Abstract

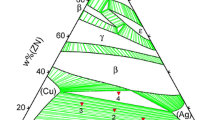

The microstructure and melting properties of ternary Ag–Cu–In intermediate-temperature alloys (400–600 °C) prepared by electric arc melting were investigated in this work. The melting properties, phase compositions, microstructure and hardness were characterized by differential scanning calorimetry (DSC), X-ray diffraction (XRD), scanning electron microscopy (SEM) and micro-hardness tester, respectively. The results show that the melting properties, phase compositions, microstructure and hardness of Ag–Cu–In brazing alloys are substantially different when adding different levels of indium. Indium element could effectively reduce the melting temperatures of (Ag–Cu28)–xIn alloys, and the melting temperatures of (Ag–Cu28)–25In alloy are located at 497.86 and 617.48 °C. When the indium content varies from 5 wt% and 10 wt%, the dominant phases in the alloys are Ag-rich and Cu-rich phases, and their granular crystals are smaller than 0.5 µm. When the indium content is higher than 15 wt%, the phase compositions of the alloy are Ag4In and Cu11In9, and the microstructure exhibits dendritic crystals with a uniform distribution. The hardness of (Ag–Cu28)–xIn alloy decreases first and then increases with the content of indium increasing, and the highest hardness of (Ag–Cu28)–25In alloy is HV 266.0.

Similar content being viewed by others

References

Abbasi S, Barzegaramiri H, Farmany A. Determination of trace amounts of silver(I) in the presence of an activator with a kinetic method. Rare Met. 2014;33(6):731.

Tu CZ, Ye JJ, Tan CY, Yue YX. Performance of Ag–Cu–Sn–In alloy solder paste at middle temperature and its application. Hot Work Technol. 2006;35(19):43.

Duwez P, Willens RH, Klement JW. Continuous series of metastable solid solutions in silver–copper alloys. J Appl Phys. 1960;31:1136.

Kozlova O, Voytovych R, Devismes MF. Wetting and brazing of stainless steels by copper–silver eutectic. Mater Sci Eng. 2008;495(1–2):96.

Garzel G, Janczak-Rusch J, Zabdyr L. Reassessment of the Ag–Cu phase diagram for nanosystems including particle size and shape effect. Calphad. 2012;36(3):52.

Tsuji M, Hikino S, Tanabe R, Matsunaga M, Sano Y. Synthesis of Ag/Cu alloy and Ag/Cu alloy core Cu shell nanoparticles using a polyol method. Cryst Eng Comm. 2010;12(11):3900.

Dutkiewicz J, Lityńska L, Maziarz W. Structure of rapidly quenched and mechanically alloyed AgCuCd alloys. Phys Stat Solidi. 1995;150(1):257.

Li ZR, Liu B, Feng JC. Optimum design of cadmium-free silver-based filler metal contained 20 % Ag. Trans China Weld Inst. 2008;29(8):5.

Xu JF, Zhang XC, Dang B, Dai WG. Microstructure and properties of rapidly solidified Ag–Cu–Sn ternary brazing fillers. Trans China Weld Inst. 2011;32(2):85.

Yan XW, Qiu T, Li LF, Zhang ZZ. Preparation and thermal property analysis of Ag–Cu–In–Sn nano-powder. Rare Met Mater Eng. 2008;37(2):330.

Pu CJ, Xie M, Du WJ, Zhang LG, Yang YF, Zhang JM. Morphology and distribution of Ag3Sn intermetallic compounds of Sn–3.5Ag solder under different cooling rates. Chin J Rare Met. 2014;38(3):363.

Sisamoutha L, Hamdia M, Ariga T. Investigation of gap filling ability of Ag–Cu–In brazing filler metals. J Alloys Compd. 2010;504(2):325.

Yu AM, Lee CW, Kim MS, Lee JH. The effect of the addition of In on the reaction and mechanical properties of Sn–1.0Ag–0.5Cu solder alloy. Met Mater Int. 2007;13(6):517.

Bahari Z, Elgadi M, Rivet J, Dugue J. Experimental study of the ternary Ag–Cu–In phase diagram. J Alloys Compd. 2009;477(1–2):152.

Wang JX, Yin M, Lai ZM, Li X. Wettability and microstructure of Sn–Ag–Cu–In solder. Trans China Weld Inst. 2011;32(11):69.

Kanlayasiri K, Mongkolwongrojn M, Ariga T. Influence of indium addition on characteristics of Sn–0.3Ag–0.7Cu solder alloy. J Alloys Compd. 2009;485(1–2):225.

Li LF, Qiu T, Yang J, Feng YB. Synthesis of nanocrystalline Ag–Cu supersaturated solid solution by mechanical alloying. Adv Mater Res. 2010;92:271.

Acknowledgments

This study was financially supported by the Open Project of State Key Laboratory Cultivation Base for Nonmetal Composites and Functional Materials (No. 11zxfk13), the Scientific Research Fund of Sichuan Provincial Education Department (No. 14ZB0103), and the China Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, X., Li, LF., Zhang, ZH. et al. Microstructure and melting properties of Ag–Cu–In intermediate-temperature brazing alloys. Rare Met. 34, 324–328 (2015). https://doi.org/10.1007/s12598-015-0484-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0484-7