Abstract

Boron was found to be a unique grain refiner in cast TiAl alloys in the beginning of 1990s and has become an element in most of the TiAl alloys developed to date. Over the past 25 or so years, efforts to understand the role of boron in solidification, solid-phase transformation, thermal and thermomechanical processing and mechanical properties of TiAl alloys and the relevant mechanisms never ceased. As a result, abundant knowledge on boron in TiAl alloys has been accumulated but scattered in various research papers and conference proceedings. This review summarises the progress in understanding boron and its impacts on the TiAl alloy systems.

Similar content being viewed by others

References

Bewlay BP, Weimer M, Kelly T, Suzuki A, Subramanian PR. The science, technology, and implementation of TiAl alloys in commercial aircraft engines. In: MRS Proceedings 1516. Boston; 2013. 49.

Smarsly W, Esslinger J, Clemens H. TiAl for Turbine Applications—Status and Future Perspectives. Report at GTA 2015, Nanjing; 2015.

Kim Y-W. Ordered intermetallic alloys, part III: gamma titanium aluminides. JOM. 1994;46:30.

Larsen DE, Kampe S, Christodoulo L. Effect of XD™ TiB2 volume fraction on the microstructure of a cast near-gamma titanium aluminide alloy. In: MRS Proceedings 194. San Francisco, CA; 1990. 285.

Kremmer S, Chladil HF, Clemens H, Otto A, Güther V. Near conventional forging of titanium aluminides. In: Proceedings of Ti-2007 Science and Technology. Sendai; 2007. 989.

Larsen DE, Christodoulo L, Kampe S, Sadler P. Investment-cast processing of XD™ near-γ titanium aluminides. Mater Sci Eng, A. 1991;A144(1–2):45.

Bryant JD, Christodoulou L, Maisano JR. Effect of TiB2 additions on the colony size of near gamma titanium aluminides. Scr Metall Mater. 1990;24(1):33.

Hu D. Effect of composition on grain refinement in TiAl-based alloys. Intermetallics. 2001;9(12):1037.

Godfrey AB, Loretto MH. The nature of complex precipitates associated with the addition of boron to a γ-based titanium aluminide. Intermetallics. 1996;4(1):47.

Blenkinsop PA, Godfrey AB. Method of adding boron to a heavy metal containing titanium aluminide alloy. US patent; US6488073B1, 2002.

Kartavykh AV, Asnis EA, Piskun NV, Statkevich II, Gorshenkov MV, Tcherdyntsev VV. Lanthanum hexaboride as advanced structural refiner/getter in TiAl-based refractory intermetallics. J Alloys Compd. 2014;588:122.

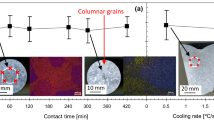

Yang C, Hu D, Huang A, Dixon M. Solidification and grain refinement in Ti45Al2Mn2Nb1B subjected to fast cooling. Intermetallics. 2013;32:64.

Christodoulou L. Microstructural Effects in γ-Titanium Aluminides; XD TiAl alloys as an Example. Report in 1st IRC International Gamma TiAl Workshop, Birmingham; 1995.

Shih D, Kim Y-W. Sheet rolling and performance evaluation of beta-gamma (β–γ) alloys. In: Proceedings of Ti-2007 Science and Technology. Sendai; 2007. 1021.

Kremmer S, Chladil HF, Clemens H, Otto A, Güther V. Near conventional forging of titanium aluminides. In: Proceedings of Ti-2007 Science and Technology. Sendai; 2007. 989.

Hu D, Jiang H, Wu X. Microstructure and tensile properties of cast Ti–44Al–4Nb–4Hf–0.1Si–0.1B alloy with refined lamellar microstructures. Intermetallics. 2009;17(9):744.

Larson DJ, Liu CT, Miller MK. Boron solubility and boride compositions in α2+γ titanium aluminides. Intermetallics. 1997;5(6):411.

Hecht U, Witusiewicz V, Drevermann A, Zollinger J. Grain refinement by low boron additions in niobium-rich TiAl alloys. Intermetallics. 2008;16(8):969.

