Abstract

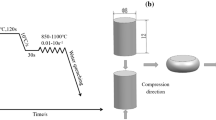

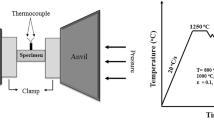

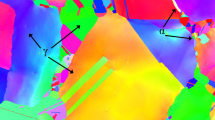

Hot compression tests were performed to investigate the hot deformation behavior of Fe-27.34Mn-8.63Al-1.03C lightweight steel and optimize the hot workability parameters. The temperature range was 900–1150°C and the strain rate range was 0.01–5 s−1 on a Gleeble-3800 thermal simulator machine. The results showed that the flow stress increased with decreasing deformation temperature and increasing strain rate. According to the constitutive equation, the activation energy of hot deformation was 422.88 kJ·mol−1. The relationship between the critical stress and peak stress of the tested steel was established, and a dynamic recrystallization kinetic model was thus obtained. Based on this model, the effects of strain rate and deformation temperature on the volume fraction of dynamically recrystallized grains were explored. The microstructural examination and processing map results revealed that the tested steel exhibited a good hot workability at deformation temperatures of 1010–1100°C and strain rate of 0.01 s−1.

Similar content being viewed by others

References

S.P. Chen, R. Rana, A. Haldar, and R.K. Ray, Current state of Fe-Mn-Al-C low density steels, Prog. Mater. Sci., 89(2017), p. 345.

R. Rana, C. Lahaye, and R.K. Ray, Overview of lightweight ferrous materials: Strategies and promises, JOM, 66(2014), No. 9, p. 1734.

K. Lu, The future of metals, Science, 328(2010), No. 5976, p. 319.

B. Wietbrock, W. Xiong, M. Bambach, and G. Hirt, Effect of temperature, strain rate, manganese and carbon content on flow behavior of three ternary Fe-Mn-C (Fe-Mn23-C0.3, Fe-Mn23-C0.6, Fe-Mn28-C0.3) high-manganese steels, Steel Res. Int., 82(2011), No. 1, p. 63.

H.L. Yi, L. Sun, and X.C. Xiong, Challenges in the formability of the next generation of automotive steel sheets, Mater. Sci. Technol., 34(2018), No. 9, p. 1112.

W. Bleck, New insights into the properties of high-manganese steel, Int. J. Miner. Metall. Mater., 28(2021), No. 5, p. 782.

B.C. de Cooman, Y. Estrin, and S.K. Kim, Twinning-induced plasticity (TWIP) steels, Acta Mater., 142(2018), p. 283.

S.S. Li and H.W. Luo, Medium-Mn steels for hot forming application in the automotive industry, Int. J. Miner. Metall. Mater., 28(2021), No. 5, p. 741.

Y.J. Wang, S. Zhao, R.B. Song, and B. Hu, Hot ductility behavior of a Fe-0.3C–9Mn-2Al medium Mn steel, Int. J. Miner. Metall. Mater., 28(2021), No. 3, p. 422.

J. Hu, J.M. Zhang, G.S. Sun, et al., High strength and ductility combination in nano-/ultrafine-grained medium-Mn steel by tuning the stability of reverted austenite involving intercritical annealing, J. Mater. Sci., 54(2019), No. 8, p. 6565.

J. Hu, L.X. Du, W. Xu, et al., Ensuring combination of strength, ductility and toughness in medium-manganese steel through optimization of nano-scale metastable austenite, Mater. Charact., 136(2018), p. 20.

S.W. Hwang, J.H. Ji, and K.T. Park, Effects of Al addition on high strain rate deformation of fully austenitic high Mn steels, Mater. Sci. Eng. A, 528(2011), No. 24, p. 7267.

C.Y. Chao and C.H. Liu, Effects of Mn contents on the microstructure and mechanical properties of the Fe-10Al-.xMn-1.0C alloy, Mater. Trans., 43(2002), No. 10, p. 2635.

D. Raabe, H. Springer, I. Gutierrez-Urrutia, et al., Alloy design, combinatorial synthesis, and microstructure-property relations for low-density Fe-Mn-Al-C austenitic steels, JOM, 66(2014), No. 9, p. 1845.

I. Kalashnikov, A. Shalkevich, O. Acselrad, and L.C. Pereira, Chemical composition optimization for austenitic steels of the Fe-Mn-Al-C system, J. Mater. Eng. Perform., 9(2000), No. 6, p. 597.

