenol using Fe3+–TiO2/UV-C was greater than that through visible light. This was attributed to an increased number of active sites on the catalyst surface with the help of UV radiation (Nahar et al. 2006); these results, too, were in accordance with the results of the current research.

Effect of time on photocatalytic removal of amoxicillin from aquatic environments using the Fe3+–TiO2/UV-C method

The results of investigations into the effect of time on the removal efficiency of amoxicillin in the Fe3+–TiO2/UV-C process and in the absence of the nanocatalyst are illustrated and compared in Fig. 12.

Determining the time required to reach appropriate and economical time intervals is very important. Contact time is an important parameter in chemical reactions and needs to be optimized (Dehghani et al. 2013b, 2014a). The current results demonstrated that amoxicillin removal efficiency increases under a longer duration. The application of nanocatalyst with UV radiation had greater removal efficiency in comparison with UV radiation alone. Its maximum removal efficiency in the presence of the nanocatalyst was 99.14% (p < 0.05) under the time duration of 120 min. This is explained by the fact that the contaminant had longer exposure to UV-C rays, and the oxidation process was enhanced in the presence of hydroxyl radicals. The extent of removal reached an almost constant value after 120 min. In Iran, Dehghani et al. (2013b) and Baghapour et al. (2015) reported maximum removal efficiency after 120 min for the photocatalytic removal of penicillin-G and atrazine, respectively. This was attributed to further contact with UV-C rays and the increased number of active sites of the nanocatalyst in response to ultraviolet radiation (Baghapour et al. 2015; Dehghani et al. 2013a); these results are in accordance with the results of the current research. Salaices et al. (2001) in the USA showed that the removal efficiency of phenol and TOC by the photocatalytic process with titanium dioxide and UV radiation rose with residence time; at 180 min, TOC removal efficiency with an initial concentration of 50 mg/L was approximately 100%. The reason for this result was increased oxidation by the hydroxyl radicals in response to longer contact with the catalyst and UV rays (Dehghanifard et al. 2012); these results are in line with those of the current study. Li et al. (2015) achieved the highest photodegradation (100%) and mineralization (78.1%) after 300 min of photocatalytic reaction (Li et al. 2015).

Kinetic study of amoxicillin removal

The removal of amoxicillin by nanophotocatalyst (Fe3+–TiO2/UV-C) was observed to follow the pseudo first-order kinetics (Eq. 14):

where k is the rate constant of the reaction, Ct and C0 are the amoxicillin concentration (mg/L) after exposure time t and the initial concentration of amoxicillin (mg/L), respectively, and t is the exposure time (min). The pseudo second-order kinetics is (Eq. 15):

The pseudo first-order degradation curves are depicted in Fig. 13. A plot of Ln(C0/Ct) shows a linear relationship with the irradiation time where the slope equals the rate constant (k = 0.0393) and R2 = 0.8942.

Influence of nanophotocatalyst on pharmaceutical wastewater

Results of investigation of the physiochemical quality of wastewater of the Dana pharmaceutical factory are provided in Table 1.

After applying optimal conditions, removal efficiency in the Fe+3–TiO2/UV-C process was 88.92% and in the UV-C process was 75.86%, having lower efficiency compared to synthetic solutions. Moreover, amounts of residual antibiotic, COD, and BOD in the Fe+3–TiO2/UV-C were 281, 54,300, and 35,000 mg/L, respectively. For the UV-C process, values were 616, 55,900, and 42,000 mg/L, respectively.

The results indicate that removal efficiency at the amoxicillin concentration of 2544 mg/L from real wastewater was 88.92% in the Fe3+–TiO2/UV-C process, while it was 75.86% in the absence of nanocatalyst. Removal efficiency was lower in the real sample than in synthetic samples. The application of nanocatalyst with UV radiation had greater removal efficiency than did UV radiation alone. Interfering factors such as organic and cyclic compounds along with turbidity of wastewater resulted in diminished removal efficiency compared with that of synthetic samples. Lower removal efficiency was due to the fact that under an increased concentration of contaminant, there is a larger area of nanocatalyst occupied by it. In addition, the destruction of interfering factors leads to the occupation of the nanocatalytic surface, resulting in adverse effects in the application of hydroxyl radicals with positive pores in the capacity band of the nanocatalytic surface. Furthermore, under increased concentrations of contaminant, there is further absorption of UV light by its molecules, and this causes internal filtration, which, in turn, results in the decreased reception of photons by the nanocatalytic surface (Farzadkia et al. 2015).

