Abstract

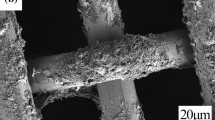

This study reports the fabrication of copper nanoparticles (CuNPs)-based superhydrophobic electrode using flashlight sintering. To fabricate superhydrophobic electrode, CuNPs with polyvinylpyrrolidone (PVP) of various concentrations was sintered by flashlight irradiations. After then, the self-assembled monolayers (SAM) were formed by vapor-deposition of 1-dodecanethiol (DDT) on the CuNPs film. During flashlight sintering, the surface roughness of CuNPs film could be controlled by changing the concentration PVP. The surface roughness was tended to increase with the decreasing concentration of PVP. As a result, the largest roughness of 7.28 μmRa was obtained with 0.01 g of PVP. Due to the unique characteristic of flashlight sintering, the highly porous and rough surface could be obtained with superior electric conductivity from CuNPs. The harmonic effects of secondary roughness and hydrophobic surface were achieved by the flashlight sintering process and SAM, respectively. These led to the successful fabrication of superhydrophobic copper tracks (contact angle: 169.08° ± 11.36, resistance: 0.13 ± 0.05 Ω/sq). By dropping the water droplet on the electrode, the performance of short-circuit for water prevention was investigated.

Similar content being viewed by others

References

Shaker, G., Safavi-Naeini, S., Sangary, N., & Tentzeris, M. M. (2011). Inkjet printing of ultrawideband (UWB) antennas on paper-based substrates. IEEE Antenna Wirel Propag Lett, 10, 111–114. https://doi.org/10.1109/lawp.2011.2106754

Perelaer, J., Smith, P. J., Mager, D., Soltman, D., Volkman, S. K., Subramanian, V., et al. (2010). Printed electronics: the challenges involved in printing devices, interconnects, and contacts based on inorganic materials. Journal of Materials Chemistry, 20(39), 8446–8453. https://doi.org/10.1039/c0jm00264j

Yu, J. H., Rho, Y., Kang, H., et al. (2015). Electrical behavior of laser-sintered Cu based metal-organic decomposition ink in air environment and application as current collectors in supercapacitor. Int J Pr Eng Manuf-Green Technol, 2(4), 333–337. https://doi.org/10.1007/s40684-015-0040-9

Noguchi, Y., Sekitani, T., Yokota, T., & Someya, T. (2008). Direct inkjet printing of silver electrodes on organic semiconductors for thin-film transistors with top contact geometry. Applied Physics Letters, 93(4), 043303. https://doi.org/10.1063/1.2959728

Kang, M., & Kang, K.-T. (2018). Flexible 2-layer paper printed circuit board fabricated by inkjet printing for 3-D origami electronics. Int J Pr Eng Manuf-Green Technol, 5(3), 421–426. https://doi.org/10.1007/s40684-018-0045-2

Lee, J., Kim, H.-C., Choi, J.-W., & Lee, I. H. (2017). A review on 3D printed smart devices for 4D printing. Int J Pr Eng Manuf-Green Technol, 4(3), 373–383. https://doi.org/10.1007/s40684-017-0042-x

Zhang, T., Wang, X., Li, T., Guo, Q., & Yang, J. (2013). Fabrication of flexible copper-based electronics with high-resolution and high-conductivity on paper via inkjet printing. J Mater Chem C, 2(2), 286–294. https://doi.org/10.1039/c3tc31740d

Merilampi, S. L., Bjorninen, T., Vuorimaki, A., Ukkonen, L., Ruuskanen, P., & Sydanheimo, L. (2010). The effect of conductive ink layer thickness on the functioning of printed UHF RFID antennas. Proceedings of the IEEE, 98(9), 1610–1619. https://doi.org/10.1109/jproc.2010.2050570

