Abstract

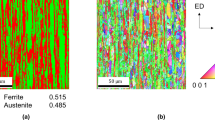

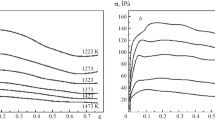

Hot torsion tests were performed on a duplex stainless steel (DSS)-type EN1.4462 steel. The temperature was varied in the range from 950 °C to 1200 °C, while the strain rate was varied from 0.01/s to 2/s. The mean flow stress (MFS) was fitted to the hyperbolic sine function proposed by Sellars and Tegart. An activation energy for plastic deformation of Q HW = 425 kJ/mol was obtained. The high value was explained by the fact that, in addition to the softening of ferrite (α) and austenite (γ), there was a decrease in the volume fraction of the high-strength austenite with increasing temperature. For higher values of the Zener-Holomon parameter (Z), the MFS showed a linear dependence on ln (Z), which was related to the gradual disappearance of a yield-point-elongation-like effect. This yield-point-elongation-like effect was characterized by a nonstrengthening plateau during the initial stages of plastic deformation. The strain to rupture and the dynamic softening were both found to decrease for higher values of ln (Z). Therefore, the ductility was directly related to the amount of dynamic softening, i.e., dynamic recrystallization (DRX) of the austenitic phase. At higher strain rates, significant dynamic softening was only observed for temperatures above 1100 °C. The strain-rate sensitivity (m) was found to vary from 0.13 at 950 °C to 0.22 at 1200 °C.

Similar content being viewed by others

References

H.J. McQueen, N.D. Ryan, R. Zaripova, and K. Frakhutdinov; Proc. 37th MWSP Conf., Hamilton, Canada, 1995, ISS, Warrendale, PA, p. 883.

J.S. Rege, C.I. Garcia, and A.J. DeArdo: Proc. 37th MWSP Conf., Hamilton, Canada, 1995, ISS, Warrendale, PA, p. 871.

L.P. Karjalainen, J.A. Koskiniemi, and X.D. Liu; Proc. 37th MWSP Conf., Hamilton, Canada, 1995, ISS, Warrendale, PA, p. 861.

N.D. Ryan; Proc. Hot Workability of Steels and Light Alloys Composites, Montréal, Canada, 1996, CIM, p. 411.

B. Ahlblom and R. Sandström; Int. Met. Rev., 1982, No. 1. p. 1.

N.D. Ryan and H.J. McQueen: J. Mater. Processing Technol., 1990, vol. 21, p. 177.

H.J. McQueen and N.D. Ryan: Proc. ICSMA 8, P.O. Hettunen, T.K. Leppisto, M.E. Lehtonen, eds., Pergamon Press, Oxford, United Kingdom, 1988, p. 1323.

K.A. Bywater and T. Gladman: Met. Technol., 1976, p. 358.

P. Bocher and J.J. Jonas: Conf. Proc. on Hot Workability of Steels and Light Alloys Composites, Montréal, Canada, 1996, CIM, p. 443.

P. Cizek and B.P. Wynne: Mater. Sci. Eng. A, 1997, p. 88

M. Barteri, E. Evangelista, M. Niewczas, and L. Scoppio: Conf. Proc. Innovation Stainless Steel, Florence, Italy, 1993, AIM, Milano, Italy, 1993, p. 3.285.

A. Iza-Mendia, A. Piñol, J.J. Urcola, and I. Gutiérrez: Metall. Mater. Trans. A, 1998, vol. 29A, p. 2975.

T. Chandra, D. Bendeich, and D.P. Dunne: Proc. ICSMA 6, Melbourne, Australia, 1982, Pergamon Press, Oxford, United Kingdom, 1982, R.C. Gifkins, ed., p. 505.

O. Balancin, W.A.M. Hoffmann, and J.J. Jonas: Metall. Mater. Trans. A, 2000, vol. 31A, p. 1353.

C.G. Schmidt, C.M. Young, B. Walser, R.H. Klundt, and O.D. Sherby: Mater. Trans. A, 1982, vol. 13A, p. 447.

M. Barteri and M.G. Mecozzi: Proc. Duplex Stainless Steels, T.G. Gooch, ed., TWI, Woodhead Publishing, Abington, Cambridge, United Kingdom, 1995, 3285–90.

E. Evangelista, H.J. McQueen, B. Verlinden, and M. Barteri: Proc. 3rd Eur. Conf. Stainless Steels, Science and Market, Sardinia, Italy, 1999, AIM, Milano, 1999, p. 253.

J. Roos and Jozef Dilewijns: RUG, Ghent, Belgium, 1997, p. 311.

J. Charles: Proc. Int. Conf. on Duplex Stainless Steels, Glasgow, Scotland, 1994, T.G. Gooch, ed., TWI, Woodhead Publishing, Abington, Cambridge, United Kingdom, 1995, p. 1.

J. Li, T. Wu, and Y. Riquier: Mater. Sci. Eng., 1994, vol. A174, p. 149.

G. Kurdjumov and G. Sachs: Z. Phys., 1930, vol. 64, p. 325.

L. Duprez, B.C. De Cooman, and N. Akdut: Proc. 6th World Duplex Conf., Venice, Italy, 2000, AIM, Milano, 2000, p. 133.

C.M. Sellars and W.J.McG. Tegart: Int. Metall. Rev., 1972, vol. 17, 1999, p. 1.

H.J. McQueen, N.D. Ryan, and P. Sakaris: Proc. 3rd Eur. Conf. Stainless Steels, Science and Market, Sardinia, Italy, 1999, AIM, Milano, 1999, p. 265.

Y.V.R.K. Prasad and T. Seshacharyulu: Int. Mater. Rev., 1998, vol. 43, p. 243.

K. Pöhlandt, A.E. Tekkaya, and E. Lach: Arch. Eisenhüttenwes., 1984, vol. 55 (4), p. 149.

A. Gräber and K. Pöhlandt: Steel Res., 1990, vol. 61 (5), p. 212.

F. Garofalo: Trans. TMS-AIME, 1963, vol. 227, p. 351.

W.F. Hosford and R.M. Caddell: Mech. Metall., p. 80.

D. Hernandez, G. Frommeyer, and H. Hofmann: Steel Res., 1996, vol. 67, p. 444.

T.M. Maccagno, J.J. Jonas, S. Yue, B.J. McCrady, R. Slobodian, and D. Deeks: Iron Steel Inst. Jpn. Int., 1994, vol. 34, pp. 917–22.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Duprez, L., De Cooman, B.C. & Akdut, N. Flow stress and ductility of duplex stainless steel during high-temperature torsion deformation. Metall Mater Trans A 33, 1931–1938 (2002). https://doi.org/10.1007/s11661-002-0026-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0026-4