Abstract

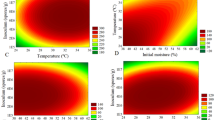

This study focuses on the influence of operating conditions on Alcalase-catalyzed egg white protein hydrolysis performed in a continuously stirred tank reactor coupled with ultrafiltration module (10 kDa). The permeate flow rate did not significantly affect the degree of hydrolysis (DH), but a significant increase in process productivity was apparent above flow rate of 1.9 cm3 min−1. By contrast, an increase in enzyme/substrate (E/S) ratio provided an increase in DH, but a negative correlation was observed between E/S ratio and productivity. The relationship between operating conditions and antioxidant properties of the hydrolysates, measured by three methods, was studied using Box-Behnken experimental design and response surface methodology. The statistical analysis showed that each variable (impeller speed, E/S ratio, and permeate flow rate) had a significant effect on the antioxidant capacity of all tested systems. Nevertheless, obtained response functions revealed that antioxidative activity measured by DPPH, ABTS and FRAP methods were affected differently by the same operating conditions. High impeller speeds and low permeate flow rates favor ABTS while high impeller speeds and high permeate flow rates had a positive effect on the DPPH scavenging activity. On the other hand, the best results obtained with FRAP method were achieved under moderate operating conditions. The integration of the reaction and ultrafiltration membrane separation in a continuous manner appears to be a right approach to improve and intensify the enzymatic process, enabling the production of peptides with desired antioxidant activity.

Similar content being viewed by others

References

Berends P, Appel D, Eisele T, Rabe S, Fischer L (2014) Performance of enzymatic wheat gluten hydrolysis in batch and continuous processes using Flavourzyme. LWT Food Sci Technol 58:534–540

Bhat ZF, Kumar S, Bhat HF (2015) Bioactive peptides of animal origin: a review. J Food Sci Technol 52:5377–5392

Chen C, Chi YJ (2012) Antioxidant, ACE inhibitory activities and functional properties of egg white protein hydrolysate. J Food Biochem 36:383–394

Chiang WD, Tsou MJ, Weng CH, Tsai TC (2008) Production of angiotensin I-converting enzyme inhibitor derived from egg white protein hydrolysates using a membrane reactor. J Food Drug Anal 16:54–60

Das R, Ghosh S, Bhattacharjee C (2012) Enzyme membrane reactor in isolation of antioxidative peptides from oil industry waste: a comparison with non-peptidic antioxidants. LWT Food Sci Technol 47:238–245

de Oliveira CF, Correa AP, Coletto D, Daroit DJ, Cladera-Olivera F, Brandelli A (2015) Soy protein hydrolysis with microbial protease to improve antioxidant and functional properties. J Food Sci Technol 52:2668–2678

Demirhan E, Apar DK, Özbek B (2010) Sesame cake protein hydrolysis by alcalase: effects of process parameters on hydrolysis, solubilisation, and enzyme inactivation. Korean J Chem Eng 28:195–202

Dryáková A, Pihlanto A, Marnila P, Čurda L, Korhonen HT (2010) Antioxidant properties of whey protein hydrolysates as measured by three methods. Eur Food Res Technol 230:865–874

Fan S, Hu Y, Li C, Liu Y (2014) Optimization of preparation of antioxidative peptides from pumpkin seeds using response surface method. PLoS ONE 9:e92335

Guadix A, Camacho F, Guadix EM (2006) Production of whey protein hydrolysates with reduced allergenicity in a stable membrane reactor. J Food Eng 72:398–405

Jakovetić S, Luković N, Jugović B, Gvozdenović M, Grbavčić S, Jovanović J, Knežević-Jugović Z (2015) Production of antioxidant egg white hydrolysates in a continuous stirred tank enzyme reactor coupled with membrane separation unit. Food Bioprocess Technol 8:287–300

Jiang H, Tong T, Sun J, Xu Y, Zhao Z, Liao D (2014) Purification and characterization of antioxidative peptides from round scad (Decapterus maruadsi) muscle protein hydrolysate. Food Chem 154:158–163

Kedare S, Singh RP (2011) Genesis and development of DPPH method of antioxidant assay. J Food Sci Technol 48:412–422

