Abstract

TiO2-based materials have been considered as one of most promising alternatives for high-performance Li(Na)-ion batteries because of the low cost, simple composition, easy synthesis, good environmental protection, excellent safety and relatively high specific capacity. Nonetheless, the inferior electronic conductivity and poor ion diffusion coefficients are the biggest bottlenecks that restrict the popular application. Much effort has been focused on resolving these problems toward large-scale applications, and numerous significant advances have been accomplished. In the present work, a comprehensive overview of structure characteristics, electrochemical reaction mechanism and modification strategies of TiO2-based materials was presented. The recent advances of various efficient ways for improving conductivity, Li(Na) storage capacity, rate capability and cycle stability are systematically summarized, including surface engineering, constructing composite and element doping, etc. Constructing TiO2-based materials with novel porous heterogeneous core–shell structures have been regarded as one of the most effective ways to resolve these challenges. Finally, the future research directions and development prospects of TiO2-based anode materials used in the manufacture of high-performance Li(Na)-ion batteries are prospected. This review can provide important comprehension for the construction and optimization of high-performance of TiO2-based anode materials.

摘要

TiO2 基材料因其成本低、组成简单、易合成、环保、安全性好、相对较高的比容量等优点, 被认为是高性能锂(钠)离子电池最有希望的替代材料之一。然而, 较低的电子电导率和较差的离子扩散系数是限制其广泛应用的最大瓶颈。为了解决这些大规模应用问题, 人们付出了大量的努力, 并取得了许多重大进展。本文综述了TiO2 基材料的结构特点、电化学反应机理和性能改性策略, 系统总结了近年来提高电导率、储锂(钠)容量、倍率性能和循环稳定性的各种有效途径, 包括表面工程、构建复合材料和元素掺杂等。其中, 构建新型多孔异质核壳结构的TiO2 基材料被认为是解决这些挑战的最有效途径之一。最后, 展望了用于高性能锂(钠)离子电池用TiO2 基负极材料的未来研究方向和发展前景。本文为高性能TiO2 基负极材料的构建和优化提供了重要的参考依据。

Graphic abstract

Reproduced with permission from Ref.[32]. Copyright 2016, Royal Society of Chemistry). d TiO2-B (Reproduced with permission from Ref. [46]. Copyright 2013, American Chemical Society). Cyclic voltammetry curves of rutile TiO2: e Li-ion storage properties and f Na-ion storage properties. Reproduced with permission from Ref. [50]. Copyright 2016, Elsevier. CV profiles for anatase TiO2: g lithium storage (Reproduced with permission from Ref. [47]. Copyright 2015, Elsevier); h sodium storage (Reproduced with permission from Ref. [49]. Copyright 2018, Elsevier). Cyclic voltammograms of TiO2-B for rechargeable i LIBs (Reproduced with permission from Ref. [48]. Copyright 2019, Elsevier) and j SIBs (Reproduced with permission from Ref. [63]. Copyright 2017, Royal Society of Chemistry)

Reproduced with permission from Ref. [71]. Copyright 2015, Elsevier. f Schematic diagram of synthesis process for CCAnTHS composite, g rate capability of AmTSSs, AnTHSs, and CCAnTHSs. Reproduced with permission from Ref. [94]. Copyright 2015, Royal Society of Chemistry. h Schematic diagram of synthesis process for meso-ATCCNs; i rate performance of meso-ATCCNs, meso-TNs, and bulk TiO2. Reproduced with permission from Ref. [85]. Copyright 2016, American Chemical Society. j Schematic diagram of synthesis process for TiO2/C composites and k rate performance of TiO2/C-900. Reproduced with permission from Ref. [97]. Copyright 2015, Royal Society of Chemistry

Reproduced with permission from Ref. [103]. Copyright 2017, Elsevier. c Schematic diagram of synthesis for NTiO2@NC; d rate capability of NTiO2@NC. Reproduced with permission from Ref. [104]. Copyright 2017, Elsevier. e Preparation process of TiO2@HCNs. Reproduced with permission from Ref. [105]. Copyright 2019, Elsevier. f Long-life cycling performance of TSPC. Reproduced with permission from Ref. [109]. Copyright 2018, Royal Society of Chemistry

Reproduced with permission from Ref. [115]. Copyright 2016, Elsevier. c SEM image of TiO2 MCs; d rate performance of LiFePO4/TiO2 MCs@CNTs. Reproduced with permission from Ref. [116]. Copyright 2019, Elsevier. e Rate performance and f cycling stability of commercial TiO2, MTO, and MTO/MWCNT. Reproduced with permission from Ref. [116]. Copyright 2015, American Chemical Society. g SEM image of CNT-TiO2 NS; h rate capability of CNT-TiO2 NS and TiO2 NP. Reproduced with permission from Ref. [58]. Copyright 2018, Elsevier

Reproduced with permission from Ref. [122]. Copyright 2018, Elsevier. c TEM image of TiO2@rGO; d cycle performance of TiO2@rGO. Reproduced with permission from Ref. [130]. Copyright 2018, American Chemical Society. e Schematic illustration of synthesis process and f TEM image of TNGC. Reproduced with permission from Ref. [131]. Copyright 2019, Elsevier. g Synthesis diagram of TiO2/GNRs. Reproduced with permission from Ref. [132]. Copyright 2019, Elsevier

Reproduced with permission from Ref. [133]. Copyright 2016, Elsevier. c SEM, d TEM images and e schematic diagram of possible growth mechanism for TiO2/GA. Reproduced with permission from Ref. [135]. Copyright 2019, Elsevier. f Schematic illustration of formation process and g cycling performance of TiO2@N-G. Reproduced with permission from Ref. [137]. Copyright 2015 Elsevier

Reproduced with permission from Ref. [143]. Copyright 2015, American Chemical Society. c Preparation procedure of TiO2@ZnO array; d cycling capability of TiO2, ZnO and TiO2@ZnO. Reproduced with permission from Ref. [149]. Copyright 2015, Elsevier. e Schematic diagram of Li insertion/extraction mechanism for porous TiO2@Sn3O4. Reproduced with permission from Ref. [151]. Copyright 2018, Elsevier. f Schematic illustration of forming process for TiO2@α-Fe2O3; g rate capability of TiO2, TFN and α-Fe2O3. Reproduced with permission from Ref. [152]. Copyright 2016, American Chemical Society

Reproduced with permission from Ref. [157]. Copyright 2016, Elsevier. c Schematic illustration of forming process for TN@MNAs; d rate performance of TN@MNAs, TN@MNAs-1 TN@MNAs-2 and TN@MNAs-3. Reproduced with permission from Ref. [158]. Copyright 2018, Elsevier. e Schematic diagram of TiO2@MoS2 composites; f cycling capability of TiO2@MoS2, MoS2 and TiO2. Reproduced with permission from Ref. [159]. Copyright 2020, Elsevier. g Schematic diagram of pristine SnS2, BST-1 and BST-2 composites; h cycling capability of SnS2, BST-1 and BST-2. Reproduced with permission from Ref. [160]. Copyright 2020, Elsevier

