Abstract

Recovery processes of secondary resources usually encounter problems because of the diverse compositions of wastes. To enhance the applicability of traditional hydrometallurgical process toward secondary resources, the adjustment of components is necessary. In traditional hydrometallurgical separation, precipitation and complexation are extensively used. However, their combination as a specific metal separation method has not yet been studied in detail. This approach is very promising for solving problems caused by changeable components during recycling processes of secondary resources. This paper reviews the effects of precipitation and complexation in metal separation processes, and a metal separation method system of “complexation–precipitation” developed to adjust the components of secondary resources is introduced.

Similar content being viewed by others

References

Li JH, Li XH, Hu QY, Wang ZX, Zheng JC, Wu L, Zhang LX. Study of extraction and purification of Ni, Co and Mn from spent battery material. Hydrometallurgy. 2009;99(1–2):7.

Lee J, Pandey BD. Bio-processing of solid wastes and secondary resources for metal extraction—a review. Waste Manag. 2012;32(1):3.

Belardi G, Lavecchia R, Medici F, Piga L. Thermal treatment for recovery of manganese and zinc from zinc–carbon and alkaline spent batteries. Waste Manag. 2012;32(10):1945.

Zeng G, Deng X, Luo S, Luo X, Zou J. A copper-catalyzed bioleaching process for enhancement of cobalt dissolution from spent lithium-ion batteries. J Hazard Mater. 2012;199–200(15):164.

Pinto Isabel SS, Soares Helena MVM. Microwave-assisted selective leaching of nickel from spent hydrodesulphurization catalyst: a comparative study between sulphuric and organic acids. Hydrometallurgy. 2013;140:20.

Zhang SG, Yang M, Liu H, Pan DA, Tian JJ. Recovery of waste rare earth fluorescent powders by two steps acid leaching. Rare Met. 2013;32(6):609.

Fernandes A, Afonso JC, Dutra AJB. Separation of nickel(II), cobalt(II) and lanthanides from spent Ni-MH batteries by hydrochloric acid leaching, solvent extraction and precipitation. Hydrometallurgy. 2013;133:37.

Rácz R, Ilea P. Electrolytic recovery of Mn3O4 and Zn from sulphuric acid leach liquors of spent zinc–carbon–MnO2 battery powder. Hydrometallurgy. 2013;139:116.

Coman V, Robotin B, Ilea P. Nickel recovery/removal from industrial wastes: a review. Resour Conserv Recycl. 2013;73:229.

Chen L, Tang X, Zhang Y, Li L, Zeng Z, Zhang Y. Process for the recovery of cobalt oxalate from spent lithium-ion batteries. Hydrometallurgy. 2011;108(1–2):80.

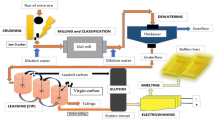

Haghighi HK, Moradkhani D, Sedaghat B, Najafabadi MR, Behnamfard A. Production of copper cathode from oxidized copper ores by acidic leaching and two-step precipitation followed by electrowinning. Hydrometallurgy. 2013;133:111.

Janin A, Zaviska F, Drogui P, Blais JF, Mercier G. Selective recovery of metals in leachate from chromated copper arsenate treated wastes using electrochemical technology and chemical precipitation. Hydrometallurgy. 2009;96(4):318.

Huang JH, Kargl-Simard C, Oliazadeh M, Alfantazi AM. pH-controlled precipitation of cobalt and molybdenum from industrial waste effluents of a cobalt electrodeposition process. Hydrometallurgy. 2004;75(1):77.

Giannopoulou I, Panias D. Differential precipitation of copper and nickel from acidic polymetallic aqueous solutions. Hydrometallurgy. 2008;90(2):137.

Zhu Z, Pranolo Y, Zhang W, Wang W, Cheng CY. Precipitation of impurities from synthetic laterite leach solutions. Hydrometallurgy. 2010;104(1):81.