Narakathu, B. B., Avuthu, S. G. R., Eshkeiti, A., Emamian, S., & Atashbar, M. Z. (2015). Development of a microfluidic sensing platform by integrating PCB technology and inkjet printing process. IEEE Sensors Journal, 15(11), 6374–6380. https://doi.org/10.1109/jsen.2015.2457239

Niittynen, J., Sowade, E., Kang, H., Baumann, R. R., & Mäntysalo, M. (2015). Comparison of laser and intense pulsed light sintering (IPL) for inkjet-printed copper nanoparticle layers. Sci Rep-Uk, 5(1), 8832. https://doi.org/10.1038/srep08832

Li, D., Sutton, D., Burgess, A., Graham, D., & Calvert, P. D. (2009). Conductive copper and nickel lines via reactive inkjet printing. Journal of Materials Chemistry, 19(22), 3719–3724. https://doi.org/10.1039/b820459d

Jang, S., Seo, Y., Choi, J., Kim, T., Cho, J., Kim, S., et al. (2010). Sintering of inkjet printed copper nanoparticles for flexible electronics. Scripta Materialia, 62(5), 258–261. https://doi.org/10.1016/j.scriptamat.2009.11.011

Qi, L., Ma, J., & Shen, J. (1997). Synthesis of copper nanoparticles in nonionic water-in-oil microemulsions. J Colloid Interf Sci, 186(2), 498–500. https://doi.org/10.1006/jcis.1996.4647

Kamyshny, A. (2011). Metal-based inkjet inks for printed electronics. Open Appl Phys J, 4(1), 19–36. https://doi.org/10.2174/1874183501104010019

Kang, J. S., Kim, H. S., Ryu, J., Hahn, H. T., Jang, S., & Joung, J. W. (2010). Inkjet printed electronics using copper nanoparticle ink. Journal of Materials Science: Materials in Electronics, 21(11), 1213–1220. https://doi.org/10.1007/s10854-009-0049-3

Perelaer, J., Jani, R., Grouchko, M., Kamyshny, A., Magdassi, S., & Schubert, U. S. (2012). Plasma and microwave flash sintering of a tailored silver nanoparticle ink, yielding 60% bulk conductivity on cost-effective polymer foils. Advanced Materials, 24(29), 3993–3998. https://doi.org/10.1002/adma.201200899

Park, S.-H., Chung, W.-H., & Kim, H.-S. (2014). Temperature changes of copper nanoparticle ink during flash light sintering. J Mater Process Tech, 214(11), 2730–2738. https://doi.org/10.1016/j.jmatprotec.2014.06.007

Hwang, H.-J., Chung, W.-H., & Kim, H.-S. (2012). In situ monitoring of flash-light sintering of copper nanoparticle ink for printed electronics. Nanotechnology, 23(48), 485205. https://doi.org/10.1088/0957-4484/23/48/485205

Dugdale, I., & Cotton, J. B. (1963). An electrochemical investigation on the prevention of staining of copper by benzotriazole. Corrosion Science, 3(2), 69–74. https://doi.org/10.1016/s0010-938x(63)80001-3

Chadwick, D., & Hashemi, T. (1979). Electron spectroscopy of corrosion inhibitors: Surface films formed by 2-mercaptobenzothiazole and 2-mercaptobenzimidazole on copper. Surface Science, 89(1–3), 649–659. https://doi.org/10.1016/0039-6028(79)90646-0

Raut, N. C., & Al-Shamery, K. (2018). Inkjet printing metals on flexible materials for plastic and paper electronics. J Mater Chem C, 6(7), 1618–1641. https://doi.org/10.1039/c7tc04804a

Määttänen, A., Ihalainen, P., Pulkkinen, P., Wang, S., Tenhu, H., & Peltonen, J. (2012). Inkjet-printed gold electrodes on paper: characterization and functionalization. Acs Appl Mater Inter, 4(2), 955–964. https://doi.org/10.1021/am201609w

Quéré, D. (2008). Wetting and roughness. Annual Review of Materials Research, 38(1), 71–99. https://doi.org/10.1146/annurev.matsci.38.060407.132434