Reproduced with permission from Ref. [164]. Copyright 2016, Royal Society of Chemistry. c Cycle performances and d rate performances of pure TiO2 and Co-doped TiO2 samples. Reproduced with permission from Ref. [165]. Copyright 2019, Elsevier. e Schematic diagrams of insertion/extraction processes of Li ion of TiO2 fiber, HTFSs and Mn- HTFSs; f cycle performance of TiO2 fiber and Mn-HTFSs samples. Reproduced with permission from Ref. [167]. Copyright 2019, Elsevier. g Schematic illustration and h rate capability of TiO2−δ, TiO2-200 and TiO2-400. Reproduced with permission from Ref. [169]. Copyright 2016, American Chemical Society

Reproduced with permission from Ref. [172]. Copyright 2017, American Chemical Society. c Synthetic procedure for Nb-doped TiO2, d cycle property of Nb-doped TiO2 samples. Reproduced with permission from Ref. [178]. Copyright 2015, Royal Society of Chemistry. e Cycling performances of MTO and TO. Reproduced with permission from Ref. [182]. Copyright 2016, Elsevier. f Cycling stability of TiO2, I/S–TiO2 and I–TiO2 anodes. Reproduced with permission from Ref. [184]. Copyright 2015, Royal Society of Chemistry. g Rate performances of N–TiO2 and commercial TiO2. Reproduced with permission from Ref. [188]. Copyright 2016, Royal Society of Chemistry

Similar content being viewed by others

References

Yang Z, Zhang J, Kintner-Meyer MC, Lu X, Choi D, Lemmon JP, Liu J. Electrochemical energy storage for green grid. Chem Rev. 2011;111(5):3577.

Yu P, Tang W, Wu FF, Zhang C, Luo HY, Liu H, Wang ZG. Recent progress in plant-derived hard carbon anode materials for sodium-ion batteries: a review. Rare Met. 2020;39(9):1019.

Cao X, Zhou J, Pan A, Liang S. Recent advances in phosphate cathode materials for sodium-ion batteries. Acta Phys Chim Sin. 2020;36(5):1905018.

Li X, Qi SH, Zhang WC, Feng YZ, Ma JM. Recent progress on FeS2 as anodes for metal-ion batteries. Rare Met. 2020;39(11):1239.

Cao B, Li X. Recent progress on carbon-based anode materials for Na-ion batteries. Acta Phys Chim Sin. 2020;36(5):1905003.

Han MC, Zhang JH, Cui P, Yi TF, Li X. Porous ZnTiO3 rods as a novel lithium storage material for Li-ion batteries. Ceram Int. 2020;46(9):14030.

Zhu H, Liu T, Peng L, Yao W, Kang F, Shu J, Yang C. A compact Bi2WO6 microflowers anode for potassium-ion storage: taming a sequential phase evolution toward stable electrochemical cycling. Nano Energy. 2021;82:105784.

Pan WL, Guan WH, Jiang YZ. Research advances in polyanion-type cathodes for sodium-ion batteries. Acta Phys Chim Sin. 2020;36(5):1905017.

Liang JM, Zhang LJ, XiLi DG, Kang J. Research progress on tin-based anode materials for sodium ion batteries. Rare Met. 2020;39(9):1005.

Han MC, Zhang JH, Li YM, Zhu YR, Yi TF. Li5Cr7Ti6O25/multiwalled carbon nanotubes composites with fast charge-discharge performance as negative electrode materials for lithium-ion batteries. J Electrochem Soc. 2019;166(4):A626.

Han MC, Zhang JH, Cui P, Zhu YR, Yi TF. Construction of spherical ZnTiO3/MWCNTs composites as anode material for high-performance Li-ion batteries. Sustain Mater Technol. 2020;25:e00207.

Li B, Han C, He YB, Yang C, Du H, Yang QH, Kang F. Facile synthesis of Li4Ti5O12/C composite with super rate performance. Energy Environ Sci. 2012;5(11):9595.

Dong L, Xu C, Li Y, Wu C, Jiang B, Yang Q, Zhou E, Kang F, Yang QH. Simultaneous production of high-performance flexible textile electrodes and fiber electrodes for wearable energy storage. Adv Mater. 2016;28(8):1675.

Zhou D, Liu R, He YB, Li F, Liu M, Li B, Yang QH, Cai Q, Kang F. SiO2 Hollow nanosphere-based composite solid electrolyte for lithium metal batteries to suppress lithium dendrite growth and enhance cycle life. Adv Energy Mater. 2016;6(7):1502214.

Liu T, Peng N, Zhang X, Zheng R, Xia M, Yu H, Shui M, Xie Y, Shu J. Controllable defect engineering enhanced bond strength for stable electrochemical energy storage. Nano Energy. 2021;79:105460.

Zhou D, He YB, Liu R, Liu M, Du H, Li B, Cai Q, Yang QH, Kang F. In situ synthesis of a hierarchical all-solid-state electrolyte based on nitrile materials for high-performance lithium-ion batteries. Adv Energy Mater. 2015;5(15):1500353.

Wu ZH, Yang JY, Yu B, Shi BM, Zhao CR, Yu ZL. Self-healing alginate-carboxymethyl chitosan porous scaffold as an effective binder for silicon anodes in lithium-ion batteries. Rare Met. 2019;38(9):832.

Mei Y, Huang Y, Hu X. Nanostructured Ti-based anode materials for Na-ion batteries. J Mater Chem A. 2016;4(31):12001.

Wang XY, Zhao D, Wang C, Xia YG, Jiang WS, Xia SL, Yin SS, Zuo XX, Metwalli E, Xiao Y, Sun ZC, Zhu J, Muller-Buschbaum P, Cheng YJ. Role of nickel nanoparticles in high-performance TiO2/Ni/carbon nanohybrid lithium/sodium-ion battery anodes. Chem Asian J. 2019;14(9):1557.

Ji YR, Weng ST, Li XY, Zhang QH, Gu L. Atomic-scale structural evolution of electrode materials in Li-ion batteries: a review. Rare Met. 2020;39(3):205.

Ma J, Wei Y, Gan L, Wang C, Xia H, Lv W, Li J, Li B, Yang QH, Kang F, He YB. Abundant grain boundaries activate highly efficient lithium ion transportation in high rate Li4Ti5O12 compact microspheres. J Mater Chem A. 2019;7(3):1168.

Huang F, Ma J, Xia H, Huang Y, Zhao L, Su S, Kang F, He YB. Capacity loss mechanism of the Li4Ti5O12 microsphere anode of lithium-ion batteries at high temperature and rate cycling conditions. ACS Appl Mater Interface. 2019;11(40):37357.

Tang LK, He YB, Wang C, Wang S, Wagemaker M, Li BH, Yang QH, Kang FY. High-density microporous Li4Ti5O12 microbars with superior rate performance for lithium-ion batteries. Adv Sci. 2017;4(5):1600311.

Gao Y, Yin L, Kim SJ, Yang H, Jeon I, Kim JP, Jeong SY, Lee HW, Cho CR. Enhanced lithium storage by ZnFe2O4 nanofibers as anode materials for lithium-ion battery. Electrochim Acta. 2019;296:565.

