Abstract

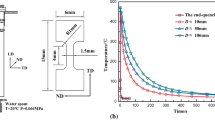

The effect of copper content on quench sensitivity in novel Al–Zn–Mg–Cu alloys containing high zinc content was investigated by Jominy end quench test. Electrical conductivity and hardness test, temperature collecting, and transmission electron microscopy (TEM) technique were adopted for the properties and microstructure characterization of three alloys with different copper contents. The results indicate that the electrical conductivity of all three alloys increases with the increase of distance from the quenched end, while the hardness shows an opposite trend. If the dropping of 10% hardness is defined as the critical evaluation standard of quenching, the depth of quenched layer of Alloys I, II, and III are 70, 55, and 40 mm, respectively. The precipitation behavior on grain boundaries of three alloys is similar except for a little difference in size, while the size of precipitates in grains of Alloy III with higher copper content is larger than those of the other two alloys at the same location. Considering all results, the stability of the supersaturated solid solution of Alloy III is lower than those of the other two alloys, meaning that Alloy III shows the highest quench sensitivity. Higher copper content leads to higher quench sensitivity in novel Al–Zn–Mg–Cu alloys with the same content of magnesium, zinc, and other trace elements.

Similar content being viewed by others

References

Xiong BQ, Li XW, Zhang YA, Li ZH, Zhu BH, Wang F, Liu HW. Novel Al–7.5Zn–1.65Mg–1.4Cu–0.12Zr alloys with high strength high toughness and low quench sensitivity. Chin J Nonferrous Metals. 2009;19(9):1539.

Wang T, Yin ZM, Sun Q. Effect of homogenization treatment on microstructure and hot workability of high strength 7B04 aluminum alloy. Trans Nonferrous Metals Soc China. 2007;17(2):335.

Heinz A, Haszler A, Keidel C. Recent development in aluminium alloys for aerospace applications. Mater Sci Eng A. 2000;280(1):102.

Liu J. Advanced aluminum and hybrid aerostructures for future aircraft. Mater Sci Forum. 2006;519–521(6):1233.

James T, Staley JT. Aluminum alloys for aerostructures. Adv Mater Process. 1997;152(4):17.

Lucasak DA, Hart RM. Aluminum alloy development efforts for compression dominated structure of aircraft. Light Metal Age. 1991;2(9):11.

Fang HC, Chen KH, Chen X. Effect of Cr, Yb and Zr additions on localized corrosion of Al–Zn–Mg–Cu alloy. Corros Sci. 2009;51(12):287.

Morere B, Shahani R, Maurice C. The influence of Al3Zr dispersoids on the recrystallization of hot-deformed AA 7010 alloys. Metall Mater Trans A. 2001;32(3):625.

Stiller K, Warren PJ, Hansen V, Angenete J, Gjonnes J. Investigation of precipitation in an Al–Zn–Mg alloy after two-step ageing treatment at 100 °C and 150 °C. Mater Sci Eng A. 1999;270(1):55.

Godard D, Archambault P, Aeby-Gautier E, Lapasset G. Precipitation sequences during quenching of the AA 7010 alloy. Acta Mater. 2002;50(9):2319.

Wen K, Xiong BQ, Fan YQ, Zhang YA, Li ZH, Li XW, Wang F, Liu HW. Transformation and dissolution of second phases during solution treatment of Al–Zn–Mg–Cu alloy containing high zinc. Rare Met. 2016;. https://doi.org/10.1007/s12598-016-0768-6.

Deschamps A, Texier G, Ringeval S, Delfaut-Durut L. Influence of cooling rate on the precipitation microstructure in a medium strength Al–Zn–Mg alloy. Mater Sci Eng A. 2009;501(1–2):133.

Gable BM, Csontos AA, Starke EA Jr. A quench sensitivity study on the novel Al–Li–Cu–X alloy AF/C 458. J Light Met. 2002;2(2):65.

Xu DK, Birbilis N, Lashansky D. Effect of solution treatment on the corrosion behaviour of aluminium alloy AA7150: optimisation for corrosion resistance. Corros Sci. 2011;53(1):217.

Han NM, Zhang XM, Liu SD, Liu DG, Zhang R. Effect of solution treatment on the strength and fracture toughness of aluminum alloy 7050. J Alloys Compd. 2011;509(10):4138.

Mazibuko NE, Curle UA. Effect of solution heat treatment time on a rheocast Al–Zn–Mg–Cu alloy. Mater Sci Forum. 2011;690(15):9.

Wang H, Xu J, Kang Y. Study on inhomogeneous characteristics and optimize homogenization treatment parameter for large size DC ingots of Al–Zn–Mg–Cu alloys. J Alloys Compd. 2014;585(5):19.

Dumont D, Deschamps A, Brechet Y. Characterisation of precipitation microstructures in aluminium alloys 7040 and 7050 and their relationship to mechanical behaviour. Mater Sci Eng A. 2004;20(5):567.

Deng YL, Wan L, Zhang Y. Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments. J Alloys Compd. 2010;498(1):88.

Robson JD. Microstructural evolution in aluminium alloy 7050 during processing. Mater Sci Eng A. 2004;382(1):112.

Zhang XM, Liu SD, You JH, Zhang C, Zhang XY. Influence of aging on quench sensitivity effect of 7055 aluminum alloy. Chin J Nonferrous Met. 2007;59(1):53.

Starink MJ, Li XM. A model for the electrical conductivity of peak-aged and overaged Al-ZN-Mg-Cu alloys. Metall Mater Trans A. 2003;34(4):899.

Deschamps A, Bréchet Y. Influence of quench and heating rates on the ageing response of an Al–Zn–Mg–Zr alloy. Mater Sci Eng A. 1998;251(1–2):200.

Ma SH, Maniruzzam MD, Mackenzie DS, Sisson RD Jr. A methodology to predict the effects of quench rates on mechanical properties of cast aluminum alloys. Metall Mater Trans B. 2007;38(4):583.

Liu SD, Zhang Y, Liu WJ, Deng YL, Zhang XM. Effect of step-quenching on microstructure of aluminum alloy 7055. Trans Nonferrous Met Soc China. 2010;20(1):1.

Underwood EE. Quantitative Stereology. Paris: Addision-Wesley Longman; 1970. 98.

Milman YV, Sirko AJ, Lotsko DV. Microstructure and mechanical properties of cast and wrought Al–Zn–Mg–Cu alloys modified with Zr and Sc. Mater Sci Forum. 2002;396–402(2):1217.

Srivatsan TS. Microstructure, tensile properties and fracture behaviour of aluminium alloy 7150. J Mater Sci. 1992;27(17):4772.

Pierre A, David G. High temperature precipitation kinetics and TTT curve of a 7xxx alloy by in situ electrical resistivity measurements and differential calorimetry. Scr Mater. 2000;42(7):675.

Tanner DA, Robinson JS. Effect of precipitation during quenching on the mechanical properties of the aluminium alloy 7010 in the W-temper. J Mater Process Technol. 2004;s153-154(22):998.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (No. 2016YFB0300803), the National Natural Science Foundation of China (No. 51274046), and the National Key Basic Research Program (No. 2012CB619504).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, JS., Li, XW., Xiong, BQ. et al. Quench sensitivity of novel Al–Zn–Mg–Cu alloys containing different Cu contents. Rare Met. 39, 1395–1401 (2020). https://doi.org/10.1007/s12598-017-0981-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0981-y