Bai, J. G., Zhang, Z. Z., Calata, J. N., & Lu, G.-Q. (2006). Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material. IEEE Transactions on Components and Packaging Technologies, 29(3), 589–593. https://doi.org/10.1109/tcapt.2005.853167

Nicula, R., Lüthen, F., Stir, M., Nebe, B., & Burkel, E. (2007). Spark plasma sintering synthesis of porous nanocrystalline titanium alloys for biomedical applications. Biomolecular Engineering, 24(5), 564–567. https://doi.org/10.1016/j.bioeng.2007.08.008

Yim, C., Sandwell, A., & Park, S. S. (2016). Hybrid copper-silver conductive tracks for enhanced oxidation resistance under flash light sintering. Acs Appl Mater Inter, 8(34), 22369–22373. https://doi.org/10.1021/acsami.6b07826

Kim, Y.-J., Ryu, C.-H., Park, S.-H., & Kim, H.-S. (2014). The effect of poly (N-vinylpyrrolidone) molecular weight on flash light sintering of copper nanopaste. Thin Solid Films, 570, 114–122. https://doi.org/10.1016/j.tsf.2014.09.035

López-Delgado, A., Cano, E., Bastidas, J. M., & López, F. A. (2001). A comparative study on copper corrosion originated by formic and acetic acid vapours. Journal of Materials Science, 36(21), 5203–5211. https://doi.org/10.1023/a:1012497912875

Bastidas, D.-M., Iglesia, V. M. L., Cano, E., Fajardo, S., & Bastidas, J. M. (2008). Kinetic study of formate compounds developed on copper in the presence of formic acid vapor. Journal of the Electrochemical Society, 155(12), C578. https://doi.org/10.1149/1.2988059

Rosen, Y., Marrach, R., Gutkin, V., & Magdassi, S. (2018). Thin copper flakes for conductive inks prepared by decomposition of copper formate and ultrafine wet milling. Adv Mater Technol, 4(1), 1800426. https://doi.org/10.1002/admt.201800426

Rosen, Y. S., Yakushenko, A., Offenhäusser, A., & Magdassi, S. (2017). Self-reducing copper precursor inks and photonic additive yield conductive patterns under intense pulsed light. ACS Omega, 2(2), 573–581. https://doi.org/10.1021/acsomega.6b00478

Woo, K., Kim, Y., Lee, B., Kim, J., & Moon, J. (2011). Effect of carboxylic acid on sintering of inkjet-printed copper nanoparticulate films. Acs Appl Mater Inter, 3(7), 2377–2382. https://doi.org/10.1021/am2002907

Poirier, G. E., & Pylant, E. D. (1996). The self-assembly mechanism of alkanethiols on Au. Science, 272(5265), 1145–1148. https://doi.org/10.1126/science.272.5265.1145

Lee, S. H., Lee, J. H., Park, C. W., et al. (2014). Continuous fabrication of bio-inspired water collecting surface via roll-type photolithography. Int J Pr Eng Manuf-Green Technol, 1(2), 119–124. https://doi.org/10.1007/s40684-014-0016-1

Acknowledgements

This research was supported by Kyungpook National University Research Fund, 2020.

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Additional file 1 Short circuit test (without DDT deposition)

Additional file 2 Short circuit test (with DDT deposition)

Additional file 3 Water droplet demonstration of Cu-P1 film without DDT deposition (tilted at 20°)

Additional file 4 Water droplet demonstration of Cu-P1 film with DDT deposition (tilted at 20°)

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kim, T., Yun, T.H., Yim, C. et al. Fabrication of Short Circuit-Preventing Electrodes with a Self-assembled Monolayer on Flashlight-Sintered Porous Copper Nanofilms. Int. J. Precis. Eng. Manuf. 24, 43–52 (2023). https://doi.org/10.1007/s12541-022-00728-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00728-w