Abstract

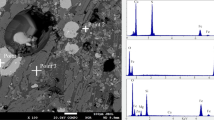

Cleaning of high antimony smelting slag from an oxygen-enriched bottom-blown was tested by direct reduction in a laboratory-scale electric furnace. The effects of added CaO, mass ratio of coal (experimental) to coal (theoretical) (ω) and the slag type on the reduction procedure were considered. The contents of Sb and Au were investigated. Iron contamination of the metal phase was analyzed as this may impede the economical viability of this process. The initial slag, coal and CaO were mixed and homogenized before charging into the furnace, and the residual slag averagely contains 1.26 g·ton−1 Au and 1.17 wt% Sb. However, the iron contamination of antimony alloy becomes unacceptably high in this case as the metal phases contain up to 10 wt% Fe. In the slag system with mass ratio of SiO2:FeO:CaO = 45:27:18, the residual slag obtained after reduction under these conditions averagely contains <1 g·ton−1 Au and <1 wt% Sb, and the metal phase contains <7 wt% Fe. The recoveries of Au in the metal phase are >98 % in all experiments which is proved to be an economic and cleaning process.

Similar content being viewed by others

References

Lager T, Forssberg KSE. Current processing technology for antimony-bearing ores a review—part 2. Miner Eng. 1989;2(4):543.

Mahlangu T, Gudyanga FP, Simbi DJ. Reductive leaching of stibnite (Sb2S3) flotation concentrate using metallic iron in a hydrochloric acid medium I: thermodynamics. Hydrometallurgy. 2006;84(3):192.

Yang J. Separation of antimony from a stibnite concentrate through a low-temperature smelting process to eliminate SO2 emission. Metall Mater Trans B. 2011;42(1):30.

Shen H, Forssberg E. An overview of recovery of metals from slags. Waste Manag. 2003;23(10):933.

Banda W, Morgan N, Eksteen JJ. The role of slag modifiers on the selective recovery of cobalt and copper from waste smelter slag. Miner Eng. 2002;15(11):899.

Zhai X. Recovery of cobalt from converter slag of Chambishi copper smelter using reduction smelting process. Trans Nonferrous Metals Soc China. 2011;21(9):2117.

Banda W, Morgan N, Eksteen JJ. The role of slag modifiers on the selective recovery of cobalt and copper from waste smelter slag. Miner Eng. 2002;15(11):899.

Kaiura GH, Watanabe K, Yazawa A. Behaviour of lead in silica-saturated, copper smelting systems. Can Metall Q. 1980;19(2):191.

Mackey PJ. Physical chemistry of copper smelting slag—a review. Can Metall Q. 1982;21(3):221.

Heo JH, Kim B, Park JH. Effect of CaO addition on iron recovery from copper smelting slags by solid carbon. Metall Mater Trans B. 2013;44(6):1352.

Hu T. Reduction behavior of panzhihua titanomagnetite concentrates with coal. Metall Mater Trans B. 2013;44(2):252.

Padilla R, Ruiz MC, Sohn HY. Reduction of molybdenite with carbon in the presence of lime. Metall Mater Trans B. 1997;28(2):265.

Altundogan HS, Tümen F. Metal recovery from copper converter slag by roasting with ferric sulphate. Hydrometallurgy. 1997;44(1–2):261.

Maweja K, Mukongo T, Mutombo I. Cleaning of a copper matte smelting slag from a water-jacket furnace by direct reduction of heavy metals. J Hazard Mater. 2009;164(2–3):856.

Li L, Chen JY, Liu YJ. Temperature stability of magnetic field for periodic permanent-magnet focusing system. Rare Met. 2014;33(2):180.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51204210), the National High Technology Research and Development Program of China (No. 2011AA061001) and the National “Twelfth Five-Year” Plan for Science and Technology (No. 2012BAC12B04).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, HL., Liu, W., Qin, WQ. et al. Cleaning of high antimony smelting slag from an oxygen-enriched bottom-blown by direct reduction. Rare Met. 38, 800–804 (2019). https://doi.org/10.1007/s12598-015-0468-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0468-7