Abstract

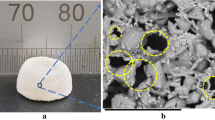

Porous scaffolds as succedaneum of natural bone were investigated and applied in medical field. In this work, we carried out studies on mechanical properties of solid parts and porous scaffolds obtained by additive manufacturing (AM) technique. It is found that productions of AM process have a higher yield strength and higher microhardness compared to commercial Ti6Al4V. Roughened surface was observed for layer-by-layer process of AM and sticking of powder particles. The machining accuracy is affected by both dimensions and angles. Meanwhile, mechanical properties of porous scaffolds are influenced by machining accuracy and microdefects. In addition, the unit cell structures also impact the mechanical properties of porous scaffolds in terms of elastic modulus, yield strength and failure mode. Overall, considering the mechanical properties and biological properties, scaffolds with cube (CB) crystal cells are the best choice in our study.

Similar content being viewed by others

Change history

19 August 2019

In the original publication, incorrect version of Table 5 has been published.

References

Ford S, Despeisse M. Additive manufacturing and sustainability: an exploratory study of the advantages and challenges. J Clean Prod. 2016;137:1573.

Kietzmann J, Pitt L, Berthon P. Disruptions, decisions, and destinations: enter the age of 3-D printing and additive manufacturing. Bus Horiz. 2015;58(2):209.

Baumers M, Dickens P, Tuck C, Hague R. The cost of additive manufacturing: machine productivity, economies of scale and technology-push. Technol Forecast Soc Chang. 2016;102:193.

Riza SH, Masood SH, Wen C. Laser-assisted additive manufacturing for metallic biomedical scaffolds. In: Hashmi S, Batalha GF, Van Tyne CJ, Yilbas B, editors. Comprehensive Materials Processing. Oxford: Elsevier; 2014. 285.

Emelogu A, Marufuzzaman M, Thompson SM, Shamsaei N, Bian L. Additive manufacturing of biomedical implants: a feasibility assessment via supply-chain cost analysis. Addit Manuf. 2016;11:97.

Brunello G, Sivolella S, Meneghello R, Ferroni L, Gardin C, Piattelli A, Zavan B, Bressan E. Powder-based 3D printing for bone tissue engineering. Biotechnol Adv. 2016;34(5):740.

Ramsden JJ, Allen DM, Stephenson DJ, Alcock JR, Peggs GN, Fuller G, Goch G. The design and manufacture of biomedical surfaces. CIRP Ann. 2007;56(2):687.

Munsch M. Laser additive manufacturing of customized prosthetics and implants for biomedical applications. In: Brandt M, editor. Laser Additive Manufacturing. Sawston: Woodhead Publishing; 2017. 399.

Murr LE. Frontiers of 3D printing/additive manufacturing: from human organs to aircraft fabrication. J Mater Sci Technol. 2016;32(10):987.

Volkmer TM, Lengler F, Barreiro O, Sousa VC, dos Santos LA. Novel method for the obtainment of nanostructured calcium phosphate cements: synthesis, mechanical strength and cytotoxicity. Powder Technol. 2013;235:599.

Yablokova G, Speirs M, Van Humbeeck J, Kruth JP, Schrooten J, Cloots R, Boschini F, Lunay G, Luyten J. Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants. Powder Technol. 2015;283:199.

Koike M, Martinez K, Guo L, Chahine G, Kovacevic R, Okabe T. Evaluation of titanium alloy fabricated using electron beam melting system for dental applications. J Mater Process Technol. 2011;211(8):1400.

Li J, Zhu JX, Bassi AS, Kofman SH. Evaluation of different dental materials using a slugging fluidized bed. Powder Technol. 2001;118(3):275.

Noushad M, Ab Rahman I, Husein A, Mohamad D. Nanohybrid dental composite using silica from biomass waste. Powder Technol. 2016;299:19.

Rodrigues WC, Broilo LR, Schaeffer L, Knörnschild G, Espinoza FRM. Powder metallurgical processing of Co–28%Cr–6%Mo for dental implants: physical, mechanical and electrochemical properties. Powder Technol. 2011;206(3):233.

Cui Z, Yang B, Li RK. Application of biomaterials in cardiac repair and regeneration. Engineering. 2016;2(1):141.

Cox SC, Jamshidi P, Eisenstein NM, Webber MA, Hassanin H, Attallah MM, Shepherd DET, Addison O, Grover LM. Adding functionality with additive manufacturing: fabrication of titanium-based antibiotic eluting implants. Mater Sci Eng C. 2016;64:407.

Jardini AL, Larosa MA, Filho RM, Zavaglia CAdC, Bernardes LF, Lambert CS, Calderoni DR, Kharmandayan P. Cranial reconstruction: 3D biomodel and custom-built implant created using additive manufacturing. J Cranio-Maxillofac Surg. 2014;42(8):1877.

Taniguchi N, Fujibayashi S, Takemoto M, Sasaki K, Otsuki B, Nakamura T, Matsushita T, Kokubo T, Matsuda S. Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: an in vivo experiment. Mater Sci Eng C. 2016;59:690.

Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci. 2009;54(3):397.