Avila M, Grinbaum B, Carranza F, Mazuelos A, Romero R, Iglesias N, Lozano JL, Perez G, Valiente M. Zinc recovery from an effluent using Ionquest 290: from laboratory scale to pilot plant. Hydrometallurgy. 2011;107(3–4):63.

Lu MN, Das RP, Li W, Peng JH, Zhang LB. Microwave mediated precipitation and aging of iron oxyhydroxides at low temperature for possible hydrometallurgical applications. Hydrometallurgy. 2013;134–135:110.

Silva AM, Cunha EC, Silva FDR, Leão VA. Treatment of high-manganese mine water with limestone and sodium carbonate. J Clean Prod. 2012;29–30:11.

Formanek J, Jandova J, Capek J. Iron removal from zinc liquors originating from hydrometallurgical processing of spent Zn/MnO2 batteries. Hydrometallurgy. 2013;138:100.

Lewis AE. Review of metal sulphide precipitation. Hydrometallurgy. 2010;104(2):222.

Xie Y, Xu Y, Yan L, Yang R. Recovery of nickel, copper and cobalt from low-grade Ni–Cu sulfide tailings. Hydrometallurgy. 2005;80(1–2):54.

Deniz U, Bekmezci OK, Kaksonen AH, Sahinkaya E. Sequential precipitation of Cu and Fe using a three-stage sulfidogenic fluidized-bed reactor system. Miner Eng. 2011;24(11):1100.

Paulino JF, Busnardo NG, Afonso JC. Recovery of valuable elements from spent Li-batteries. J Hazard Mater. 2008;150(3):843.

Chen X, Chen A, Zhao Z, Liu X, Shi Y, Wang D. Removal of Cu from the nickel electrolysis anolyte using nickel thiocarbonate. Hydrometallurgy. 2013;133:106.

Rabah MA, Farghaly FE, Abd-El MMA. Recovery of nickel, cobalt and some salts from spent Ni-MH batteries. Waste Manag. 2008;28(7):1159.

du Plessis CA, Slabbert W, Hallberg KB, Barrie JD. Ferredox: a biohydrometallurgical processing concept for limonitic nickel laterite. Hydrometallurgy. 2011;109(3–4):221.

Song Y, Wang M, Liang J, Zhou L. High-rate precipitation of iron as jarosite by using a combination process of electrolytic reduction and biological oxidation. Hydrometallurgy. 2014;143:23.

Wang M, Zhou L. Simultaneous oxidation and precipitation of iron using jarosite immobilized acidithiobacillus ferrooxidans and its relevance to acid mine drainage. Hydrometallurgy. 2012;125–126:152.

Dutrizac JE, Chen TT. The behaviour of phosphate during jarosite precipitation. Hydrometallurgy. 2010;102(1):55.

Mohapatra M, Anand S, Das RP. Behaviour of Co(II) in solutions obtained by dissolution of cobalto–cobaltic oxide in NH3–SO2–H2O medium. Hydrometallurgy. 2001;61(3):169.

Zhang W, Zhao Z, Chen X. The behaviour of phosphorus impurities in the novel selective precipitation process. Hydrometallurgy. 2013;139:111.

Nathsarma KC, Rout PC, Sarangi K. Manganese precipitation kinetics and cobalt adsorption on MnO2 from the ammoniacal ammonium sulfate leach liquor of Indian Ocean manganese nodule. Hydrometallurgy. 2013;133:133.

Zhang W, Singh P, Muir D. Oxidative precipitation of manganese with SO2/O2 and separation from cobalt and nickel. Hydrometallurgy. 2002;63(2):127.

Zhang W, Cheng CY, Pranolo Y. Investigation of methods for removal and recovery of manganese in hydrometallurgical processes. Hydrometallurgy. 2010;101(1–2):58.

Zhao HP, Guo YF, Zhang XX. Electrolytic recovery of nickel powder from acid-washing solution containing nickel in artificial diamond production. Chin J Process Eng. 2004;4(4):310.