Yao ZJ, Xia XH, Zhou CA, Zhong Y, Wang YD, Deng SJ, Wang WQ, Wang XL, Tu JP. Smart construction of integrated CNTs/Li4Ti5O12 core/shell arrays with superior high-rate performance for application in lithium-ion batteries. Adv Sci. 2018;5(3):1700786.

Zheng SQ, Wu ZH, Wang JT, Zhang XJ. Performance of high capacity silicon/carbon anodes with different pore structures. Chin J Rare Metals. 2020;44(3):225.

Wang C, Wang S, Tang LK, He YB, Gan L, Li J, Du HD, Li BH, Lin ZQ, Kang FY. A robust strategy for crafting monodisperse Li4Ti5O12 nanospheres as superior rate anode for lithium ion batteries. Nano Energy. 2016;21:133.

Wang C, Wang SA, He YB, Tang LK, Han CP, Yang C, Wagemaker M, Li BH, Yang QH, Kim JK, Kang FY. Combining fast Li-ion battery cycling with large volumetric energy density: grain boundary induced high electronic and ionic conductivity in Li4Ti5O12 spheres of densely packed nanocrystallites. Chem Mater. 2015;27(16):5647.

Belharouak I, Sun YK, Lu W, Amine K. On the safety of the Li4Ti5O12/LiMn2O4 lithium-ion battery system. J Electrochem Soc. 2017;154(12):A1083.

Zhang X, Zhu Y, Bruck AM, Housel LM, Wang L, Quilty CD, Takeuchi KJ, Takeuchi ES, Marschilok AC, Yu G. Understanding aggregation hindered Li-ion transport in transition metal oxide at mesoscale. Energy Storage Mater. 2019;19:439.

Shi S, Deng S, Zhang M, Zhao M, Yang G. Rapid microwave synthesis of self-assembled hierarchical Mn2O3 microspheres as advanced anode material for lithium ion batteries. Electrochim Acta. 2017;224:285.

Ge M, Cao C, Huang J, Li S, Chen Z, Zhang KQ, Al-Deyab SS, Lai Y. A review of one-dimensional TiO2 nanostructured materials for environmental and energy applications. J Mater Chem A. 2016;4(18):6772.

Zhang G, Chu C, Yang J, Tung CH, Wang Y. Preparation of porous TiO2 from an iso-polyoxotitanate cluster for rechargeable sodium-ion batteries with high performance. J Phys Chem C. 2019;123(12):7025.

Wei D, Xu F, Xu J, Fang J, Sun Z. Rambutan-pitaya-like structured TiO2@Co-CNT-NC nanocomposite as high-performance lithium ion battery anodes. Ceram Int. 2019;45(17):22131.

Yan D, Pan L. A new sodium storage mechanism of TiO2 for sodium ion batteries. Inorg Chem Front. 2016;3(4):464.

Wu N, Qiao X, Shen J, Liu G, Sun T, Wu H, Hou H, Liu X, Zhang Y, Ji X. Anatase inverse opal TiO2-x@N-doped C induced the dominant pseudocapacitive effect for durable and fast lithium/sodium storage. Electrochim Acta. 2019;299:540.

Nie S, Liu L, Liu J, Xie J, Zhang Y, Xia J, Yan H, Yuan Y, Wang X. Nitrogen-doped TiO2-C composite nanofibers with high-capacity and long-cycle life as anode materials for sodium-ion batteries. Nanomicro Lett. 2018;10(4):71.

Lu Y, Zhang Q, Chen J. Recent progress on lithium-ion batteries with high electrochemical performance. Sci China Chem. 2019;62(5):533.

Guan Z, Wang X, Li T, Zhu Q, Jia M, Xu B. Facile synthesis of rutile TiO2/carbon nanosheet composite from MAX phase for lithium storage. J Mater Sci Technol. 2019;35(9):1977.

Song T, Paik U. TiO2 as an active or supplemental material for lithium batteries. J Mater Chem A. 2016;4(1):14.

Fehse M, Ventosa E. Is TiO2(B) the future of titanium-based battery materials? ChemPlusChem. 2015;80(5):785.

Yuwono JA, Burr P, Galvin C, Lennon A. Atomistic insights into lithium storage mechanisms in anatase, rutile, and amorphous TiO2 electrodes. ACS Appl Mater Interfaces. 2021;13(1):1791.

Auer A, Kunze-Liebhaeuser J. Recent progress in understanding ion storage in self-organized anodic TiO2 nanotubes. Small Methods. 2019;3(8):1800385.

Yan X, Wang Z, He M, Hou Z, Xia T, Liu G, Chen X. TiO2 nanomaterials as anode materials for lithium-ion rechargeable batteries. Energy Technol. 2015;3(8):801.

Wang X, Zhao Y, Molhave K, Sun H. Engineering the surface/interface structures of titanium dioxide micro and nano architectures towards environmental and electrochemical applications. Nanomaterials. 2017;7(11):382.

Dylla AG, Henkelman G, Stevenson KJ. Lithium insertion in nanostructured TiO2(B) architectures. Acc Chem Res. 2013;46(5):1104.

Li T, Lun N, Qi YX, Wei C, Sun YK, Zhu HL, Liu JR, Bai YJ. Enhancing the reversible capacity and rate performance of anatase TiO2 by combined coating and compositing with N-doped carbon. J Power Sour. 2015;273:472.

Opra DP, Gnedenkov SV, Sokolov AA, Mayorov VY, Sinebryukhov SL. Correlation between microstructure of TiO2-anatase precursor and lithium storage properties of hydrothermally synthesized TiO2-B. Scripta Mater. 2019;165:150.

Zhang Y, Hong W, Zhang Y, Xu W, Shi Z, Li X, Hou H, Ji X. TiO2 nanosheets anchoring on carbon nanotubes for fast sodium storage. Electrochim Acta. 2018;283:1514.

Hong Z, Hong J, Xie C, Huang Z, Wei M. Hierarchical rutile TiO2 with mesocrystalline structure for Li-ion and Na-ion storage. Electrochim Acta. 2016;202:203.

Li Y, Wang S, Lei D, He YB, Li B, Kang F. Acetic acid-induced preparation of anatase TiO2 mesocrystals at low temperature for enhanced Li-ion storage. J Mater Chem A. 2017;5(24):12236.

Li Y, Wang S, He YB, Tang L, Kaneti YV, Lv W, Lin Z, Li B, Yang QH, Kang F. Li-ion and Na-ion transportation and storage properties in various sized TiO2 spheres with hierarchical pores and high tap density. J Mater Chem A. 2017;5(9):4359.

He YB, Liu M, Xu ZL, Zhang B, Li B, Kang F, Kim JK. Li-ion reaction to improve the rate performance of nanoporous anatase TiO2 anodes. Energy Technol. 2013;1(11):668.