Conclusion

Application of the Fe3+–TiO2/UV-C process for removing the antibiotic amoxicillin from the wastewater of the pharmaceutical industry was justified by its high efficacy (88.92%). Pretreatment methods are recommended to enhance removal efficiency in real wastewater for removing interfering factors before performing the photocatalytic process. Moreover, it is proposed that future studies further investigate larger numbers of concentrations of the nanocatalyst as well as amoxicillin together with different intensities of the light radiation source with various wavelengths.

References

Baghapour MA, Shamsedini N, Dehghani M, Naseri S (2015) Photodegradation of atrazine by ultraviolet radiation in different conditions. J Health Sci Surveill Syst 3:94–100

Baghapour MA, Shamsedini N, Dehghani M, Nasseri S, Moghaddam MS (2016) Optimization of atrazine degradation in the aqueous phase using titanium catalyst doped with iron (Fe+3–TiO2) Processes. J Health Scope. 5:6. https://doi.org/10.17795/jhealthscope-33065

Chen J et al (2016) Removal of antibiotics and antibiotic resistance genes from domestic sewage by constructed wetlands: effect of flow configuration and plant species. Sci Total Environ 571:974–982. https://doi.org/10.1016/j.scitotenv.2016.07.085

Daghrir R, Drogui P, Ka I, El Khakani MA (2012) Photoelectrocatalytic degradation of chlortetracycline using Ti/TiO2 nanostructured electrodes deposited by means of a pulsed laser deposition process. J Hazard Mater 199–200:15–24. https://doi.org/10.1016/j.jhazmat.2011.10.022

Dehghani M, Ahmadi M, Nasseri S (2013a) Photodegradation of the antibiotic penicillin G in the aqueous solution using UV-A radiation. Iran J Health Sci 1:43–50

Dehghani M, Naseri S, Hashemi H (2013b) Study the bioremediation of atrazine under variable carbon and nitrogen sources by mixed bacterial consortium isolated from corn field soil in Fars province of Iran. J Environ Public Health. https://doi.org/10.1155/2013/973165

Dehghani M, Naseri S, Karamimanesh M (2014a) Removal of 2,4-Dichlorophenolyxacetic acid (2,4-D) herbicide in the aqueous phase using modified granular activated carbon. J Environ Health Sci Eng 12:28. https://doi.org/10.1186/2052-336X-12-28

Dehghani M, Nasseri S, Ahmadi M, Samaei M, Anushiravani A (2014b) Removal of penicillin G from aqueous phase by Fe+3–TiO2/UV-A process. J Environ Health Sci Eng 12:1–7. https://doi.org/10.1186/2052-336x-12-56

Dehghanifard E, Jonidi Jafari A, Rezae Kalantari R, Gholami M, Esrafili A (2012) Photocatalytic removal of aniline from synthetic wastewater using ZnO nanoparticle under ultraviolet irradiation Iranian. J Mazandaran Univ Med Sci. 5:167–178

Dimitrakopoulou D, Rethemiotaki I, Frontistis Z, Xekoukoulotakis NP, Venieri D, Mantzavinos D (2012) Degradation, mineralization and antibiotic inactivation of amoxicillin by UV-A/TiO2 photocatalysis. J Environ Manag 98:168–174. https://doi.org/10.1016/j.jenvman.2012.01.010

el mehdi Benacherine MM, Debbache N, Ghoul I, Mameri Y (2017) Heterogeneous photoinduced degradation of amoxicillin by goethite under artificial and natural irradiation. J Photochem Photobiol A Chem 335:70–77. https://doi.org/10.1016/j.jphotochem.2016.11.008

Elmolla ES, Chaudhuri M (2010a) Comparison of different advanced oxidation processes for treatment of antibiotic aqueous solution. Desalination 256:43–47. https://doi.org/10.1016/j.desal.2010.02.019

Elmolla ES, Chaudhuri M (2010b) Photocatalytic degradation of amoxicillin, ampicillin and cloxacillin antibiotics in aqueous solution using UV/TiO2 and UV/H2O2/TiO2 photocatalysis. Desalination 252:46–52. https://doi.org/10.1016/j.desal.2009.11.003

