Abstract

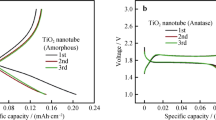

TiO2 nanotube arrays, growing on three-dimensional (3D) porous Ti membrane, were synthesized using a facile nonsolvent-induced phase separation and anodization process. The length of those three-dimensional nanotube arrays could be tuned by prolonging the anodizing time. When the anodizing time is 8 h, the three-dimensional TiO2 nanotube arrays/porous Ti electrode exhibits well cycling stability and ultra-high specific capacity, which is used in lithium-ion batteries, attributed to the high utilization rate of the substrate and the high growth intensity of the active materials. Three-dimensional TiO2 nanotube arrays/porous Ti electrode, at 100 μA·cm−2 with 8 h anodizing time, shows a typical discharge plateau at 1.78 V and exhibits the specific capacity with 2126.7 μAh·cm−2. The novel nanotube arrays@3D porous architecture effectively shortens the electron/ion transmission path, which could pave way for optimizing the design of high-performance anode materials for next-generation energy storage system.

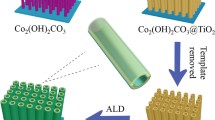

Graphic abstract

Similar content being viewed by others

References

Wang H, He J, Liu J, Qi S, Wu M, Wen J, Chen Y, Feng Y, Ma J. Electrolytes enriched by crown ethers for lithium metal batteries. Adv Funct Mater. 2020. https://doi.org/10.1002/adfm.202002578.

Wu ZH, Yang JY, Yu B, Shi BM, Zhao CR, Yu ZL. Self-healing alginate-carboxymethyl chitosan porous scaffold as an effective binder for silicon anodes in lithium-ion batteries. Rare Met. 2019;38(9):832.

Yue X-Y, Abulikemu A, Li XL, Qiu QQ, Wang F, Wu XJ, Zhou Y-N. Vermiculite derived porous silicon nanosheet as a scalable and low cost anode material for lithium-ion batteries. J Power Sour. 2019;410:132.

Wang H, Tan R, Yang Z, Feng Y, Duan X, Ma J. Stabilization perspective on metal anodes for aqueous batteries. Adv Energy Mater. 2020. https://doi.org/10.1002/aenm.202000962.

Jun M, Ayoko GA, Hu C, Bell JM, Sun ZQ. Two-dimensional fluorine-free mesoporous Mo2C MXene via UV-induced selective etching of Mo2Ga2C for energy storage. Sustain Mater Technol. 2020;25:e00156.

Lyu Y, Liu Y, Yu ZE, Su N, Liu Y, Li W, Li Q, Guo B, Liu B. Recent advances in high energy-density cathode materials for sodium-ion batteries. Sustain Mater Technol. 2019;21:e00098.

Yue XY, Wang WW, Wang QC, Meng JK, Wang XX, Song Y, Fu ZW, Wu XJ, Zhou YN. Cuprite-coated Cu foam skeleton host enabling lateral growth of lithium dendrites for advanced Li metal batteries. Energy Storage Mater. 2019;21:180.

Yue X-Y, Li X-L, Wang W-W, Chen D, Qiu QQ, Wang QC, Wu XJ, Fu Z-W, Shadike Z, Yang XQ, Zhou YN. Wettable carbon felt framework for high loading Li-metal composite anode. Nano Energy. 2019;60:257.

Xu B, Qi S, Jin M, Cai X, Lai L, Sun Z, Han X, Lin Z, Shao H, Peng P, Xiang Z, Elshof JE, Tan R, Liu C, Zhang Z, Duan X, Ma J. 2020 roadmap on two-dimensional materials for energy storage and conversion. Chin Chem Lett. 2019;30(12):2053.

Wang L, Xie X, Dinh KN, Yan Q, Ma J. Synthesis, characterizations, and utilization of oxygen-deficient metal oxides for lithium/sodium-ion batteries and supercapacitors. Coord Chem Rev. 2019;397:138.

Chen D, Tan H, Rui X, Zhang Q, Feng Y, Geng H, Li C, Huang S, Yu Y. Oxyvanite V3O5: a new intercalation-type anode for lithium-ion battery. InfoMat. 2019;1(2):251.

Xu ZX, Wang AQ, Zhu YF. Controllable synthesis and tunable photocatalytic activity of TiO2 nanowires via alcohol-thermal method. Rare Met. 2019;38(5):390.

Zhang Z, Hou Y, Zhang S, Zhang G, Li M, Lu H, Li Y, Zheng X, Qiao Z, Yu Z, Huang Q, Kang J. Facile synthesized Cu-SnO2 anode materials with three-dimensional metal cluster conducting architecture for high performance lithium-ion batteries. Chin Chem Lett. 2018;29(11):1656.

Huang L, Su K, Zheng YF, Yeung KWK, Liu XM. Construction of TiO2/silane nanofilm on AZ31 magnesium alloy for controlled degradability and enhanced biocompatibility. Rare Met. 2019;38(6):588.

Opra DP, Gnedenkov SV, Sinebryukhov SL. Recent efforts in design of TiO2 (B) anodes for high-rate lithium-ion batteries: a review. J Power Sour. 2019;442:227225.