Lewis CS, Li YR, Wang L, Li J, Stach EA, Takeuchi KJ, Marschilok AC, Takeuchi ES, Wong SS. Correlating titania nanostructured morphologies with performance as anode materials for lithium-ion batteries. ACS Sustain Chem Eng. 2016;4(12):6299.

Liu Q, Wang LL, Zhao KN, Yan W, Liu MM, Wei DH, Xi LL, Zhang JJ. 3D branched rutile TiO2@rutile SnO2 nanorods array heteroarchitectures/carbon cloth with an adjustable band gap to enhance lithium storage reaction kinetics for flexible lithium-ion batteries. Electrochim Acta. 2020;354:136727.

Imazeki D, van Gils CC, Nishio K, Shimizu R, Hitosugi T. Effects of anisotropy in rutile TiO2 on the performance of solid-state lithium batteries. ACS Appl Energy Mater. 2020;3(9):8338.

Zhang Y, Pu X, Yang Y, Zhu Y, Hou H, Jing M, Yang X, Chen J, Ji X. An electrochemical investigation of rutile TiO2 microspheres anchored by nanoneedle clusters for sodium storage. Phys Chem Chem Phys. 2015;17(24):15764.

Lan T, Wang T, Zhang W, Wu NL, Wei M. Rutile TiO2 mesocrystals with tunable subunits as a long-term cycling performance anode for sodium-ion batteries. J Alloy Compd. 2017;699:455.

Su D, Liu L, Liu Z, Dai J, Wen J, Yang M, Jamil S, Deng H, Cao G, Wang X. Electrospun Ta-doped TiO2/C nanofibers as a high-capacity and long-cycling anode material for Li-ion and K-ion batteries. J Mater Chem A. 2020;8(39):20666.

Ma J, Xing M, Yin L, San Hui K, Hui KN. Porous hierarchical TiO2/MoS2/RGO nanoflowers as anode material for sodium ion batteries with high capacity and stability. Appl Surf Sci. 2021;536:147735.

Cao M, Tao L, Lv X, Bu Y, Li M, Yin H, Zhu M, Zhong Z, Shen Y, Wang M. Phosphorus-doped TiO2-B nanowire arrays boosting robust pseudocapacitive properties for lithium storage. J Power Sour. 2018;396:327.

He J, Yang J, Jiang J, Xu M, Wang Q. Constructing reduced graphene oxide network aerogel supported TiO2(B) (Bronze phase TiO2) as anode material for lithium-ion storage. J Alloy Compd. 2021;853:157330.

Yang Y, Liao S, Shi W, Wu Y, Zhang R, Leng S. Nitrogen-doped TiO2(B) nanorods as high-performance anode materials for rechargeable sodium-ion batteries. RSC Adv. 2017;7(18):10885.

Lee J, Lee JK, Chung KY, Jung HG, Kim H, Mun J, Choi W. Electrochemical investigations on TiO2-B nanowires as a promising high capacity anode for sodium-ion batteries. Electrochim Acta. 2016;200:21.

Opra DP, Gnedenkov SV, Sokolov AA, Podgorbunsky AB, Ustinov AY, Mayorov VY, Kuryavyi VG, Sinebryukhov SL. Vanadium-doped TiO2-B/anatase mesoporous nanotubes with improved rate and cycle performance for rechargeable lithium and sodium batteries. J Mater Sci Technol. 2020;54:181.

Liu G, Wu HH, Meng Q, Zhang T, Sun D, Jin X, Guo D, Wu N, Liu X, Kim JK. Role of the anatase/TiO2(B) heterointerface for ultrastable high-rate lithium and sodium energy storage performance. Nanoscale Horiz. 2020;5(1):150.

Kang M, Ruan Y, Lu Y, Luo L, Huang J, Zhang JM, Hong Z. An interlayer defect promoting the doping of the phosphate group into TiO2(B) nanowires with unusual structure properties towards ultra-fast and ultra-stable sodium storage. J Mater Chem A. 2019;7(28):16937.

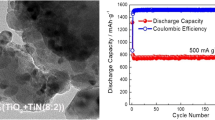

Wang YW, Liu SF, Zhang N, Qian X, Zhou ZF. Novel core-shell structure TiO2@TiN spheres as high-performance anode material for lithium-ion battery. Int J Electrochem Sci. 2019;14(1):618.

Zhang YJ, Zhao SB, Zeng XY, Xiao J, Dong P, Zhao JB, Sun SG, Huang L, Li X. TiO2–MoS2 hybrid nano composites with 3D network architecture as binder-free flexible electrodes for lithium ion batteries. J Mater Sci Mater El. 2017;28(13):9519.

Zheng H, Ncube NM, Raju K, Mphahlele N, Mathe M. The effect of polyaniline on TiO2 nanoparticles as anode materials for lithium ion batteries. Springerplus. 2016;5:630.

Bai X, Li T, Qi YX, Gao XP, Yin LW, Li H, Zhu HL, Lun N, Bai YJ. Simple fabrication of TiO2/C nanocomposite with enhanced electrochemical performance for lithium-ion batteries. Electrochim Acta. 2015;169:241.

Fu Z, Li R, Kan Z. Hexagonal hollow mesoporous TiO2/carbon composite as an advanced anode material for lithium-ion batteries. J Solid State Electr. 2019;23(6):1779.

Yang J, Chen Z, Wang H, Liang F, Chen R, Wu R. Highly ordered three-dimensional TiO2@C nanotube arrays as freestanding electrode for sodium-ion battery. Mater Lett. 2017;207:149.

Wu F, Luo R, Xie M, Li L, Zhang X, Zhao L, Zhou J, Wang K, Chen R. Facile synthesis of carbon-mediated porous nanocrystallite anatase TiO2 for improved sodium insertion capabilities as an anode for sodium-ion batteries. J Power Sour. 2017;362:283.

Zhao C, Liu L, Zhang Q, Rogers J, Zhao H, Li Y. Synthesis of carbon-TiO2 nanocomposites with enhanced reversible capacity and cyclic performance as anodes for lithium-ion batteries. Electrochim Acta. 2015;155:288.

Lin X, Wang Y, Chai W, Liu T, Mou J, Liu J, Huang J, Liu M. Solvothermal alcoholysis synthesis of hierarchically porous TiO2-carbon tubular composites as high-performance anodes for lithium-ion batteries. Electrochim Acta. 2019;308:253.

Tao H, Zhou M, Wang K, Cheng S, Jiang K. Glycol derived carbon-TiO2 as low cost and high performance anode material for sodium-ion batteries. Sci Rep. 2017;7(1):43895.

Chen J, Li Y, Mu J, Zhang Y, Yu Z, Han K, Zhang L. C@TiO2 nanocomposites with impressive electrochemical performances as anode material for lithium-ion batteries. J Alloy Compd. 2018;742:828.

Chen J, Zhang Y, Zou G, Huang Z, Li S, Liao H, Wang J, Hou H, Ji X. Size-tunable olive-like anatase TiO2 coated with carbon as superior anode for sodium-ion batteries. Small. 2016;12(40):5554.