C.M. Chu, H. Huang, P.W. Kao, and D. Gan, Effect of alloying chemistry on the lattice constant of austenitic Fe-Mn-Al-C alloys, Scripta Metall. Mater., 30(1994), No. 4, p. 505.

H. Kim, D.W. Suh, and N.J. Kim, Fe-Al-Mn-C lightweight structural alloys: A review on the microstructures and mechanical properties, Sci. Technol. Adv. Mater., 14(2013), No. 1, art. No. 014205.

A.S. Hamada, L.P. Karjalainen, M.C. Somani, and R.M. Ramadan, Deformation mechanisms in high-Al bearing high-Mn TWIP steels in hot compression and in tension at low temperatures, Mater. Sci. Forum, 550(2007), p. 217.

R. Rana, C. Liu, and R.K. Ray, Evolution of microstructure and mechanical properties during thermomechanical processing of a low-density multiphase steel for automotive application, Acta Mater., 75(2014), p. 227.

C. Haase, C. Zehnder, T. Ingendahl, et al., On the deformation behavior of κ-carbide-free and κ-carbide-containing high-Mn light-weight steel, Acta Mater., 122(2017), p. 332.

Y.H. Mozumder, K. Babu, R. Saha, and S. Mandal, Deformation mechanism and nano-scale interplay of dual precipitation during compressive deformation of a duplex lightweight steel at high strain rate, Mater. Sci. Eng. A, 823(2021), art. No. 141725.

R.W.K. Honeycombe and R.W. Pethen, Dynamic recrystallization, J. Less Common Met., 28(1972), No. 2, p. 201.

T.K. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions, Prog. Mater. Sci., 60(2014), p. 130.

H.R. Abedi, A.Z. Hanzaki, Z. Liu, R. Xin, N. Haghdadi, and P.D. Hodgson, Continuous dynamic recrystallization in low density steel, Mater. Des., 114(2017), p. 55.

L.X. Xu, H.B. Wu, and X.T. Wang, Influence of microstructural evolution on the hot deformation behavior of an Fe-Mn-Al duplex lightweight steel, Acta Metall. Sinica Engl. Lett., 31(2018), No. 4, p. 389.

D.G. Liu, H. Ding, X. Hu, D. Han, and M.H. Cai, Dynamic re-crystallization and precipitation behaviors during hot deformation of a κ-carbide-bearing multiphase Fe-11Mn-10Al-0.9C lightweight steel, Mater. Sci. Eng. A, 772(2020), art. No. 138682.

D.T. Pierce, D.M. Field, K.R. Limmer, T. Muth, and K.M. Sebeck, Hot deformation behavior of an industrially cast large grained low density austenitic steel, Mater. Sci. Eng. A, 825(2021), art. No. 141785.

J. Sun, J.H. Li, P. Wang, and Z.Y. Huang, Hot deformation behavior, dynamic recrystallization and processing map of Fe-30Mn-10Al-1C low-density steel, Trans. Indian Inst. Met., 75(2022), No. 3, p. 699.

L. Duprez, B.C. De Cooman, and N. Akdut, Flow stress and ductility of duplex stainless steel during high-temperature torsion deformation, Metall. Mater. Trans. A, 33(2002), No. 7, p. 1931.

F. Montheillet, Moving grain boundaries during hot deformation of metals: Dynamic recrystallization, [in] F.D. Fischer, ed., Moving Interfaces in Crystalline Solids, CISM International Centre for Mechanical Sciences, Vol. 453, Springer, Vienna, 2004, p. 203.

C. Zener and J.H. Hollomon, Effect of strain rate upon plastic flow of steel, J. Appl. Phys., 15(1944), No. 1, p. 22.

Y.S. Li, Y.W. Dong, Z.H. Jiang, Q.F. Tang, S.Y. Du, and Z.W. Hou, Influence of rare earth Ce on hot deformation behavior of as-cast Mn18Cr18N high nitrogen austenitic stainless steel, Int. J. Miner. Metall. Mater., 30(2023), No. 2, p. p.

C.M. Sellars and W.J. McTegart, On the mechanism of hot deformation, Acta Metall., 14(1966), No. 9, p. 1136.

Y.P. Li, R.B. Song, E.D. Wen, and F.Q. Yang, Hot deformation and dynamic recrystallization behavior of austenite-based low-density Fe-Mn-Al-C steel, Acta Metall. Sinica Engl. Lett., 29(2016), No. 5, p. 441.

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodríguez, and R.E. Logé, Hot deformation of a Fe-Mn-Al-C steel susceptible of κ-carbide precipitation, Mater. Sci. Eng. A, 689(2017), p. 269.

