Abstract

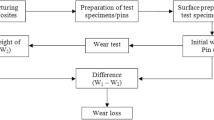

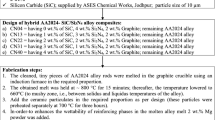

In this present study, SiC, B4C and waste porcelain reinforced AA7075 alloy composites are fabricated by adopting stir casting approach. Twelve formulations based on different weight percentages of reinforcers (3 wt.%, 4.5 wt.%, 6 wt.% and 7.5 wt.%.) were manufactured and afterward analysed in terms of physical, mechanical, corrosion and tribological performances. The reinforcers of less than 53 μm size were consistently blended in molten AA7075 accompanied by stirring process. To identify the best suitable formulation the density, hardness, tensile strength, compressive strength, flexural strength, friction coefficient, wear and corrosion rate were fixed as selection criteria. The composite containing 7.5 wt.% B4C (ASBP-8) exhibited the highest mechanical strength (Hardness=162 Hv; Tensile strength= 298 MPa; Compressive strength= 221 MPa; and Flexural strength= 267 MPa), whereas wear performance (at 40 N load and 1300 m SD= 0.00261 g; and at 5.026 m/s SV and 1300 m SD= 0.0231 g) and coefficient of friction (at 40 N load and 1300 m SD= 0.536 g; and at 5.026 m/s SV and 1300 m SD= 0.47 g) remain the lowest for 6 wt.% porcelain (ASBP-11) based composites. The density and corrosion rate remains lowest for the composite containing 7.5 wt.% porcelain (ASBP-12).Since no single composite(ASBP-1 to ASBP-12) could merely satisfy all the desired characteristics; to this end, this study applied a novel hybrid AHP/CRITIC-COPRAS method for the selection of optimal alternative material for automotive components. The weight of each material evaluated was determined by establishing a criterion of importance by applying inter-criteria correlation (CRITIC) and analytic hierarchy process (AHP) methods. The alternative ranking was evaluated using the complex proportional assessment (COPRAS) method. The evaluation indicated that the AA7075 containing 7.5 wt.% porcelain (ASBP-12) composite possesses the best material solution to be used in automotive applications.

Similar content being viewed by others

Data Availability

The authors declare that the data supporting the findings of this study are available within the article.

Change history

03 January 2022

A Correction to this paper has been published: https://doi.org/10.1007/s12633-021-01639-7

References

Prasad S, Asthana R (2004) Aluminum metal-matrix composites for automotive applications: tribological considerations. Tribol Lett 17(3):445–453. https://doi.org/10.1023/B:TRIL.0000044492.91991.f3

Kumar GV, Rao C, Selvaraj N (2011) Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites–a review. J Miner Mater Charact Eng 10(01):59–91

Suthar J, Patel K (2018) Processing issues, machining, and applications of aluminum metal matrix composites. Mater Manuf Process 33(5):499–527

Hariprasad T, Varatharajan K, Ravi S (2014) Wear characteristics of B4C and Al2O3 reinforced with Al 5083 metal matrix based hybrid composite. J Procedia Eng 97:925–929

Chan JW, Tong TK (2007) Multi-criteria material selections and end-of-life product strategy: Grey relational analysis approach. J Materials Design 28(5):1539–1546

Maniya K, Bhatt M (2010) A selection of material using a novel type decision-making method: preference selection index method. J Materials Design 31(4):1785–1789

Gangwar S, Arya P, Pathak VK (2020) Optimal material selection for ship body based on fabricated zirconium dioxide/silicon carbide filled aluminium hybrid metal alloy composites using novel fuzzy based preference selection index. Silicon 1–18. https://doi.org/10.1007/s12633-020-00600-4

Bhaskar S, Kumar M, Patnaik A (2019) Application of hybrid AHP-TOPSIS technique in analyzing material performance of silicon carbide ceramic particulate reinforced AA2024 alloy composite. Silicon 12:1075–1084. https://doi.org/10.1007/s12633-019-00211-8

Rajak SK, Aherwar A, Unune DR, Mia M, Pruncu CI (2019) Evaluation of copper-based alloy (C93200) composites reinforced with marble dust developed by stir casting under vacuum environment. Materials (Basel) 12(10). https://doi.org/10.3390/ma12101574

Dewangan S, Gangopadhyay S, Biswas C (2015) Study of surface integrity and dimensional accuracy in EDM using fuzzy TOPSIS and sensitivity analysis. Measurement 63:364–376

Ozdemir S, Sahin G (2018) Multi-criteria decision-making in the location selection for a solar PV power plant using AHP. Measurement 129:218–226

Sahu AK, Sahu NK, Sahu AK, Rajput MS, Narang HK (2019) T-SAW methodology for parametric evaluation of surface integrity aspects in AlMg3 (AA5754) alloy: comparison with T-TOPSIS methodology. Measurement 132:309–323

Majumder H, Maity K (2018) Prediction and optimization of surface roughness and micro-hardness using grnn and MOORA-fuzzy-a MCDM approach for nitinol in WEDM. Measurement 118:1–13

Aherwar A, Patnaik A, Bahraminasab M (2019) Effect of molybdenum content on structure and properties of a co-Cr biomedical alloy. J Mater Eng Perform 28(10):6340–6353. https://doi.org/10.1007/s11665-019-04356-w

Ahmed SK, Sivakumar G, Kabir G, Ali SM, Science M (2020) Regional aircraft selection integrating fuzzy analytic hierarchy process (FAHP) and efficacy method. J Product Syst 1(2):12–12