Zuniga L, Agubra V, Flores D, Campos H, Villareal J, Alcoutlabi M. Multichannel hollow structure for improved electrochemical performance of TiO2/carbon composite nanofibers as anodes for lithium ion batteries. J Alloy Compd. 2016;686:733.

Plylahan N, Letiche M, Samy Barr MK, Ellis B, Maria S, Phan TNT, Bloch E, Knauth P, Djenizian T. High energy and power density TiO2 nanotube electrodes for single and complete lithium-ion batteries. J Power Sour. 2015;273:1182.

Ge Y, Zhu J, Lu Y, Chen C, Qiu Y, Zhang X. The study on structure and electrochemical sodiation of one-dimensional nanocrystalline TiO2@C nanofiber composites. Electrochim Acta. 2015;176:989.

Wang N, Gao Y, Wang YX, Liu K, Lai W, Hu Y, Zhao Y, Chou SL, Jiang L. Nanoengineering to achieve high sodium storage: a case study of carbon coated hierarchical nanoporous TiO2 microfibers. Sci Rep. 2016;3(8):1600013.

Ge Y, Jiang H, Zhu J, Lu Y, Chen C, Hu Y, Qiu Y, Zhang X. High cyclability of carbon-coated TiO2 nanoparticles as anode for sodium-ion batteries. Electrochim Acta. 2015;157:142.

Wu R, Shen S, Xia G, Zhu F, Lastoskie C, Zhang J. Soft-templated self-assembly of mesoporous anatase TiO2/carbon composite nanospheres for high-performance lithium ion batteries. ACS Appl Mater Interface. 2016;8(31):19968.

Zhang Q, He H, Huang X, Yan J, Tang Y, Wang H. TiO2@C nanosheets with highly exposed (001) facets as a high-capacity anode for Na-ion batteries. Chem Eng J. 2018;332:57.

Zou G, Chen J, Zhang Y, Wang C, Huang Z, Li S, Liao H, Wang J, Ji X. Carbon-coated rutile titanium dioxide derived from titanium-metal organic framework with enhanced sodium storage behavior. J Power Sour. 2016;325:25.

Zou F, Liu K, Cheng CF, Ji Y, Zhu Y. Metal-organic frameworks (MOFs) derived carbon-coated NiS nanoparticles anchored on graphene layers for high-performance Li-S cathode material. Nanotechnology. 2020;31(48):485404.

Lu G, Wang H, Zheng Y, Zhang H, Yang Y, Shi J, Huang M, Liu W. Metal-organic framework derived N-doped CNT@porous carbon for high-performance sodium- and potassium-ion storage. Electrochim Acta. 2019;319:541.

Sun S, Chen D, Shen M, Qin L, Wang Z, Wu Y, Chen J. Plasma modulated MOF-derived TiO2/C for enhanced lithium storage. Chem Eng J. 2020;2020:128003.

Sun W, Tao X, Du P, Wang Y. Carbon-coated mixed-metal sulfide hierarchical structure: MOF-derived synthesis and lithium-storage performances. Chem Eng J. 2019;366:622.

Liu X, Li X, Lu X, He X, Jiang N, Huo Y, Xu C, Lin D. Metal-organic framework derived in-situ nitrogen-doped carbon-encapsulated CuS nanoparticles as high-rate and long-life anode for sodium ion batteries. J Alloy Compd. 2021;854:157132.

Li Y, Zhang J, Chen M. MOF-derived carbon and composites as advanced anode materials for potassium ion batteries: a review. Sustain Mater Techno. 2020;26:e00217.

Zhang Y, Yang Y, Hou H, Yang X, Chen J, Jing M, Jia X, Ji X. Enhanced sodium storage behavior of carbon coated anatase TiO2 hollow spheres. J Mater Chem A. 2015;3(37):18944.

Zhang K, Zhang Y, Zhang Q, Liang Z, Gu L, Guo W, Zhu B, Guo S, Zou R. Metal-organic framework-derived Fe/Cu-substituted Co nanoparticles embedded in CNTs-grafted carbon polyhedron for Zn-air batteries. Carbon Energy. 2020;2(2):283.

Zheng G, Chen M, Zhang H, Zhang J, Liang X, Qi M, Yin J. Zn-MOFs derived porous carbon nanofiber for high performance lithium-ion batteries. Surf Coat Technol. 2019;359:384.

Wang P, Lang J, Liu D, Yan X. TiO2 embedded in carbon submicron-tablets: synthesis from a metal-organic framework precursor and application as a superior anode in lithium-ion batteries. Chem Commun. 2015;51(57):11370.

Wen Y, Yun JH, Luo B, Lyu M, Wang L. Tuning the carbon content on TiO2 nanosheets for optimized sodium storage. Electrochim Acta. 2016;219:163.

Yang F, Zhang Z, Han Y, Du K, Lai Y, Li J. TiO2/carbon hollow spheres as anode materials for advanced sodium ion batteries. Electrochim Acta. 2015;178:871.

Wang WL, Park JY, Nguyen VH, Jin EM, Gu HB. Hierarchical mesoporous rutile TiO2/C composite nanospheres as lithium-ion battery anode materials. Ceram Int. 2016;42(1):598.

Bresser D, Oschmann B, Tahir MN, Mueller F, Lieberwirth I, Tremel W, Zentel R, Passerini S. Carbon-coated anatase TiO2 nanotubes for Li- and Na-ion anodes. J Electrochem Soc. 2015;162(2):A3013.

Liang Y, Li N, Li F, Xu Z, Hu Y, Jing M, Teng K, Yan X, Shi J. Controllable nitrogen doping and specific surface from freestanding TiO2@carbon nanofibers as anodes for lithium ion battery. Electrochim Acta. 2019;297:1063.

Shen J, Hu W, Li Y, Li L, Lv XJ, Zhang L. Fabrication of free-standing N-doped carbon/TiO2 hierarchical nanofiber films and their application in lithium and sodium storages. J Alloy Compd. 2017;701:372.

Ren M, Xu H, Li F, Liu W, Gao C, Su L, Li G, Hei J. Sugarapple-like N-doped TiO2@carbon core-shell spheres as high-rate and long-life anode materials for lithium-ion batteries. J Power Sour. 2017;353:237.

Yuan Y, Chen F, Cai G, Yin S, Zhu M, Wang L, Yang J, Guo S. Ultrafine TiO2 nanocrystalline anchored on nitrogen-doped amorphous mesoporous hollow carbon nanospheres as advanced anode for lithium ion batteries. Electrochim Acta. 2019;296:669.

He H, Huang D, Pang W, Sun D, Wang Q, Tang Y, Ji X, Guo Z, Wang H. Plasma-induced amorphous shell and deep cation-site S doping endow TiO2 with extraordinary sodium storage performance. Adv Mater. 2018;30(26):1801013.

Chen C, Li P, Wang T, Wang S, Zhang M. S-doped carbon fibers uniformly embedded with ultrasmall TiO2 for Na+/Li+ storage with high capacity and long-time stability. Small. 2019;15(38):1902201.

Li F, Liu W, Lai Y, Qin F, Zou L, Zhang K, Li J. Nitrogen and sulfur co-doped hollow carbon nanofibers decorated with sulfur doped anatase TiO2 with superior sodium and lithium storage properties. J Alloy Compd. 2017;695:1743.