Nishimura T, Umetsu Y. Oxidative precipitation of arsenic(III)/with manganese(II)/and iron(II) in dilute acidic solution by ozone. Hydrometallurgy. 2001;62(2):83.

Kim T-H, Senanayake G, Kang J-G, Sohn J-S, Rhee K-I, Lee S-W, Shin S-M. Reductive acid leaching of spent zinc–carbon batteries and oxidative precipitation of Mn–Zn ferrite nanoparticles. Hydrometallurgy. 2009;96(1–2):154.

Yin Z, Ding Z, Hu H, Liu K, Chen Q. Dissolution of zinc silicate (hemimorphite) with ammonia–ammonium chloride solution. Hydrometallurgy. 2010;103(1–4):215.

Park K-H, Mohapatra D, Reddy BR, Nam C-W. A study on the oxidative ammonia/ammonium sulphate leaching of a complex (Cu–Ni–Co–Fe) matte. Hydrometallurgy. 2007;86(3):164.

Ma B, Wang C, Yang W, Yin F, Chen Y. Screening and reduction roasting of limonitic laterite and ammonia-carbonate leaching of nickel–cobalt to produce a high-grade iron concentrate. Miner Eng. 2013;50–51:106.

Li L, Ge J, Chen RJ, Wu AF, Chen S, Zhang XX. Environmental friendly leaching reagent for cobalt and lithium recovery from spent lithium-ion batteries. Waste Manag. 2010;30(12):2615.

Li L, Ge J, Wu F, Chen R, Chen S, Wu B. Recovery of cobalt and lithium from spent lithium ion batteries using organic citric acid as leachant. J Hazard Mater. 2010;176(1–3):288.

Goel S, Gautam A. Effect of chelating agents on mobilization of metal from waste catalyst. Hydrometallurgy. 2010;101(3–4):120.

Wang XF, Kong XH, Zhao ZY. Recovery of noble metal in lithium ion battery. Battery. 2001;31(1):14.

Zhang X, Ji L, Wang J, Li R, Liu Q, Zhang M, Liu L. Removal of uranium(VI) from aqueous solutions by magnetic Mg–Al layered double hydroxide intercalated with citrate: kinetic and thermodynamic investigation. Colloids Surf A Physicochem Eng Asp. 2012;414:220.

Wang T, Liu W, Xiong L, Xu N, Ni J. Influence of pH, ionic strength and humic acid on competitive adsorption of Pb(II), Cd(II) and Cr(III) onto titanate nanotubes. Chem Eng J. 2013;215–216(1):366.

Cao HZ, Zheng GQ, Zhi B, Tang MT. Cathodic process of zinc electrowinning in solution containing ammonia complex. Chin J Nonferr Met. 2005;15(4):655.

Zhang LJ, Tao HC, Wei XY, Lei T, Li JB, Wang AJ, Wu WM. Bioelectrochemical recovery of ammonia–copper(II) complexes from wastewater using a dual chamber microbial fuel cell. Chemosphere. 2012;89(10):1177.

Almeida MRH, Barbano EP, Carvalho MF, Carlos IA, Siqueira JLP, Barbosa LL. Electrodeposition of copper–zinc from an alkaline bath based on EDTA. Surf Coat Technol. 2011;206(1):95.

Liu ZX, Yin ZL, Xiong SF, Chen YG, Chen QY. Leaching and kinetic modeling of calcareous bornite in ammonia ammonium sulfate solution with sodium persulfate. Hydrometallurgy. 2014;144–145:86.

Deutsch JL, Dreisinger DB. Silver sulfide leaching with thiosulfate in the presence of additives Part I: copper–ammonia leaching. Hydrometallurgy. 2013;137:156.

Zhang W, Tsang DCW, Lo IMC. Removal of Pb and MDF from contaminated soils by EDTA- and SDS-enhanced washing. Chemosphere. 2007;66(11):2025.

