Abstract

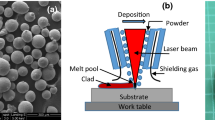

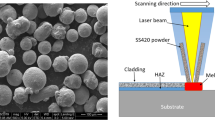

Ti–6Al–4V is commonly used material in automobile, aerospace, biomedical and marine due to its excellent properties. However, their uses are reduced because their its poor tribological performance. In the current study, stainless steel 420 alloy powder was cladded on Ti–6Al–4V base material using high-power Yb: YAG disc laser. Then, the cladded surfaces were evaluated to reveal their new phase formation, hardness changes and improved wear properties. Besides, the various wear mechanisms and their corresponding rough averages were studied. Results showed that the microhardness of laser cladded specimen is 613HV while base material shows 303HV. The wear rate of laser cladded specimen reduces remarkably compared to un-clad specimen. The identified major wear mechanisms are abrasive, adhesive and oxidation wear. The worn-out cladded surface shows lesser roughness than base material.

Similar content being viewed by others

References

Kuriachen B, Lijesh K P, and Kuppan P, Trans Indian Inst Met71 (2018) 1331.

Jeyaprakash N, Yang C-H, and Tseng S-P, Int J Adv Manuf Technol106 (2019) 2347.

Jeyaprakash N, Yang C-H, and Sivasankaran S, Mater Manuf Process35 (2019) 142.

Liu F, Ji Y, Sun Z, Wang G, and Bai Y, Mater Manuf Process34 (2019) 1458.

García-Rodríguez S, Torres B, Pulido-González N, and Otero E, Surf Coat Technol378 (2019) 124994.

Lou M, Whiteb D R, Banerjia A, Alpas A T, Wear432 (2019) 102921.

Baiamonte L, Tuluic M, Bartuli C, Marini D, Marino A, Menchetti F, Pileggic R, Pulci G, and Marra F, Surf Coat Technol371 (2019) 322.

Marquer M, Philippon S, Faure L, Chassaing G, Tardelli J, and Demmou K, Tribol Int136 (2019) 13.

Mao Y S, Wang L, Chen K M, Wang S Q, and Cui X H, Wear297 (2013) 1032.

Qu J, Blau P J, Watkins T R, Cavin O B and Kulkarni N S, Wear258 (2005) 1348.

Li X X, Zhou Y, Ji X L, Li Y and Wang S Q, Tribol Int91 (2015) 228.

Arayibi P K, Abioye T E, Clare A T, Int J Adv Manuf Technol87 (2016) 3349.

Roy T, Lai Q, Abrahams R, Mutton P, Paradowska A, Soodi M, and Yan W, Wear412–413 (2018) 69.

Gao F, Liu R, Wu X J, Thin Solid Films519 (2011) 4809.

Jeyaprakash N, Duraiselvam M, and Raju R, Arch Metall Mater63 (2018) 1303.

Moore M, Wear 28 (1974) 59.

Jeyaprakash N, Yang C-H, Tseng S-P, Metals Mater Int (2019) https://doi.org/10.1007/s12540-019-00526-6.

Birol Y, Wear269 (2010) 664.

Cui X H, Mao Y S, Wei M X, and Wang S Q. Tribol Trans55 (2012) 185.

Wang L, Zhang Q Y, Li X X, Cui X H, Wang S Q, Tribol Lett53 (2014) 511.

Wang L, Zhang Q Y, Li X X, Cui X H, and Wang S Q, Metall Mater Trans A 45 (2014) 2284.

Ramkumar K R, Sivasankaran S, Al-Mufadi F A, Siddharth S, and Raghu R, Achieves Civ Mech Eng19 (2019) 428.

Jeyaprakash N, Duraiselvam M, and Aditya S V, Surf Rev Lett26 (2019) 1950009.

Davis J R, ASM International, Metals Park, 6 (1993) 789.

Umanskii A P, Storozhenko M S, Hussainova I V, Terentiev A E, Kovalchenko A M and Antonov M M, Powder Metall Metal Ceram53 (2015) 663.

Acknowledgements

Authors wish to thank Ministry of Science and Technology, Taiwan, for their financial support during the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jeyaprakash, N., Yang, CH. Microstructure and Wear Behaviour of SS420 Micron Layers on Ti–6Al–4V Substrate Using Laser Cladding Process. Trans Indian Inst Met 73, 1527–1533 (2020). https://doi.org/10.1007/s12666-020-01927-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01927-7