Elmolla ES, Chaudhuri M (2011) The feasibility of using combined TiO2 photocatalysis-SBR process for antibiotic wastewater treatment. Desalination 272:218–224. https://doi.org/10.1016/j.desal.2011.01.020

Evgenidou E, Bizani E, Christophoridis C, Fytianos K (2007) Heterogeneous photocatalytic degradation of prometryn in aqueous solutions under UV–Vis irradiation. Chemosphere 68:1877–1882. https://doi.org/10.1016/j.chemosphere.2007.03.012

Farzadkia M, Bazrafshan E, Esrafili A, Jae-Kyu Y, Hirzad-Siboni M (2015) Photocatalytic degradation of metronidazole with illuminated TiO2 nanoparticles. J Environ Health Sci Eng 13:35. https://doi.org/10.1186/s40201-015-0194-y

Gad-Allah TA, Ali MEM, Badawy MI (2011) Photocatalytic oxidation of ciprofloxacin under simulated sunlight. J Hazard Mater 186:751–755. https://doi.org/10.1016/j.jhazmat.2010.11.066

Garza-Arévalo JI, García-Montes I, Reyes MH, Guzmán-Mar JL, Rodríguez-González V, Reyes LH (2016) Fe doped TiO2 photocatalyst for the removal of As(III) under visible radiation and its potential application on the treatment of As-contaminated groundwater. Mater Res Bull 73:145–152. https://doi.org/10.1016/j.materresbull.2015.08.034

Giraldo AL, Peñuela GA, Torres-Palma RA, Pino NJ, Palominos RA, Mansilla HD (2010) Degradation of the antibiotic oxolinic acid by photocatalysis with TiO2 in suspension. Water Res 44:5158–5167. https://doi.org/10.1016/j.watres.2010.05.011

Hapeshi E, Achilleos A, Vasquez MI, Michael C, Xekoukoulotakis NP, Mantzavinos D, Kassinos D (2010) Drugs degrading photocatalytically: kinetics and mechanisms of ofloxacin and atenolol removal on titania suspensions. Water Res 44:1737–1746. https://doi.org/10.1016/j.watres.2009.11.044

Haque MM, Muneer M (2007) Photodegradation of norfloxacin in aqueous suspensions of titanium dioxide. J Hazard Mater 145:51–57. https://doi.org/10.1016/j.jhazmat.2006.10.086

Hemati Borji S, Nabizadeh R, Mahvi AH, Javadi AH (2010) Photocatalytic degradation of phenol in aqueous solutions by Fe(III)-doped TiO2/UV process. Iranian J Health Environ 3:369–380

Hoseini M, Nabizadeh R, Nazmara S, Safari GH (2013) Influence of under pressure dissolved oxygen on trichloroethylene degradation by the H2O2/TiO2 process. J Environ Health Sci Eng 11:38. https://doi.org/10.1186/2052-336X-11-38

Kazuhito H, Hiroshi I, Akira F (2005) TiO2 photocatalysis: a historical overview and future prospects. Jpn J Appl Phys 44:8269. https://doi.org/10.1143/JJAP.44.8269

Klavarioti M, Mantzavinos D, Kassinos D (2009) Removal of residual pharmaceuticals from aqueous systems by advanced oxidation processes. Environ Int 35:402–417. https://doi.org/10.1016/j.envint.2008.07.009

Konstantinou I, Albanis T (2002) Photocatalytic transformation of pesticides in aqueous titanium dioxide suspensions using artificial and solar light: intermediates and degradation pathways. Appl Catal B 1310:1–17. https://doi.org/10.1016/S0926-3373(02)00266-7

Kümmerer K (2009) Antibiotics in the aquatic environment—a review—part I. Chemosphere 75:417–434. https://doi.org/10.1016/j.chemosphere.2008.11.086

Laport MS et al (2016) Antibiotic resistance genes detected in the marine sponge Petromica citrina from Brazilian coast. Braz J Microbiol. 47:617–620. https://doi.org/10.1016/j.bjm.2016.04.016

Li D, Zhu Q, Han C, Yang Y, Jiang W, Zhang Z (2015) Photocatalytic degradation of recalcitrant organic pollutants in water using a novel cylindrical multi-column photoreactor packed with TiO2-coated silica gel beads. J Hazard Mater 285:398–408. https://doi.org/10.1016/j.jhazmat.2014.12.024