Li Y, Jiang B, Zhang T, Mu W, Liu J (2008) Antioxidant and free radical-scavenging activities of chickpea protein hydrolysate (CPH). Food Chem 106:444–450

Lin S, Guo Y, You Q, Yin Y, Liu J (2012) Preparation of antioxidant peptide from egg white protein and improvement of its activities assisted by high-intensity pulsed electric field. J Sci Food Agric 92:1554–1561

Lin S, Jin Y, Liu M, Yang Y, Zhang M, Guo Y, Jones G, Liu J, Yin Y (2013) Research on the preparation of antioxidant peptides derived from egg white with assisting of high-intensity pulsed electric field. Food Chem 139:300–306

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Malaguti M, Dinelli G, Leoncini E, Bregola V, Bosi S, Cicero AFG, Hrelia S (2014) Bioactive peptides in cereals and legumes: agronomical, biochemical and clinical aspects. Int J Mol Sci 15:21120–21135

Milutinović M, Šiler-Marinković S, Antonović D, Mihajlovska K, Pavlović M, Dimitrijević-Branković S (2013) The antioxidant properties of dried extracts from the spent espresso coffee. Hem Ind 67:261–267

Nouri L, Legrand J, Popineau Y, Belleville P (1997) Enzymatic hydrolysis of wheat proteins Part I. Enzymatic kinetics and study of limited hydrolysis in a batch stirred reactor. Chem Eng J 65:187–194

Prieto CA, Guadix EM, Guadix A (2008) Influence of temperature on protein hydrolysis in a cyclic batch enzyme membrane reactor. Biochem Eng J 42:217–223

Prieto CA, Guadix EM, Guadix A (2010) Optimal operation of a protein hydrolysis reactor with enzyme recycle. J Food Eng 97:24–30

Qu P, Tang H, Gao Y, Zhang L (2010) Polyethersulfone composite membrane blended with cellulose fibrils. BioResources 5:2323–2336

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Sarmadi BH, Ismail A (2010) Antioxidative peptides from food proteins: a review. Peptides 31:1949–1956

Schlesier K, Harwat M, Böhm V, Bitsch R (2002) Assessment of antioxidant activity by using different in vitro methods. Free Radic Res 36:177–187

Shi L-E, Ying G-Q, Tang Z-X, Chen J-S, Xiong W-Y, Wang H (2009) Continuous enzymatic production of 5′-nucleotides using free nuclease P1 in ultrafiltration membrane reactor. J Membr Sci 345:217–222

Stefanović A, Jovanović J, Grbavčić S, Šekuljica N, Manojlović V, Bugarski B, Knežević-Jugović Z (2014) Impact of ultrasound on egg white proteins as a pretreatment for functional hydrolysates production. Eur Food Res Technol 239:979–993

Van der Plancken I, Van Loey A, Hendrickx ME (2005) Combined effect of high pressure and temperature on selected properties of egg white proteins. Innov Food Sci Emerg Technol 6:11–20

Vaštag Ž, Popović L, Popović S, Krimer V, Peričin D (2010) Hydrolysis of pumpkin oil cake protein isolate and free radical scavenging activity of hydrolysates: influence of temperature, enzyme/substrate ratio and time. Food Bioprod Process 88:277–282

Yu Z, Yin Y, Zhao W, Chen F, Liu J (2014) Application and bioactive properties of proteins and peptides derived from hen eggs: opportunities and challenges. J Sci Food Agric 94:2839–2845

Zhu L, Chen J, Tang X, Xiong YL (2008) Reducing, radical scavenging, and chelation properties of in vitro digests of alcalase-treated zein hydrolysate. J Agric Food Chem 56:2714–2721

Acknowledgements

This work was supported by EUREKA Project E!6750 and III-46010 from the Ministry of Education, Science and Technological Development of the Republic of Serbia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jakovetić Tanasković, S., Luković, N., Grbavčić, S. et al. Production of egg white protein hydrolysates with improved antioxidant capacity in a continuous enzymatic membrane reactor: optimization of operating parameters by statistical design. J Food Sci Technol 55, 128–137 (2018). https://doi.org/10.1007/s13197-017-2848-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2848-5