Abstract

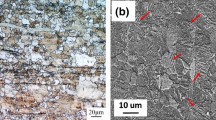

The effects of temperature and strain rate on the semisolid deformation behavior of a high Zr WE54 magnesium alloys were studied at temperatures of 570, 595 and 620 °C. A flow stress peak was appeared during deformation of the feedstock experimental material at deformation conditions of 570 °C, 0.010 and 0.100 s−1, and 595 °C, 0.100 s−1. The latter results were connected to the occurrence of dynamic recrystallization in solid globules. Also, these conditions were gauged to be able to activate “lubricated flow” mechanism. At 570 °C and strain rate of 0.001 s−1 as well as 595 °C and rates of 0.010 and 0.001 s−1, the flow stress increases and reaches a plateau, where dynamic recovery is considered as the dominant mechanism. However, at 620 °C under all the strain rates, the flow stress drops for a limited strain range and then increases again. The results show that as the liquid removes from the boundaries between the solid parts, the densification of the globules occurs at higher strains, causing an increase in the flow stress. Comparative analysis points out that the feedstock material exhibits a lower flow stress than as-cast alloy associating with a modified morphology of Zr particles after deformation.

Similar content being viewed by others

References

Liu X, Zhang Z, Hu W, Le Q, Bao L, Cui J. Effects of extrusion speed on the microstructure and mechanical properties of Mg9Gd3Y1.5Zn0.8Zr alloy. J Mater Sci Technol. 2016;32(4):313.

Liu H, Xue F, Bai J, Ma A, Jiang J. Formation behavior of 14H long period stacking ordered structure in Mg–Y–Zn cast alloys with different α-Mg fractions. J Mater Sci Technol. 2016;32(12):1267.

Liu L, Chen X, Pan F, Gao S, Zhao C. A new high-strength Mg–Zn–Ce–Y–Zr magnesium alloy. J Alloy Compd. 2016;688(1):537.

Cheng K, Zhou H, Du Y, Liu S, Xu H. Experimental investigation and thermodynamic description of the Mg–Y–Zr system. J Mater Sci. 2014;49(20):7124.

Kleiner S, Beffort O, Uggowitzer PJ. Microstructure evolution during reheating of an extruded Mg–Al–Zn alloy into the semisolid state. Scripta Mater. 2004;51(5):405.

Tahreen N, Chen DL, Nouri M, Li DY. Influence of aluminum content on twinning and texture development of cast Mg–Al–Zn alloy during compression. J Alloy Compd. 2015;623(1):15.

Wang C, Wu G, Lavernia EJ, Ding W. Influences of heat treatment on microstructural evolution and tensile behavior of squeeze-cast Mg–Gd–Y–Zr alloy. J Mater Sci. 2017;52(4):1831.

Zhang L, Cao ZY, Liu YB. Microstructure evolution of semi-solid Mg–14Al–0.5Mn alloys during isothermal heat treatment. Trans Nonferrous Metals Soc China. 2010;20(7):1244.

Xu HY, Ji ZS, Hu ML, Wang ZY. Microstructure evolution of hot pressed AZ91D alloy chips reheated to semi-solid state. Trans Nonferrous Metals Soc China. 2012;22(12):2906.

Yu Z, Huang Y, Gan W, Zhong Z, Hort N, Meng J. Effects of extrusion ratio and annealing treatment on the mechanical properties and microstructure of a Mg–11Gd–4.5Y–1Nd–1.5Zn–0.5Zr (wt%) alloy. J Mater Sci. 2017;52(11):6670.

Alizadeh R, Mahmudi R, Ngan AHW, Langdon TG. Microstructural evolution during hot shear deformation of an extruded fine-grained Mg–Gd–Y–Zr alloy. J Mater Sci. 2017;52(13):7843.

Asqardoust S, Zarei-Hanzaki A, Fatemi SM, Moradjoy-Hamedani M. High temperature deformation behavior and microstructural evolutions of a high Zr containing WE magnesium alloy. J Alloy Compd. 2016;669:108.

Máthis K, Nyilas K, Axt A, Dragomir-Cernatescu I, Ungár T, Lukáč P. The evolution of non-basal dislocations as a function of deformation temperature in pure magnesium determined by X-ray diffraction. Acta Mater. 2004;52(10):2889.

Zhang W, Xiao W, Wang F, Ma C. Development of heat resistant Mg–Zn–Al-based magnesium alloys by addition of La and Ca: microstructure and tensile properties. J Alloy Compd. 2016;684(1):8.

