Abstract

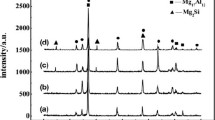

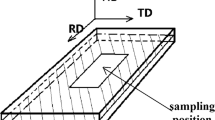

The extruded Mg–7Y–1Nd–0.5Zr (wt%) alloy were performed to the same strain hot rolling with different temperatures. The microstructure and texture evolution of the sheets were investigated by optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and electron back-scattered diffraction (EBSD). The results indicate that the microstructure becomes homogeneous after hot rolling process and precipitated phase distributes at grain boundaries along rolling direction. With the increase in rolling temperature, the grains of sheet grow up. The sheet rolling at 400 °C is composed of recrystallization grains, the necklace of the precipitated phase in the grain boundaries and excessive dislocations. The structure of necklace of the precipitated phase is fcc structure with lattice constant of a = 0.75 nm. With rolling temperatures increasing from 400 to 450 °C, the content of recrystallized grains in volume fraction with relatively random orientations increases significantly. Compared with the rolling process at 400 °C, the amount of precipitated phases is reduced at the grain boundary, and the precipitated phase begins to appear in the grain interior when rolling at 450 °C. The structure of the precipitated phase is fcc with lattice constant of a = 2.22 nm. The recrystallization grains begin to grow in the rolling process at 500 °C. The basal texture is obviously produced during the rolling process at 400 and 450 °C; however, the basal texture is weak in the rolling process at 500 °C.

Graphical Abstract

The pole point of the (0002) pole figure is concentrated in the center. It can be seen that the basal surface is parallel to RD–TD surface of the rolling sheets. Compared with as-extruded alloy, the basal texture is significantly enhanced with a small increase in basal texture intensity from 6.127 to 7.175, and \((10\bar{1}0)\) and \((11\bar{2}0)\) textures change to random textures.

Similar content being viewed by others

References

Liu Z, Zhang K, Zeng XQ. Magnesium Matrix of Lightweight Alloy Theoretical Basis and Application. Beijing: Mechanical Industry Press; 2002. 16.

Liu Z, Wang Y, Wang ZG. The research and application of magnesium matrix of lightweight materials. J Mater Res. 2000;14(5):449.

Bi G, Li Y, Zang S. Microstructure, mechanical and corrosion properties of Mg–2Dy–xZn (x = 0, 0.1, 0.5 and 1 at.%) alloys. J Magnes Alloys. 2014;2(1):6471.

Huang Y, Gan W, Kainer KU, Hort N. Role of multi-microalloying by rare earth elements in ductilization of magnesium alloys. J Magnes Alloys. 2014;2:1.

Kang YH, Wu D, Chen RS, Han EH. Microstructures and mechanical properties of the age hardened Mg–4.2 Y–2.5 Nd–1Gd–0.6 Zr (WE43) microalloyed with Zn. J Magnes Alloys. 2014;2(2):109.

Ma ML, Zhang K, Li YJ. Effect of homogenization on microstructure and properties of WE91 alloys. J Rare Earths. 2013;31(8):830.

Ma ML, Zhang K, Li XG, Li YJ, Shi GL, Yuan JW. Influence of solution and aging on the microstructures and mechanical properties of complex deformed WE93 alloy. Mater Des. 2013;51(5):73.

He LQ, Li YJ, Li XG. Microstructure and properties of WE93 alloy. Trans Nonferr Met Soc China. 2011;21(4):791.

Yang Y, Zhang K, Ma ML, Yuan JW. Microstructure and phase compositions of as-cast Mg–3.9Zn–0.6RE (Gd, Y) alloy with different Gd/Y ratios. Rare Met. 2015;34(3):160.

Lv BJ, Peng J, Peng Y, Tang AT, Pan FS. Mechanical properties and energy absorption of extruded Mg–2.0Zn–0.3Zr alloy with Y addition. Rare Met. 2015;34(5):314.

Li T, Zhang K, Li XG, Du ZW, Li YJ, Ma ML, Shi GL. Dynamic precipitation during multi-axial forging of an Mg–7Gd–5Y–1Nd–0.5Zr alloy. J Magnes Alloys. 2013;1(1):47.

Koike J, Yoshida Y, Kamado S, Suzuki M, Maruyama K, Kojima Y. Grain size dependence of active slip systems in an AZ31 magnesium alloy. J Jpn Inst Met. 2003;67:149.

Li T, Du ZW, Zhang K. Morphology and crystallography of β precipitate phase in Mg–Gd–Y–Nd–Zr alloy. Trans Nonferr Met Soc China. 2012;22(12):2877.

Xu C, Zheng MY, Xu SW, Wu K, Wang ED, Kamado S, Wang GJ, Lv XY. Microstructure and mechanical properties of rolled sheets of Mg–Gd–Y–Zn–Zr alloy: as-cast versus as-homogenized. J Alloy Compd. 2012;528(13):40.

Huang X, Suzuki K, Chino Y, Mabuchi M. Influence of rolling temperature on static recrystallization behavior of AZ31 magnesium alloy. J Mater Sci. 2012;47(11):4561.

Xu C, Xu SW, Zheng MY, Wu K, Wang ED, Kamado S, Wang GJ, Lv XY. Microstructures and mechanical properties of high-strength Mg–Gd–Y–Zn–Zr alloy sheets processed by severe hot rolling. J Alloy Compd. 2012;524(524):46.

Alireza Sadeghi, Mihriban Pekguleryuz. Recrystallization and texture evolution of Mg–3%Al–1%Zn–(0.4–0.8)%Sr alloys during extrusion. Mater Sci Eng, A. 2011;52(3):1678.

Yuan J, Zhang K, Li T, Li X, Li YJ, Ma M, Luo P. Anisotropy of thermal conductivity and mechanical properties in Mg–5Zn–1Mn alloy. Mater Des. 2012;40:257.

Acknowledgments

This study was financially supported by the National Basic Research Program of China (No. 2013CB632202) and the National Natural Science Foundation of China (No. 51204020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, JB., Zhang, K., Han, JT. et al. Microstructure and texture evolution of Mg–7Y–1Nd–0.5Zr alloy sheets with different rolling temperatures. Rare Met. 39, 1273–1278 (2020). https://doi.org/10.1007/s12598-016-0740-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0740-5