Yang C, Jiang H, Hu D, Huang A, Dixon M. Effect of boron concentration on phase transformation texture in as-solidified Ti44Al8NbxB. Scr Mater. 2012;67(1):85.

Cagran C, Wilthan B, Pottlacher G, Roebuck B, Wickins M, Harding RA. Thermophysical properties of a Ti–44%Al–8%Nb–1%B alloy in the solid and molten states. Intermetallics. 2003;11(11–12):1327.

Witusiewicz VT, Bondar AA, Hecht U, Zollinger J, Artyukh LV, Velikanova TY. The Al–B–Nb–Ti system V. Thermodynamic description of the ternary system Al–B–Ti. J Alloys Compd. 2009;474(1–2):86.

Bermingham MJ, McDonald SD, Dargusch MS, StJohn DH. Grain-refinement mechanisms in titanium alloys. J Mater Res. 2008;23(1):97.

Easton M, StJohn DH. Grain refinement of aluminum alloys: part I. The nucleant and solute paradigms—a review of the literature. Metall Mater Trans A. 1999;30A:1613.

Hu D, Yang C, Huang A, Dixon M, Hecht U. Solidification and grain refinement in Ti45Al2Mn2Nb1B. Intermetallics. 2012;22:68.

Cheng TT. The mechanism of grain refinement in TiAl alloys by boron addition—an alternative hypothesis. Intermetallics. 2000;8(1):29.

Gosslar D, Hartig C, Günther R, Hecht U, Bormann R. Heterogeneous nucleation and growth of the β(Ti) phase in the Ti–Al system—experiments and model calculations. J Phys Condens Matter. 2009;21(46):464111.

Gosslar D, Günther R, Hecht U, Hartig C, Bormann R. Grain refinement of TiAl-based alloys: the role of TiB2 crystallography and growth. Acta Mater. 2010;58(20):6744.

Inkson BJ, Boothroyd CB, Humphreys CJ. Boron segregation in a (Fe, V, B) TiAl based alloy. Le Journal de Physique IV. 1993;3(C7):397.

Kitkamthorn U, Zhang LC, Aindow M. The structure of ribbon borides in a Ti–44Al–4Nb–4Zr–1B alloy. Intermetallics. 2006;14(7):759.

Godfrey AB. Grain refinement of a gamma-based titanium aluminide using microalloy additions. Birmingham: University of Birmingham; 1996. 1.

Okamoto H. Ti-Al phase diagram. J. Phase. Equilibria. 1993;14(1):120.

Imayev RM, Imayev VM, Oehring M, Appel F. Alloy design concept for refined gamma titanium aluminide based alloys. Intermetallics. 2007;15(4):451.

Burgers WG. On the process of transition of the cubic-body-centered modification into the hexagonal-close-packed modification of zirconium. Physica. 1934;1:561.

Hu D, Yang C, Huang A, Dixon M, Hecht U. Grain refinement in beta-solidifying Ti44Al8Nb1B. Intermetallics. 2012;23:49.

Kartavykh AV, Gorshenkov MV, Podgorny DA. Grain refinement mechanism in advanced gamma-TiAl boron-alloyed structural intermetallics: the direct observation. Mater Lett. 2015;142:294.

Hu D, Wu X. Tensile ductility of cast TiAl alloys. Mater Sci Forum. 2010;638–642(1–4):1336.

Chen CL, Lu W, Lin JP, He LL, Chen GL, Ye HQ. Orientation relationship between TiB precipitate and γ-TiAl phase. Scr Mater. 2007;56(6):441.

Wang Y, Wang JN, Yang J, Zhang B. Control of a fine-grained microstructure for cast high-Cr TiAl alloys. Mater Sci Eng A. 2005;392(1–2):235.

Chen GL, Zhang WJ, Liu ZC, Li SL, Kim Y-W. Microstructure and properties of high-Nb containing TiAl-based alloys. In: Proceedings of Gamma Titanium Aluminides 1999. San Diego; 1999. 371.

Huang ZW. Inhomogeneous microstructure in highly alloyed cast TiAl-based alloys, caused by microsegregation. Scr Mater. 2005;52(10):1021.