Li J, Zhang X, Han L, Yan D, Hou S, Lu T, Yao Y, Pan L. TiO2 nanocrystals embedded in sulfur-doped porous carbon as high-performance and long-lasting anode materials for sodium-ion batteries. J Mater Chem A. 2018;6(47):24224.

Cheng Y, Chen Z, Wu H, Zhu M, Lu Y. Ionic liquid-assisted synthesis of TiO2-carbon hybrid nanostructures for lithium-ion batteries. Adv Funct Mater. 2016;26(9):1338.

Tang Y, Liu L, Wang X, Jia D, Xia W, Zhao Z, Qiu J. TiO2 quantum dots embedded in bamboo-like porous carbon nanotubes as ultra high power and long life anodes for lithium ion batteries. J Power Sour. 2016;319:227.

Yan L, Xu Y, Zhou M, Chen G, Deng S, Smirnov S, Luo H, Zou G. Porous TiO2 conformal coating on carbon nanotubes as energy storage materials. Electrochim Acta. 2015;169:73.

Liu X, Xu G, Xiao H, Wei X, Yang L. Free-standing hierarchical porous assemblies of commercial TiO2 nanocrystals and multi-walled carbon nanotubes as high-performance anode materials for sodium ion batteries. Electrochim Acta. 2017;236:33.

Peng Y, Le Z, Wen M, Zhang D, Chen Z, Wu HB, Li H, Lu Y. Mesoporous single-crystal-like TiO2 mesocages threaded with carbon nanotubes for high-performance electrochemical energy storage. Nano Energy. 2017;35:44.

Liu Y, Elzatahry AA, Luo W, Lan K, Zhang P, Fan J, Wei Y, Wang C, Deng Y, Zheng G, Zhang F, Tang Y, Mai L, Zhao D. Surfactant-templating strategy for ultrathin mesoporous TiO2 coating on flexible graphitized carbon supports for high-performance lithium-ion battery. Nano Energy. 2016;25:80.

Liu X, Zhao L, Wang S, Chao M, Li Y, Leng J, Zhang J, Tang Z. Hierarchical-structure anatase TiO2 with conductive network for high-rate and high-loading lithium-ion battery. Sci Bull. 2019;64(16):1148.

Trang NT, Ali Z, Kang DJ. Mesoporous TiO2 spheres interconnected by multiwalled carbon nanotubes as an anode for high-performance lithium ion batteries. ACS Appl Mater Interfaces. 2015;7(6):3676.

Zhou N, Wu Y, Li Y, Yang J, Zhou Q, Guo Y, Xia M, Zhou Z. Interconnected structure Si@TiO2-B/CNTs composite anode applied for high-energy lithium-ion batteries. Appl Surf Sci. 2020;500:144026.

Chen J, Wang E, Mu J, Ai B, Zhang T, Ge W, Zhang L. CNTs–C@TiO2 composites with 3D networks as anode material for lithium/sodium ion batteries. J Mater Sci. 2018;54(1):592.

Kim HK, Mhamane D, Kim MS, Roh HK, Aravindan V, Madhavi S, Roh KC, Kim KB. TiO2-reduced graphene oxide nanocomposites by microwave-assisted forced hydrolysis as excellent insertion anode for Li-ion battery and capacitor. J Power Sour. 2016;327:171.

Das SK, Jache B, Lahon H, Bender CL, Janek J, Adelhelm P. Graphene mediated improved sodium storage in nanocrystalline anatase TiO2 for sodium ion batteries with ether electrolyte. Chem Commun. 2016;52(7):1428.

Li C, Zhao M, Sun CN, Jin B, Yang CC, Jiang Q. Surface-amorphized TiO2 nanoparticles anchored on graphene as anode materials for lithium-ion batteries. J Power Sour. 2018;397:162.

Wang C, Xin X, Shu M, Huang SP, Zhang Y, Li X. Scalable synthesis of one-dimensional Na2Li2Ti6O14 nanofibers as ultrahigh rate capability anodes for lithium-ion batteries. Inorg Chem Front. 2019;6(3):646.

Fu YX, Dai Y, Pei XY, Lyu SS, Heng Y, Mo DC. TiO2 nanorods anchor on reduced graphene oxide (R-TiO2/rGO) composite as anode for high performance lithium-ion batteries. Appl Surf Sci. 2019;497:143553.

Gan Y, Zhu L, Qin H, Xia Y, Xiao H, Xu L, Ruan L, Liang C, Tao X, Huang H, Zhang W. Hybrid nanoarchitecture of rutile TiO2 nanoneedle/graphene for advanced lithium-ion batteries. Solid State Ionics. 2015;269:44.

Zhang Z, Chu Q, Li H, Hao J, Yang W, Lu B, Ke X, Li J, Tang J. One-pot solvothermal synthesis of graphene-supported TiO2(B) nanosheets with enhanced lithium storage properties. J Colloid Interf Sci. 2013;409:38.

Zhang R, Wang Y, Zhou H, Lang J, Xu J, Xiang Y, Ding S. Mesoporous TiO2 nanosheets anchored on graphene for ultra long life Na-ion batteries. Nanotechnology. 2018;29(22):225401.

Xiu Z, Hao X, Wu Y, Lu Q, Liu S. Graphene-bonded and -encapsulated mesoporous TiO2 microspheres as a high-performance anode material for lithium ion batteries. J Power Sources. 2015;287:334.

Kim JH, Choi W, Jung HG, Oh SH, Chung KY, Cho WI, Oh IH, Nah IW. Anatase TiO2-reduced graphene oxide nanostructures with high-rate sodium storage performance. J Alloy Compd. 2017;690:390.

Liu Y, Liu J, Bin D, Hou M, Tamirat AG, Wang Y, Xia Y. Ultrasmall TiO2-coated reduced graphene oxide composite as a high-rate and long-cycle-life anode material for sodium-ion batteries. ACS Appl Mater Interace. 2018;10(17):14818.

Ma Y, Li Y, Li D, Liu Y, Zhang J. Uniformly distributed TiO2 nanorods on reduced graphene oxide composites as anode material for high rate lithium ion batteries. J Alloy Compd. 2019;771:885.

Li X, Liu Y, Zhang X, Yao C, Wang R, Xu C, Lei J. Porous spheres of TiO2(B)/anatase entwined by graphene nanoribbons for high Li+ rate performance. Electrochim Acta. 2019;298:14.

Ren G, Hoque MNF, Liu J, Warzywoda J, Fan Z. Perpendicular edge oriented graphene foam supporting orthogonal TiO2(B) nanosheets as freestanding electrode for lithium ion battery. Nano Energy. 2016;21:162.

Wu G, Chen J, Guo Y, Li X, Luo B, Chu L, Han Y, Jiang B, Xu L, Li M. Freestanding sodium-ion batteries electrode using graphene foam coaxially integrated with TiO2 nanosheets. J Electrochem Soc. 2017;164(13):A3060.