Mahvi AH, Ghanbarian M, Nasseri S, Khairi A (2009) Mineralization and discoloration of textile wastewater by TiO2 nanoparticles. Desalination 239:309–316. https://doi.org/10.1016/j.desal.2008.04.002

Malakootian M, Mansuri F (2015) Hexavalent chromium removal by TiO2 photocatalytic reduction and the effect of phenol and humic acid on its removal efficiency. Int J Health Eng 4:19. https://doi.org/10.4103/2277-9183.157720

Malakootian M, Yaghmaeian K, Mansoori F (2014) Effect of cations Ca2+ and Mg2+ on the removal efficiency of humic acid by UV/TiO2. J Shahrekord Univ Med Sci. 16:9–20

Malakootian M, Bahraini S, Zarrabi M, Malakootian M (2016a) Removal of Tetracycline antibiotic from aqueous solutions using natural and modified pumice with magnesium chloride. Adv Environ Biol 10:46–56

Malakootian M, Ehrampoush M, Hossaini H, Pourshaban Mazandarani M (2016b) Acetaminophen removal from aqueous solutions by TiO2-X photo catalyst. Tolooebehdasht 14:200–213

Malakootian M, Pourshaban-Mazandarani M, Hossaini H, Ehrampoush MH (2016c) Preparation and characterization of TiO2 incorporated 13X molecular sieves for photocatalytic removal of acetaminophen from aqueous solutions. Process Saf Environ Prot 104:334–345. https://doi.org/10.1016/j.psep.2016.09.018

Malakootian M, Olama N, Dehghani M (2017) Photocatalytic degradation of metronidazole from aquatic solution by TiO2 doped Fe3+ nano-photocatalyst. Int J Environ Sci Technol (IJEST). https://doi.org/10.1007/s13762-018-1836-2

Mendez-Arriaga F, Otsu T, Oyama T, Gimenez J, Esplugas S, Hidaka H (2011) Photooxidation of the antidepressant drug Fluoxetine in aqueous media by hybrid catalytic/ozonation processes. Water Res 45:2782–2794. https://doi.org/10.1016/j.watres.2011.02.030

Momenzadeh R, Malakootian M, Yaghmaeian K (2015) Efficiency of titanium dioxide photocatalytic activity in removing anionic surfactant of sodium dodecyl sulfate from waste water. Koomesh J 16:648–654

Moreira NF, Orge CA, Ribeiro AR, Faria JL, Nunes OC, Pereira MF, Silva AM (2015) Fast mineralization and detoxification of amoxicillin and diclofenac by photocatalytic ozonation and application to an urban wastewater. Water Res 87:87–96. https://doi.org/10.1016/j.watres.2015.08.059

Nahar MS, Hasegawa K, Kagaya S (2006) Photocatalytic degradation of phendol by visible light-responsive iron-doped TiO2 and spontaneous sedimentation of the TiO2 particles. Chemosphere 65:1976–1982. https://doi.org/10.1016/j.chemosphere.2006.07.002

Nasseri S, Hemmati Borji S, Mahvi AH, Nabizadeh R, Javadi AH (2011) Investigation of photocatalytic degradation of phenol by Fe(III)-doped TiO2 and TiO2 nanoparticles. J Environ Health Sci Eng. 12:101. https://doi.org/10.1186/2052-336X-12-101

Nasuhoglu D, Rodayan A, Berk D, Yargeau V (2012) Removal of the antibiotic levofloxacin (LEVO) in water by ozonation and TiO2 photocatalysis. Chem Eng J 189–190:41–48. https://doi.org/10.1016/j.cej.2012.02.016

Pouretedal HR, Sadegh N (2014) Effective removal of Amoxicillin, Cephalexin, Tetracycline and Penicillin G from aqueous solutions using activated carbon nanoparticles prepared from vine wood. J Water Process Eng 1:64–73. https://doi.org/10.1016/j.jwpe.2014.03.006

Qu X, Wu CFJ (2005) One-factor-at-a-time designs of resolution V. J Stat Plan Inference 131:407–416. https://doi.org/10.1016/j.jspi.2004.03.002

