Abstract

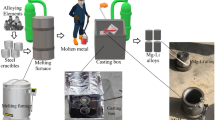

In this article, Mg–Cu–Y alloys with two different Mg/Cu ratios (in at%) were prepared using a water-cooled copper mold. Scanning electron microscopy and X-ray diffraction were applied to analyze the microstructure and phase composition. Moreover, corrosion resistance and wear resistance were studied systematically. The results show that both Mg65Cu25Y10 and Mg60Cu30Y10 alloys could form a composition of crystalline and amorphous phases. Although the microstructure of Mg65Cu25Y10 consists of an amorphous phase and α-Mg, Mg2Cu, and Cu2Y crystalline phases, the microstructure of Mg60Cu30Y10 alloy mainly consists of the amorphous phase and α-Mg, Mg2Cu. With reducing Mg/Cu ratio, the alloys have better corrosion resistance and wear resistance. The mechanism has also been discussed in detail.

Similar content being viewed by others

References

ASM International. ASM specialty handbook. In: Avedesian MM, Baker H, editors. Magnesium and Magnesium Alloys. Materials Park, Ohio: The Materials Information Society; 1999. 218.

Aghion E, Bronfin B, Eliezer D. The role of the magnesium industry in protecting the environment. J Mater Process Technol. 2001;117(3):381.

Zhang K, Ma ML, Li XG, Li YJ, Liang LC, Bing MF. Hot deformation behavior of Mg-7.22Gd-4.84Y-1.26Nd-0.58Zr magnesium alloy. Rare Met. 2011;30(1):87.

Li DQ, Wang QD, Ding WJ. Effects of Ho on the microstructure and mechanical properties of Mg–Zn–Ho–Zr magnesium alloys. Rare Met. 2011;30(2):131.

Wan DQ, Yang GC, Zhu M, Zhou YH. Growth morphology and evolution of icosahedral quasicrystal in Mg–Zn–Y ternary alloys. Rare Met Mater Eng. 2006;35(9):1404.

Ma H, Xu J, Ma E. Mg-based bulk metallic glass composites with plasticity and high strength. Appl Phys Lett. 2003;83(14):2372.

Hui X, Dong W, Chen GL, Yao KF. Formation, microstructure and properties of long-period order structure reinforced Mg-based bulk metallic glass composites. Acta Metall. 2007;55(3):907.

Li ZG, Hui X, Zhang CM, Chen GL. Formation of Mg–Cu–Zn–Y bulk metallic glasses with compressive strength over gigapascal. J Alloys Compd. 2008;454(1–2):168.

Takagi M, Kawamura Y, Saka H, Imura T. Effect of preparation technique and atmosphere on the mechanical properties of bulk amorphous alloy compacts. Mater Sci Eng A. 1991;133(15):30l.

Huang K, Chen G, Zhao YT, Wang GL, Shao Y. Crystallization microstructure of Mg65Cu25Y10 bulk amorphous alloy. Trans Nonferrous Met Soc China. 2012;22(4):831.

Inoue A, Kato A, Zhang T, Kim SG, Masumoto T. Mg–Cu–Y amorphous alloys with high mechanical strengths produced by a metallic mold casting method. Mater Trans. 1991;32(7):609.

Inoue A, Takeuchi A. Recent progress in bulk glassy alloys. Mater Trans. 2002;43(8):1892.

Ma H, Shi LL, Xu J, Ma E. Chill-cast in situ composites in the pseudo-ternary Mg–(Cu, Ni)–Y glass-forming system: microstructure and compressive properties. J Mater Res. 2007;22(2):314.

Mezbahul-Islam M, Kevorkov D, Medraj M. The equilibrium phase diagram of the magnesium–copper–yttrium system. J Chem Thermodyn. 2008;40(3):1064.

Inoue A. Bulk amorphous and nanocrystalline alloys with high functional properties. Mater Sci Eng, A. 2011;304–306(31):1.

Yao HB, Li Y, Wee ATS. Corrosion behavior of melt-spun Mg65Ni20Nd15 and Mg65Cu25Y10 metallic glasses. Electrochim Acta. 2003;48(18):2641.

Gebert A, Wolff U, John A, Eckert J. Corrosion behaviour of Mg65Y10Cu25 metallic glass. Scripta Mater. 2000;43(3):279.

Acknowledgments

This work was financially supported by the Natural Science Foundation of Jiangxi Province (No. 20114BAB216015), the Foundation of Jiangxi Educational Committee (No. GJJ12320), and the National Natural Science Foundation of China (No. 50671083).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, DQ. Phase selection and performance of Mg–Cu–Y amorphous composite with different Mg/Cu ratios. Rare Met. 33, 91–94 (2014). https://doi.org/10.1007/s12598-013-0062-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0062-9