Cheng L, Qiao D, Zhao P, He Y, Sun W, Yu H, Jiao Z. Template-free synthesis of mesoporous succulents-like TiO2/graphene aerogel composites for lithium-ion batteries. Electrochim Acta. 2019;300:417.

Yan X, Li Y, Li M, Jin Y, Du F, Chen G, Wei Y. Ultrafast lithium storage in TiO2–bronze nanowires/N-doped graphene nanocomposites. J Mater Chem A. 2015;3(8):4180.

Li S, Xue P, Lai C, Qiu J, Ling M, Zhang S. Pseudocapacitance of amorphous TiO2@nitrogen doped graphene composite for high rate lithium storage. Electrochim Acta. 2015;180:112.

An CS, Zhang B, Tang LB, Xiao B, He ZJ, Zheng JC. Binder-free carbon-coated TiO2@graphene electrode by using copper foam as current collector as a high-performance anode for lithium ion batteries. Ceram Int. 2019;45(10):13144.

Zhang Z, An Y, Xu X, Dong C, Feng J, Ci L, Xiong S. Metal-organic framework-derived graphene@nitrogen doped carbon@ultrafine TiO2 nanocomposites as high rate and long-life anodes for sodium ion batteries. Chem Commun. 2016;52(87):12810.

Kim SH, Choi SY. Fabrication of Cu-coated TiO2 nanotubes and enhanced electrochemical performance of lithium ion batteries. J Electroanal Chem. 2015;744:45.

Zhang Y, Li J, Li W, Kang D. Synthesis of one-dimensional mesoporous Ag nanoparticles-modified TiO2 nanofibers by electrospinning for lithium ion batteries. Materials. 2019;12(16):2630.

Kim H, Kim MC, Choi S, Moon SH, Kim YS, Park KW. Facile one-pot synthesis of Ge/TiO2 nanocomposite structures with improved electrochemical performance. Nanoscale. 2019;11(37):17415.

Xu Y, Zhou M, Wen L, Wang C, Zhao H, Mi Y, Liang L, Fu Q, Wu M, Lei Y. Highly ordered three-dimensional Ni-TiO2 nanoarrays as sodium ion battery anodes. Chem Mater. 2015;27(12):4274.

Ding H, Zhang XK, Fan JQ, Zhan XQ, Xie L, Shi D, Jiang T, Tsai FC. MOF-templated synthesis of Co3O4@TiO2 hollow dodecahedrons for high-storage-density lithium-ion batteries. ACS Omega. 2019;4(8):13241.

Zhu Q, Hu H, Li G, Zhu C, Yu Y. TiO2 Nanotube arrays grafted with MnO2 nanosheets as high-performance anode for lithium ion battery. Electrochim Acta. 2015;156:252.

Chen XQ, Lin HB, Zheng XW, Cai X, Xia P, Zhu YM, Li XP, Li WS. Fabrication of core–shell porous nanocubic Mn2O3@TiO2 as a high-performance anode for lithium ion batteries. J Mater Chem A. 2015;3(35):18198.

Choi SH, Kang YC. Using simple spray pyrolysis to prepare yolk-shell-structured ZnO-Mn3O4 systems with the optimum composition for superior electrochemical properties. Chem Eur J. 2014;20(11):3014.

Shen X, Mu D, Chen S, Huang R, Wu F. Electrospun composite of ZnO/Cu nanocrystals-implanted carbon fibers as an anode material with high rate capability for lithium ion batteries. J Mater Chem A. 2014;2(12):4309.

Gao L, Li S, Huang D, Shen Y, Wang M. ZnO decorated TiO2 nanosheet composites for lithium ion battery. Electrochim Acta. 2015;182:529.

Yoo H, Lee G, Choi J. Binder-free SnO2–TiO2 composite anode with high durability for lithium-ion batteries. RSC Adv. 2019;9(12):6589.

Chen X, Huang Y, Zhang K, Feng X, Wang M. Porous TiO2 nanobelts coated with mixed transition-metal oxides Sn3O4 nanosheets core-shell composites as high-performance anode materials of lithium ion batteries. Electrochim Acta. 2018;259:131.

Yang J, Wu Q, Yang X, He S, Khan J, Meng Y, Zhu X, Tong S, Wu M. Chestnut-like TiO2@alpha-Fe2O3 core-shell nanostructures with abundant interfaces for efficient and ultralong life lithium-ion storage. ACS Appl Mater Interfaces. 2017;9(1):354.

Dai R, Zhang A, Pan Z, Al-Enizi AM, Elzatahry AA, Hu L, Zheng G. Epitaxial growth of lattice-mismatched core-shell TiO2@MoS2 for enhanced lithium-ion storage. Small. 2016;12(20):2792.

Zhang Y, Wang Y, Kong D, Yang Y, Wang Y, Guo Y, Lu Y, Kim JK, Luo Y. In situ growth of Sn nanoparticles confined carbon-based TiO2/TiN composite with long-term cycling stability for sodium-ion batteries. Electrochim Acta. 2020;367:137450.

Yu Y. Oxygen vacancy transforms flexible sodium-ion battery. Acta Phys-Chim Sin. 2020;36(5):1910035.

Kure-Chu SZ, Sakuyama H, Saito S, Miura S, Yashiro H, Hirahara H, Segawa H, Wada K, Inoue S. Controllable fabrication of multi-tiered nanoporous anodic TiO2–TiN composite films as high-performance anode materials for lithium-ion batteries. Electrochim Acta. 2016;212:481.

Balogun MS, Li C, Zeng Y, Yu M, Wu Q, Wu M, Lu X, Tong Y. Titanium dioxide@titanium nitride nanowires on carbon cloth with remarkable rate capability for flexible lithium-ion batteries. J Power Sour. 2014;272:946.

Zhang D, Pan A, Zhong X, Song H, Zhang Y, Tang Y, Wang J. MoS2 nanosheets uniformly coated TiO2 nanowire arrays with enhanced electrochemical performances for lithium-ion batteries. J Alloy Compd. 2018;758:91.

Bai YL, Wu XY, Liu YS, Ma C, Wei X, Wang KX, Chen JS. Dandelion-clock-inspired preparation of core-shell TiO2@MoS2 composites for high performance sodium ion storage. J Alloy Compd. 2020;815:152386.

Wu Y, Lin G, Zhou X, Chen J, Zhuang J, Chen Q, Luo Y, Lu D, Ganesh V, Zeng R. Exploring structural stability mechanism of TiO2 encapsulated in 3D flower-like SnS2 anode for lithium ion batteries. J Electroanal Chem. 2020;857:113740.

Dziewoński PM, Grzeszczuk M. Towards TiO2-conducting polymer hybrid materials for lithium ion batteries. Electrochim Acta. 2010;55(9):3336.

Yang X, Wang S, Zhuang X, Tomanec O, Zboril R, Yu DYW, Rogach AL. Polypyrrole and carbon nanotube co-composited titania anodes with enhanced sodium storage performance in ether-based electrolyte. Adv Sustain Syst. 2019;3(4):1800154.

