Abstract

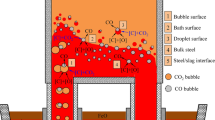

Herein, the mechanism of nitrogen absorption of the molten steel by injecting N2 was studied during the RH vacuum refining process. The dissolution behaviour of N2 in the molten steel was analyzed through the thermodynamic and kinetic calculations. For the N2 bubbles in the upward flow, the phenomenon of the nitrogen absorption, equilibrium, and denitrification occurred simultaneously in the up snorkel. The process is divided into three stages: (1) the larger static pressure of the molten steel makes the equilibrium value higher than the [N] content when the N2 bubbles begin to rise at the N2 inlet. Then, the nitrogen diffuses from N2 bubbles to the molten steel and the [N] content increases; (2) the [N] content in the molten steel reaches the equilibrium value; (3) the smaller static pressure of the molten steel makes the equilibrium value lower than the [N] content when N2 bubbles are close to the surface of the molten steel in the vacuum chamber. Then, the nitrogen diffuses from the molten steel to N2 bubbles and the [N] content decreases. In addition, a nitrogen dissolution model was established which took into account the static pressure both the molten steel and the vacuum chamber. The nitrogen dissolution model was verified by the industrial trials in a 300 t ladle RH treatment. The predicted results by the optimized nitrogen dissolution model agreed well with the measured results. Results showed that the nitrogen dissolution rate increased significantly with the increasing of the vacuum chamber pressure and the decreasing of the initial [N] content in the molten steel, respectively, while the temperature of molten steel had less effect on the nitrogen dissolution rate.

Similar content being viewed by others

References

T.L. Shchennikova, G.G. Zalazinskii, and B.R. Gel’chinskii: Russ. Metall. (Metally), 2014, vol. 2014, pp. 618–23.

L.N. Belyanchikov: Russ. Metall. (Metally), 2008, vol. 2008, pp. 761–65.

D.W. Kim, W.G. Kim, and W.S. Ryu: Int. J. Fatigue, 2003, vol. 25, pp. 1203–07.

M.M. Cisneros, H.F. Lopez, and H. Mancha: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 2139–44.

J. Shen, B. Chen, J. Umeda, and K. Kondoh: JOM, 2018, vol. 70, pp. 626–31.

H. Berns: ISIJ Int., 1996, vol. 36, pp. 909–14.

S. Yamasaki, M. Mitsuhara, and H. Nakashima: ISIJ Int., 2018, vol. 58, pp. 1146–54.

F. Hao, S.C. Zhang, and L.F. Xia: Steel Res. Int., 2022, vol. 93, p. 2200321.

L.F. Tong, S.C. Liu, and J.C. Jie: Materials, 2020, vol. 13, 132508.

J. Riipi, T. Fabritius, and E.P. Heikkinen: ISIJ Int., 2009, vol. 49, pp. 1468–73.

X.L. Su and W.F. Liu: Steelmaking (in Chinese), 2011, vol. 27, pp. 31–33.

Y. Li, W. Wu, and Q.Z. Zhu: Iron Steel (in Chinese), 2012, vol. 47, pp. 39–43.

W.H. Wang and S. Li: Tianjin Metall. (in Chinese), 2018, vol. 15, pp. 14–15.

T. Ou, C.H. Yu, and L.T. Liu: Special Steel (in Chinese), 2004, vol. 25, pp. 9–11.

H.Y. Zhao: Special Steel (in Chinese), 2008, vol. 29, pp. 43–44.

A.M. Chen, L.S. Qiao, and L. Jiang: Ferro-alloys (in Chinese), 2009, vol. 40, pp. 43–45.

O.N. Hideki, K. Tomotsugu, and U. Tateo: ISIJ Int., 2003, vol. 43, pp. 298–303.

O.N. Hideki, D. Yusuke, and Y. Daisuke: ISIJ Int., 2006, vol. 46, pp. 1306–11.

O. Hideki, F. Hirokazu, and M. Kazuki: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 848–53.

C.H. Eom, M.H. Song, and D.J. Min: ISIJ Int., 2015, vol. 55, pp. 2694–96.

J. Lee and K. Morita: ISIJ Int., 2003, vol. 43(1), pp. 14–19.

S.M. Han, J.H. Park, and S.M. Jung: ISIJ Int., 2009, vol. 49, pp. 487–94.

H. Saito, A. Yoshizawa, and T. Soma: Tetsu-to-Hagane, 1984, vol. 70, pp. 58–64.

D. Tang and P.C. Pistorius: Metall. Mater. Trans. B, 2022, vol. 53, pp. 1383–95.

J. Chipman and D.A. Corrigan: Trans. Metall. Soc. AIME., 1965, vol. 233, p. 1249.

Acknowledgments

The authors deeply appreciate Shougang Group Co., Ltd. for permission to publish this paper.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, W., Xu, A., Liu, B. et al. Mechanism and Model of Nitrogen Absorption of Molten Steel During N2 Injection Process in RH Vacuum. Metall Mater Trans B 55, 72–82 (2024). https://doi.org/10.1007/s11663-023-02937-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02937-8