Saien J, Shahrezaei F (2012) Organic pollutants removal from petroleum refinery wastewater with nanotitania photocatalyst and UV light emission. Int J Photoenergy 2012:5. https://doi.org/10.1155/2012/703074

Salaices M, Serrano B, Lasa H (2001) Photo-catalytic conversion of organic pollutants Extinction coefficients and quantum efficiencies. Ind Eng Chem Res 40:5455–5464. https://doi.org/10.1021/ie0102551

Sohrabi S, Akhlaghian F (2016) The effect of Fe-loading and calcination temperature on the activity of Fe/TiO2 in phenol. Iran J Chem Chem Eng 35:43–50

Son HS, Ko G, Zoh KD (2009) Kinetics and mechanism of photolysis and TiO2 photocatalysis of triclosan. J Hazard Mater 166:954–960. https://doi.org/10.1016/j.jhazmat.2008.11.107

Song W, Chen W, Cooper WJ, Greaves J, Miller GE (2008) Free-radical destruction of beta-lactam antibiotics in aqueous solution. J Phys Chem A 112:7411–7417. https://doi.org/10.1021/jp803229a

Sood S, Umar A, Mehta SK, Kansal SK (2015) Highly effective Fe-doped TiO2 nanoparticles photocatalysts for visible-light driven photocatalytic degradation of toxic organic compounds. J Colloid Interface Sci 450:213–223. https://doi.org/10.1016/j.jcis.2015.03.018

Sun L, Li J, Wang CL, Li SF, Chen HB, Lin CJ (2009) An electrochemical strategy of doping Fe3+ into TiO2 nanotube array films for enhancement in photocatalytic activity. Sol Energy Mater Sol Cells 93:1875–1880. https://doi.org/10.1016/j.solmat.2009.07.001

Thakur RS, Chaudhary R, Singh C (2010) Fundamentals and applications of the photocatalytic treatment for the removal of industrial organic pollutants and effects of operational parameters: a review. J Renew Sustain Energy. https://doi.org/10.1063/1.3467511

Tian X, Fei J, Pi Z, Yang C, Luo D (2005) Synthesis and characterization of amoxicillin nanostructures. Nanomedicine 1:323–325. https://doi.org/10.1016/j.nano.2005.10.001

Yang L, Yu LE, Ray MB (2008) Degradation of paracetamol in aqueous solutions by TiO2 photocatalysis. Water Res 42:3480–3488. https://doi.org/10.1016/j.watres.2008.04.023

Zhang X, Wu F, Wu X, Chen P, Deng N (2008) Photodegradation of acetaminophen in TiO2 suspended solution. J Hazard Mater 157:300–307. https://doi.org/10.1016/j.jhazmat.2007.12.098

Zhang J, Fu D, Xu Y, Liu C (2010) Optimization of parameters on photocatalytic degradation of chloramphenicol using TiO2 as photocatalyist by response surface methodology. J Environ Sci (China) 22:1281–1289. https://doi.org/10.1016/S1001-0742(09)60251-5

Zhou M, Yu J, Cheng B, Yu H (2005) Preparation and photocatalytic activity of Fe-doped mesoporous titanium dioxide nanocrystalline photocatalysts. Mater Chem Phys 93:159–163. https://doi.org/10.1016/j.matchemphys.2005.03.007

Acknowledgements

This paper is the result of a Master of Science Thesis in Environmental Health Engineering conducted in the Environmental Health Engineering Research Center of Kerman University of Medical Sciences and was sponsored by the Vice-Chancellor for Research and Technology of Kerman University of Medical Sciences. The authors wish to express their appreciation to the Deputy Research Center in Kerman University of Medical Sciences for its financial support, Shiraz University of Medical Sciences—Health and Nutrition Faculty—for its cooperation, Dr. Mohammad Reza Kazemi, Head of the Statistics Sector and Financial Deputy of Fasa University for his assistance, Pars Daru Pharmaceutical Company, and Dana Pharmaceutical Company. We hereby gratefully acknowledge their assistance and great support of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Olama, N., Dehghani, M. & Malakootian, M. The removal of amoxicillin from aquatic solutions using the TiO2/UV-C nanophotocatalytic method doped with trivalent iron. Appl Water Sci 8, 97 (2018). https://doi.org/10.1007/s13201-018-0733-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0733-7