Yan D, Yu C, Zhang X, Li J, Li J, Lu T, Pan L. Enhanced electrochemical performances of anatase TiO2 nanotubes by synergetic doping of Ni and N for sodium-ion batteries. Electrochim Acta. 2017;254:130.

Yan D, Yu C, Li D, Zhang X, Li J, Lu T, Pan L. Improved sodium-ion storage performance of TiO2 nanotubes by Ni2+ doping. J Mater Chem A. 2016;4(28):11077.

Kashale AA, Rasal AS, Kamble GP, Ingole VH, Dwivedi PK, Rajoba SJ, Jadhav LD, Ling YC, Chang JY, Ghule AV. Biosynthesized Co-doped TiO2 nanoparticles based anode for lithium-ion battery application and investigating the influence of dopant concentrations on its performance. Compos Part B-Eng. 2019;167:44.

Hong Z, Kang M, Chen X, Zhou K, Huang Z, Wei M. Synthesis of mesoporous Co2+-doped TiO2 nanodisks derived from metal organic frameworks with improved sodium storage performance. ACS Appl Mater Interfaces. 2017;9(37):32071.

Wang J, Yang G, Wang L, Wang S, Yan W, Ding S. In-situ fabrication of transition-metal-doped TiO2 nanofiber/nanosheet structure for high-performance Li storage. J Alloy Compd. 2019;787:1110.

Duan J, Hou H, Liu X, Yan C, Liu S, Meng R, Hao Z, Yao Y, Liao Q. In situ Ti3+-doped TiO2 nanotubes anode for lithium ion battery. J Porous Mat. 2016;23(3):837.

Huang S, Zhang L, Lu X, Liu L, Liu L, Sun X, Yin Y, Oswald S, Zou Z, Ding F, Schmidt OG. Tunable pseudocapacitance in 3D TiO2-delta nanomembranes enabling superior lithium storage performance. ACS Nano. 2017;11(1):821.

Chen J, Song W, Hou H, Zhang Y, Jing M, Jia X, Ji X. Ti3+ self-doped dark rutile TiO2 ultrafine nanorods with durable high-rate capability for lithium-ion batteries. Adv Funct Mater. 2015;25(43):6793.

Lai Y, Liu W, Li J, Zhang K, Qin F, Wang M, Fang J. High performance sodium storage of Fe-doped mesoporous anatase TiO2/amorphous carbon composite. J Alloy Compd. 2016;666:254.

He H, Sun D, Zhang Q, Fu F, Tang Y, Guo J, Shao M, Wang H. Iron-doped cauliflower-like rutile TiO2 with superior sodium storage properties. ACS Appl Mater Interfaces. 2017;9(7):6093.

Reddy MV, Sharma N, Adams S, Rao RP, Peterson VK, Chowdari BVR. Evaluation of undoped and M-doped TiO2, where M = Sn, Fe, Ni/Nb, Zr, V, and Mn, for lithium-ion battery applications prepared by the molten-salt method. RSC Adv. 2015;5(37):29535.

Luebke M, Johnson I, Makwana NM, Brett D, Shearing P, Liu Z, Darr JA. High power TiO2 and high capacity Sn-doped TiO2 nanomaterial anodes for lithium-ion batteries. J Power Sour. 2015;294:94.

Yan D, Yu C, Bai Y, Zhang W, Chen T, Hu B, Sun Z, Pan L. Sn-doped TiO2 nanotubes as superior anode materials for sodium ion batteries. Chem Commun. 2015;51(39):8261.

Lübke M, Shin J, Marchand P, Brett D, Shearing P, Liu Z, Darr JA. Highly pseudocapacitive Nb-doped TiO2 high power anodes for lithium-ion batteries. J Mater Chem A. 2015;3(45):22908.

Usui H, Domi Y, Shimizu M, Imoto A, Yamaguchi K, Sakaguchi H. Niobium-doped titanium oxide anode and ionic liquid electrolyte for a safe sodium-ion battery. J Power Sour. 2016;329:428.

Zhao F, Wang B, Tang Y, Ge H, Huang Z, Liu HK. Niobium doped anatase TiO2 as an effective anode material for sodium-ion batteries. J Mater Chem A. 2015;3(45):22969.

Trang VuT, Rai AK, Gim J, Kim S, Kim J. Effect of Mo6+ doping on electrochemical performance of anatase TiO2 as a high performance anode material for secondary lithium-ion batteries. J Alloy Compd. 2014;598:16.

Xia Y, Rong C, Yang X, Lu F, Kuang X. Encapsulating Mo-doped TiO2 anatase in N-doped amorphous carbon with excellent lithium storage performances. Front Mater. 2019;6:1.

Bauer D, Roberts AJ, Patnaik SG, Brett DJL, Shearing PR, Kendrick E, Matsumi N, Darr JA. High power sodium-ion batteries and hybrid electrochemical capacitors using Mo or Nb-doped nano-titania anodes. J Electrochem Soc. 2018;165(9):A1662.

Liao H, Xie L, Zhang Y, Qiu X, Li S, Huang Z, Hou H, Ji X. Mo-doped gray anatase TiO2: lattice expansion for enhanced sodium storage. Electrochim Acta. 2016;219:227.

Ni J, Fu S, Wu C, Maier J, Yu Y, Li L. Self-supported nanotube arrays of sulfur-doped TiO2 enabling ultrastable and robust sodium storage. Adv Mater. 2016;28(11):2259.

Zhang Y, Fu Q, Xu Q, Yan X, Zhang R, Guo Z, Du F, Wei Y, Zhang D, Chen G. Improved electrochemical performance of nitrogen doped TiO2-B nanowires as anode materials for Li-ion batteries. Nanoscale. 2015;7(28):12215.

Appadurai T, Subramaniyam C, Kuppusamy R, Karazhanov S, Subramanian B. Electrochemical performance of nitrogen-doped TiO2 nanotubes as electrode material for supercapacitor and li-ion battery. Molecules. 2019;24(16):2952.

Lin J, Ma D, Li Y, Zhang P, Mi H, Deng L, Sun L, Ren X. In situ nitrogen doping of TiO2 by plasma enhanced atomic layer deposition for enhanced sodium storage performance. Dalton Trans. 2017;46(38):13101.

Wu Y, Liu X, Yang Z, Gu L, Yu Y. Nitrogen-doped ordered mesoporous anatase TiO2 nanofibers as anode materials for high performance sodium-ion batteries. Small. 2016;12(26):3522.

Liu S, Cai Z, Zhou J, Pan A, Liang S. Nitrogen-doped TiO2 nanospheres for advanced sodium-ion battery and sodium-ion capacitor applications. J Mater Chem A. 2016;4(47):18278.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51774002), the Key Program for International S&T Cooperation Projects of China (No. 2017YFE0124300) and the “333 Talent Project” of Hebei Province (No. A202005018).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Peng, PP., Wu, YR., Li, XZ. et al. Toward superior lithium/sodium storage performance: design and construction of novel TiO2-based anode materials. Rare Met. 40, 3049–3075 (2021). https://doi.org/10.1007/s12598-021-01742-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01742-z