Lu HH, Shi CS, Zhao NQ, Liu EZ, He CN, He F. Carbon and few-layer MoS2 nanosheets co-modified TiO2 nanosheets with enhanced electrochemical properties for lithium storage. Rare Met. 2018;37(2):107.

Mujtaba J, Sun H, Zhao YY, Guo LX, Sheng MX, Jing Z. High-performance lithium storage based on the synergy of atomic-thickness nanosheets of TiO2 (B) and ultrafine Co3O4 nanoparticles. J Power Sour. 2017;363:110.

Zhang Z, Ren Z, Zhang S, Yuan D, Dou Y, Qiao Z, Yu Z, Kang J, Li W, Chou S. High-yielding carbon nanofibers grown on NIPS derived porous nickel as flexible electrode for supercapacitors. Mater Chem Front. 2020. https://doi.org/10.1039/D0QM00483A.

Wu D, Wang C, Wu M, Chao Y, He P, Ma J. Porous bowl-shaped VS2 nanosheets/graphene composite for high-rate lithium-ion storage. J Energy Chem. 2020;43:24.

Xu H, Liu SQ, Zhou S, Yuan TZJ, Wang X, Tang X, Yin J, Tao HJ. Morphology and photocatalytic performance of nano-sized TiO2 prepared by simple hydrothermal method with different pH values. Rare Mater. 2018;37(9):750.

Qian D, Gu Y, Guo S, Liu H, Chen Y, Wang J, Ma G, Wu C. Effect of rich R-TiO2 on the rate and cycle properties of Li4Ti5O12 as anode for lithium ion batteries. J Energy Chem. 2019;32:182.

Liu GY, Zhao YY, Tang YF, Liu XD, Liu M, Wu PJ. In situ sol-gel synthesis of Ti2Nb10O29/C nanoparticles with enhanced pseudocapacitive contribution for a high-rate lithium-ion battery. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01462-w.

Liang X, Chen X, Zhao H, Yang Z, Wei F, Tu H. Preparation methods of nano-TiO2 electron transport layers and properties for perovskite solar cells. Chin J Rare Met. 2019;43(2):164.

Wang HP, Tan R, Yang ZX, Feng YZ, Duan XC, Ma JM. Stabilization perspective on metal anodes for aqueous batteries. Adv Energy Mater. 2020. https://doi.org/10.1002/aenm.202000962.

Cao ML, Gao L, Lv XW, Shen Y. TiO2-B@VS2 heterogeneous nanowire arrays as superior anodes for lithium-ion batteries. J Power Sour. 2017;350:87.

Cai X, Liu W, Yang S, Zhang SS, Gao QZ, Yu XY, Li J, Wang HQ, Fang YP. Dual-confined SiO embedded in TiO2 shell and 3D carbon nanofiber web as stable anode material for superior lithium storage. Adv Mater Interfaces. 2019;6(10):1801800.

Li Z, Fu JY, Feng Y, Dong CK, Liu H, Du XW. A silver catalyst activated by stacking faults for the hydrogen evolution reaction. Nat Catal. 2019;2:1107.

Chen J, Zhang Q, Tan F, Zhou M. Effect of different SiO2 content on dielectric properties of BaO-SrO-PbO-TiO2-SiO2-Nb2O5 glass-ceramic composites. Chin J Rare Met. 2019;43(9):935.

Li S, Zhang YM, Huang JG. Three-dimensional TiO2 nanotubes immobilized with Fe2O3 nanoparticles as an anode material for lithium-ion batteries. J Alloys Compd. 2019;783:793.

Guan X, Zhang Z, Zhang S, Wang Y, Yang H, Wang J, Li M, Lu H, Li Y, Huang Q, Zheng X, Qiao Z, Yu Z, Kang J. NIPS derived three-dimensional porous copper membrane for high-energy-density lithium-ion batteries. Electrochim Acta. 2019;312:424.

Zhang ZJ, Zeng QY, Chou SL, Li XJ, Li HJ, Ozawa K, Liu HK, Wang JZ. Tuning three-dimensional TiO2 nanotube electrode to achieve high utilization of Ti substrate for lithium storage. Electrochim Acta. 2014;133:570.

Ariga K, Li J. Nanoarchitectonics for advanced materials: strategy beyond nanotechnology. Adv Mater. 2016;28(6):987.

Opra DP, Gnedenkov SV, Sinebryukhov SL, Voit EI, Sokolov AA, Ustinov AY, Zheleznov VV. Zr4+/F-co-doped TiO2 (anatase) as high performance anode material for lithium-ion battery. Prog Nat Sci Met Mater Int. 2018;28(5):542.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51801136, 51701142 and 51871165), Tianjin Municipal Education Committee Scientific Research Projects (No. 2017KJ075) and the Australian Research Council Discovery Project (No. DP200100965).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, ZJ., Zhao, J., Qiao, ZJ. et al. Nonsolvent-induced phase separation-derived TiO2 nanotube arrays/porous Ti electrode as high-energy-density anode for lithium-ion batteries. Rare Met. 40, 393–399 (2021). https://doi.org/10.1007/s12598-020-01571-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01571-6