Abstract

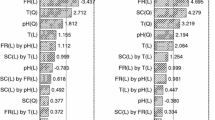

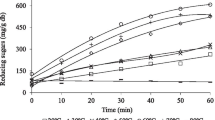

This paper presents a procedure by which a simple and economical analytical column containing immobilized invertase was developed. This column has high efficiency of converting sucrose into inverted syrup rapidly. Gelatine beads were used for the immobilization of invertase. The enzyme was entrapped efficiently and was found to be stable and retained its activity over a period of 3 months. Immobilization parameters for maximum enzyme activity were estimated as temperature optima at 60 °C, pH optima 7.0 and 30 mg/mL enzyme concentration was found to give maximum immobilization (72 %). The reusability of the gelatine immobilized invertase was found to be seven times with a time interval of 24 h. The immobilized invertase presented a KM of 51.28 mM and Vmax of 0.334 mM/min. The time required to hydrolyse 50 % sucrose solution by a column of length 10 cm and diameter of 1.5 cm was found to be 15 min at room temperature. The column was found effective for inversion of biological samples like sugar cane juice.

Similar content being viewed by others

References

Akgöl S, Kacar Y, Denizli A, Arıca M (2001) Hydrolysis of sucrose by invertase immobilized onto novel magnetic polyvinylalcohol microspheres. Food Chem 74(3):281–288

Amaya-Delgado L, Hidalgo-Lara M, Montes-Horcasitas M (2006) Hydrolysis of sucrose by invertase immobilized on nylon-6 microbeads. Food Chem 99(2):299–304

Arruda LMO, Vitolo M (1999) Characterization of invertase entrapped into calcium alginate beads. Appl Biochem Biotechnol 81(1):23–33

D’Souza S, Melo J (2001) Immobilization of bakers yeast on jute fabric through adhesion using polyethylenimine: application in an annular column reactor for the inversion of sucrose. Process Biochem 36(7):677–681

Danisman T, Tan S, Kacar Y, Ergene A (2004) Covalent immobilization of invertase on microporous pHEMA–GMA membrane. Food Chem 85(3):461–466

de Queiroz AAA, Vitolo M, de Oliveira RC, Higa OZ (1996) Invertase immobilization onto radiation-induced graft copolymerized polyethylene pellets. Radiat Phys Chem 47(6):873–880

Emregul E, Sungur S, Akbulut U (2006) Polyacrylamide–gelatine carrier system used for invertase immobilization. Food Chem 97(4):591–597

Erginer R, Toppare L, Alkan S, Bakir U (2000) Immobilization of invertase in functionalized copolymer matrices. React Funct Polym 45(3):227–233

Jen Tien C, Huang Chiang B (1999) Immobilization of α-amylase on a zirconium dynamic membrane. Process Biochem 35(3):377–383

Kotwal S, Shankar V (2009) Immobilized invertase. Biotechnol Adv 27(4):311–322

Mahmoud DAR (2007) Immobilization of invertase by a new economical method using wood sawdust waste. Aust J Appl Sci 1:364–372

Mansfeld J, Schellenberger A, Römbach J (1992) Application of polystyrene–bound invertase to continuous sucrose hydrolysis on pilot scale. Biotechnol Bioeng 40(9):997–1003

Marconi W, Gulinelli S, Morisi F (1974) Properties and use of invertase entrapped in fibers. Biotechnol Bioeng 16(4):501–511

Melo J, Kubal B, D’Souza S (1992) Production of inverted sucrose syrup using yeast cells adhered to polyethylenimine treated cotton threads. Food Biotechnol 6(2):175–186

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Monsan P, Combes D (2004) Application of immobilized invertase to continuous hydrolysis of concentrated sucrose solutions. Biotechnol Bioeng 26(4):347–351

Rai A, Prabhune A, Perry CC (2012) Entrapment of commercially important invertase in silica particles at physiological pH and the effect of pH and temperature on enzyme activity. Mater Sci Eng C 32(4):785–789

Regan MR, Banerjee IA (2007) Immobilization of invertase in Germania matrix and a study of its enzymatic activity. J Sol–Gel Sci Technol 43(1):27–33

Ribeiro R, Vitolo M (2009) Anion exchange resin as support for invertase immobilization. Rev Ciênc Farm Básica Apl 26(3):175–179

Tanriseven A, Doğan Ş (2001) Immobilization of invertase within calcium alginate gel capsules. Process Biochem 36(11):1081–1083

Tomotani EJ, Vitolo M (2007) Production of high-fructose syrup using immobilized invertase in a membrane reactor. J Food Eng 80(2):662–667

Tümtürk H, Arslan F, Disli A, Tufan Y (2000) Immobilization of invertase attached to a granular dimer acid-co-alkyl polyamine. Food Chem 69(1):5–9

Vu T, Le V (2008) Biochemical studies on the immobilization of the enzyme invertase (EC. 3.2. 1.26) in alginate gel and its kinetics. ASEAN Food J 15(1):73–78

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Upadhyay, L.S.B., Verma, N. Highly efficient production of inverted syrup in an analytical column with immobilized invertase. J Food Sci Technol 51, 4120–4125 (2014). https://doi.org/10.1007/s13197-013-0957-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-0957-3