Hyman ME, McCullough C, Levi CG, Mehrabian R. Evolution of boride morphologies in TiAl–B alloys. Metall Trans A. 1991;22A:1647.

Witusiewicz VT, Bondar AA, Hecht U, Velikanova TY. The Al–B–Nb–Ti system IV. Experimental study and thermodynamic re-evaluation of the binary Al–Nb and ternary Al–Nb–Ti systems. J Alloys Compd. 2009;472(1–2):133.

Campbell J. Castings. 2nd ed. Oxford: Elsevier Butterworh-Heinemann; 2003. 70.

Zhang J. High Nb content TiAl Alloys Specified to Cast Process. Report at ISGTA 2014, TMS. San Diego; 2014.

Hu D. Effect of boron addition on tensile ductility in lamellar TiAl alloys. Intermetallics. 2002;10(9):851.

Hu D, Mei JF, Wickins M, Harding RA. Microstructure and tensile properties of investment cast Ti–46Al–8Nb–1B alloy. Scr Mater. 2002;47(4):273.

De Graef M, Löfvander JPA, McCullough C, Levi CG. The evolution of metastable Bf borides in a Ti–Al–B alloy. Acta Metall Mater. 1992;40(12):3395.

Kartavykh AV, Gorshenkov MV, Podgorny DA. On the state of boride precipitates in grain refined TiAl-based alloys with high Nb content. J Alloys Compd. 2014;586(S1):S153.

Hu D, Huang A, Jiang H, Mota-Solis N, Wu X. Pre-yielding and pre-yield cracking in TiAl-based alloys. Intermetallics. 2006;14(1):82.

Chan KS, Kim Y-W. Effects of lamellae spacing and colony size on the fracture resistance of a fully-lamellar TiAl alloy. Acta Metall Mater. 1995;43(2):439.

Fuch GE. Homogenization and hot working of Ti–48Al–2Nb–2Cr alloys. In: Proceedings of Structural Intermetallics. Champion; 1993. 193.

Hu D, Blenkinsop PA, Loretto MH. Alpha phase decomposition during continuous cooling in Ti48Al2Cr2Mn with and without boron addition. In: Proceedings of Titaium’99: Science and Technology. St Petersburg; 1999. 290.

Godfrey AB, Hu D, Loretto MH. Thermal stability and properties of lamellar and duplex TiAl-based alloys. In: Proceedings of International Symposium on Designing, Processing and Properties of Advanced Engineering Materials. Toyohashi; 1997. 37.

Chan KS, Shin DS. Fundamental aspects of fatigue and fracture in a TiAl sheet alloy. Metall Mater Trans A. 1998;29A:73.

Oehring M, Stark A, Paul JDH, Lippmann T, Pyczak F. Microstructural refinement of boron-containing β-solidifying γ-titanium aluminide alloys through heat treatments in the β phase field. Intermetallics. 2013;32:12.

Couret A, Molénat G, Galy J, Thomas M. Microstructures and mechanical properties of TiAl alloys consolidated by spark plasma sintering. Intermetallics. 2008;16(9):1134.

Luo JS, Voisin T, Monchoux JP, Couret A. Refinement of lamellar microstructures by boron incorporation in GE–TiAl alloys processed by spark plasma sintering. Intermetallics. 2013;36:12.

Habel U, McTiernan BJ. HIP temperature and properties of a gas-atomized γ-titanium aluminide alloy. Intermetallics. 2004;12(1):63.

Yang C, Hu D, Wu X, Huang A, Dixon M. Microstructures and tensile properties of hot isostatic pressed Ti4522XD powders. Mater Sci Eng A. 2012;534:268.

Larson DJ, Liu CT, Miller MK. The alloying effects of tantalum on the microstructure of an α2+γ titanium aluminide. Mater Sci Eng A. 1999;270(1):1.

Yang C, Hu D, Wu X, Huang A, Dixon M. The influence of cooling rate and alloy composition on the formation of borides during solidification of boron-containing TiAl alloys. In: Proceedings of Ti-2011. Beijing; 2012. 1416.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, D. Role of boron in TiAl alloy development: a review. Rare Met. 35, 1–14 (2016). https://doi.org/10.1007/s12598-015-0615-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0615-1