A. Khosravifard, A.S. Hamada, M.M. Moshksar, R. Ebrahimi, D.A. Porter, and L.P. Karjalainen, High temperature deformation behavior of two as-cast high-manganese TWIP steels, Mater. Sci. Eng. A, 582(2013), p. 15.

A.S. Hamada, L.P. Karjalainen, and M.C. Somani, The influence of aluminum on hot deformation behavior and tensile properties of high-Mn TWIP steels, Mater. Sci. Eng. A, 467(2007), No. 1–2, p. 114.

Z.Q. Wu, Y.B. Tang, W. Chen, et al., Exploring the influence of Al content on the hot deformation behavior of Fe-Mn-Al-C steels through 3D processing map, Vacuum, 159(2019), p. 447.

H. Mirzadeh, J.M. Cabrera, J.M. Prado, and A. Najafizadeh, Hot deformation behavior of a medium carbon microalloyed steel, Mater. Sci. Eng. A, 528(2011), No. 10–11, p. 3876.

E.I. Poliak and J.J. Jonas, A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization, Acta Mater., 44(1996), No. 1, p. 127.

G.M. Liu, J.B. Wang, Y.F. Ji, et al., Hot deformation behavior and microstructure evolution of Fe-5Mn-3Al-0.1C high-strength lightweight steel for automobiles, Materials, 14(2021), No. 10, art. No. 2478.

S. Mandal, M. Jayalakshmi, A.K. Bhaduri, and V.S. Sarma, Effect of strain rate on the dynamic recrystallization behavior in a nitrogen-enhanced 316L(N), Metall. Mater. Trans. A, 45(2014), No. 12, p. 5645.

J.J. Jonas, X. Quelennec, L. Jiang, and É. Martin, The Avrami kinetics of dynamic recrystallization, Acta Mater., 57(2009), No. 9, p. 2748.

Z.Y. Huang, Y.S. Jiang, A.L. Hou, et al., Rietveld refinement, microstructure and high-temperature oxidation characteristics of low-density high manganese steels, J. Mater. Sci. Technol., 33(2017), No. 12, p. 1531.

M. Shaban and B. Eghbali, Determination of critical conditions for dynamic recrystallization of a microalloyed steel, Mater. Sci. Eng. A, 527(2010), No. 16–17, p. 4320.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, et al., Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242, Metall. Trans. A, 15(1984), No. 10, p. 1883.

Y.V.R.K. Prasad, Processing maps: A status report, J. Mater. Eng. Perform., 12(2003), No. 6, p. 638.

P. Wan, H.X. Yu, F. Li, P.F. Gao, L. Zhang, and Z.Z. Zhao, Hot deformation behaviors and process parameters optimization of low-density high-strength Fe-Mn-Al-C alloy steel, Met. Mater. Int., 28(2022), No. 10, p. 2498.

M.S. Ghazani and B. Eghbali, Strain hardening behavior, strain rate sensitivity and hot deformation maps of AISI 321 austenitic stainless steel, Int. J. Miner. Metall. Mater., 28(2021), No. 11, p. 1799.

H. Ziegler, Some extremum principles in irreversible thermodynamics, with application to continuum mechanics, Prog. Solid Mech., 4(1963), p. 93.

A. Momeni and K. Dehghani, Hot working behavior of 2205 austenite-ferrite duplex stainless steel characterized by constitutive equations and processing maps, Mater. Sci. Eng. A, 528(2011), No. 3, p. 1448.

M.A. Davinci, D. Samantaray, U. Borah, S.K. Albert, and A.K. Bhaduri, Influence of processing parameters on hot workability and microstructural evolution in a carbon-manganese-silicon steel, Mater. Des., 88(2015), p. 567.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 52071300 and 51904278), the Special Funding Projects for Local Science and Technology Development guided by the Central Committee (No. YDZX20191400004587), the Key Research and Development Project of Zhejiang Province, China (No. 2020C01131), and the Innovation projects of colleges and universities in Shanxi Province, China (No. 2019L0577).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

To the best of our knowledge, the authors have no conflict of interest, financial, or otherwise.

Rights and permissions

About this article

Cite this article

Lu, H., Li, D., Li, S. et al. Hot deformation behavior of Fe-27.34Mn-8.63Al-1.03C lightweight steel. Int J Miner Metall Mater 30, 734–743 (2023). https://doi.org/10.1007/s12613-022-2531-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2531-3