Abstract

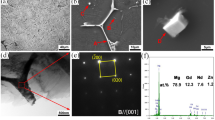

Conventional casting method was employed to prepare Mg–Zn–Y alloy only with α-Mg+I-phase; however, the grain size of quasicrystal is quite large in the as-cast state. Therefore, isothermal treatment was applied to refine the quasicrystal phase. The result shows that after the Mg–Zn–Y alloy was isothermally treated at 500 °C for several hours, the coarse quasicrystal can be gradually dissolved and thus refined. Generally, the dissolving processes of quasicrystal are slow first and then accelerate; after isothermally treated with 8 h at 500 °C, the quasicrystal is almost completely dissolved into the matrix only with 1–5 μm tiny quasicrystals remained. Refinement of quasicrystal can markedly reduce the wear resistance, but increase the corrosion resistance.

Similar content being viewed by others

References

Avedesian MM, Baker H, editors. Magnesium and Magnesium Alloys—ASM Specialty Handbook, ASM International. Ohio: The Materials Information Society, 1999. 52.

Aghion E, Bronfín B, Buch FV, Schumann S, Friedrich H. Newly developed magnesium alloys for powertrain applications. JOM. 2003;55(11):30.

Kulekci MK. Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol. 2008;39(9–10):851.

Singh A, Tsai AP, Nakamura M, Watanabe M, Kato A. Nanoprecipitates of icosahedral phase in quasicrystal-strengthened Mg–Zn–Y alloys. Philos Mag Lett. 2003;83(9):543.

Wan DQ, Yang GC, Zhu M, Zhou YH. Growth morphology and evolution of icosahedral quasicrystal in Mg–Zn–Y ternary alloys. Rare Metal Mat Eng. 2006;35(9):1404.

Luo ZP, Zhang SQ, Tang YL, Zhao DS. Quasicrystals in as-cast Mg–Zn–RE alloys. Scr Metall. 1993;28(12):1513.

Bae DH, Lee MH, Kim KT, Kim WT, Kim DH. Application of quasicrystal particles as a strengthening phase in Mg–Zn–Y alloys. J Alloys Compd. 2002;342(1-2):445.

Tsai AP, Niikura A, Inoue A, Masumoto T, Nishida Y, Tsuda K, Tanaka M. Highly ordered structure of icosahedral quasicrystals in Zn–Mg–RE (RE = rare earth metals) systems. Philos Mag Lett. 1994;70(3):169.

Yuan GY, Liu ZL, Wang QD, Ding WJ. Microstructure refinement of Mg–Al–Zn–Si alloys. Mater Lett. 2002;56(1–2):53.

Lu QL. The ECAP deformation microstructure of quasicrystal reinforced Mg–Zn–Y alloys and its mechanical properties. Jinan: Shandong University; 2006. 43.

Yi S, Park ES, Ok JB, Kim WT, Kim DH. (Icosahedral phase+α-Mg) Two phase microstructures in the Mg–Zn–Y ternary system. Mater Sci Eng A. 2001;300:312.

Shao G, Varsani V, Fan Z. Thermodynamic modelling of the Y–Zn and Mg–Zn–Y systems. Calphad. 2006;30(3):286.

Shechtman D, Blech I, Gratias D, Cahn JW. Metallic phase with long-range orientational order and no translation symmetry. Phys Rev Lett. 1984;53(20):1951.

Huang ZH, Liang SM, Chen RS, Han EH. Solidification pathways and constituent phases of Mg–Zn–Y–Zr alloys. J Alloys Compd. 2009;468(1–2):170.

Wang Y, Liu G, Fan Z. Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment. Acta Metall. 2006;54(3):689.

Zhu XY, Yu SR, Liu ZZ. Friction and wear behavior of Mg–Zn–Y quasicrystal materials. Tribology. 2009;29(2):152.

Qi YH, Zhang ZP, Hei ZK, Yan L, Dong C. Tribological properties of Al65Cu20Cr15 quasicrystalline particles/Al matrix composite alloys. Tribology. 1998;18(2):129.

Morales ED, Ghali E, Hort N, Dietzel W, Kainer KU. Corrosion behaviour of magnesium alloys with RE additions in sodium chloride solutions. Mater Sci Forum. 2003;419–422(1):867.

Pardo A, Merino MC, Coy AE, Arrabal R, Viejo F, Matykina E. Corrosion behaviour of magnesium/aluminium alloys in 3.5 wt% NaCl. Corros Sci. 2008;50(3):823.

Shi F, Yu YC, Guo XF, Zhang ZM, Li YY. Corrosion behavior of as-cast Mg68Zn28Y4 alloy with I-phase. Trans Nonferrous Met Soc China. 2009;19(5):1093.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51361010), Natural Science Foundation of Jiangxi province (No.196 20114BAB216015), the Foundation of Jiangxi Educational Committee (No. GJJ12320) and the State Key Laboratory of Solidification Processing in NWPU (No. SKLSP201321).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, DQ., Luo, X., Liu, YJ. et al. Quasicrystal dissolution and performance of isothermally heat-treated Mg–Zn–Y alloy. Rare Met. 34, 452–456 (2015). https://doi.org/10.1007/s12598-013-0119-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0119-9