Steglich D, Jeong Y, Andar MO, Kuwabara T. Biaxial deformation behaviour of AZ31 magnesium alloy: crystal-plasticity-based prediction and experimental validation. Int J Solids Struct. 2012;49(25):3551.

Wang H, Wu PD, Tomé CN, Wang J. Study of lattice strains in magnesium alloy AZ31 based on a large strain elastic-viscoplastic self-consistent polycrystal model. Int J Solids Struct. 2012;49(15–16):2155.

Chayong S, Atkinson HV, Kapranos P. Thixoforming 7075 aluminium alloys. Mater Sci Eng, A. 2005;390(1–2):3.

Fadavi Boostani A, Tahamtan S. Effect of a novel thixoforming process on the microstructure and fracture behavior of A356 aluminum alloy. Mater Des. 2010;31(8):3769.

Chen Q, Chen G, Han L, Hu N, Han F, Zhao Z, Xia X, Wan Y. Microstructure evolution of SiCp/ZM6 (Mg–Nd–Zn) magnesium matrix composite in the semi-solid state. J Alloy Compd. 2016;656(1):67.

Fan Z. Semisolid metal processing. Int Mater Rev. 2013;47(2):49.

Haitao J, Yalin L, Weichao H, Xiaoli L, Miaoquan L. Microstructural evolution and mechanical properties of the semisolid Al–4Cu–Mg alloy. Mater Charact. 2003;51(1):1.

Birol Y. Thixoforming of EN AW-2014 alloy at high solid fraction. J Mater Process Technol. 2011;211(11):1749.

Rogal Ł, Dutkiewicz J, Atkinson HV, Lityńska-Dobrzyńska L, Czeppe T, Modigell M. Characterization of semi-solid processing of aluminium alloy 7075 with Sc and Zr additions. Mater Sci Eng, A. 2013;580(1):362.

Birol Y. Semi-solid processing of the primary aluminium die casting alloy A365. J Alloy Compd. 2009;473(1–2):133.

Birol Y. Thermomechanical processing of an aluminium casting alloy for thixoforming. J Alloy Compd. 2009;479(1–2):113.

Meng Y, Sugiyama S, Yanagimoto J. Microstructural evolution during RAP process and deformation behavior of semi-solid SKD61 tool steel. J Mater Process Technol. 2012;212(8):1731.

Birol Y. Comparison of thixoformability of AA6082 reheated from the as-cast and extruded states. J Alloy Compd. 2008;461(1–2):132.

Bolouri A, Kang CG. Characteristics of thixoformed A356 aluminum thin plates with microchannels. Mater Charact. 2013;82(1):86.

Salleh MS, Omar MZ, Syarif J, Alhawari KS, Mohammed MN. Microstructure and mechanical properties of thixoformed A319 aluminium alloy. Mater Des. 2014;64(1):142.

Haitao J, Miaoquan L. Effects of isothermal heat treatment on microstructural evolution of semisolid Al–4Cu–Mg alloy. J Mater Eng Perform. 2004;13(4):488.

Liu D, Atkinson HV, Kapranos P, Jirattiticharoean W, Jones H. Microstructural evolution and tensile mechanical properties of thixoformed high performance aluminium alloys. Mater Sci Eng, A. 2003;361(1–2):213.

Bolouri A, Shahmiri M, Kang CG. Study on the effects of the compression ratio and mushy zone heating on the thixotropic microstructure of AA 7075 aluminum alloy via SIMA process. J Alloy Compd. 2011;509(2):402.

Sirong Yu, Dongcheng Li, Kim N. Microstructure evolution of SIMA processed Al2024. Mater Sci Eng, A. 2006;420(1–2):165.

Bolouri A, Shahmiri M, Cheshmeh ENH. Microstructural evolution during semisolid state strain induced melt activation process of aluminum 7075 alloy. Trans Nonferrous Metals Soc China. 2010;20(9):1663.

Wang LP, Jiang WY, Chen T, Feng YC, Zhou HY, Zhao SC, Liang ZQ, Zhu Y. Spheroidal microstructure formation and thixoforming of AM60B magnesium alloy prepared by SIMA process. Trans Nonferrous Metals Soc China. 2012;22(1):s435.

Yang MB, Pan FS, Cheng RJ, Shen J. Effects of holding temperature and time on semi-solid isothermal heat-treated microstructure of ZA84 magnesium alloy. Trans Nonferrous Metals Soc China. 2008;18(3):566.