Arifvianto B, Leeflang MA, Zhou J. The compression behaviors of titanium/carbamide powder mixtures in the preparation of biomedical titanium scaffolds with the space holder method. Powder Technol. 2015;284:112.

Jiao LA, Li X, Ren LL, Kong LY, Hong YL, Li ZW, Huang XB, Tao XF. 3D structural properties study on compact LiFePO4s based on X-ray computed tomography technique. Powder Technol. 2015;281:1.

Xu Q, Gabbitas B, Matthews S. Titanium compacts with controllable porosity by slip casting of binary powder mixtures. Powder Technol. 2014;266:396.

Murr LE, Esquivel EV, Quinones SA, Gaytan SM, Lopez MI, Martinez EY, Medina F, Hernandez DH, Martinez E, Martinez JL, Stafford SW, Brown DK, Hoppe T, Meyers W, Lindhe U, Wicker RB. Microstructures and mechanical properties of electron beam-rapid manufactured Ti–6Al–4V biomedical prototypes compared to wrought Ti–6Al–4V. Mater Charact. 2009;60(2):96.

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth J-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010;58(9):3303.

Yan M, Yu P. An overview of densification, microstructure and mechanical property of additively manufactured Ti–6Al–4V—comparison among selective laser melting, electron beam melting, laser metal deposition and selective laser sintering, and with conventional powder. Sinter Tech Mater. 2015;5:77.

Dutta B, Froes FH. The additive manufacturing (AM) of titanium alloys. In: Qian M, Froes FH, editors. Titanium Powder Metallurgy. Boston: Butterworth-Heinemann; 2015. 447.

Takaichi A, Suyalatu Nakamoto T, Joko N, Nomura N, Tsutsumi Y, Migita S, Doi H, Kurosu S, Chiba A, Wakabayashi N, Igarashi Y, Hanawa T. Microstructures and mechanical properties of Co–29Cr–6Mo alloy fabricated by selective laser melting process for dental applications. J Mech Behav Biomed Mater. 2013;21:67.

Carroll BE, Palmer TA, Beese AM. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015;87:309.

Herzog D, Seyda V, Wycisk E, Emmelmann C. Additive manufacturing of metals. Acta Mater. 2016;117:371.

Frazier WE. Metal additive manufacturing: a review. J Mater Eng Perform. 2014;23(6):1917.

Simpson TW, Williams CB, Hripko M. Preparing industry for additive manufacturing and its applications: summary and recommendations from a National Science Foundation workshop. Addit Manuf. 2017;13:166.

Mullen L, Stamp RC, Brooks WK, Jones E, Sutcliffe CJ. Selective laser melting: a regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J Biomed Mater Res B Appl Biomater. 2009;89(2):325.

Pattanayak DK, Fukuda A, Matsushita T, Takemoto M, Fujibayashi S, Sasaki K, Nishida N, Nakamura T, Kokubo T. Bioactive Ti metal analogous to human cancellous bone: fabrication by selective laser melting and chemical treatments. Acta Biomater. 2011;7(3):1398.

Amin Yavari S, Wauthle R, van der Stok J, Riemslag AC, Janssen M, Mulier M, Kruth JP, Schrooten J, Weinans H, Zadpoor AA. Fatigue behavior of porous biomaterials manufactured using selective laser melting. Mater Sci Eng C. 2013;33(8):4849.

Singh S, Ramakrishna S. Biomedical applications of additive manufacturing: present and future. Current Opin Biomed Eng. 2017;2:105.

Xue W, Krishna BV, Bandyopadhyay A, Bose S. Processing and biocompatibility evaluation of laser processed porous titanium. Acta Biomater. 2007;3(6):1007.

Rumpler M, Woesz A, Dunlop John WC, van Dongen Joost T, Fratzl P. The effect of geometry on three-dimensional tissue growth. J R Soc Interface. 2008;5(27):1173.

Van Bael S, Chai YC, Truscello S, Moesen M, Kerckhofs G, Van Oosterwyck H, Kruth JP, Schrooten J. The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds. Acta Biomater. 2012;8(7):2824.

Campoli G, Borleffs MS, Amin Yavari S, Wauthle R, Weinans H, Zadpoor AA. Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater Des. 2013;49:957.

Empme Committee. Practical Manual of Engineering Materials. Beijing: Standards Press of China; 1989. 589.

Gibson LJ, Ashby MF. The mechanics of three-dimensional cellular materials. Proc R Soc. 1982;382(1782):43.

Chen SY, Kuo CN, Su YL, Huang JC, Wu YC, Lin YH, Chung YC, Ng CH. Microstructure and fracture properties of open-cell porous Ti–6Al–4V with high porosity fabricated by electron beam melting. Mater Charact. 2018;138:255.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51472089), the Fundamental Research Funds for the Central Universities (No. 2018KZ15), the Natural Science Foundation of Guangdong Province (No. 2018A030313803) and the Guangdong Science and Technology Project (No. 2017B090911008).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zheng, HD., Liu, LL., Deng, CL. et al. Mechanical properties of AM Ti6Al4V porous scaffolds with various cell structures. Rare Met. 38, 561–570 (2019). https://doi.org/10.1007/s12598-019-01231-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01231-4