Hernández CMF, Banza AN, Gock E. Recovery of metals from Cuban nickel tailings by leaching with organic acids followed by precipitation and magnetic separation. J Hazard Mater. 2007;139(1):25.

Senanayake G. Catalytic role of ammonia in the anodic oxidation of gold in copper-free thiosulfate solutions. Hydrometallurgy. 2005;77(3–4):287.

Pedersen AJ, Ottosen LM, Villumsen A. Electrodialytic removal of heavy metals from municipal solid waste incineration fly ash using ammonium citrate as assisting agent. J Hazard Mater. 2005;122(1–2):103.

Zhang W, Cheng CY. Manganese metallurgy review. Part II: manganese separation and recovery from solution. Hydrometallurgy. 2007;89(3–4):160.

Shen QF, Yang XW. Solubility of Fe2+/Mn2+/Zn2+ in NH3–H2O system. Nonferr Met. 2003;55(4):65.

Nadirov RK, Syzdykova LI, Zhussupova AK, Usserbaev MT. Recovery of value metals from copper smelter slag by ammonium chloride treatment. Int J Miner Process. 2013;124:145.

Chen L, Tang XC, Zhang Y, Qu Y, Wang ZM. Separation and recovery of Ni, Co and Mn from spent lithium-ion batteries. Chin J Nonferr Met. 2011;21(5):1192.

Zhao ZW, Wang DD, Chen AL, Huo GS, Chen XY. Application and prospect of leaching processes of cobalt from Cu–Co alloy and slag. Hydrometall China. 2008;27(4):195.

Dean JA, Wei J (Translator). Lange’s Handbook of Chemistry. 2nd edition. Beijing: Science Press; 2003. 8.80.

Zhang P. Advanced Chemistry for Engineering. Changsha: Hunan Educational Press; 2002. 337.

Zhang CF, Yao YL, Zhan J. Thermodynamics of precipitation–coordination equilibrium in Fe2+–Ni2+–NH3–NH4+–C2O4 2−–H2O system. Chin J Nonferr Met. 2012;22(10):2938.

Chai LY, Chang H, Wang YY, Shu YD, Li J, Yuan L, Wang P, Fang Y, Zhao K. Equilibrium of hydroxyl complex ions in Cd2+–H2O system. Chin J Nonferr Met. 2007;17(3):487.

Su JT, Su YC, Lai ZG, Yu P, He XD. Thermodynamic analysis of preparation of multiple carbonate of Ni, Co and Mn by coprecipitation method. J Chin Ceram Soc. 2006;34(6):695.

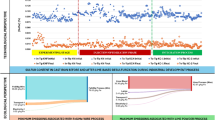

Ma LW, Nie ZR, Xi XL, Han XG. Thermodynamic equilibrium in Co–Ni–Fe–Mn complexation–precipitation system. Chin J Nonferr Met. 2013;23(2):516.

Ma LW, Nie ZR, Xi XL, Li XK. Theoretical simulation and experimental study on nickel, cobalt, manganese separation in complexation–precipitation system. Sep Purif Technol. 2013;108(19):124.

Ma LW, Nie ZR, Xi XL, Han XG. Cobalt recovery from cobalt-bearing waste in sulphuric and citric acid systems. Hydrometallurgy. 2013;136:1.

Zhu ZY, Zhu LW. Synthesis of layered cathode material 0.5Li2MnO3 0.5LiMn1/3Ni1/3Co1/3O2 by an improved co-precipitation method for lithium-ion battery. J Power Sources. 2014;256(6):178.

Acknowledgements

This work was financially supported by the National High-tech R&D Program of China (No. 2013AA040208), the National Natural Science Foundation of China (No. 51304010), and the Beijing Natural Science Foundation (No. 2132016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, ZR., Ma, LW. & Xi, XL. “Complexation–precipitation” metal separation method system and its application in secondary resources. Rare Met. 33, 369–378 (2014). https://doi.org/10.1007/s12598-014-0352-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0352-x