Zhao GZ, Yang L, Duan XX, Ren XH, Zhu LM, Yang TJ, Guo XY, Hao SN. Microstructure evolution and mechanical properties of AZ80 alloy reheated from as-cast and deformed states. Trans Nonferrous Metals Soc China. 2012;22(1):s450.

Hu XG, Zhu Q, Lu HX, Zhang F, Li DQ, Midson SP. Microstructural evolution and thixoformability of semi-solid aluminum 319s alloy during re-melting. J Alloy Compd. 2015;649(1):204.

Zhao Z, Chen Q, Kang F, Shu D. Microstructural evolution and tensile mechanical properties of thixoformed AZ91D magnesium alloy with the addition of yttrium. J Alloy Compd. 2009;482(1–2):455.

Lentz M, Gall S, Schmack F, Mayer HM, Reimers W. Hot working behavior of a WE54 magnesium alloy. J Mater Sci. 2013;49(3):1121.

Liu ZJ, Wu GH, Liu WC, Pang S, Ding WJ. Effect of heat treatment on microstructures and mechanical properties of sand-cast Mg–4Y–2Nd–1Gd–0.4Zr magnesium alloy. Trans Nonferrous Metals Soc China. 2012;22(7):1540.

Ma M, He L, Li X, Li Y, Zhang K. Hot workability of Mg–9Y–1MM–0.6Zr alloy. J Rare Earths. 2011;29(5):460.

Stanford N. The effect of rare earth elements on the behaviour of magnesium-based alloys: part 2—recrystallisation and texture development. Mater Sci Eng, A. 2013;565(1):469.

Beladi H, Barnett MR. Influence of aging pre-treatment on the compressive deformation of WE54 alloy. Mater Sci Eng, A. 2007;452–453(1):306.

Li J, Chen R, Ma Y, Ke W. Effect of Zr modification on solidification behavior and mechanical properties of Mg–Y–RE (WE54) alloy. J Magnes Alloys. 2013;1(4):346.

Moradjoy-Hamedani M, Zarei-Hanzaki A, Fatemi SM, Asqardoust S. The microstructure evolution of a high Zr-containing WE magnesium alloy through isothermal semi-solid treatment. Adv Eng Mater. 2015;17(11):1623.

Zhao C, Song R. Evolution of microstructure and mechanical properties for 9Cr18 stainless steel during thixoforming. Mater Des. 2014;59(1):502.

Atkinson HV, Liu D. Microstructural coarsening of semi-solid aluminium alloys. Mater Sci Eng, A. 2008;496(1–2):439.

Wang XJ, Wu K, Zhang HF, Huang WX, Chang H, Gan WM, Zheng MY, Peng DL. Effect of hot extrusion on the microstructure of a particulate reinforced magnesium matrix composite. Mater Sci Eng, A. 2007;465(1–2):78.

Zhao YQ, Wu WL, Chang H. Research on microstructure and mechanical properties of a new α + Ti2Cu alloy after semi-solid deformation. Mater Sci Eng, A. 2006;416(1–2):181.

Tahamtan S, Golozar MA, Karimzadeh F, Niroumand B. Microstructure and tensile properties of thixoformed A356 alloy. Mater Charact. 2008;59(3):223.

Chino Y, Kobata M, Iwasaki H, Mabuchi M. An investigation of compressive deformation behaviour for AZ91Mg alloy containing a small volume of liquid. Acta Mater. 2003;51(11):3309.

Paes M, Zoqui EJ. Semi-solid behavior of new Al–Si–Mg alloys for thixoforming. Mater Sci Eng, A. 2005;406(1–2):63.

Wang J, Phillion AB, Lu G. Development of a visco-plastic constitutive modeling for thixoforming of AA6061 in semi-solid state. J Alloy Compd. 2014;609(1):290.

Nagira T, Morita S, Yokota H, Yasuda H, Gourlay CM, Yoshiya M, Sugiyama A, Uesugi K, Takeuchi A, Suzuki Y. In situ observation of deformation in semi-solid Fe–C alloys at high shear rate. Metall Mater Trans A. 2014;5613(12):5623.

Acknowledgements

The authors acknowledge supports from University of Tehran and Shahid Rajaee Teacher Training University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moradjoy-Hamedani, M., Zarei-Hanzaki, A. & Fatemi, S.M. Characterization of semisolid deformation behavior of a high Zr-containing WE magnesium alloy. Rare Met. 41, 4201–4208 (2022). https://doi.org/10.1007/s12598-018-1046-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1046-6