Rao RV (2006) A material selection model using graph theory and matrix approach. J Materials Sci Eng: A 431(1–2):248–255

Rajan K, Narasimhan K (2002) An approach to selection of material and manufacturing processes for rocket motor cases using weighted performance index. J Mater Eng Performance 11(4):444–449

Shanian A, Savadogo O (2006) A material selection model based on the concept of multiple attribute decision making. J Materials Design 27(4):329–337

Chatterjee P, Athawale VM, Chakraborty S (2009) Selection of materials using compromise ranking and outranking methods. J Materials Design 30(10):4043–4053

Karande P, Chakraborty S (2012) Application of multi-objective optimization on the basis of ratio analysis (MOORA) method for materials selection. Materials Design 37:317–324

Hambali A, Sapuan S, Ismail N, Nukman Y (2010) Material selection of polymeric composite automotive bumper beam using analytical hierarchy process. J Cent S Univ Technol 17(2):244–256

Yadav S, Pathak VK, Gangwar S (2019) A novel hybrid TOPSIS-PSI approach for material selection in marine applications. Sādhanā 44(3):58

Kumar N, Singh T, Grewal J, Patnaik A, Fekete G (2019) A novel hybrid AHP-SAW approach for optimal selection of natural fiber reinforced non-asbestos organic brake friction composites. Mater Res Express 6(6):065701

Ishizaka A, Labib A (2011) Selection of new production facilities with the group analytic hierarchy process ordering method. Expert Syst Appl 38(6):7317–7325

Satapathy B, Bijwe J (2004) Performance of friction materials based on variation in nature of organic fibres: part II. Optimisation by balancing and ranking using multiple criteria decision model (MCDM). Wear 257(5–6):585–589

Anand VK, Aherwar A, Mia M, Elfakir O, Wang L (2020) Influence of silicon carbide and porcelain on tribological performance of Al6061 based hybrid composites. J Tribology International 151:106514. https://doi.org/10.1016/j.triboint.2020.106514

Agarwal BD, Broutman LJ, Chandrashekhara K (2017) Analysis and performance of fiber composites, 4th edn. Wiley, New York

Standard ASTM (2003) E92 2003 Standard test method for Vickers hardness of metallic materials. West Conshohocken

ASTM E9 (2001) Standard test methods for tension testing of metallic materials. Annual book of ASTM standards. ASTM

Standard ASTM E9-09 (2012) Standard test methods of compression testing of metallic materials at room temperature. ASTM International, West Conshohocken, PA, USA

ASTM A E290-14 (2014) Standard test methods for bend testing of material for ductility. ASTM International, West Conshohocken, PAASTM Std

ASTM G99-95 (2000) Standard Test method for wear testing with a pin-on disc apparatus. Annual Book of Standards. ASTM International, West Conshohocken

Kumar RA, Devaraju A (2020) Modeling of Mechanical properties and high temperature wear behavior of Al7075/SiC/CRS composite using RSM. Silicon 1–21. https://doi.org/10.1007/s12633-020-00801-x

Kumar A, Patnaik A, Bhat I (2020) Parametric analysis of tribological for gear materials behaviour and mechanical study of cobalt metal powder filled Al-7075 alloy composites. Materials Today: Proceedings 27(3):2787–2800. https://doi.org/10.1016/j.matpr.2019.12.200

Suresha S, Sridhara B (2010) Effect of silicon carbide particulates on wear resistance of graphitic aluminium matrix composites. Mater Design 31(9):4470–4477

Diakoulaki D, Mavrotas G, Papayannakis L (1995) Determining objective weights in multiple criteria problems: the critic method. Comput Operations Res 22(7):763–770

Baradeswaran A, Elaya Perumal A (2013) Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Compos Part B 54:146–152. https://doi.org/10.1016/j.compositesb.2013.05.012

Baradeswaran A, Elaya Perumal A (2014) Study on mechanical and wear properties of Al 7075/Al2O3/graphite hybrid composites. Compos Part B 56:464–471. https://doi.org/10.1016/j.compositesb.2013.08.013

Samuel Ratna Kumar PS, Robinson Smart DS, John Alexis S (2018) Corrosion behaviour of Aluminium metal matrix reinforced with multi-wall carbon nanotube. J Asian Ceramic Soc 5(1):71–75. https://doi.org/10.1016/j.jascer.2017.01.004

Dev S, Aherwar A, Patnaik A (2019) Material selection for automotive piston component using entropy-VIKOR method. Silicon 12:155–169. https://doi.org/10.1007/s12633-019-00110-y

Acknowledgments

The authors gratefully acknowledge MRC and Tribology Centre of MNIT, Jaipur, India for all kinds of support for material testing, characterization and measurement.

Conflict of Interest

The author(s) declare that they have no conflict of interest.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Author information

Authors and Affiliations

Contributions

Amit Aherwar: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Resources, Supervision, Roles/Writing - original draft; Catalin I. Pruncu: Conceptualization, Methodology, Software, Visualization, Writing – review & editing; Mozammel Mia: Software, Validation, Visualization, Writing - review & editing.

Corresponding author

Ethics declarations

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aherwar, A., Pruncu, C.I. & Mia, M. Optimal Design Based on Fabricated SiC/B4C/Porcelain Filled Aluminium Alloy Matrix Composite Using Hybrid AHP/CRITIC-COPRAS Approach. Silicon 14, 603–615 (2022). https://doi.org/10.1007/s12633-020-00916-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00916-1